FineTek SIS User manual

2

Contents

1. READING LABELS ..........................................................................................3

2. PRODUCT WARRANTY...................................................................................4

2.1 New Product Warranty..............................................................................4

2.2 Repair Warranty........................................................................................4

2.3 Service Network......................................................................................5

3. PRODUCT INSPECTION..................................................................................6

3.1 Item Check................................................................................................6

3.2 Safety Check.............................................................................................6

4. PRODUCT FEATURES ....................................................................................6

5. SCOPE OF APPLICATION...............................................................................7

6. AMBIENT CONDITIONS...................................................................................8

7. WORKING PRINCIPLE ....................................................................................9

7.1 Output Status...........................................................................................9

8. TECHNICAL PERFORMANCE.......................................................................10

8.1 Specifications..........................................................................................10

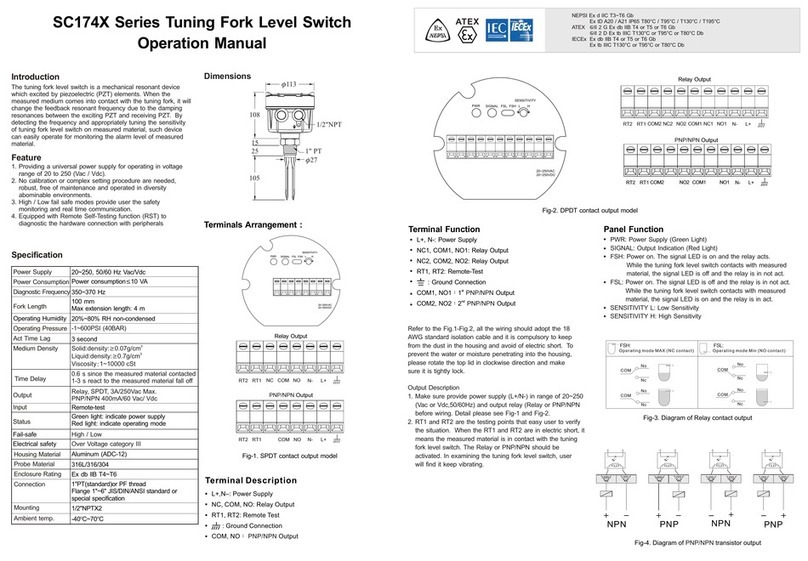

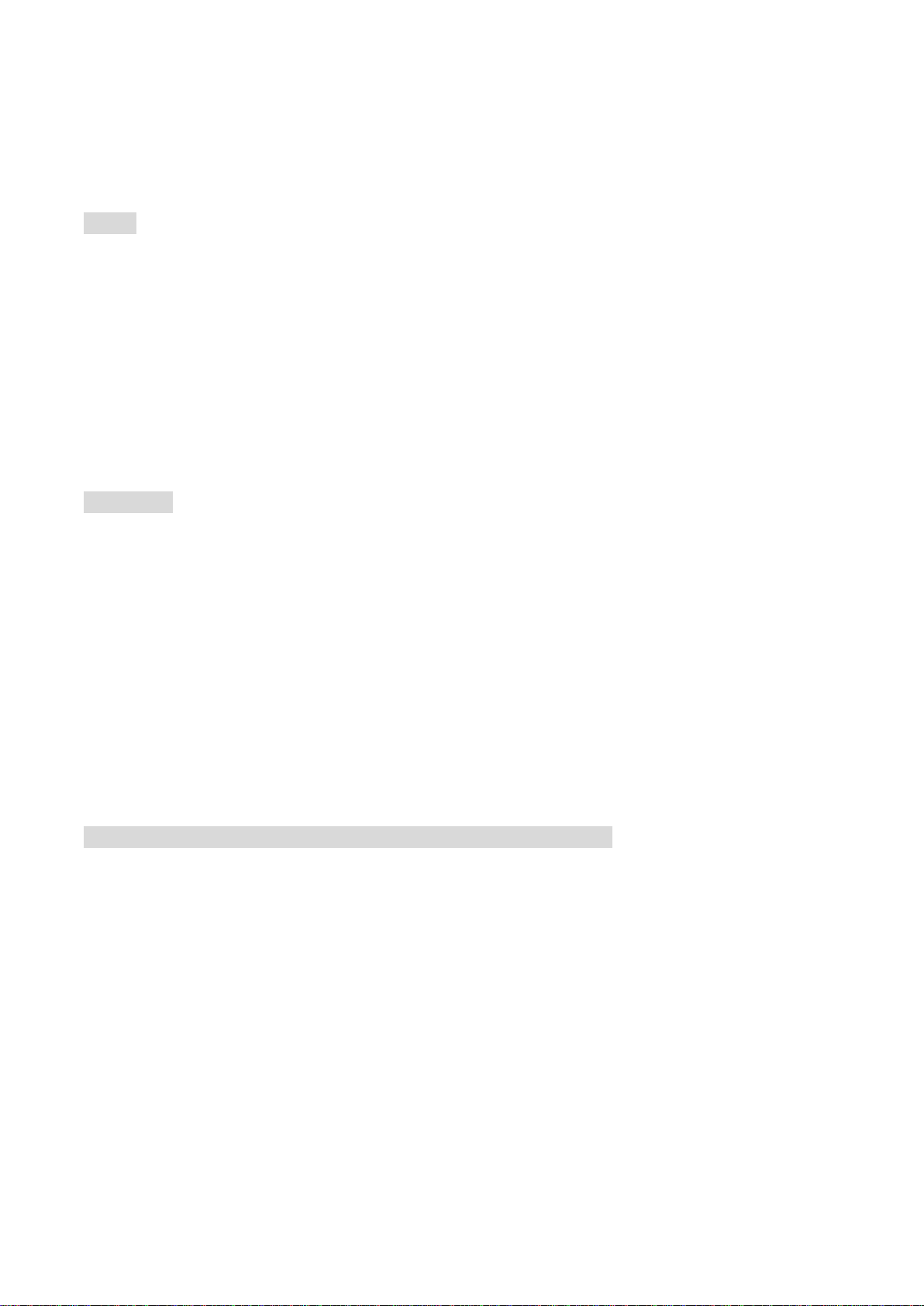

9. EXTERNAL DIMENSIONS .............................................................................13

9.1 Dimensions.............................................................................................13

10. INSTALLATION ............................................................................................14

