FineTek SC174X Series User manual

The tuning fork level switch is a mechanical resonant device

which excited by piezoelectric (PZT) elements. When the

measured medium comes into contact with the tuning fork, it will

change the feedback resonant frequency due to the damping

resonances between the exciting PZT and receiving PZT. By

detecting the frequency and appropriately tuning the sensitivity

of tuning fork level switch on measured material, such device

can easily operate for monitoring the alarm level of measured

material.

1. Providing a universal power supply for operating in voltage

range of 20 to 250 (Vac / Vdc).

2. No calibration or complex setting procedure are needed,

robust, free of maintenance and operated in diversity

abominable environments.

3. High / Low fail safe modes provide user the safety

monitoring and real time communication.

4. Equipped with Remote Self-Testing function (RST) to

diagnostic the hardware connection with peripherals

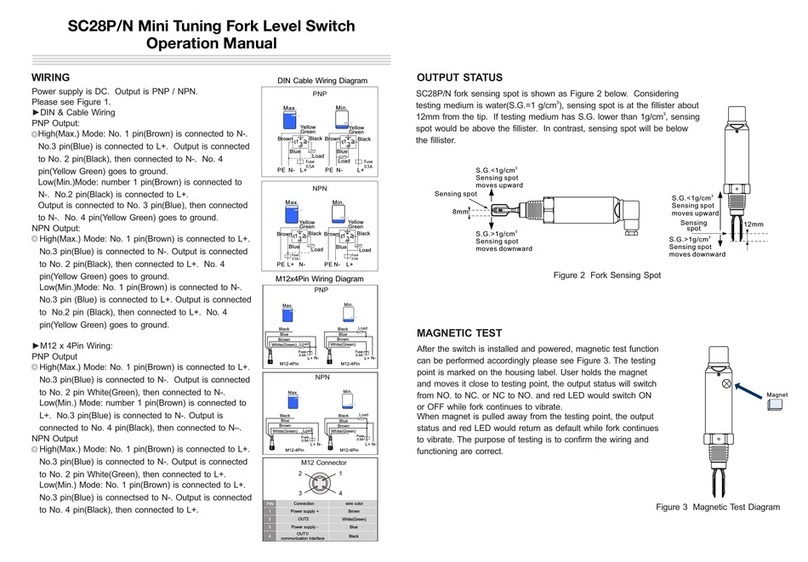

Dimensions

Terminals Arrangement :

Power Supply

Power Consumption

Diagnostic Frequency

Fork Length

Operating Humidity

Operating Pressure

Act Time Lag

Medium Density

Output

Fail-safe

Electrical safety

Housing Material

Probe Material

Enclosure Rating

Connection

Mounting

20~250, 50/60 Hz Vac/Vdc

Power consumption£10 VA

350~370 Hz

100 mm

Max extension length: 4 m

20%~80% RH non-condensed

-1~600PSI (40BAR)

3 second

3

Solid:density:³0.07g/cm

3

Liquid:density:³0.7g/cm

Viscosity:1~10000 cSt

0.6 s since the measured material contacted

1-3 s react to the measured material fall off

Relay, SPDT, 3A/250Vac Max.

PNP/NPN 400mA/60 Vac/ Vdc

Remote-test

Green light: indicate power supply

Red light: indicate operating mode

High / Low

Over Voltage category III

Aluminum (ADC-12)

316L/316/304

Ex db llB T4~T6

1"PT(standard)or PF thread

Flange 1"~6" JIS/DIN/ANSI standard or

special specification

Time Delay

Input

Status

1/2"NPT

f27

f113

108

1" PT

105

25

15

SENSITIVITY

HLFSL FSHSIGNAL

PWR

20~250VAC

20~250VDC

SENSITIVITY

HLFSL FSHSIGNAL

PWR

20~250VAC

20~250VDC

FSH:

Operating mode MAX (NC contact)

COM

No

Nc

No

Nc

COM

FSL:

Operating mode Min (NO contact)

COM

No

Nc

COM

No

Nc

Introduction

Feature

RT2 RT1 NC NO N- L+

COM

SC174X Series Tuning Fork Level Switch

Operation Manual

Specification

RT2 RT1 NC2 NO2 N- L+

COM2 NC1 NO1COM1

Relay Output

PNP/NPN Output

L+, N-: Power Supply

NC1, COM1, NO1: Relay Output

NC2, COM2, NO2: Relay Output

RT1, RT2: Remote-Test

: Ground Connection

st

COM1, NO1:1 OutputPNP/NPN

nd

COM2, NO2:2 OutputPNP/NPN

Terminal Function

PWR: Power Supply (Green Light)

SIGNAL: Output Indication (Red Light)

FSH: Power on. The signal LED is on and the relay acts.

While the tuning fork level switch contacts with measured

material, the signal LED is off and the relay is in not act.

FSL: Power on. The signal LED is off and the relay is in not act.

