FIORENTINI ASPIRIK-P User manual

Contents

1 Safety Standards......................................2

1.1

Symbols used in the instructions .............. 2

1.2

General warnings....................................... 2

1.3

Driving mode.............................................. 2

1.4

Appliances with Combustion Engine.......... 3

1.5

Compliant and Intended Use ..................... 3

1.6

Symbols on the Machine............................ 4

2 Description...............................................4

2.1

Control and operating parts ....................... 4

2.2

Identification Plate...................................... 5

3 Before putting into Service......................5

3.1

Unloading the appliance............................. 5

3.2

Drive Disengaged....................................... 5

3.3

Drive Engaged ........................................... 6

4 Commissioning........................................6

4.1

Fuelling....................................................... 6

4.2

Control Interventions.................................. 6

4.3

Positioning the Waste Container................ 6

5 Operation..................................................7

5.1

Starting the machine.................................. 7

5.2

Driving........................................................ 8

5.3

Suction ....................................................... 8

5.4

Dust Removal............................................. 8

5.5

Cleaning the Filter...................................... 9

5.6

Stopping..................................................... 9

5.7

Transport........................................9

6 Care and Maintenance.............................9

6.1

General Warnings...................................... 9

6.2

Cleaning................................................... 10

6.3

Maintenance frequency............................ 10

6.4

Battery Maintenance................................ 10

6.5

Motor Oil................................................... 11

6.6

Air Filter.................................................... 11

6.7

Spark plug................................................ 12

6.8

Hydraulic oil.............................................. 12

6.9

Transmission Belts................................... 12

7 Disposal..................................................13

8 Warranty .................................................13

9 Accessories and Spare Parts................13

10 Troubleshooting...................................14

11 Technical Specifications ....................14

rev.01

Operating instructions

ASPIRIK-P

Petrol Vers.

EN

2

1 Safety Standards

This document contains important information

relating to appliance safety.

As well as a guide for its proper use. Before

putting the unit into operation for the first time,

you must read and understand this instruction

manual carefully. Keep the instructions for

further

reference.

1.1 Symbols used in the instructions

1.2 General warnings

Immediately inform your dealer should damage be

discovered when unpacking due to transport.

Read the operating manual of the machine and

especially comply with the safety standards

before operating it.

The warning plates on the appliance provide important

information for safe use.

In addition to the operating instructions and

mandatory regulations for the prevention of

accidents in the country of use, you must observe

the general safety and operating rules.

1.3 Driving mode

HAZARD

Risk of tipping over when driving

fast on curves.

•

Drive bends at low speed.

HAZARD

Risk of tipping over on unstable

ground.

•

Only drive the appliance on

stable floors.

HAZARD

Hazard that leads directly to serious or

irreversible injuries, or even death.

WARNING

Hazard that can lead to serious or

irreversible injuries, or even death.

CAUTION

Hazard that can lead to minor

injuries.

HAZARD

Risk of tipping over in case of

excessive lateral inclination.

•

Drive on slopes no greater than 10%

diagonally to the direction of travel.

•

Comply in principle with the rules,

regulations and provisions that apply

to motor vehicles.

•

The operator must use the

appliance according to the intended

use. While driving, he must take

account of conditions on site and pay

attention to third parties (in particular

children) when using the machine.

•

The appliance must only be used by

personnel trained on its use or who

have proven to know how to use the

machine and are expressly in charge

of its use.

•

Prior to use, try using the appliance

in a non-public area.

•

It is prohibited for children or

adolescents to use the machine.

•

It is prohibited to transport other

people.

•

Remove the ignition key to prevent

unauthorised persons from using the

appliance.

•

Never leave the appliance

unintended while the engine is

running.

•

The operator may only leave the

appliance after having switched off

the engine, blocked it against

movements, engaged the brake and

removed the ignition key.

HAZARD

Risk of tipping over on steep

slopes.

•

Do not drive or operate on slopes

greater than 10%.

•

For short straight segments and with

the waste container empty, it is possible

to exceed 30% slopes (e.g. truck ascent

ramp). In any case do not operate on

slopes greater than 10%.

HAZARD

CAUTION

WARNING

HAZARD

HAZARD

HAZARD

HAZARD

EN

3

1.4 Appliances with Combustion Engine time frame, keep absolutely away

from the transmission area.

•

Open the bonnet of the appliance only

with the engine off.

•

Do not insert your fingers into the

steering column lock mechanism.

•

Do not remove the safety devices.

1.5 Compliant and Intended Use

Use this light waste vacuum cleaner only in

accordance with the directions given by

this operating manual.

Before use, check the perfect condition and safe

operation of the appliance and of the work

equipment. Otherwise it is forbidden to use it.

Before starting work, the operator must ensure that

all the safety devices are correctly placed and

functioning.

In the standard version (with coarse filter) the

appliance is suitable for suction of light waste (e.g.

jars and beverage bottles, cigarette boxes etc.).

This appliance is designed to vacuum clean

outside environments.

The appliance is not suitable to vacuum and

collect dust harmful to health.

No changes may be made to the

appliance.

Never vacuum explosive liquids, flammable gases,

or acids and solvents. This includes petrol, paint or

gasoline thinners that, together with the intake air,

may form explosive vapours or mixtures, as well as

acetone, acids and solvents that may corrode the

materials of the machine.

Reactive metal powders (e.g. aluminium,

magnesium, zinc) form explosive gases together

with strongly alkaline detergents and acids.

Do not vacuum burning objects.

It is forbidden to remain in the danger areas.

It is forbidden to use the appliance in explosive

environments.

Keep the appliance away from any easily

flammable substance.

Protect the appliance against freezing.

Any other use is considered improper use. The

manufacturer does not accept responsibility for

any damage caused by improper use. The risk

resulting from such use is the sole responsibility of

the user. Suitable use includes appropriate

operation, maintenance and repairs as specified

by the manufacturer.

CAUTION

Before commissioning the appliance,

read the operating manual supplied by

the manufacturer of the engine.

In particular observe the safety-related

warnings.

