Finwing SABRE 1900 User manual

USER MANUAL

FINWING SABRE 1900FINWING SABRE 1900

FINWING TECHNOLOGY

WWW FINWINGHOBBY COM

PATENT PENDING

..

Finwing Sabre

.

This manual aims to help direct the user on how to build the Sabre RC plane.

Please visit the Finwinghobby com official website for more introductions.

Please read through the manual carefully before installation and flying

Warning:

1 This model airplane is not a toy not recommended for children under 14 years old., ,

2. Be cautious and prepared while flying this plane as a range of issues could lead to a crash

including the environment/weather, speed, pilot error, improper building/testing,

interference or other component failures

3. Flying field: Choose an adequate flying space at least 100 meters long/wide and in an unpopulated

and non-built up area for safe flying. This includes avoiding flying over cities or other populated areas.

4. Please don't fly this model airplane in bad weather including rainy and/or windy environments.

5. Remember to unplug your flight/video battery when not in use to avoid any interference to others

who might be on similar channels.

6. Please remember switch on the transmitter first before connecting the battery, and disconnect

the battery first before switching off your transmitter.

7. Keep away from the propeller when the Airplane is powered as it can be dangerous and could

lead to injury. Keep the powered plane away from children at all times to avoid any accidents or injury.

.

The Tail-boom has been split from the fuselage in order to fit into a smaller package

that will also help to save on overall shipping costs.

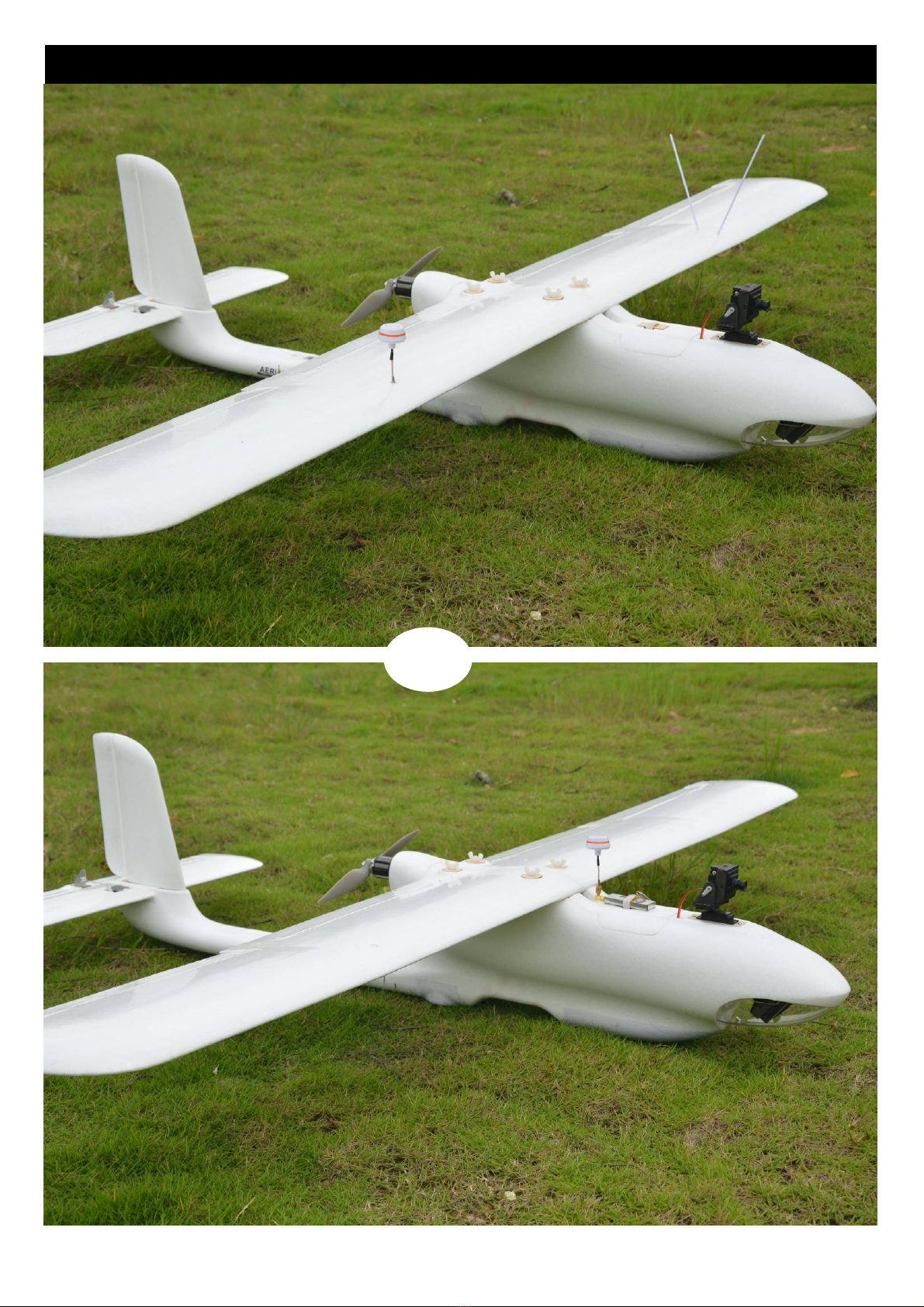

Finwing Sabre Basic information

Wingspan:1900MM (74.8”)

Length :1320MM (52”)

Propeller :11*5.5" / 11*6"

Flap :Available (Options)

Max.AUW :4.0kg (8.8IB)

EFFICIENT AUW:3.1-3.5kg (6.8-7.7IB)