10.1 Installation Environment........................................................................14

10.2 Installation Process...............................................................................15

10.3 Installation Examples............................................................................17

10.4 Grounding instructions for dust-explosion zone....................................18

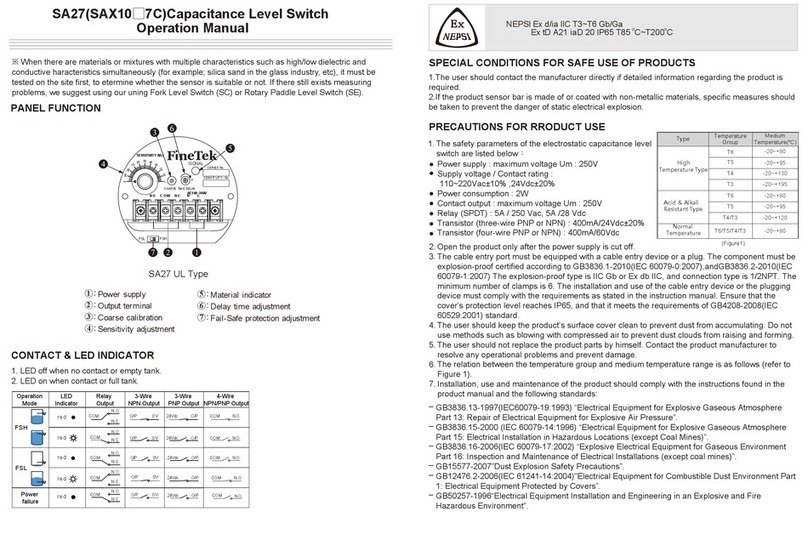

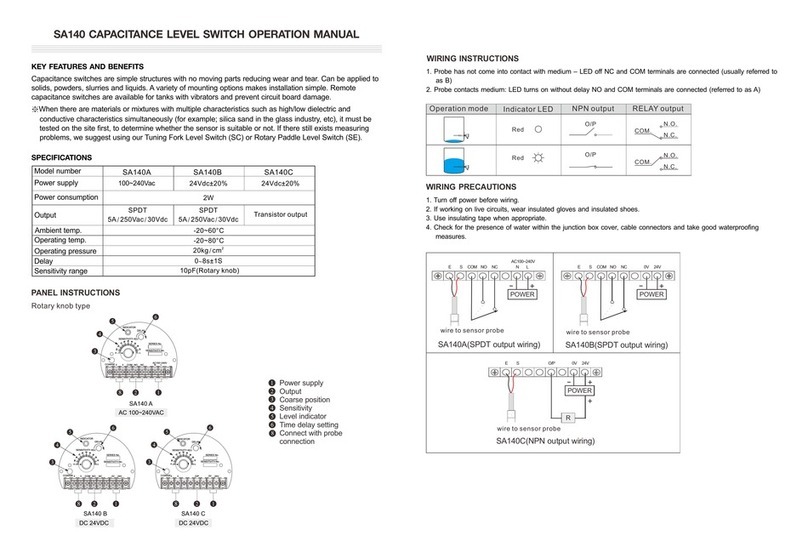

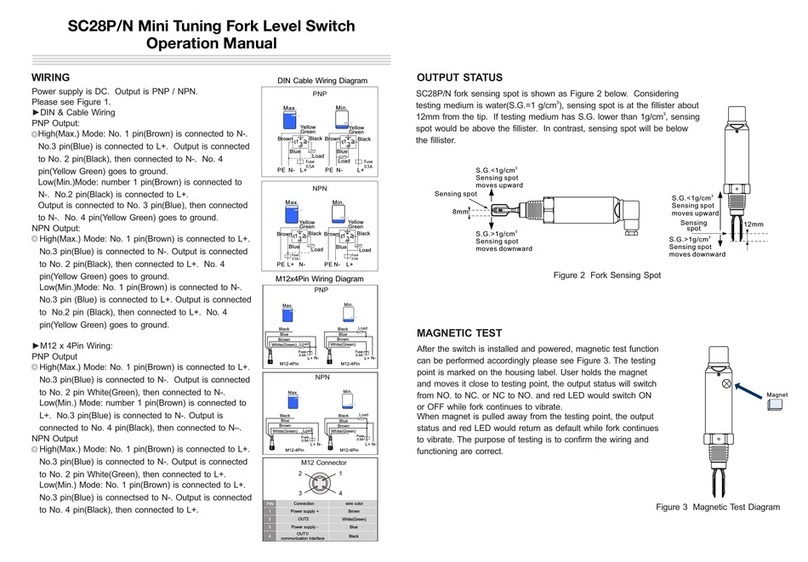

11. WIRING INSTRUCTIONS .............................................................................19

11.1 Simulation output test ...........................................................................20

11.2 M12 cable connector for dust-explosion zone.......................................20

12. DAILY MAINTENANCE AND HANDLING....................................................21

12.1 Euipment cleaning for dust-explosion zone ..........................................21

13. SIMPLE TROUBLESHOOTING....................................................................22

14. LIST OF APPLICABLE MEDIA ....................................................................23

3

1. Reading Labels

Thanks for purchasing FineTek’s Product. This operation manual describes the product

features, working principles, operation and maintenance methods. It makes the user fully

understand how to use the product correctly, so as to prevent dangerous situations such as

device damage or operator injury.

Please read this operation manual completely and carefully before using the product.

Please contact the company if this operation manual can’t satisfy your demands.

The content of the operation manual is updated based on the version upgrade, which

will be uploaded to the website for the user to access.

Please don’t disassemble or repair the product on your own, as this will make you

disqualified from availing of the warranty service. Please send the product back to the