HAZARD

Risk of explosion.

•

Refuel only with the engine off.

•

Only use the fuel stated in the engine

operating instructions.

•

Do not refuel in closed

environments.

•

Do not smoke or use naked flames.

•

Make sure that the fuel does not come

into contact with hot surfaces.

WARNING

Risk of burns.

•

The gas exhaust outlet must not be

closed.

•

Do not lean over the gas exhaust

outlet.

•

Do not touch the gas exhaust outlet.

•

Before carrying out any maintenance

or repair, let the appliance cool down

sufficiently.

•

Do not touch the drive engine.

HAZARD

Risk of poisoning.

•

Exhaust gases contain carbon

monoxide, and therefore are harmful

and injurious to health and should not

be inhaled.

•

It is prohibited to use the

machine in closed environments.

HAZARD

Risk of shearing.

•

After switching off, the engine takes

about 3-4 seconds to stop completely.

During this

CAUTION

HAZARD

WARNING

HAZARD

HAZARD

EN

4

1.6 Symbols on the Machine

The following symbols are displayed on

adhesive labels on the external surfaces of the

machine. Their presence is essential to ensure

the safe use of the machine.

The operator is responsible to replace missing,

damaged or illegible labels due to wear. The

ordering code of the corresponding label is

shown below next to its description.

2

2 Description

2.1 Control and operating parts

1.

Steering column

2.

Bonnet

3.

Suction hose

4.

Flashing light

5.

Suction head

6.

Waste container

7.

Fire extinguisher

Code ET054

Crushing hazard. Keep

hands away from moving

parts of the machine or wait

until all moving parts have

stopped.

Code ET085

Burning hazard. Do not

touch surfaces near the

symbol as they are hot. Let

the engine and exhaust

system cool down before

attempting any work on the

appliance.

Risk of shearing.

Forbidden to remove the

guards and safety

devices.

Fire hazard. Do not

smoke or use naked

flames near the machine.

Keep easily flammable

materials and substances

away from the machine.

Code ET065

Code ET058

Code ET085

Code ET054

EN

5

8.

Dashboard

9.

Fuel tank

10.

Suction filter

11.

Rigid suction pipe

12.

Handle

13.

Steering column unlock lever

14.

Exhaust gas outlet

15.

Water tank for dust removal

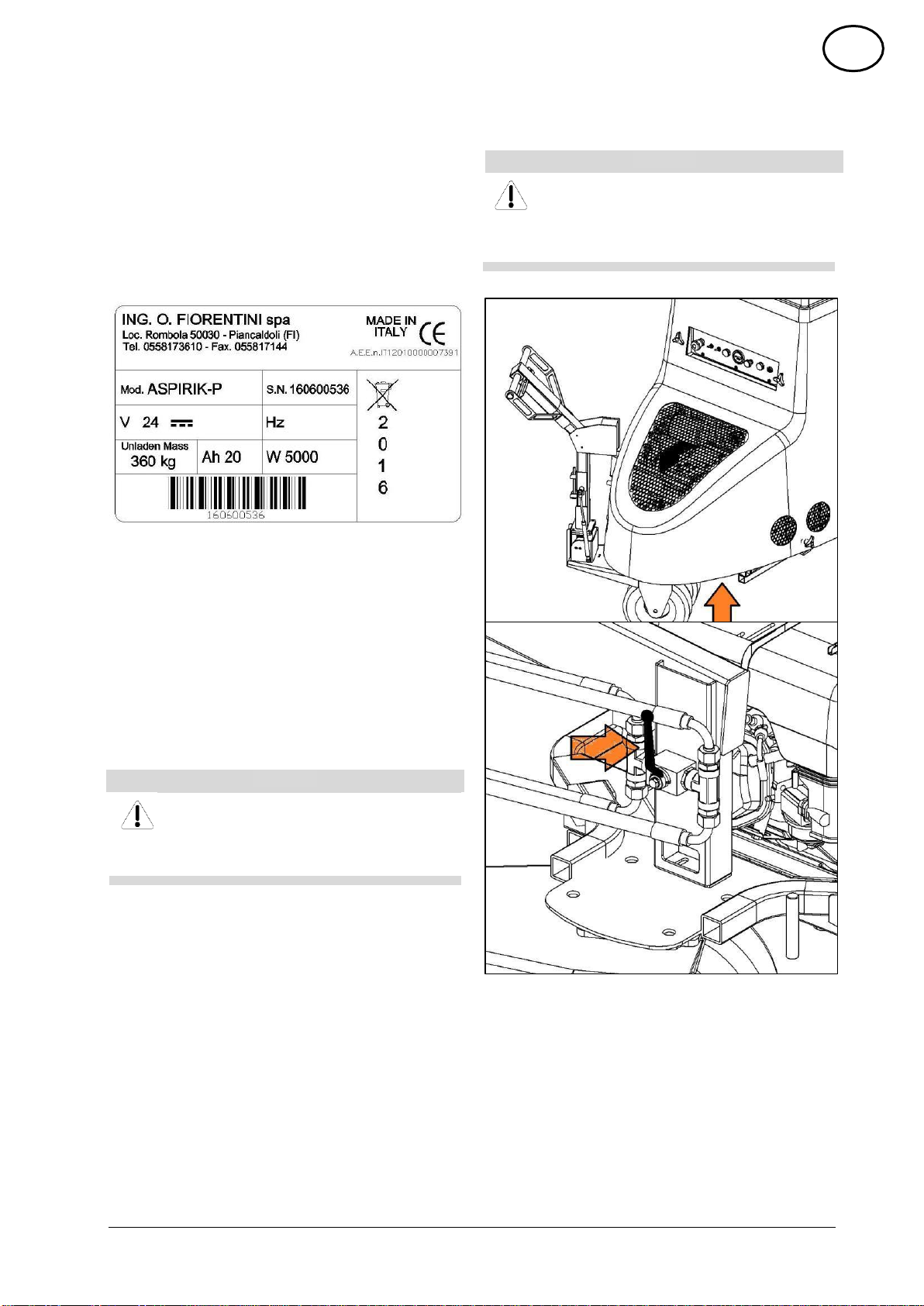

2.2 Identification Plate

An adhesive machine identification label

containing indelible “CE” marking details is

affixed on the outside of the bonnet.