While the tuning fork level switch contacts with measured

material, the signal LED is on and the relay is in act.

SENSITIVITY L: Low Sensitivity

SENSITIVITY H: High Sensitivity

Panel Function

Relay Output

PNP/NPN Output

Output Description

1. Make sure provide power supply (L+/N-) in range of 20~250

(Vac or Vdc,50/60Hz) and output relay (Relay or PNP/NPN

before wiring. Detail please see Fig-1 and Fig-2.

2. RT1 and RT2 are the testing points that easy user to verify

the situation. When the RT1 and RT2 are in electric short, it

means the measured material is in contact with the tuning

fork level switch. The Relay or PNP/NPN should be

activated. In examining the tuning fork level switch, user

will find it keep vibrating.

Fig-1. SPDT contact output model

Fig-2. DPDT contact output model

Refer to the Fig.1-Fig.2, all the wiring should adopt the 18

AWG standard isolation cable and it is compulsory to keep

from the dust in the housing and avoid of electric short. To

prevent the water or moisture penetrating into the housing,

please rotate the top lid in clockwise direction and make

sure it is tightly lock.

Fig-3. Diagram of Relay contact output

Fig-4. Diagram of transistor outputPNP/NPN

1/2"NPTX2

+

NPN

+

PNP

+

PNP

+

NPN

RT2 RT1 NO2 N- L+

COM2 NO1COM1

RT2 RT1 NO2 N- L+

COM2 NO1COM1

RT2 RT1 N- L+

NOCOM

ATEX

NEPSI Ex d IIC T3~T6 Gb

Ex tD A20 / A21 IP65 T80°C / T95°C / T130°C / T195°C

ATEX II 2 G Ex db IIB T4 or T5 or T6 Gb

II 2 D Ex tb IIIC T130°C or T95°C or T80°C Db

IECEx Ex db IIB T4 or T5 or T6 Gb

Ex tb IIIC T130°C or T95°C or T80°C Db

L+,N–: Power Supply

NC, COM, NO: Relay Output

RT1, RT2: Remote Test

: Ground Connection

COM, NO: OutputPNP/NPN

Terminal Description

Ambient temp. -40°C~70°C

4. Be sure to obey the safe regulation of electric appliance for dangerous field when install and maintain.

5. Corrosive gas or liquid application isn't available for Aluminum & Stainless (SUS) material.

7. Customers can't change the internal components and have to check the outer.

6. The level of temperature class for explosion sign and its maximum allowed temperature relating to the medium as below:

1. There is an internal/external ground terminal in the housing. Please be sure to ground terminals when you use.

2. When install or maintain in the field, to comply with the caution "Open after power off"

3. Cable conduit should equip with explosion approval device (AD105DS). It can't be revised arbitrarily and have to lock

well.

Inlet

Horizontal Installation:

1. Can be applied in viscosity, powder, and liquid. Do

not install near substance inlet.

3. To be installed with the surface of two fork blades

facing each other horizontally.

Vertical Installation:

3

1. For detected medium of water (density 1g/cm ),the switching point is

located at the grooved part of fork, about 23mm from the end of fork.

2. Opening of the two fork blades is to be as the flow direction.

3. Do not install near substance inlet.

2. Conduit faces downward at installation.

For instance, turning the SENSITIVITY 10 turns counterclockwise (sensitivity L) and will get the acting point moving 30 mm

upward of the fork.

3

Factory default is calibrated (by water density 1g/cm ) and set the acting point at front end of tuning fork 23mm

For higher sensitivity need, user please turn the knob clockwise toward H and counterclockwise toward L for lower

sensitivity.

It will slightly moving upward or downward along the axis of fork while the sensitivity is changed. For example, the point

will move downward for H sensitivity and vice versa. The total movement range of acting point can be adjusted for around

60mm.

Sensitivity Adjustment/Calibration

(at the groove area) ( ) Fig-5.

Sensitivity knob located on the right side of the PCB board. It approximately allows 22 turns for sensitivity adjustment.

Normal Status: NO & COM contact of the relay are conducted and the Signal Lamp lights up when tuning fork level switch

doesn't sense any materials.

On the OUTPUT MODE, select Fail-Safe High Mode (FSH)and install the tuning fork switch at the high position. Please

refer to Fig-3 - Fig-4.

FSH (FAIL-SAFE HIGH) PROTECTION:

Relay Output:

Failure: Output is not conducted and the Signal Lamp is out when tuning fork level switch senses the material or when

there is power breakdown.

FSL (FAIL-SAFE LOW) PROTECTION:

On the OUTPUT MODE, select Fail-Safe Low Mode (FSL)and install the tuning fork switch at the low position.

Please refer to Fig-3 - Fig-4.

Failure: NC & COM contact of the relay are conducted and the Signal Lamp is out when tuning fork level switch does not

sense the material or when there is power breakdown.

Failure: Output is not conducted and the Signal Lamp is out when tuning fork level switch does not sense the material or

when there is power breakdown.