company for repair and calibration, or just contact the company.

Explanation of warning signs:

Danger→ It indicates that wrong operation will cause death or major disasters.

Note→ It indicates that wrong operation will cause injury and device damage to

some extent.

Electric shock→ It warns of possible electric shock.

Fire→ It warns of possible fire.

Prohibited→ It indicates the prohibited wrong behavior.

4

2. Product Warranty

2.1 New Product Warranty

We don’t charge for the inspection, part/s and repair for the product of the company

that has a defect within 12 months from the delivery date and meets the warranty

terms.

If the product defect is not due to human error during its transportation, user may

change to a new unit from the company within 7 days from delivery date.

When the product needs to be sent back to the factory for repair, please send the whole

set, and don’t disassemble the parts. Moreover, please be sure it is completely packed

to avoid damage and causing more loss and defect during the transportation.

The warranty is not available for causes that fall under the following circumstances, for

which the company shall charge for the inspection, part/s and repair according to the

actual condition:

The product or its parts are beyond the warranty period.

Fault or damage is caused by not following the instruction and use environment

described on the operation manual.

The product damage is caused by a force majeure factor (natural disasters, floods,

fire, earthquakes, lightning, typhoon, etc.), human destruction (scratches, dropping,

latch broken, tapping, cracks and punching), human error (using improper voltage,

high-humidity, water leakage, stain, corrosion, loss, improper storage, etc.) and

other abnormal factors.

The damage is caused by the customer or the 3rd party through the installation,

addition, expansion, modification and repair of parts not authorized or certified by

the company.

The volume label information is wrong or unclear, so the product serial number

can’t be confirmed.