The plate must never be removed and must

always be legible. If it should be damaged, another

must be requested. The appliance cannot be

marketed without the plate.

3 Before putting into Service

3.1 Unloading the appliance

3.2 Drive Disengaged

•

Open the cardboard box.

•

The machine is fixed to a wooden platform with

belts and with brackets to lock the wheels.

•

Cut the belts and remove the wheel brackets.

The machine can then be moved and pushed

off the platform.

•

The appliance can be handled in two ways:

with or without drive engaged.

Reach the hydraulic bypass valve through the

open bottom part of the bonnet. The valve is

located at the front of the machine. Operate the

lever.

This disengages the drive and the machine

is free to move.

Do not move the machine with drive disengaged

over long tracts and at speeds exceeding 6 km/h.

HAZARD

Risk of injury and damage.

Do not use a forklift truck to unload the

appliance. Proceed as follows.

HAZARD

Risk of injury and damage.

Before releasing the drive, keep the

appliance still so that it cannot move

accidentally.

HAZARD

HAZARD

EN

6

3.3 Drive Engaged

Refuel the machine (see next paragraph).

Switch on the machine and move it by means of its

hydraulic drive (see next paragraph).

Carefully move it down from the packaging

platform.

The machine can be moved with its drive only if

unpacked outdoors.

4 Commissioning

4.1 Fuelling

Turn off the engine.

If present, remove the waste container from the

back side of the machine (see next paragraph).

Unscrew the tank cap.

Top up with suitable fuel (see engine use and

maintenance manual)

Fill the tank up to 2.5 cm below the top edge of the

filler neck.

Eliminate any spilled fuel and close the tank cap.

4.2 Control interventions

For the execution of the following controls refer to

the chapter entitled "Care and maintenance".

Check the motor oil level.

Check the level of fuel tank.

Check the level of the hydraulic oil.

Empty the waste container.

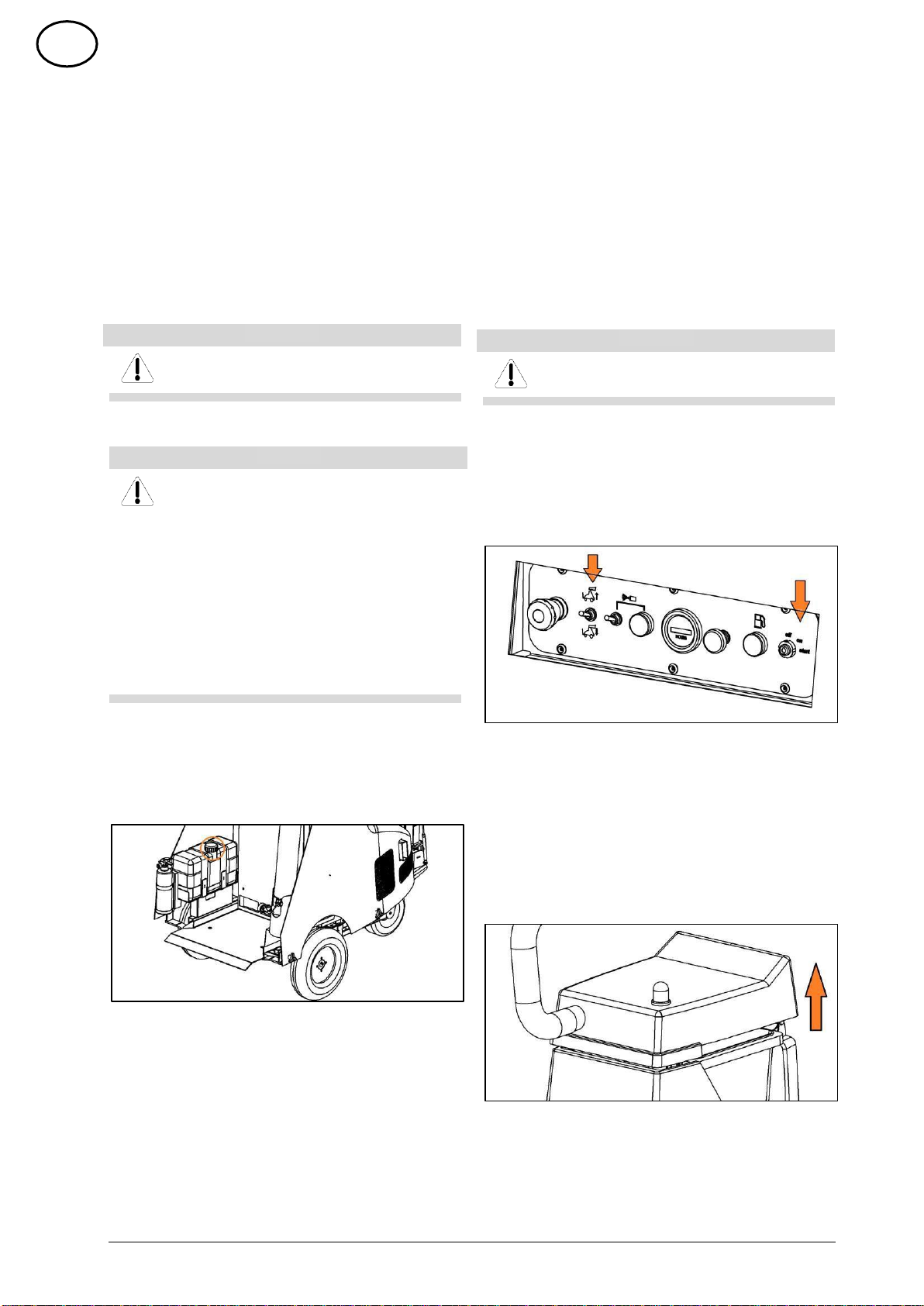

4.3 Positioning the Waste Container

To insert and remove the waste container

according to DIN EN 840-1, lift the suction head.