Hand launching :Available

Belly Armour :Options

Standard Nose cover:Included

Steerable undercarriage:Options

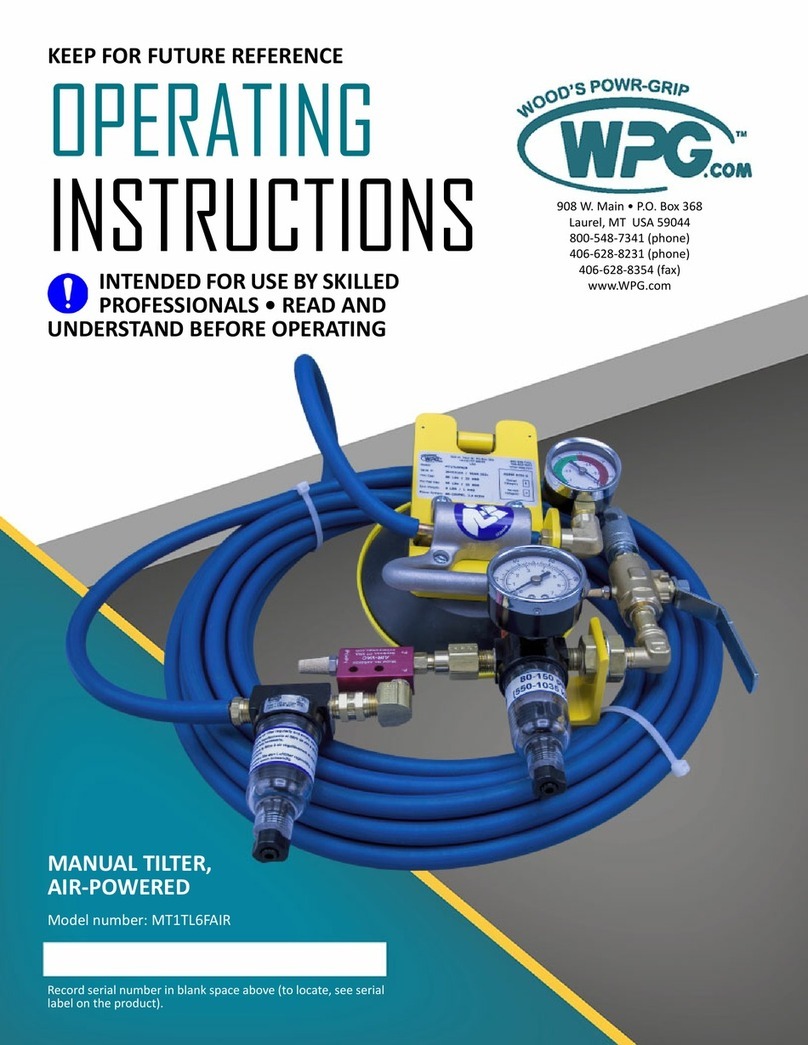

Module1:Hero Nose cover

Module2:Gimbal with transparent cover

Module3:Downward facing filming

Hero 390/300 degree Pan&Tilt system

Mini Camera 390/300 degree Pan&Tilt system

Professional Modules specially designed

ForHDaerialphotography

Options Only

()1PCS Brushless Motor M2820 3542

1PCS Premium Brushless 60A ESC OPTO

1PCS UBEC 6A

3PCS 23g Metal servo

1PCS 9g Plastic servo

()1PCS Brushless Motor M2815 3536

1PCS Brushless 60A ESC SBEC

3PCS 17g Plastic servo

1PCS 9g Plastic servo

390 300 FPV Hero Pan Tilt

00

/&

390 300

00

/&FPV Mini Pan Tilt

FSA01 Module1

Hero Filming Nose Cover

-

OPTIONS ONLY OPTIONS ONLY

FSA02 Module2

Gimbal Filming Nose Clear Cover

-

+

FSA04

Steerable Undercarriage

OPTIONS ONLY

OPTIONS ONLY

Including 1PCS 23g Metal Gear Servo

FSA03

Module3 Downward Filming

Sabre Premium Power system Sabre advanced Power system

OPTIONS ONLY OPTIONS ONLY

OPTIONS ONLY OPTIONS ONLY

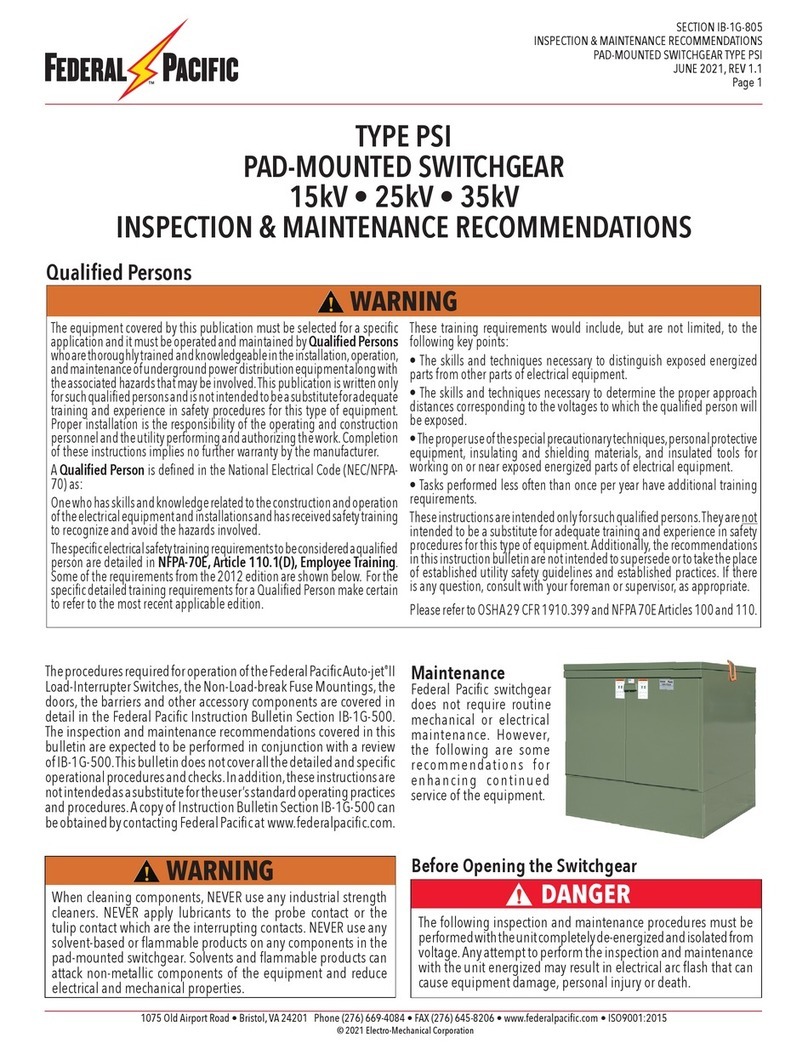

CG 82 5 85MM 3 2 3 3 From the leading edge. .- (."-.")