2.2 Repair Warranty

A 6-month warranty service is provided for the repaired part of the product, during

which the same product can be repaired free of charge in case of the same fault.

5

2.3 Service Network

Company

Address

Telephon

Fax

Taipei

Headquarters

(Taiwan)

No.16, Tzuchiang St., Tucheng

Industrial Park, New Taipei City

23678

+886 2 2269 6789

+886 2 2268 6682

Taichung

Sales office

(Taiwan)

+886 4 2465 2820

+886 4 2463 9926

Kaohsiung

Sales office

(Taiwan)

+886 7 333 6968

+886 7 536 8758

Fine automation

Co., Ltd.

(China)

No. 451, Duhui Road, Zhuanqiao

Township, Minhang District,

Shanghai City 201109

+86 021 64907260

+86 021 6490 7276

FineTek Pte Ltd.

(Singapore Branch)

37 Kaki Bukit Place, Level 4

Singapore 416215

+65 6452 6340

+65 6734 1878

FineTek GmbH

(Germany Branch)

Bei den Kämpen 26

21220 Seevetal-Ramelsloh,

Germany

+49 (0) 4185 8083 12

+49 (0) 4185 8083 80

FineTek Co., Ltd.

(Indonesia Branch)

PERGUDANGAN TUNAS BITUNG

JL. Raya Serang KM. 13,8, Blok C3

No. 12&15, Bitung Cikupa,

Tangerang 15710

+62 (21) 2923 1688

6

3. Product Inspection

3.1 Item Check

Sensor (1)

Operation manual (1)

3.2 Safety Check

Before unpacking, check the packaging for deformation or damage, and take photos to

be used as evidence.

After unpacking, checks the contents for deformation, damage or any quality problems,

and take photos to be used as evidence.

After unpacking, check whether the contents match your order and whether the quantity

is correct immediately.

In any case described above, please contact us within 7 days (attach photos).

Otherwise, free replacements or repairs will not be provided.

4. Product Features

Easy to install due to the standard connector. Protection rating IP67/IP68/IP69K.

The lightweight and compact design make it easy to carry and enable for quick

installation even in narrow spaces or difficult situations.

Surface roughness (Ra) can be customized according to customer needs for chemical

pharmaceutical and food processing industry applications.

The magnetic test action function allows immediate inspection of the wiring and device

proper operation.

Strong and durable stainless steel enclosure.

LED indicators provide field device status.

With overcurrent protection, the output would be immediately turned off when the

output circuit current is overloaded.

Can be applied to CIP and SIP environments.

Unaffected by foam and viscous medium.

Suitable for single point level detection and pump idling protection for liquid, viscous

medium, and powder medium in containers and pipelines.

2 output units can be set individually to help detect 2 different media (such as separate

layers, foam or oil + water).

Acquired NEPSI dust Explosion-proof Certificate, Ex tD A20 IP67 T85℃T200 100℃.

7

5. Scope of Application

Scope

The product is designed based on food grade structure and materials, ideal for food

and health areas.

Suitable for level detection of water-based medium, oil-based medium, powder or

sticky material as a switch output.

Can be used for liquid with separate layers (such as bubbles) and two-level or interface

detection (such as oil + water).

Can be used for almost all media; low specific gravity, low dielectric, non-conductive

media can all work properly.

Limitations

Not suitable for bulk solid or rough material (such as quartz sand).

Not suitable for highly corrosive media (strong acids and strong alkaline). Please check

the compatibility with the product material first.

Media with separate layers of different natures (such as oil on the water surface)

must be checked in advance.

Only explosion-proof type specifications can be used in dust explosion-proof

hazardous environments

The sensor must be installed with the exclusive “Thread adapter” and its sealing

ring to ensure proper sealing

The special requirement used in the dust-explosion environment

If the connection is the metal tank or pipe, it must be grounded so the danger of static

electricity generated by friction or impact can be avoided.

If the connection is not the metal tank or pipe, the sensor must be installed with the

exclusive “Thread adapter” and use “thread adapter” to complete the grounding.