Press the specific switch on the

dashboard to move the head.

The head can only be enabled electrically

with the ignition key ON.

The head cannot be lifted or lowered with the

engine running. The engine can only start if the

head is properly fit on the waste container. In any

case the waste container must be positioned with

the engine off.

WARNING

Place the appliance on a level

surface.

HAZARD

Risk of explosion.

•

Refuel only with the engine off.

•

Only use the fuel stated in the engine

operating instructions.

•

Do not refuel in closed

environments.

•

Do not smoke or use naked flames.

•

Make sure that the fuel does not come

into contact with hot surfaces.

WARNING

The waste container must be positioned

with the engine off.

HAZARD

WARNING

WARNING

EN

7

When positioning the waste container underneath

the suction head, check that the gasket fits tight

on the edge of the container.

5 Operation

5.1 Starting the machine

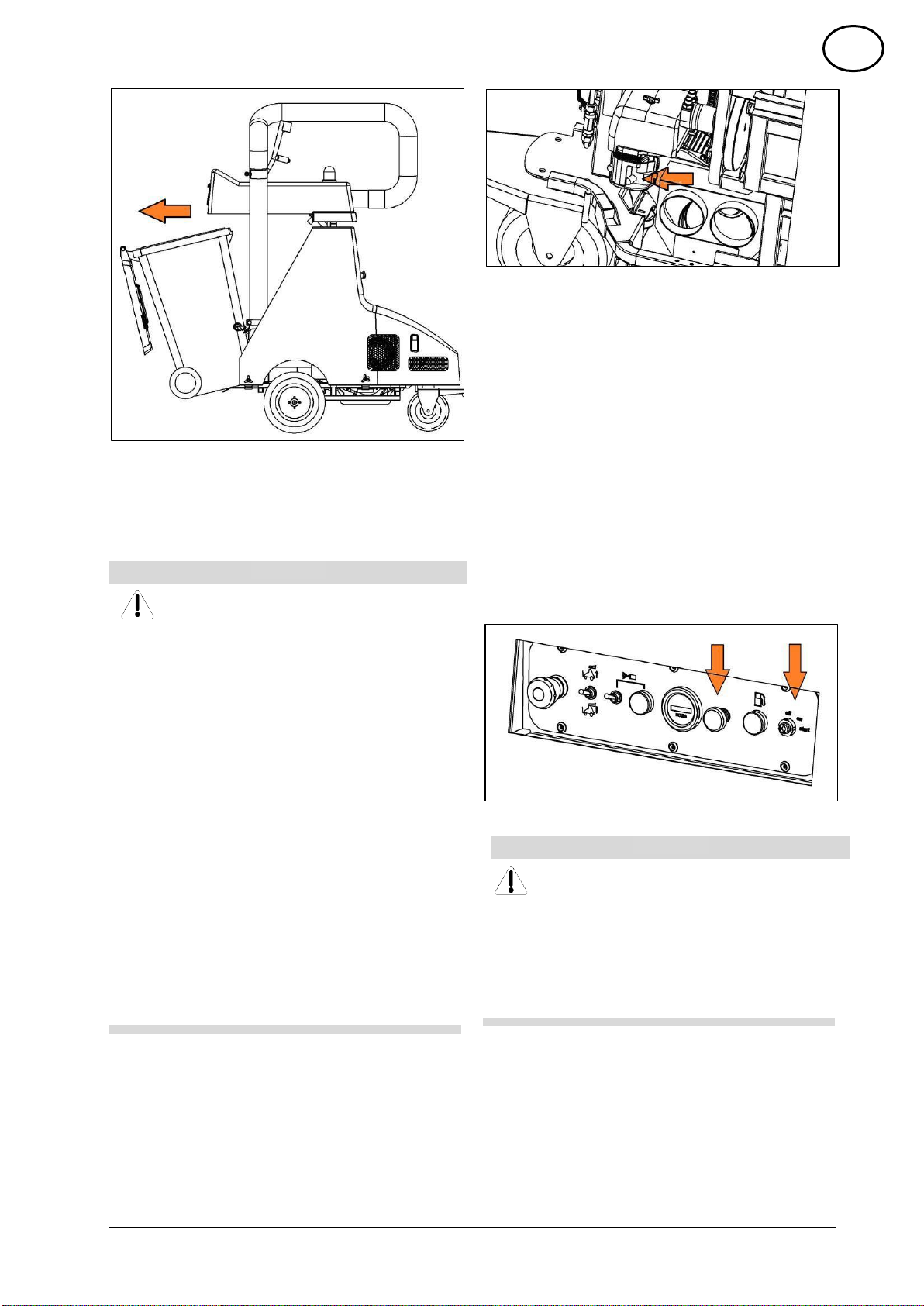

Open the fuel cock before starting the machine.

This can be reached through the bottom open

part of the bonnet.

Push the cock lever to ON.

Make sure that the steering column is in neutral,

that is locked in the centre position. The engine

does not start with the steering column in this

position.

Pull the Starter knob on the dashboard next to

the ignition key.

Turn and hold the ignition key in the START

position for no more than 5 seconds.

When the engine has started, put the Starter knob

back in position.

If the engine does not turn on the first try, wait

at least 10 seconds before operating the Starter

again.

The flashing light and the hour counter are

activated when the engine is running.

If the fuel level is at a minimum, the red light

between the ignition key and the starter knob

goes on.

WARNING

Even though the machine has an

isolation system of the vibrations

produced by the engine, stresses

transmitted to the hand and arm of the

operator through the steering column

cannot be eliminated completely.

Prolonged use may cause vascular

problems in the hands.

Generalised times of use cannot be

established, since they are subject to

several factors:

Predisposition to insufficient

blood circulation.

Low ambient temperature.

Grip excessively tight.

We recommend use interrupted by

pauses instead of continuous.

We recommend a medical examination

in case of regular and continuous use or

if phenomena like tingling of the hands

and cold fingers occur repeatedly.

WARNING

You do not need to adjust the engine

rpm. The rotation speed is adjusted and

preset at the factory.