No Dome

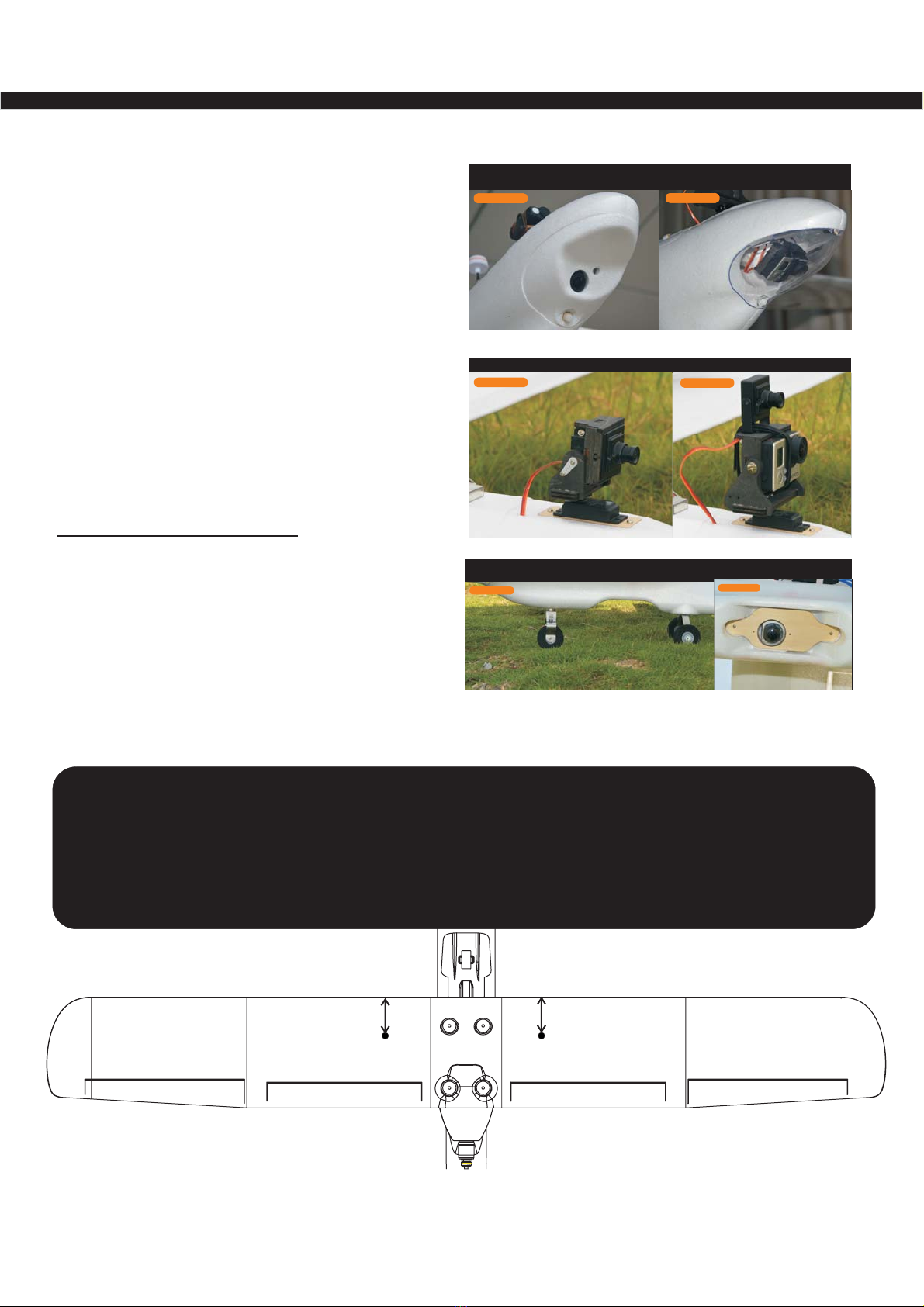

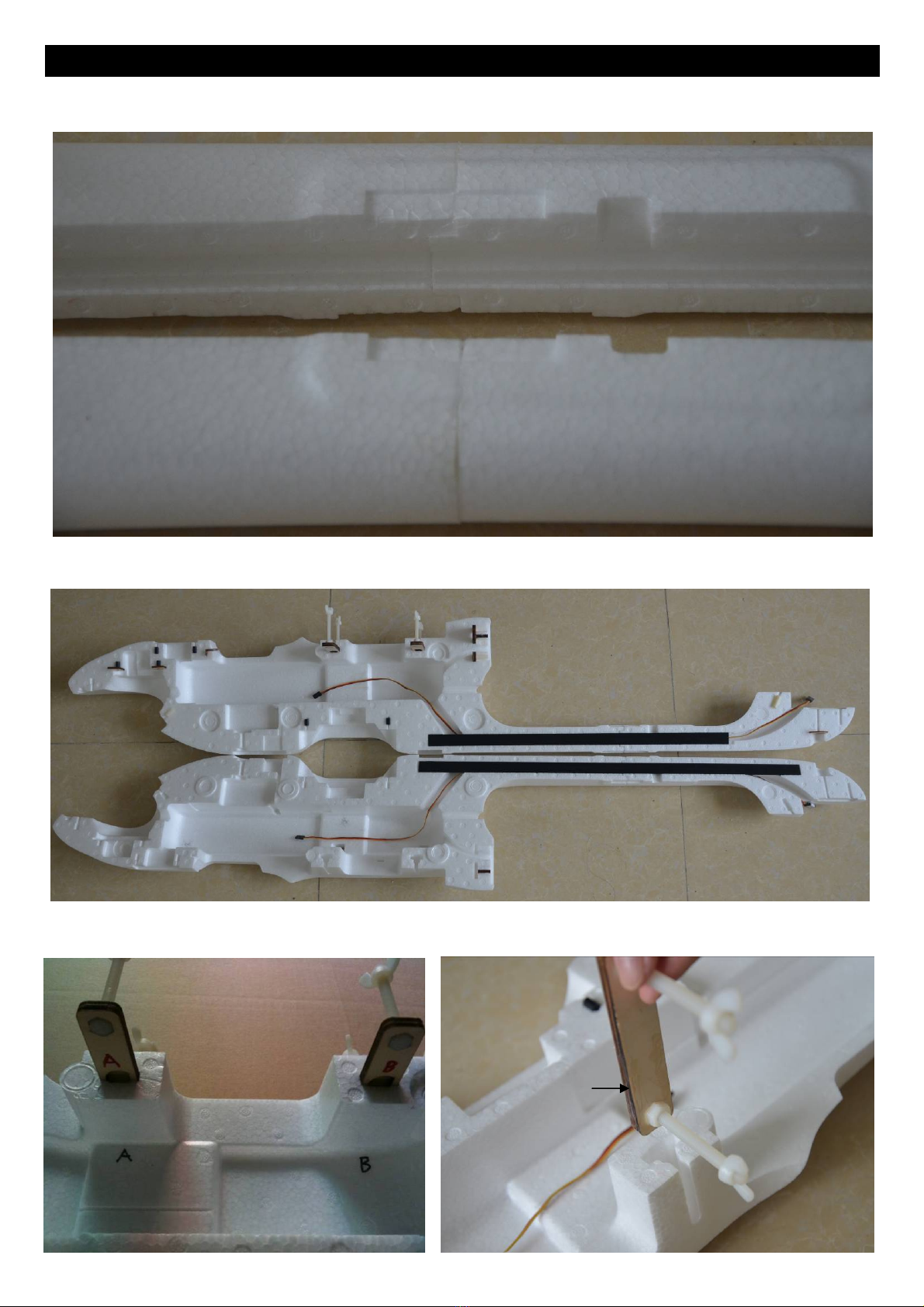

FinwingSabreWingsinstallation

Aileron:17gPlasticGearServoor23gMetalGearServo.Flap:9gservo

Flapisnotmust,Dependsonyourflyingpreference.

1>TherearetwoslotsforVTXandUHFseparatelyonleftandrightwing,thepurposeistoavoidsignal

interferenceespeciallylongrangeflyingsystem.pleasecutouttheslotfoamaccordingtoyou

equipments'sizebeforeclosingthewing‐cover,

Pleaseskipifyouwon'tputVTXandUHFonthemain‐wing.Forexampleputitonthecockpitandtail‐

boomisalsonoproblem.it'sdependsonyourpreference.

Overview

2>Preparetheextensionwiresfirst,kitspackageincludedAileronextensionwiresbutnoextension

wiresforflapservos.Spreadinggluetothemainwingcave,unnecessarygluetothewing‐cover.

Gluingtimeapproximately3‐4minutes,gluewilldryquicklyiftoolong.

Afterclosingwing‐cover,it'stimetoinstallthecarbonstripwithalittleglue,andothersmallpartsas

thephotosshown.