The cross-sectional area of the grounding wire must be greater than 4mm2

(>11AWG). (Please refer to the installation instructions above)

8

6. Ambient Conditions

Normal type (Standard type / Extension type / Mini type)

Storage temperature: -40°C ~ 85°C (-40°F ~ 185°F)

Ambient temperature:-40°C ~ 85°C (-40°F ~ 185°F)

Medium temperature: Continuous; max.100°C

@ ambient temperature -40°C~85°C (-40°F~185°F)

Short time(1hr); max.150°C (Mini type: max.135°C)

@ ambient temperature -40°C~60°C (-40°F~140°F)

Power supply: 18 VDC ~ 30 VDC

Output load current: Max. 100 mA

Rear install type

Storage temperature: -40°C~85°C (-40°F~185°F)

Ambient temperature: -40°C~80°C (-40°F~176°F)

Medium temperature: -40°C~80°C (-40°F~176°F)

Power supply: 18 VDC~30 VDC

Output load current: Max, 100 mA

Explosion-proof type

Storage temperature: -20°C ~ 85°C(-4°F ~ 185°F)

Ambient temperature: -20°C ~ 70°C(-4°F ~ 158°F)

Medium temperature: Max, 100°C @ Ambient temperature-20°C ~ 70°C(-4°F ~ 158°F)

Power supply: 18 VDC ~ 30 VDC

Output load current: Max. 50 mA

9

7. Working Principle

Working principle of this sensor is based on the frequency sweep

technology. The sensor tip will send out electric field signal, and

different resonance frequency is created according to different

medium. Thus a switching signal will be triggered if the sensor is

covered with material..

7.1 Output Status

The following table shows the corresponding output status for the factory default

values (group 1 output NO, group 2 output NC):

*IL represents load start

LED locations

10

8. Technical Performance

8.1 Specifications

Normal type

Rear install type

Explosion

proof type

Scope (optional)

Water-based media, oil-based media, powder

media, dual-level media (such as oil+water),

fluid with separation layer (such as bubbles)

Powder media

Storage

temperature

-40°C ~ 85°C (-40°F ~ 185°F)

Ambient

temperature

-40°C ~ 85°C

(-40°F ~ 185°F)

-40°C ~ 80°C

(-40°F ~ 176°F)

-20°C ~ 70°C

(-4°F ~ 158°F)

Operating

temperature

Continuous: max.100°C

while ambient temp.

-40°C~85°C(-40°F~185°F)

Short time(1hr):

max.150°C

(Mini type: max.135°C)

while ambient temp.

-40°C~60°C(-40°F~140°F)

-40°C ~ 80°C

(-40°F ~ 176°F)

Max.100°C while

ambient temp.

-20°C ~ 70°C

(-4°F ~ 158°F)

Power Supply

18 VDC ~ 30 VDC

Current

consumption

Max. 50 mA

Overvoltage

protection

Class II

Reverse

protection

Yes

Output type

(optional)

DC PNP/NPN

Number of

outputs

2 switch outputs

Switch type

(optional)

Group 1 output NO, Group 2 output NC

Output load

current

Max. 100 mA

Max. 50 mA

Output voltage

drop

Max. 2.5 VDC

11

Short circuit

protection

Short pulse

Overload

protection

Yes

Switch delay

(optional)

Standard < 1 second (max. 60 seconds)

Electrical

connection

M12 4PIN connector socket

Wetted part

material

(optional)

SUS304, SUS316, SUS316L

Operating

pressure

-1 ~ 40 bar

Process

connection

G 1/2”

M32*P1.5

G 1/2”

Probe

material/surface

roughness

PEEK/Ra<0.8

PEEK-

1000/Ra<0.8

Enclosure

protection rating

IP67/IP68/IP69K (IP68 up to 1 meter underwater for 30 days)

Status indication

Switch active LED yellow

Switch reset LED green

Simulation

output test

(Not available

for mini type)

Magnetic test (lean a magnet close to the + sing for 2 seconds,

there will be switching output)

Communication

mode

"IO-Link V1.1

Standard

compliance

IEC61000-4-2, IEC61000-4-4, IEC61000-4-11

Explosion-proof

Certificate

N/A

NEPSI Ex tD A20

IP67 T85℃T200

100℃

12

Warning !

1. Only Explosion-proof type can be installed and used in Combustible dust explosion

environment.

2. The sensor must be installed with the exclusive “Thread connector” or “Thread adapter”,

in order to ensure the installation sensor operate normally and avoid leakage.

3. The electrical connection of this device has achieved IP68/IP69K protection grade, so it

must be connected with the corresponding M12 connection cable in order to be installed

properly.

4. Explosion-proof type must be installed with M12 connection cable approved by NEPSI, in

order to use it in the explosion environment (please refer to chapterAccessories - Thread

Connector/ ADAPTOR").

13

9. External Dimensions

9.1 Dimensions

14

10. Installation

Before installing and unloading the product, make sure that the device is

not suffered to any pressure and that the material inside the pipe or

container does not have leakage. Pay attention to the potential hazards

relevant to the temperature of the device and the media.