Do not change speed by intervening on

the carburetor of the engine. This could

compromise the smooth and safe

operation of the machine.

WARNING

WARNING

EN

8

5.2 Driving

Pull the unlock lever and carefully move the

steering column forward or backward.

Pulling the steering column towards you moves

the machine forward.

Pushing the steering column towards the bonnet

moves the machine in reverse.

If the steering column is outside of the

central position, the unlock lever can be

released.

You can set the speed infinitely variable from the

steering column.

Direct the appliance in the desired direction by

turning the steering column to the right or to the

left, at the same time pushing it forward or

backward to adjust speed.

If you release the steering column, it goes

back automatically to the middle locked

position. The machine stops and remains

braked.

5.3 Suction

During use, empty the waste container at regular

intervals or replace it with an empty one.

Remove the suction hose from the support and

hold it by the handle.

Press the button on the handle to start the intake

flow. The suction fan stops when released.

Put the suction hose back into the support when

vacuuming is finished.

5.4 Dust Removal

The dust removal function is enabled from the

switch on the dashboard. The green light indicates

activation of the function.

Each time the suction button is pressed, a nozzle

inside the suction head sprays a small amount of

water for about three seconds. The duration of

dispensing depends on how much the

HAZARD

Do not attempt to pass over fixed

obstacles higher than 50 mm.

WARNING

Do not abruptly deactivate the

steering column as it could damage

the hydraulic system.

HAZARD

WARNING

EN

9

suction button on the handle of the suction hose is

pressed.

At regular intervals, fill the tank on the suction

hose support with water.

5.5 Cleaning the Filter

When there is a decrease in suction power,

clean or replace the filter.

Open the filter door on the rear of the suction

head.

Remove the filter and clean it with compressed air

and by shaking it or replace it if the filtered

material is excessively dirty.

5.6 Stopping

The machine can be stopped by releasing the

steering column and causing it to go to the locked

position.

The engine continues to run.

Turning ignition key to OFF and removing

it also stops the engine.

If the appliance is not used for a long period of

time, proceed as follows:

-

Place the appliance on a level surface.

-

Lock the drive by releasing the steering column.

-

Fill the fuel tank and close the petrol cock.

-

Change the motor oil.

-

Turn the ignition key to OFF and remove it.

-

Unscrew the spark plug and put about 3

cc of oil in the spark plug housing bore.

Rev up the engine a few times without the

spark plug. Screw on the spark plug.

-

Clean the unit inside and outside.

-

Store it in a sheltered and dry place.

-

Disconnect the battery.

-

Charge the battery every 2 months or so.

5.7 Transport

6 Care and Maintenance

6.1 General Warnings

Before cleaning and servicing the appliance or

replacing components, turn it off and remove the

ignition key.

WARNING

If none of the previous actions stops the

machine, press the red emergency

button on the dashboard.

HAZARD

Respect the weight of the appliance

during transport.

HAZARD

For transport on vehicles secure the

appliance according to directives in

force so that it cannot slip or tip over.

Ensure the immobility of the appliance by

locking it with belts and ropes.

The ropes must pass through the tubes of

the machine frame protruding at its

bottom.

Secure the wheels with wedges.

The appliance cannot be lifted by belts.

Use a ramp to load and unload the

appliance, using its own drive.

WARNING

HAZARD

HAZARD

EN

10

Make sure all engine and transmission parts have

stopped. After stopping the engine always wait 5

seconds.

Before carrying out any maintenance or repair, let

the appliance cool down sufficiently.

Never touch hot components such as the drive

motor and exhaust deflector.

When working on the electrical system,

disconnect the battery.

Repairs may only be performed by authorised

service centres or by experts in this field who are

familiar with all relevant safety regulations.

6.2 Cleaning

Weekly maintenance:

-

Make sure there are no fuel leaks.

-

Check the air filter.

-

Check that the moving parts move

perfectly.

Maintenance every 100 working hours:

-

Check the tightness of the fuel pipes.

-

Change motor oil (first change after 20

hours of operation).

-

Check the spark plug.

-

Check the battery acid level.

-

Check the tension, the wear and the

operation of transmission belts (poly-V).

Remove the machine bonnet to clean the inside.

Clean with a jet of compressed air.

The outside of the appliance should be cleaned

with a soft cloth and a mild detergent. Do not use

aggressive cleaning agents.

6.3 Maintenance frequency

The following maintenance operations are to be

carried out by the customer:

Daily maintenance:

-

Check the motor oil level.

-

Check the level of the transmission oil.

-

Check operation of all control parts.

-

Clean the gasket on the suction head.

The following maintenance operations are to

be carried out by customer service:

-

Perform the first inspection after 20 hours.

-

Maintenance every 100

working hours.

To keep the warranty valid, during the warranty

period, all servicing and maintenance must be

carried out by authorised Ing. O. Fiorentini S.p.A.

Service.