Pressitfirmlyintermittentlybythefirsthalfhour

Installcarbonstripwithalittleglue

Roomtemperaturedryingabout24hoursbeforeflying

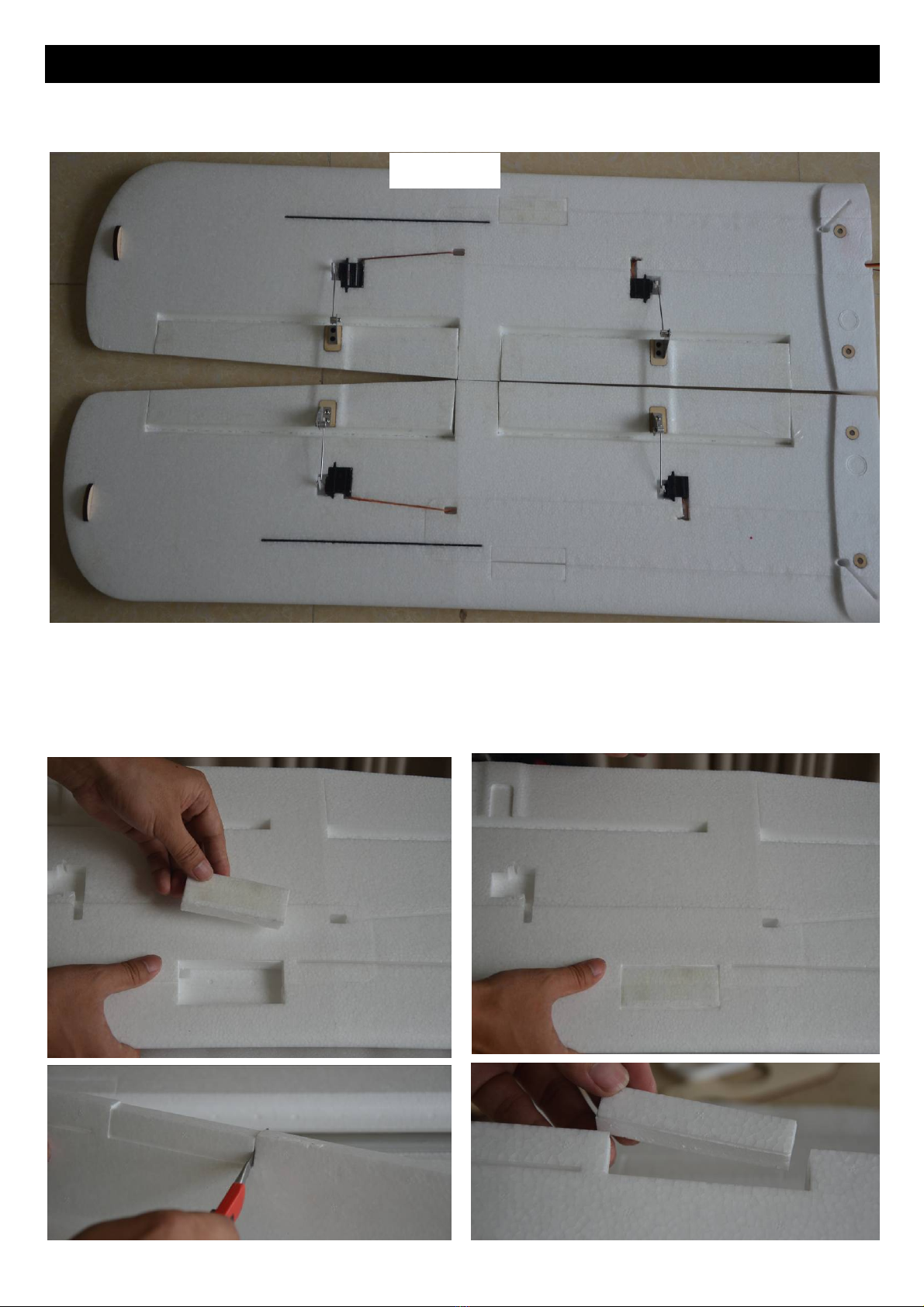

3>Cutoffthesideconnectionofthecontrolsurfaceuntilfeelingthecontrolsurfaceisrotatablefreely

Aileron,flapandElevatoralldothesame

Forexamplehowtoreinforcethebottomside,movethecontrolsurfacetothemax.upposition,then

wrappingtapeadheretotheslot,pressitfirmly.Movethecontrolsurfacetothemax.downposition

whenreinforcethetopsideaccordingly

CutofftheSideconnectionofcontrolsurface

Reinforcethehingeisnecessaryforbothsidesjustbythewrappingtape

Tips:Laminatethewing

wrappingtapetolaminateismoreefficientandeasywaytoprotectyourairplane,butthisisnotthe

mustworks.Pleaseskipifyoudon'twanttolaminate

Beforelaminating

laminated

4>Neutralizeallservos,preparetoinstallAileron,Flapservos,

Note*fla

p

travelisnotthebi

gg

erthebetter,A

pp

roximatel

y

10MMisoka

y

Aileron

Aileron

Flap

Flap

Aileron Aileron

Flap Flap

10MM

Flaptravel≈10MM

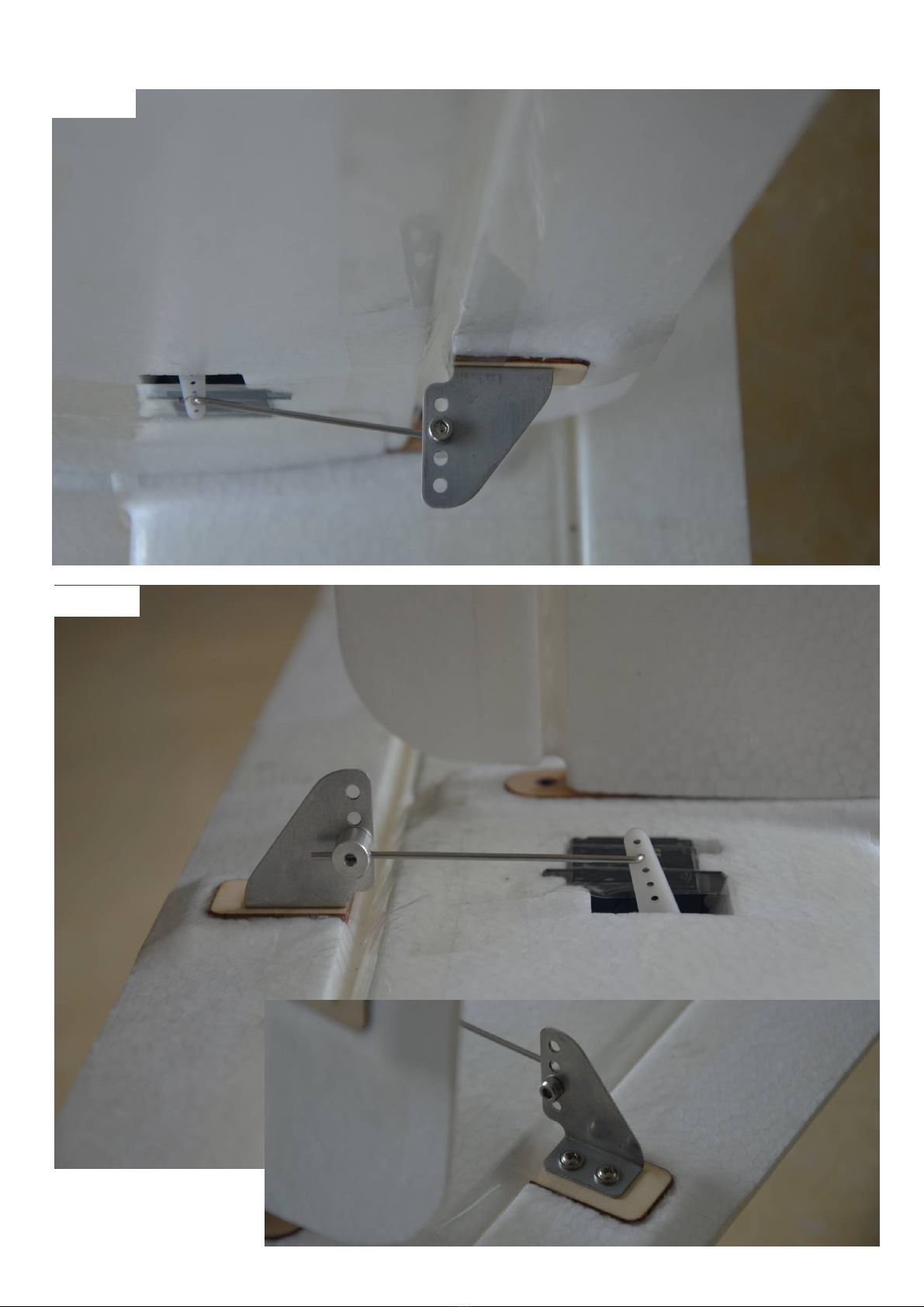

5>ElevatorandRudderinstallationissimilartoAileron.

