MAINTENANCE

08-SA140-B2-EM,02/13/2019

Tel: 886-2-22696789 Fax: 886-2-22686682

No.16, Tzuchiang St., Tucheng Industrial Park, New Taipei City 23678, Taiwan.

FineTek Co. , Ltd.

Conditions Possible

malfunctions

Noticeable

problems Solutions

Housing leaking

Level changes but

switch doesn't

actuate

Level rises and

falls but switch only

actuates once

Switch signal

unstable and

sometimes jumps

or fluctuates

Housing is loose Rattling/ looks loose Tighten and lock

Sealing loosens Usually due to age Replace item

Loose conduit Loose or slack wiring Tighten conduit screw

Conduit not facing

downwards Conduit facing upwards Change conduit

position

Electrical cable not

facing downward Cable Facing upwards As Above

Cable diameter too small Loose cabling Use f8~f10mm cable

Sensitivity knob needs

readjustment

Knob has changed from

original position Reset sensitivity

Power source or circuit

problem Check power and circuits Correct any wiring issues

Static electricity damage Dusty, powdery

environment

Switch to FineTek static

model

Medium dielectric

constant too low

Try using course and

fine tuning to detect

substance

C2 capacitor needs

changing

Tank contains high

percentage of water

vapor

Probe has water droplets Use a coated probe

model

The probe is touching

the tank wall Probe is grounded Remove the cause of the

probe and grounding

contact

Static electricity damage Dusty, powdery

environment

Switch to FineTek static

model

Medium dielectric

constant too low

Try using course and fine

tuning to detect

substance

C2 capacitor needs

changing

Terminal connections are

loose

Dusty, powdery

environment Tighten connections

Connection thread loose Dusty, powdery

environment

Tighten connection

thread or flange

Old or defective

wiring/circuit Dusty, powdery

environment Change wiring

Power supply

abnormality Dusty, powdery

environment

Restore the required

power supply

Tank vibration has

caused loosening of

electrical circuits/parts

Check tank for vibration Switch to remote model

(SA140).