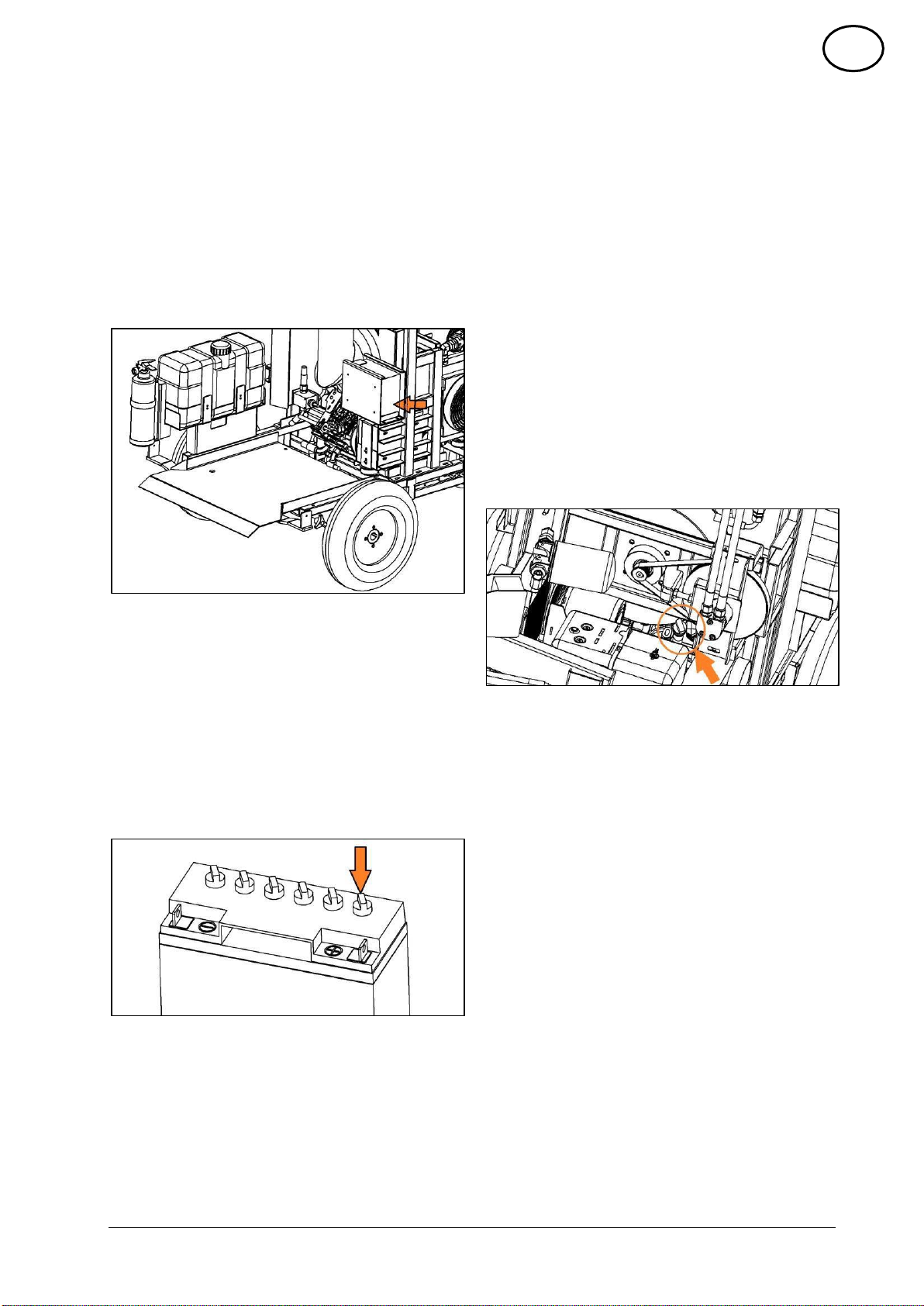

6.4 Battery maintenance

The machine is equipped with two 12-volt starting

batteries connected in series, type YUASA YB16

or FIAMM FB16B.

WARNING

Do not clean the appliance with a high

pressure water jet (risk of short circuit

or other electrical failures).

WARNING

All servicing and maintenance to be

undertaken by the customer must be

performed by a qualified technician.

WARNING

The operating hours counter indicates

the maintenance intervals.

HAZARD

Wear a dust mask and safety goggles.

HAZARD

Risk of explosion.

Never place tools or similar objects on

the battery, on the terminals and on the

connections of the battery cells. If

conductive it could cause a short circuit

resulting in ignition of the electric arc.

Provide adequate ventilation during

charging to ward off possible explosive

gases produced by the battery.

Always follow the instructions

of the battery charger.

WARNING

WARNING

WARNING

HAZARD

HAZARD

EN

11

For safety reasons, the appliance’s starting

batteries are shipped dry.

Generally the local dealer activates the batteries.

If this has not been done, they must be activated.

Completely extract the batteries from the

appliance.

Lift the suction head.

Extract the waste container.

Remove the engine and rear bonnet.

The battery holder is now visible.

Disassemble the battery holder.

Disconnect the battery from the electrical

system by removing the cables from the

battery terminals.

Remove them from the support by removing

the clamps.

The batteries must be activated with the acid

supplied.

Place the batteries on a horizontal plane,

unscrew and remove the top caps and vent plug.

Slowly pour the acid into each hole until it

reaches the UPPER LEVEL.

Never fill up to the top edge of the battery cover:

acid spills could occur.

Place the caps on the holes and allow the

battery to rest for about 30 minutes to allow the

activation of the plates. Press or tighten the top

caps all the way and leave the vent plug open.

If the voltage of the battery is below 12.7 Volts

charge it with an appropriate battery charger.

Refer to the user manual of the battery charger.

Remember that the two batteries are

connected in series and that the rated voltage

of the system is 24 Volts.

Periodically recheck (4-6 months) the levels of

acid and optionally restore them to UPPER

LEVEL using distilled water suitable for use with

Lead batteries.

6.5 Motor oil

The engine is equipped with a safety system

which prevents start-up if the oil level is below

the minimum allowed.

Do not check the oil level before 5 seconds

have passed since stopping the engine.

Remove the engine bonnet.

Remove the oil dipstick, recognisable by the

yellow end.

Clean the dipstick and put it back into the slot.

Check the level at the next extraction. If

necessary, add oil.

See the technical specifications for the type

of motor oil.

To change motor oil, in any case remove the

oil dipstick.

Unscrew the oil drain plug at the bottom of the

engine. Collect the used oil in a suitably sized

tray placed under the machine.

When all the oil has drained, screw the drain

plug back on and fill with motor oil.

Close the oil filler hole.

Wait at least 5 minutes.

Check the motor oil level.

6.6 Air Filter

Remove the engine bonnet.

Unscrew the wing nut.

Remove the filter cartridge, check it and clean it.

Insert the clean cartridge or a new cartridge into

the suction container.

EN

12

Tighten the wing nut.

6.7 Spark plug

Detach the spark plug connection.

Unscrew and clean the spark plug.

Screw the clean or a new spark plug.

Apply the spark plug connection.

It is possible to completely empty the hydraulic

circuit through two plugs on the bottom of the

tank.