Elevator

Rudder

Finwin

g

SabreFusela

g

einstallation

1>Jointail‐boomtofuselage,gluetothejointcontactsurfacethenpressingfirmly

Don'tmoveitatleasttwohoursdryingtimeatroomtemperature,besuredon'ttwistthetail‐boom!

2>Twohourslater,installthetailcarbonstrips,don'tforgetextensionwiresfirst,andsomeother

extensionwiresif

y

ouneed.Forexam

p

leUHForGPSextensionwires

3>installthewing‐fuselagejointparts,alittleglueisnecessary,AandBjointpartsatcorrectslot

Glue

Roomtemperaturedryingaboutoneortwohours

Roomtemperaturedryingaboutoneortwohours

4>installtheplywood,themotormountwillbesecuredtothisplywoodbyscrews

5>Doublecheckingthefuselageagain,besurenopartsmissing!

Glue

Glue

6>It'stimetoclosethefuselage,recommendgluetotherighthalffuselage,unnecessarygluetoboth

halffuselage,oralittlegluetothelefthalfoffuselageisokaybysomeofthecontactsurface.Costabout

8‐9minutesspreadinggluetotherighthalfoffuselage,gluewilldryquicklyiflasttoolong!

Pressingfirmlybyallpartofthefuselageintermittently,especiallyduringthefirsthour.

Roomtemperaturedryingabout24hoursbeforeinstallationofmotor

7>Installthefollowingpartswithglueduringtheperiodoffuselagedrying

Rememberletthefuselagedryabout24hoursatroomtemperature,atthisperiodyou

caninstallWings,Module2,Undercarriageetc…

Magnet

CarbonStrip

Recommendwrappingtapearoundthetail‐boomjoint

Pleaseskipthisifnoundercarriage,handlaunchingonly

Frontgearlocker Screwwasher

8>ESCandMotorinstallation

ESCsecuredtothesideoffuselage,it'sverygoodforcooling,

BacktobackVelcroincluded,cuthalfoftheVelcro,oneforESCandanotherforVTX

Securethemotortothemotormountplywoodbywashersandscrewsfromkits'package(included)

withouttraditionalcrossshapemotormountisgoodtoreducethesizeofairplane'smotormountand

produceaslessairdragaspossible

Securethemotormountplywoodtotheairplanebywashersand3PCSlongscrews(3*35MM)

MostofthePropellershouldbe:embedwordstowardthenoseofairplane,don'tbewrongdirection!

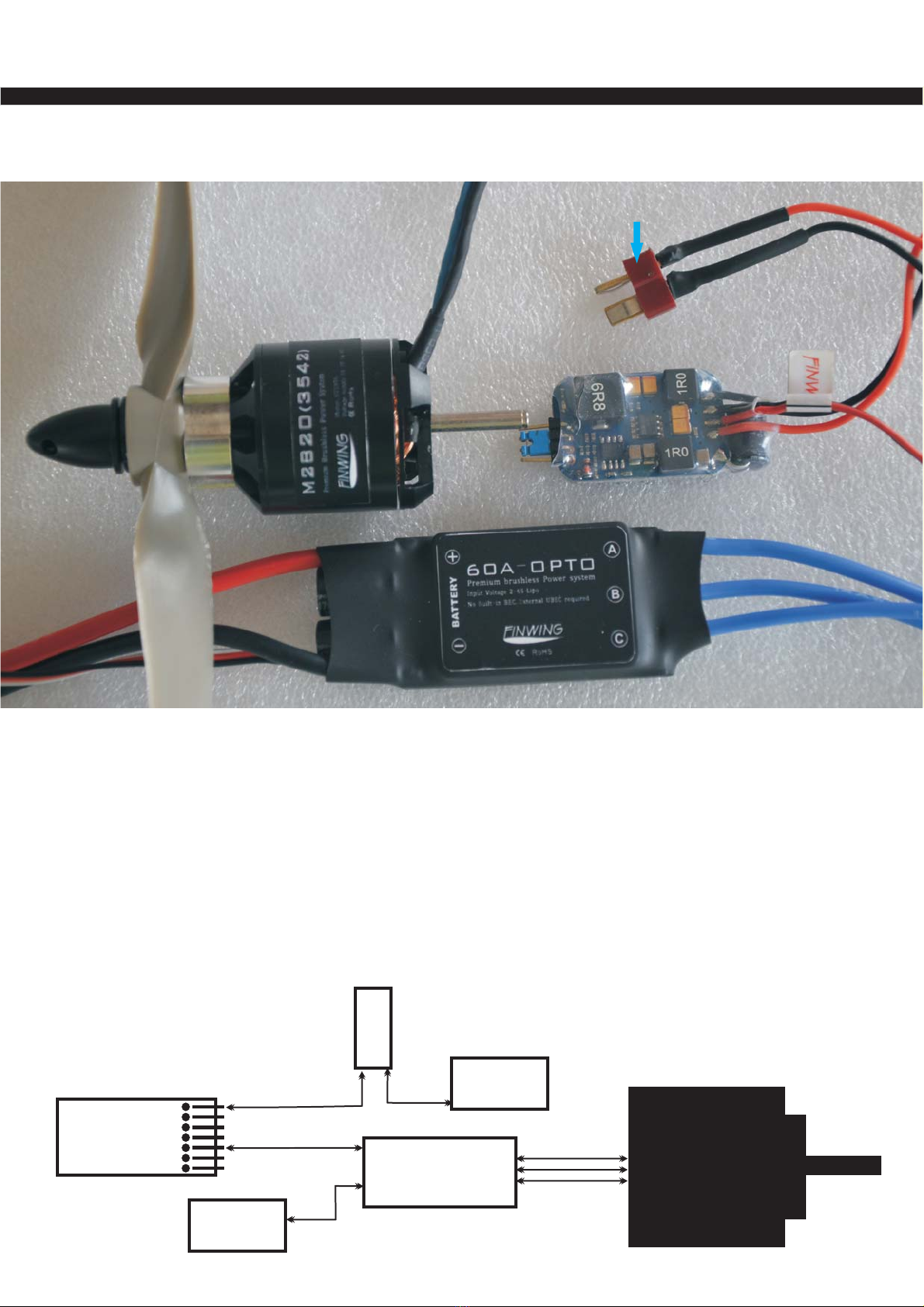

Finwing Sabre Power System

The following photo shown is sabre premium power system

Please solder a connector for the BEC power input

Connector type is depends on what type of your battery s connector'

6CH Receiver

()For Example

1

2

3

4

5

6

B

ESC A

Opto

60

34-SLipo

Battery

FINWING

()

M2820 3542

ESC A

Opto

60

BEC

26-SLipo

Battery

The premium A ESC opto plus a external BEC 6A

This combo is more safety and efficient to supply your airplane espeically

FPV flying need supply lots of FPV gears undercarriage Pan Tilt etc

Diagram of wires connection Premium power system

ESC type Opto without buit in BEC

External 6A BEC

, , & , ...