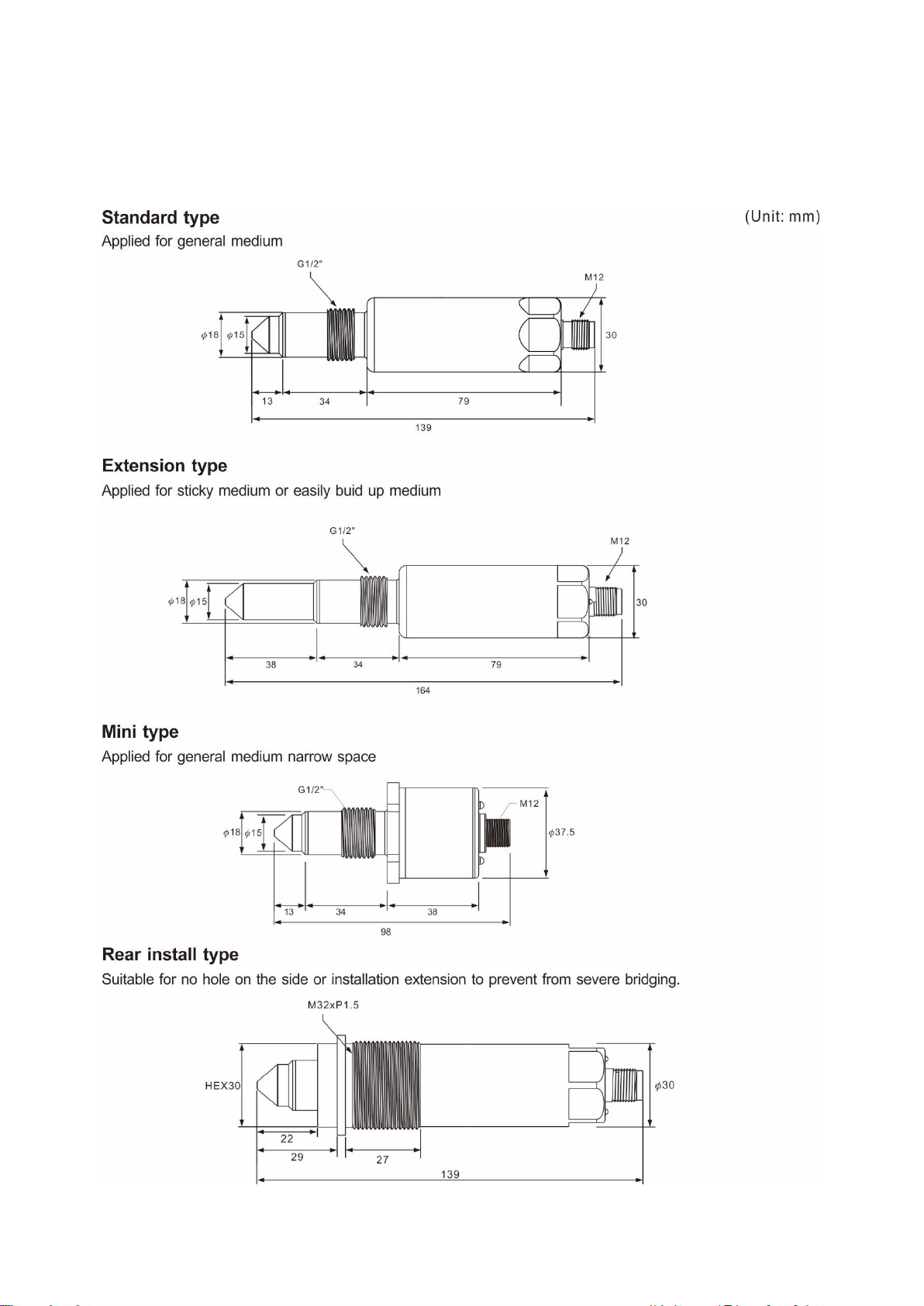

10.1 Installation Environment

Suggested to install the product in a metal container or pipe.

When installed in a plastic container, performance degradation or malfunction

may occur due to interference.

Check that the product is working properly via the field test function.

If interference occurs, take appropriate measures (shielding, grounding).

For pipe installation, the pipe size must be bigger than DN25.

Install the sensor at a distance of at least 15mm from the pipe wall, structural

parts, stirrer, and other sensors to prevent errors caused by collision or

interference (as shown below).

The insertion of the sensor should be sufficient to prevent the sediment from

being wrongly considered as the material (especially solid materials). The probe

of the sensor must be completely through the tank wall.

Do not use seal tape. The sensor must be well grounded with the container

or pipe.