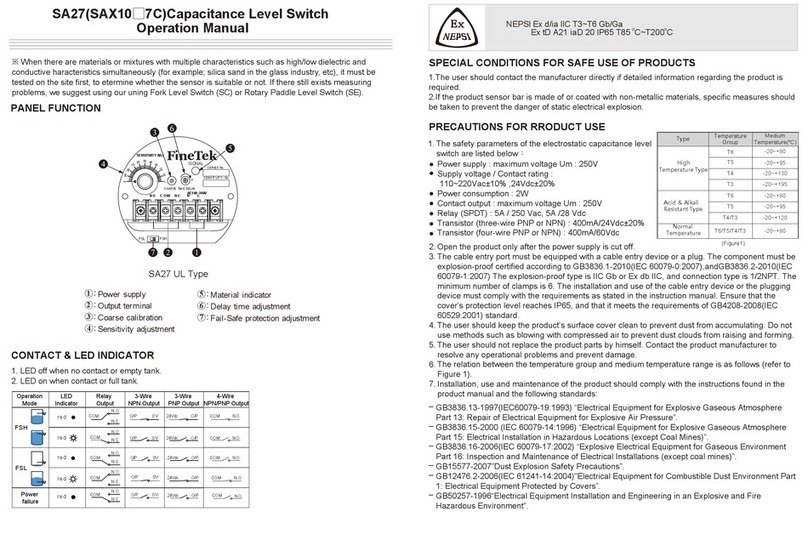

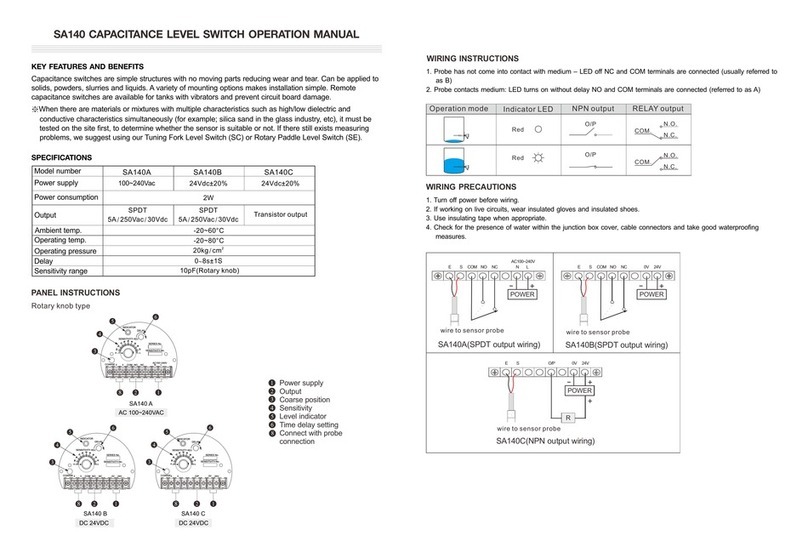

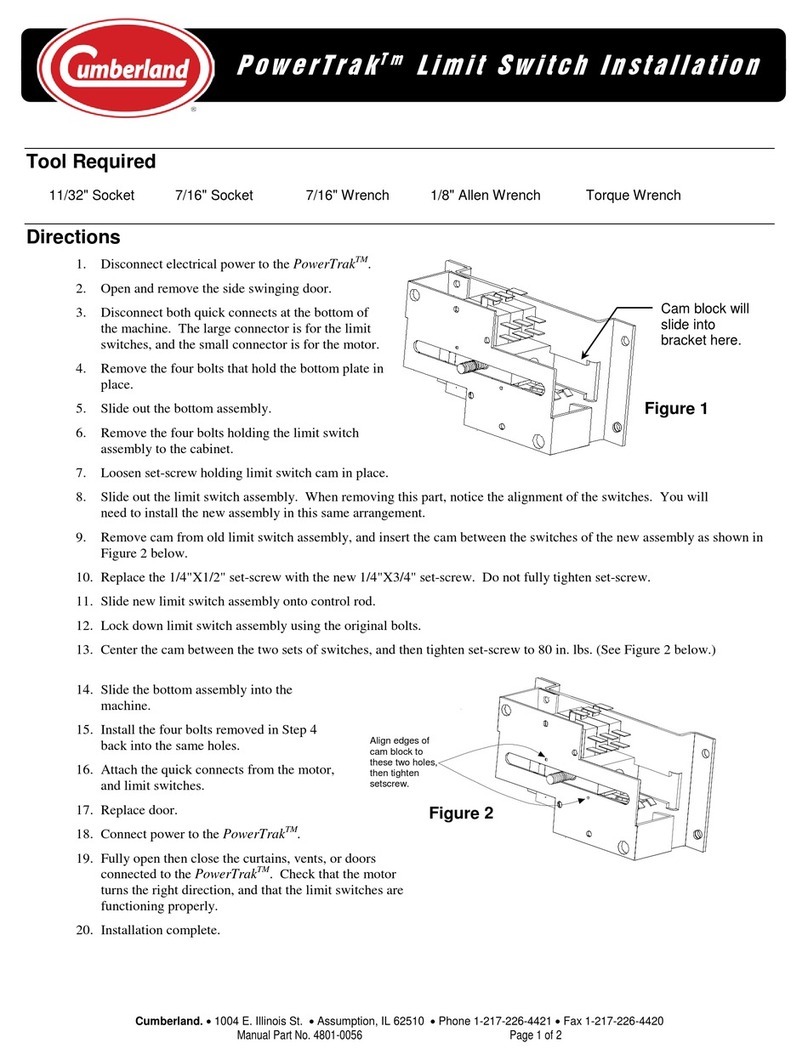

5. Switch “SENSITIVITY ADJ 1” to “ON” (Fig. 2). Check if LED indicator is OFF. If yes, rough

adjustment is complete. If not, kindly ad the rough adjustment again.

6. After complete above steps, if there is any malfunction occurred, switch “SENSITIVITY ADJ 3 and

4” to “ON”(Fig. 3).

1. After installation or hold this sensor in hand, connect with power and make sure there is no

material within 300 mm around the probe.

※“SENSITIVITY ADJ” 1~6 represent its dielectric value, 1=0.3pF, 2=0.5pF, 3=1pF, 4=2pF, 5=4pF,

6=6.8p, total 14.6pF. Increase the dielectric value to decrease the sensitivity. Decrease the

dielectric value to Increase the sensitivity.

3. Use flat-head screwdriver to turn “Coarse” clockwisely for rough adjustment until LED indicator is

ON.

If LED is keeping “OFF” and not able to switch it “ON”, For example, the dielectric value is 5 pF.

Switch on “SENSITIVITY ADJ” 3 and 5 do the rough adjustment again.

4. If LED is keeping “ON” and not able to switch it “OFF”. For example, the dielectric value is 10.8

pF. Switch on “SENSITIVITY ADJ” 5 and 6 do the rough adjustment again.

2. Fine adjustment, switch “SENSITIVITY ADJ” 1~6 to “OFF” position. (Fig. 1)

SENSITIVITY ADJUSTMENT

SW 1 2 3 4 5 6

SENSITIVITY ADJ

Fig 1

SW 1 2 3 4 5 6

SENSITIVITY ADJ

Fig 2

SW 1 2 3 4 5 6

SENSITIVITY ADJ

Fig 3