()

*: -

*

60

BEC Specification

()Output: 5V/6A,5.5V/6A,6V/6A Switchable by the Blue jumper

Input: 5V-25V (2-6S Lipo, 5-18S NiMH/Nicd)

Continuous Current 6A, Brust current 10A

UBEC should be at least 5CM away from the receiver to avoid electronic interference

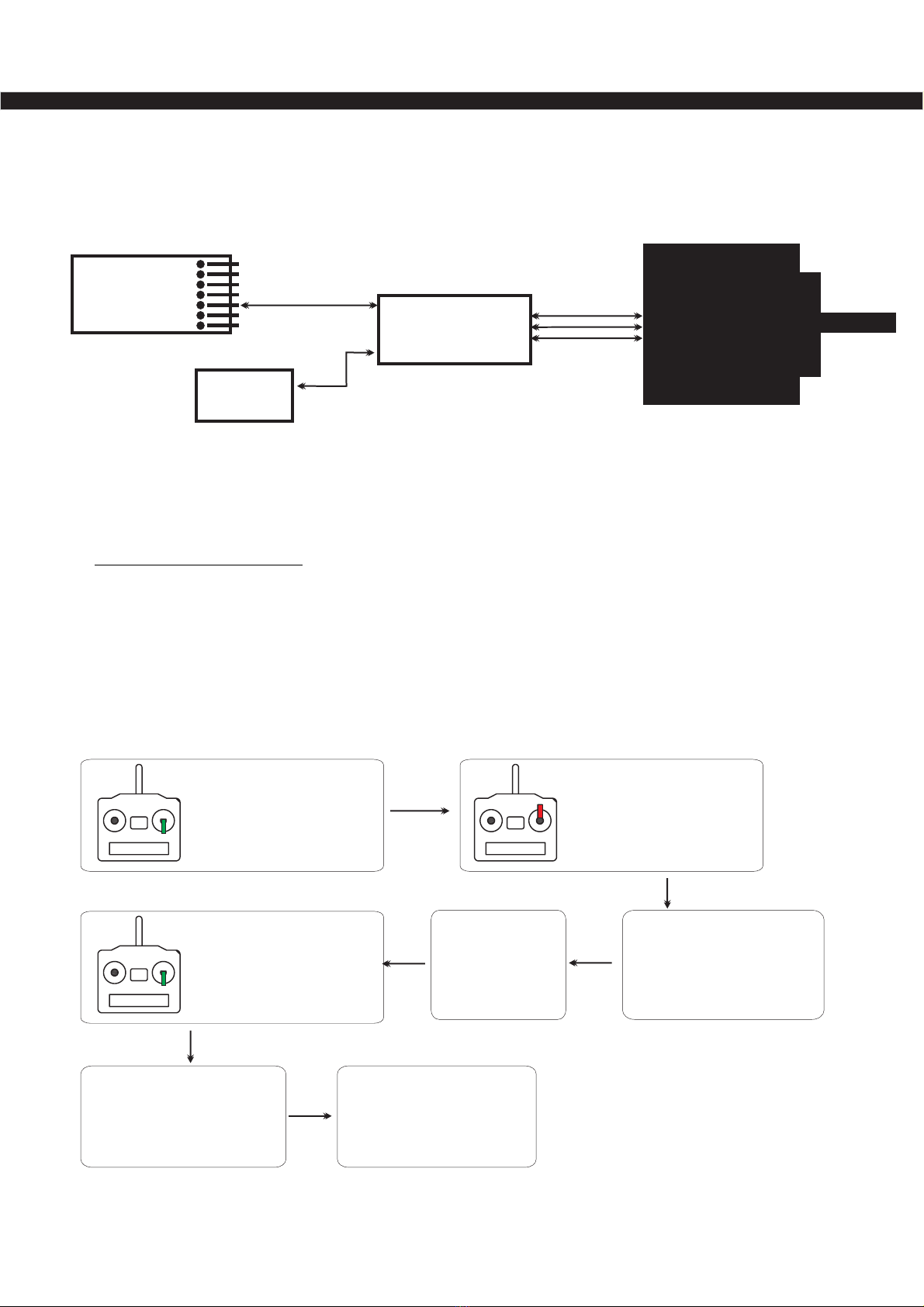

6CH Receiver

()For Example

1

2

3

4

5

6

B

ESC 60A

(-)with built in BEC

34-SLipo

Battery

FINWING

()

M2815 3536

,, .

Throttle calibration setting is required by all power system for The first time use

or changed new transmitter replaced ESC motor and battery

*: " "Note it may cause lost throttle signal if no throttle calibration

Throttle stick to

the Maximum Position

Power on BEC

Power on ESC

waiting for a moment

Seconds<>2

You can hear

the motor

Beep or Beep Beep-

Move throttle stick to

the Minimum Position

immediately

Motor Beep

Indicating cell number

and signal confirmation

Throttle calibration done

.....

Ready to fly now

Finwing Sabre Power System

Diagram of wires connection Advanced power system

ESC type with build in UBEC SBEC

()

*: -/

Switch on Transmitter

for two second

Note USA EU flyers transmitter the throttle stick should be at the left side of transmitter:, ' ,

Throttle calibration

Undercarria

g

e

1>assemblythefrontgearasthephotosshown

2>installundercarriagenow,installthereargearfirst,thenneutralizethe(23g)metalgearservo

installthefrontgearasphotosshown.Adjusttheundercarriagedirectioncorrectlybeforeflying