The sensor probe must be protected from direct sunlight (UV).

Warning !

In the dust explosion-proof environment, it is forbidden to produce the process of

propagation brush discharge type and brush discharge type. Such as the rapid

movement of dust particles, powder transfer process and spraying process in

electrostatic coating process.

15

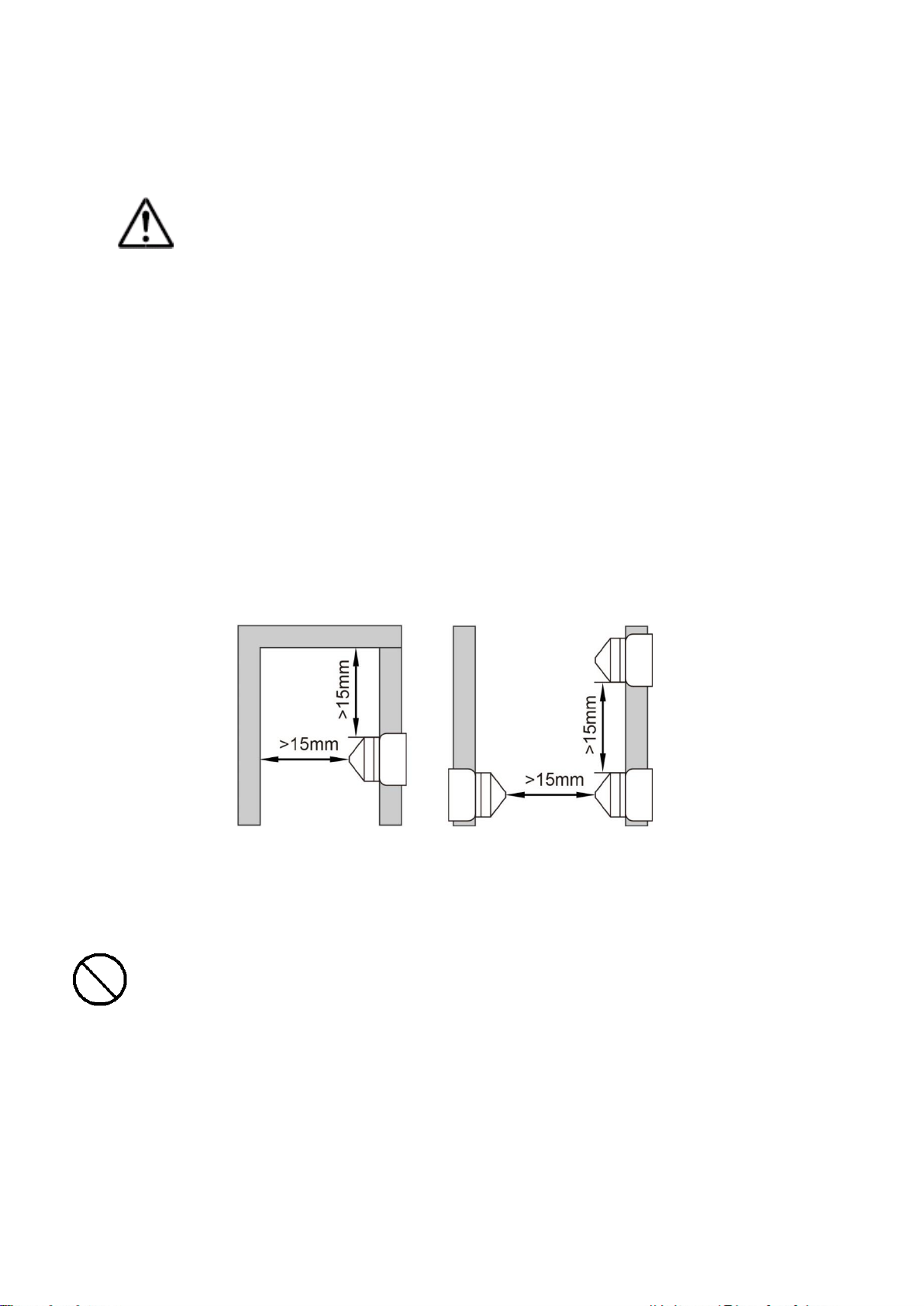

10.2 Installation Process

Make sure that the sealing surface is clean before installation and remove the

protective cover only when installing. If the sealing surface is damaged, replace

the device or adapter sleeve.

Install or weld the adapter sleeve onto the container/pipe. For the welding

operation, please refer to "SISB Welding Adapter / Thread Adaptor Operating

Instructions".