Normal Status: Output is conducted and the Signal Lamp lights up when tuning fork level switch doesn't sense any

materials.

Relay Output:

Normal Status: Output is conducted and the Signal Lamp lights up when tuning fork level switch senses materials.

Failure: NC & COM contact of the relay are conducted and the Signal Lamp is out when tuning fork level switch senses the

material or when there is power breakdown.

PNP/NPN Output:

PNP/NPN Output:

Normal Status: NO & COM contact of the relay are conducted and the Signal Lamp lights up when tuning fork level switch

senses the materials.

COMNO NC COM NCNO

Fail FailNormal Normal

COM NCNO COMNO NC

Level

Contact

Form

Indication

Status

FSL

FSH

Installation Tips

08-SC174X-B8-EM,11/06/2023

Tel: 886-2-22696789 Fax: 886-2-22686682

Email: [email protected] http://www.fine-tek.com

No.16, Tzuchiang St., Tucheng Industrial Park, New Taipei City 23678, Taiwan.

FineTek Co. , Ltd.

Temp. class T4 T5 T6

Temp. of process medium 125BC

≦80BC

≦

95BC

≦

23mm

Trigger Point

Sensitivity knob turned to L or when medium

3

is less than 1g/cm , the switch point will

become upward (contacting more medium

to actuate switching function)

Sensitivity knob turned to H or when medium

3

is more than 1g/cm , the switch point will

become downward (contacting less medium

to actuate switching function)

Fig-5.

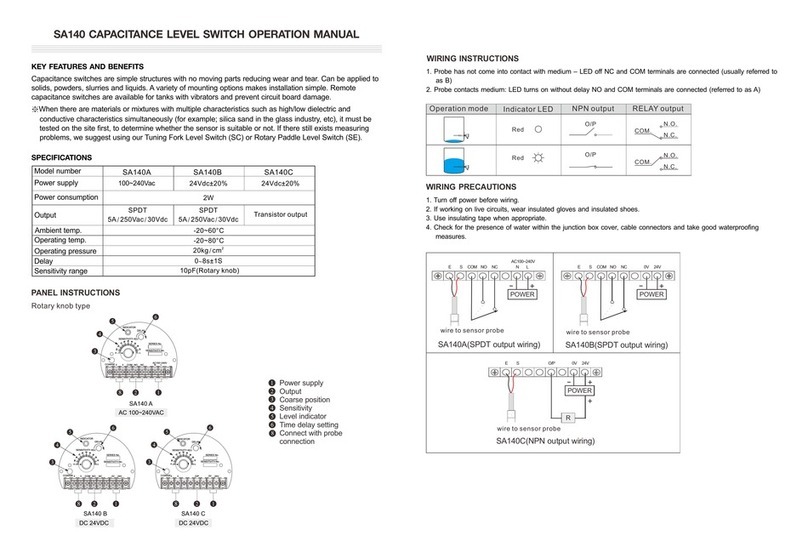

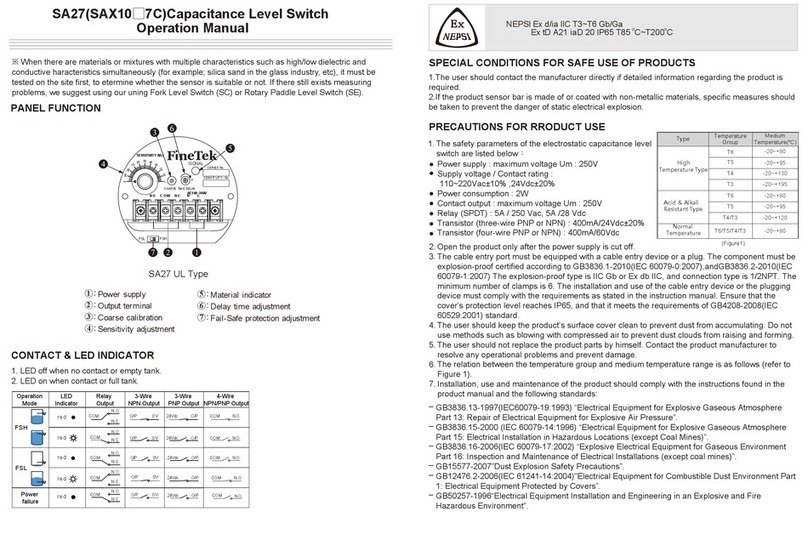

Other FineTek Switch manuals

Popular Switch manuals by other brands

Kindermann

Kindermann Multishare 41 automatic Mounting and operating instructions

Moxa Technologies

Moxa Technologies S9450I Series Quick installation guide

Energenie

Energenie DSW-HDMI-51 user manual

QuantumZERO

QuantumZERO QZHB10 Welcome guide

Raritan

Raritan Paragon II P2-UMT1664M user guide

Schaltbau

Schaltbau C195 Series Installation and maintenance instructions