Servowireoutlet

EClasp

RearGear

Module2

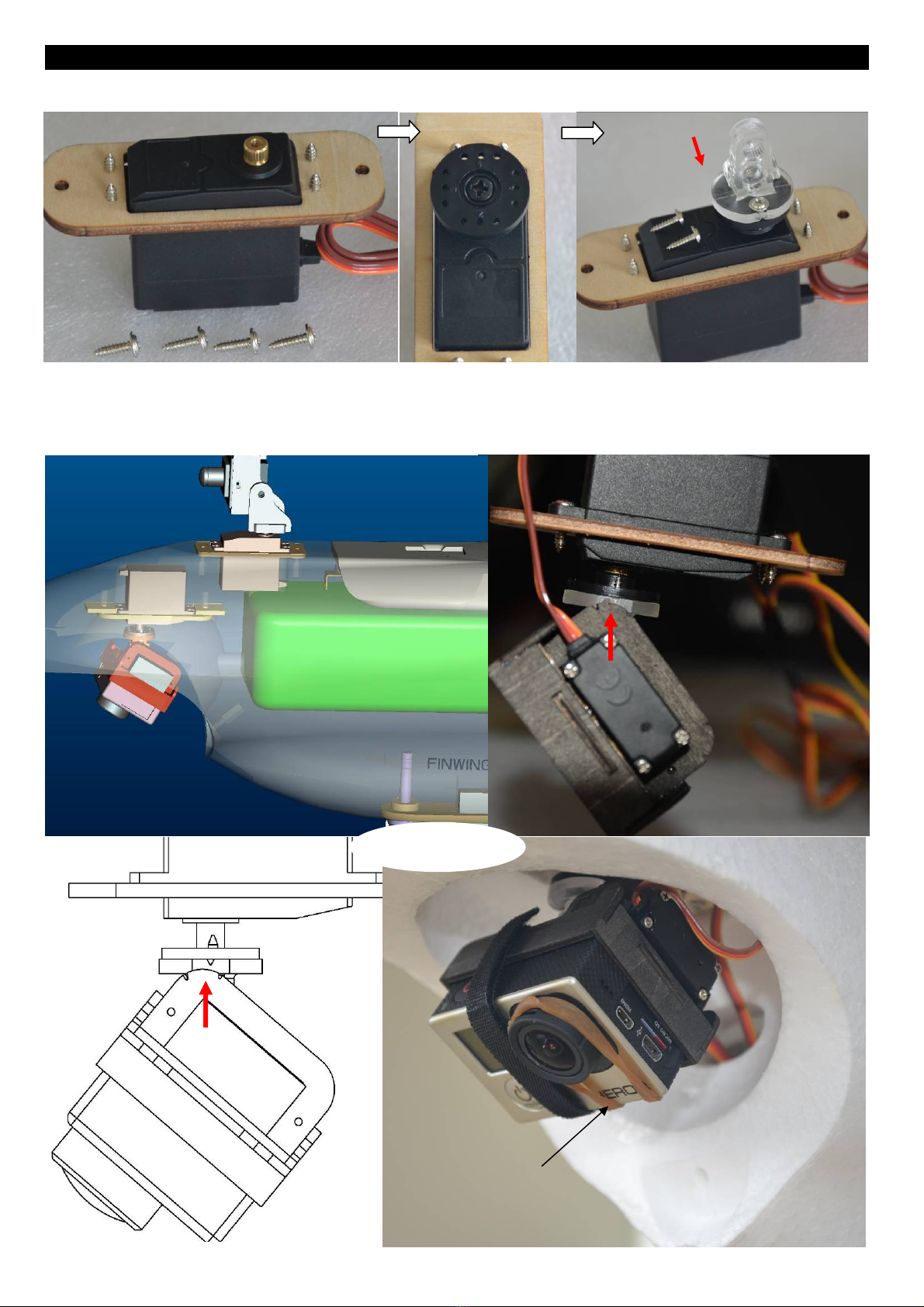

>Secureplywoodtotheservo,thenSecuretheservoarmandthejointarmsubsequently,Gearofthe

j

ointarmtowardtheri

g

htsideas

p

hotosshown

>InstalltheTiltmodule,recommendinitialpositionasthephotosshown,butyoucanadjustit

accordingtoyourreference,youcaninstallitmoredownwardifyouwouldlikedownwardvideomost