6.9 Transmission Belts

The machine has three poly-V transmission belts.

One for the intake fan, one for the pump unit and

the third for the dynamo-starter motor and battery

charger.

Periodically (approximately 300 hours of operation)

check belt tension and adjust if necessary.

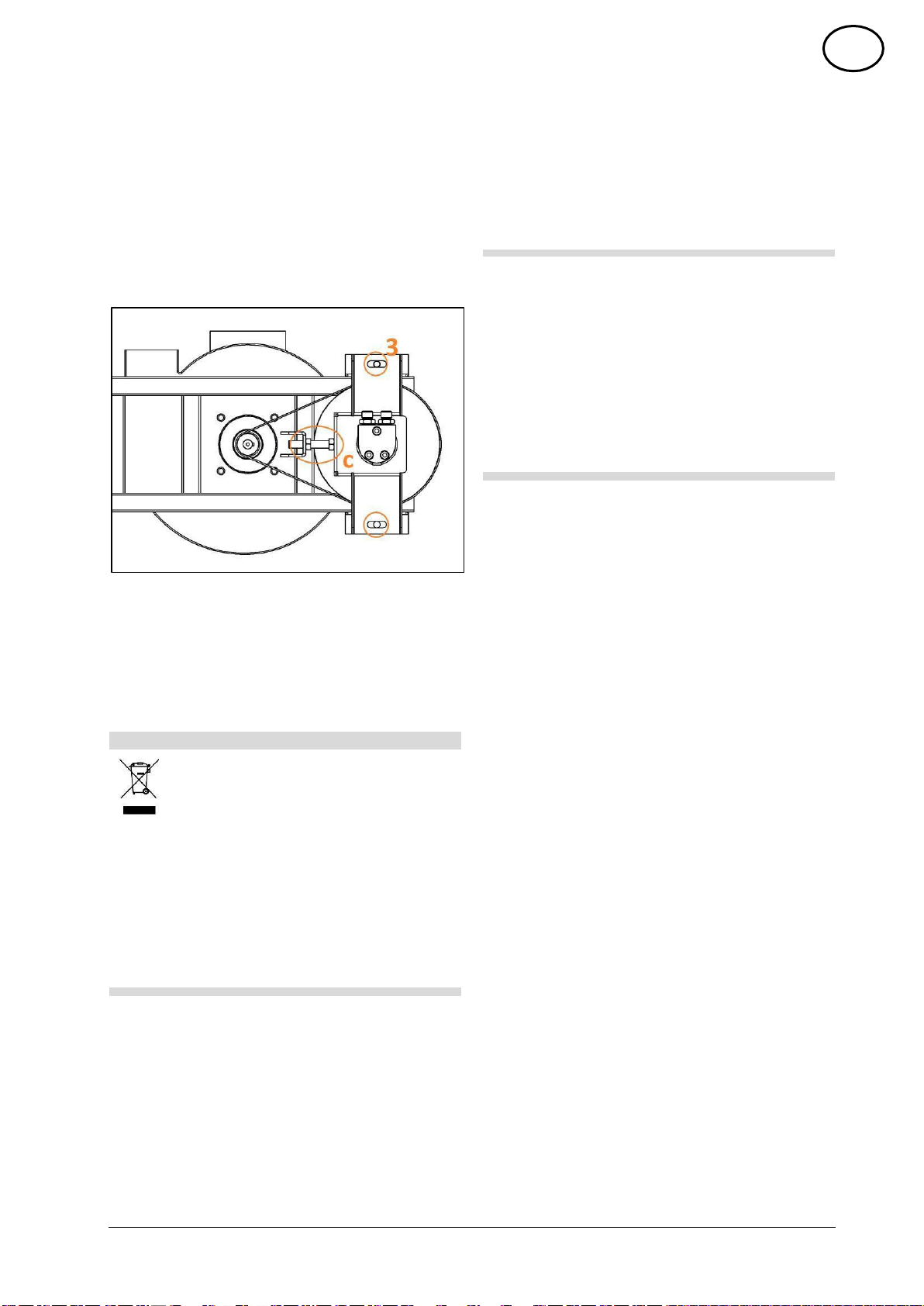

The belt tensioners A and B act respectively on

the belts of the pump unit and engine dynamo.

6.8 Hydraulic Oil

Extract the waste container.

This way the hydraulic oil level and filler cap

remain visible.

In order to adjust the tension of the belts, you must

first slightly loosen the screws 1 and 2 and then

loosen the lock nut of the belt tensioning

mechanism.

Top up if the level is not correct.

See the technical specifications for the type of

hydraulic oil.

Every 500 hours of operation, replace the filter

cartridge in the hydraulic circuit.

HAZARD

Risk of injury and damage.

A belt tension meter should be used.

Incorrect belt tension can lead to rapid

wear or sudden breakage of the

component, with possible damage to

the machine and dangerous projection

of parts of the belt.

HAZARD

EN

13

For clarity of representation, the figure shows

screws 1 and 2 without the pulleys and belts

mounted. Of course you must unscrew them

without removing them.

The tension can be adjusted by screwing or

unscrewing the belt tensioner. Once you have

found the optimal value, retighten the screws 1

and 2 and the lock nut.

Similarly, the belt tensioner C and screws 3

allow you to adjust the fan belt tension.

The correct belt tension values are:

-

Fan. 390 Newton per branch.

-

Pumps. 300 Newton per branch.

-

Dynamo. 65 Newton per branch.

7 Disposal

9 Accessories and Spare Parts

Only use accessories and spare parts

approved by the manufacturer. Original

accessories and spare parts guarantee that

the appliance can be used safely and without

problems.

ING. O. FIORENTINI S.p.A.

Via Piancaldoli 1896 Firenzuola 50033

Frazione Piancaldoli (FI) –Italy

Phone (+39) 055.81.73.610

Fax (+39) 055.81.71.44

E-mail: info@ingfiorentini.it

Website: www.ingfiorentini.it -

www.fiorentinispa.com

All packaging is recyclable. The

packaging must not be disposed of

with household waste, but brought to

relative collection centres.

