OPERATING PRINCIPLEThe SE series operating principle is simple. A unit is usually located through a bin wall at the top, middle or low level of a bin. During normal operation(no material present) a synchronous motor rotates the paddle at 1 RPM. When this paddle rotation is impeded by material, the motor will stall and cause the micro switch to change state.(Indicating an alarm or control).INSTALLATION

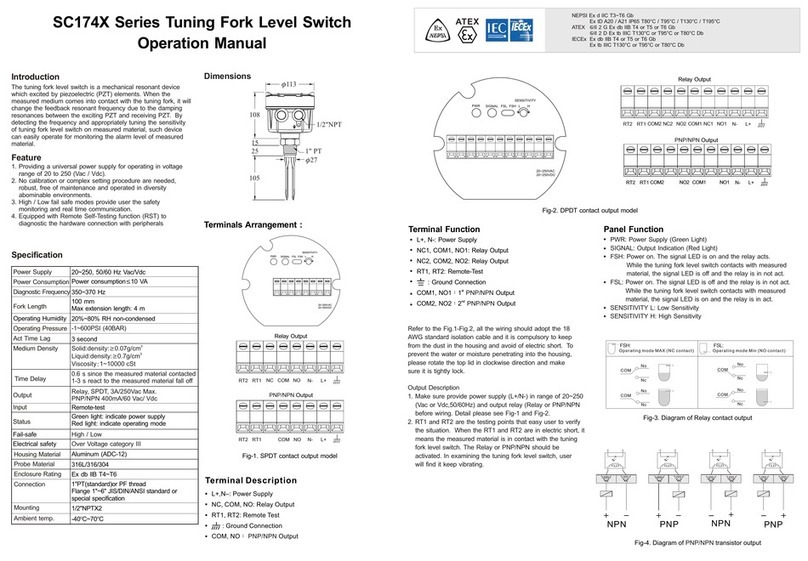

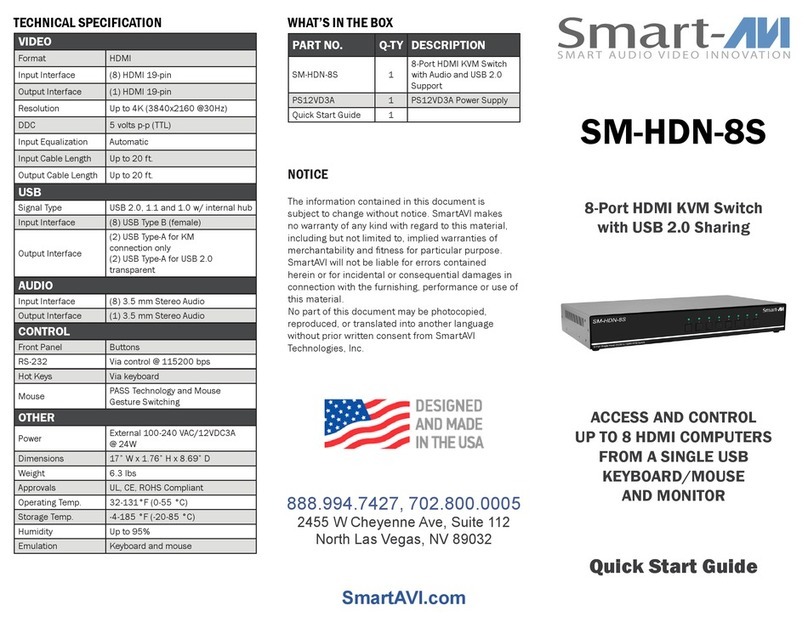

SPECIFICATION The torque force can be adjusted according to the specific gravity of the targeted materials to be measured. When the specific gravity of the material is too low (the paddle still rotates when in contact with the material), adjust the torque spring to hook on to the weaker hole, thereby increasing the sensitivity. Refer to the Panel Diagram.If the torque of paddle is insufficient (the paddle does not rotate when not in contact with the material), adjust the torque spring to hook on to the stronger hole, thereby decreasing the sensitivity.※Note! Do not tamper with the spring torque as it may cause the Rotary Paddle to malfunction.2. Please check the connection between "Shaft" & "Paddle”3. Please clean out the "Shaft" & "Paddle" regularly.1. Please check "Shaft " & "Paddle" for bending or damage.6. The operating temperature in the tank/bin shouldn't over anti temperature of products.5. Corrosive Gas application isn't available for Aluminum & Stainless (SUS) material.2. The conduit opening should be place on downward position, tight the wire connection.1. For horizontal installation by the side mounting, please take 15°~ 20° angle downward to avoid material impact the shaft & paddle directly.4. When install or maintain in the field, to comply with the caution "Open after power off”3. If the hopper (bin) already installed the Air Vibrator or Vibrator Motor, please use our SE140 Capacitance Level Switch.SE3X ROTARY PADDLE LEVEL SWITCHOPERATION MANUALTROUBLE SHOOTINGWIRINGSENSITIVITY ADJUSTMENTMAINTAINweakstrongweakeststrongest8017730383/4"PFf79DIMENSIONf8 24/110/220/240Vac 50/60Hz, 24Vdc5A/250Vac5A/30Vdc , Green Light:operatingRed Light:contact material-40~85 BC -40~85 BC Power sourceDisplay Contact capacityAmbient temperatureOperation temperatureHousing materialIP ratingConnection typeRotate speedAluminum alloy (ADC-12) IP 653/4" PF1 RPMApplicable densityPower consumptionMax. 1.5W30.3~1 g/cm08-SE3X-B2-EM,12/04/2019Tel: 886-2-22696789 Fax: 886-2-22686682Email: info@fine-tek.com http://www.fine-tek.com No.16, Tzuchiang St., Tucheng Industrial Park, New Taipei City 23678, Taiwan.FineTek Co.,Ltd.Available:SE2/SE3LNCCOMNONEAC:V+V-DC:PowerOutWhiteBlackBlueYellowRedGreenAbnormal conditionCauseSolutionThe material covers the paddle, indicating that the material does not exist.The specific gravity of the material is too low, the torque is too large.The flow of material at the mounted location is too fast.The mounting location cannot make contact with material because of the angle of repose.The device is not powered or the wiring is disconnected.Un-matching Voltage will lead to insufficient power and motor not rotating.Fastening pin is not inserted or is not folded back, the blades fall off.Internal shaft parts or motor assembly is damaged.Change the mounted location or use anothermodel.Adjust the torque spring hook to the weaker hole position.Change to the use of SE130/SE146 Adjustable Shaft Type.Repair the wiring and turn on power.Correct the matching Voltage shown on the model specification.Mount the blade, insert the fastening pin and fold the end back.Contact your local business representative.The paddle torque is too low to rotate.The paddle or shaft is deformed by impact.Material bridging, covers a wide range of peddle.The paddles are blocked or wound by foreign objects, such as filter bags.The shaft is stuck with foreign objects in the housing, such as wire.The switch contact has reached the limit of service life with poor contact.Adjust the torque spring hook to a stronger hole position.Replace with good spare parts and install baffle for protection.Order customized protective tube type extended into the tank wall length.Remove obstacles.Remove obstacles and restore the installation.Contact your local business representative.The material left the paddle, indicating that the material has arrived. ※If the failure is not listed or cannot be resolved, please contact your local business representative.