ofthetime.FYI:Wealsoflyingwithoutrubberbandandvideonovibration,

Gear

AntivibrationRubberband

FYIFPVGearsLayout

OR

UHF

UHF

VTX

VTX

Table of contents

Popular Tools manuals by other brands

Chicago Electric

Chicago Electric 92196 operating instructions

Ryobi

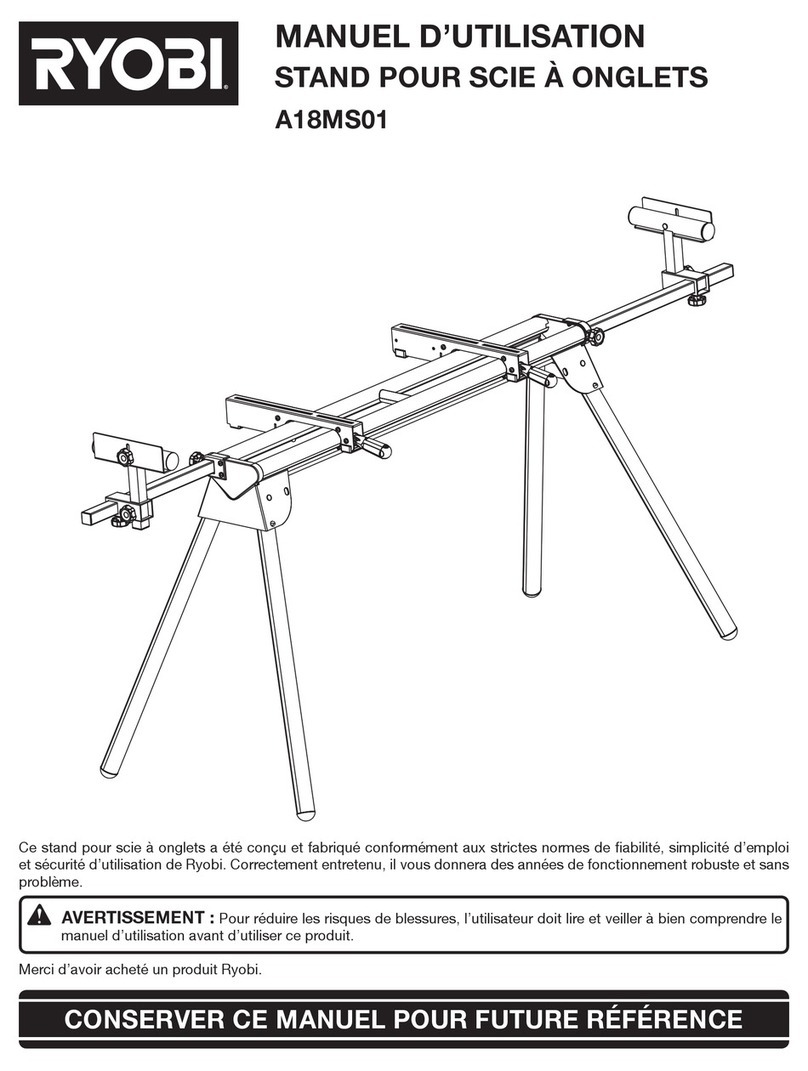

Ryobi A18MS01 Manuel d'utilisation

Hyundai power products

Hyundai power products HCOMBI336F-A Original instructions

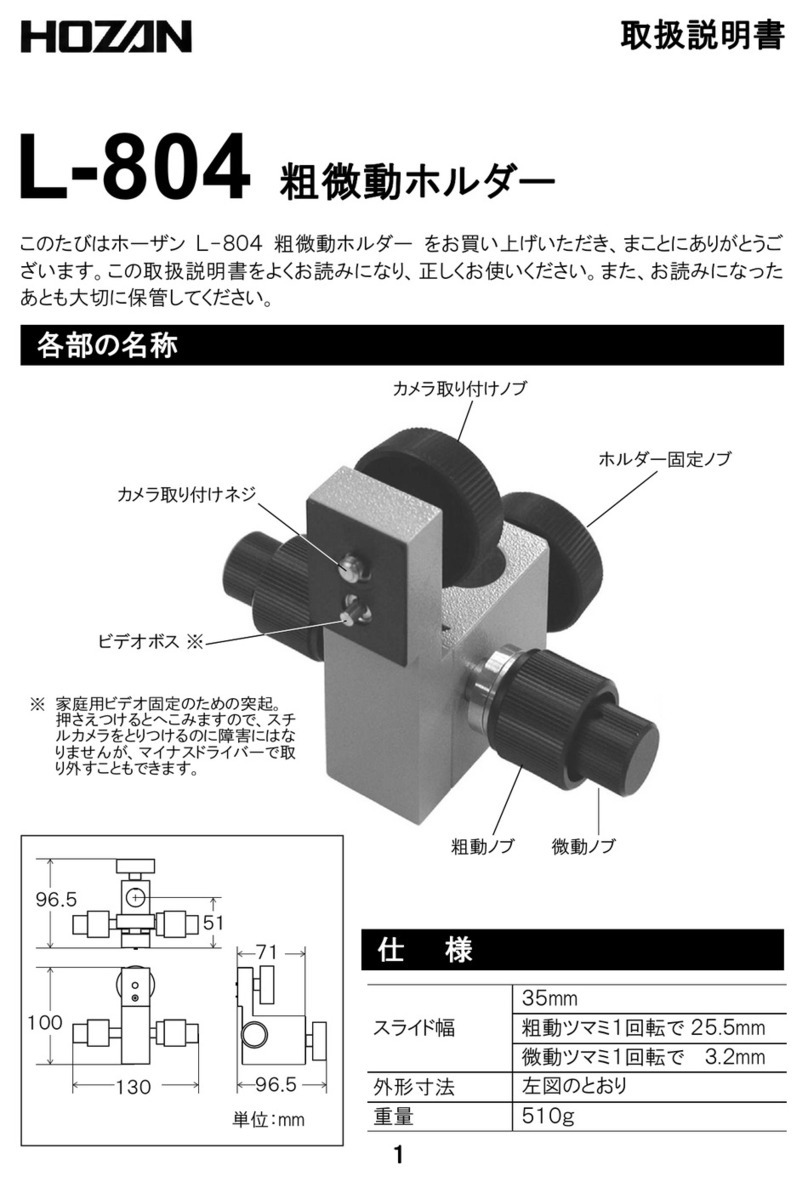

HOZAN

HOZAN L-804 instruction manual

DeWalt

DeWalt DCS438 instruction manual

BIAX

BIAX BE 309 R Translation of the original operating manual

Reelworks

Reelworks 27807153 instruction manual

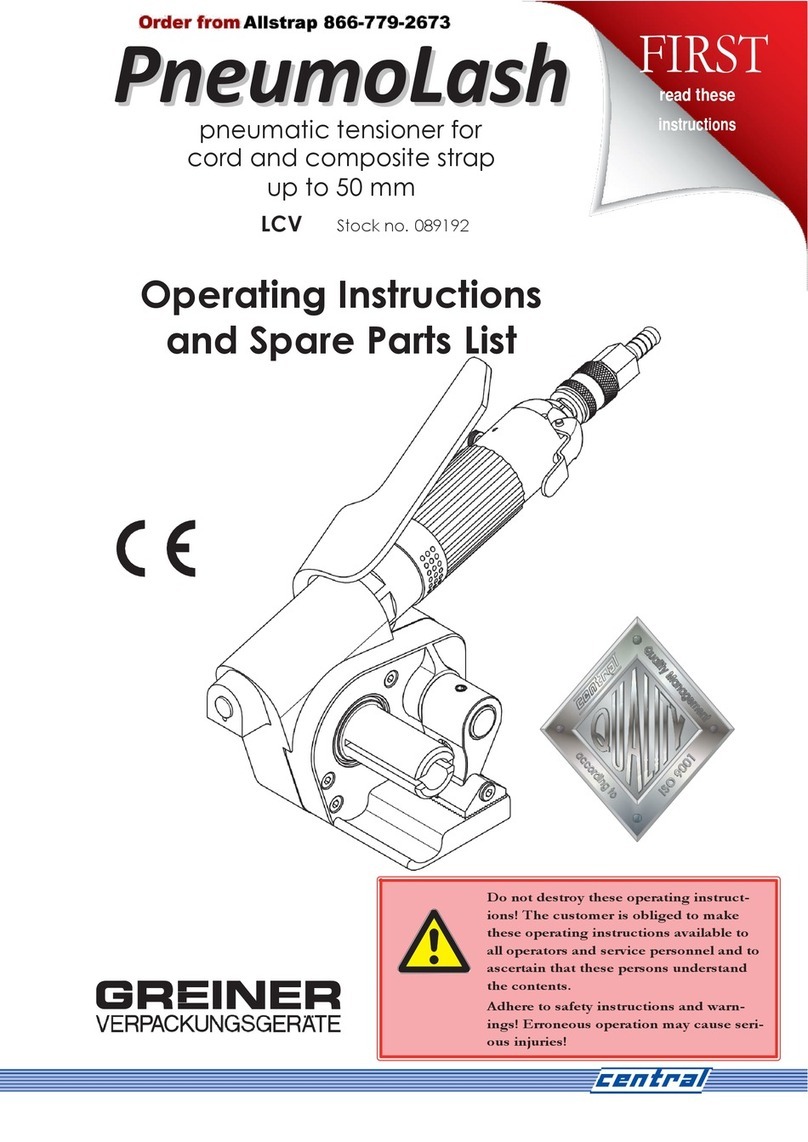

GREINER

GREINER PneumoLash LCV Operating instructions and spare parts list

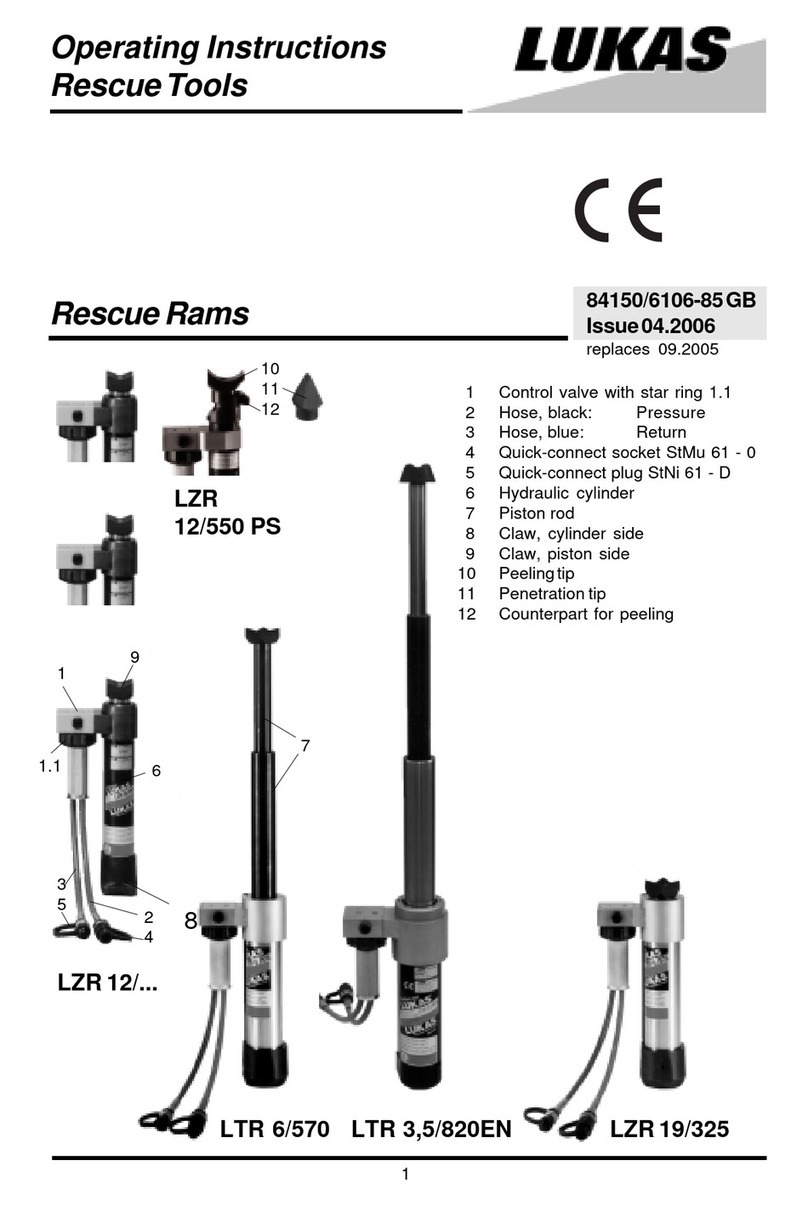

Lukas

Lukas LZR Series operating instructions

Neilsen

Neilsen CT4448 Original instruction

Hytorc

Hytorc Torque Gun Digital jGun DJ-.25 Operation manual

Performance Tool

Performance Tool W54290 user manual