For installation of the tri-clamp, follow the relevant provisions for additional

installation steps.

Attach the seal to the sensor through the thread lock sleeve. The seal must be

correctly positioned and locked. Close the gap between the sensor and the

adapter sleeve end face.

Use the seal supplied with the sensor only. An inappropriate seal may cause

installation errors.

- The seal is too thick:A gap exists between the sensor tip and the adapter

sleeve.

- The seal is too thin: The seal is insufficiently compressed between the

sensor and the adapter sleeve. Leakage may occur.

Normal type

The seal (supplied with the adapter sleeve) is

squeezed

The sealing cone of the adapter sleeve/the sealing

end face of the probe is squeezed

Apply a little grease in the thread to help locking.

Lock the sensor into the adapter sleeve and tighten with a tightening torque

of 20...25 Nm.

16

Rear install type

Auxiliary rod is needed for rear installation, auxiliary rod is not included in the

order (customized order if need)。

When tightening, the sealing ring is not exposed and must be compressed at

least 1/4 wire diameter or more than 0.3mm to ensure the seal, and the

tightening torque is controlled between 20...30 Nm.

17

10.3 Installation Examples

The sensor can be installed as shown below:

Normal type

Tank Diagram Pipeline Diagram

The figure on the left shows an example of container installation, such as for

liquid level detection or as idling protection.

The figure on the right shows an example of pipe installation as liquid level

monitoring.

Attention! For highly viscous medium, the installation location ★in the

figure is only applicable to a certain extent. Residues may be incorrectly

detected as liquid level output.

18

Rear install type

Top-mounted Side-mounted

After installation, please check whether the resistance of the container or

pipe entrance is within the allowable range.

Make sure that the top cable is properly sealed, such as installing and locking

the cable gland.

Cables cannot be routed directly upwards, please go around for a short

distance and then route them upwards to release water.

10.4 Grounding instructions for dust-explosion zone

To prevent dust or flow being generated by friction or impact, this product can

be used in the dust-explosion area. Please confirm the grounding condition in

the installation environment and take proper grounding.

If the connection is the metal tank or pipe, this product is grounded through

“thread adapter” and metal tank or pipe. Please confirm that the installation

environment is grounded to prevent electrostatic charge.

If the connection is not the metal tank or pipe, the sensor must be installed

with the exclusive “Thread adapter" and use “thread adapter” to complete the

grounding.

The probe crosses the material of

the barrel wall and effectively

inhibits bridging.

High/low alarm and to

solve the problem that

no hole in the side.

19

11. Wiring Instructions

Attention! Wiring must be carried out by an electrician.

Make sure you comply with national and international regulations related to

the installation of electrical equipment.

The input power supply must be within the specifications of the product.

Turn off the power before wiring.

Make connections according to the wiring diagram below.

Insert the connector plug into the top socket of the sensor and tighten the nut.

Wiring diagram:

R1 and R2 represent the load of OUT1 and OUT2 respectively.

To protect the sensor from damage in the event of system failure, adding FUSE

0.5A to the power circuit is recommended.

only represents the property. The actual wire color depends on the connector

purchased.

Note: The accuracy and efficiency can not be guaranteed if using NON-FineTek

connector.

20

11.1 Simulation output test

1. Finished the installation and supply the sensor with 18~30Vdc.

2. Lean a magnet close to the + sing for 2 seconds or more, there

will be switching output with corresponding LED light display.

3. Remove the magnet from the + sign, the switching output

and corresponding LED light display will return to

normal status.

11.2 M12 cable connector for dust-explosion zone

Do not open the connector when there is an explosive dust environment.

Please complete the M12 cable installation in the safety area first, and

then complete the on-site installation before providing supply power.

Please use 14mm size open-end wrench to operate with the torque around

1~1.5 Nm (0.1~0.15 kgf.m)..

Use M12 cable type in dust explosion-proof environment which approved by

NEPSI; ADOAH040VAS0005E04, ADOAH043VAS00005E04 (order code;

PC3121231415M011, PC312-1232410501)

Torque: 1.5Nm

Other manuals for SIS

1

Table of contents

Other FineTek Switch manuals

Popular Switch manuals by other brands

Brocade Communications Systems

Brocade Communications Systems VDX 6940 Series datasheet

D-Link

D-Link xStack DXS-3350SR Specifications

SOMFY

SOMFY DECOFLEX 1810897 instructions

TP-Link

TP-Link TL-SG1016D user guide

Cardin Elettronica

Cardin Elettronica SEL Series quick start guide

Leuze electronic

Leuze electronic CSL710-T05-1280.A-M12 Original operating instructions