Discarded appliances contain valuable

recyclable materials and must be

brought to relative collection centres.

Batteries, oil, and similar substances

must not be released into the

environment. Therefore please dispose

of your discarded appliances using

separate collection systems.

8 Warranty

The Ing.O.Fiorentini S.p.A. general terms

conditions also apply to the warranty.

The manufacturer cannot be held responsible in

any way for damage resulting from unauthorised

modifications made to the appliance, from the use

of unsuitable brushes and accessories and after

use of the device other than that intended.

10 Troubleshooting

FAILURE

REMEDY

The appliance does not start.

Refuel.

Open the fuel cock.

Check the fuel system and connections.

Check the general fuse, replace if necessary.

Low battery. Recharge the battery.

Check and clean the spark plug, replace it if

necessary.

Inform the assistance service.

The engine runs irregularly.

Clean or change the air filter.

Check the fuel system and connections.

Inform the assistance service.

The engine is running, but the appliance does not

start.

Check proper functioning of the steering

column.

Check the hydraulic drive disengagement lever.

Inform the assistance service.

The engine is running, but the machine moves very

slowly.

In subzero temperatures, have the appliance heat

up for 5 minutes before using it.

Inform the assistance service.

Insufficient suction power.

Check the gasket on the suction head.

Check and clean the suction head filter.

Empty the waste container.

Inform the assistance service.

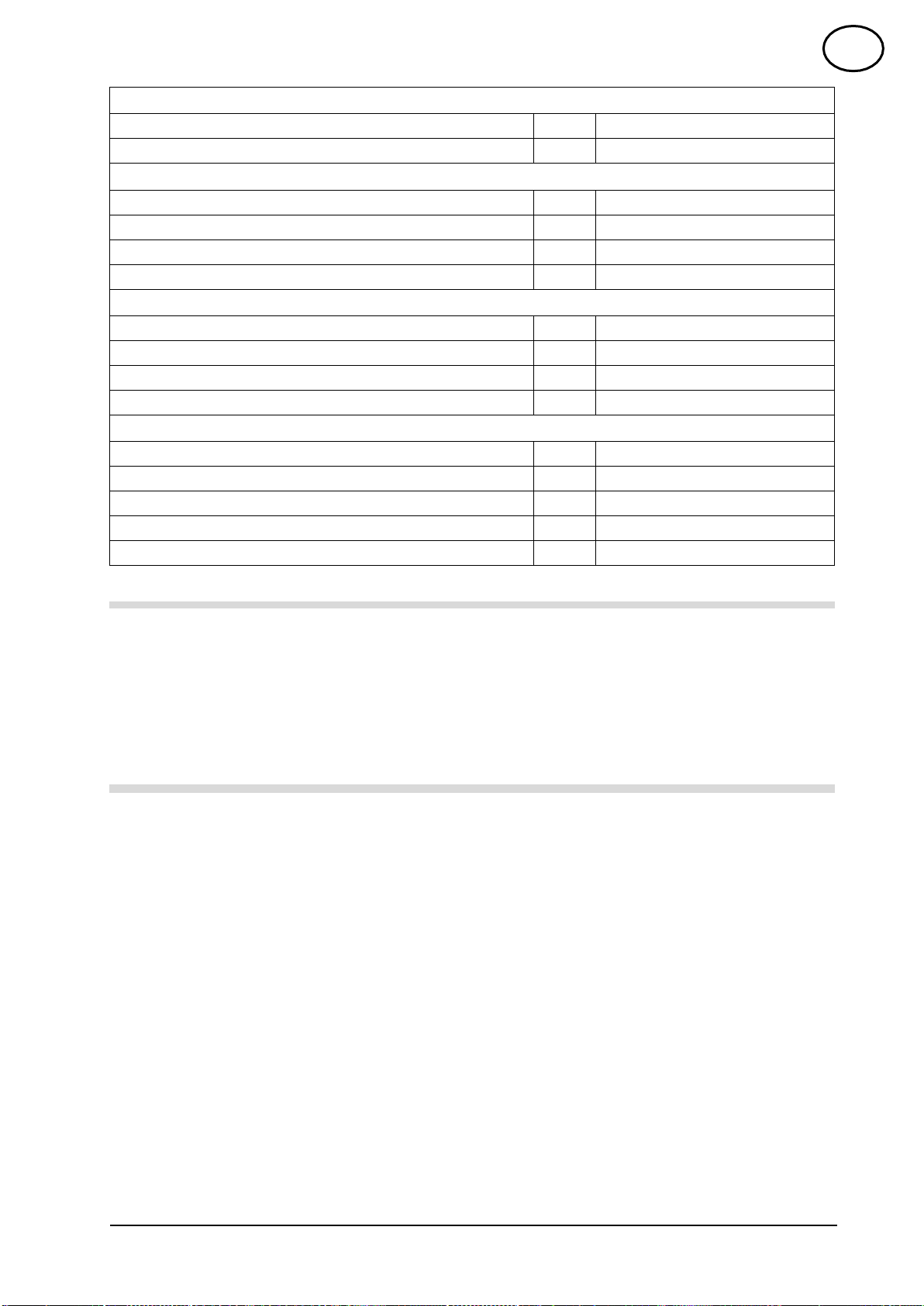

11 Technical Specifications

General Machine Data

Length x Width x Height

mm

1850 x 900 x 1600

Weight without load

kg

350

Total permitted weight

kg

450

Maximum forward speed

Km/h

6

Maximum slope allowed

%

30

Volume of waste container

l

240

Protection rating

--

IPX3

Engine

Model

--

Honda GX 270

Displacement

cc

270

Maximum power at 3600 RPM.

Kw/Hp

6.3 / 8.4

Maximum torque at 2500 RPM.

Nm

19.1

Fuel tank capacity

l

10

Starter battery

--

2x12 = 24V / 20Ah

Fuel consumption at full power

l/h

2.2

EN

15

Types of Oil

Engine SAE10W30 –API SJ

l

1.1

Hydraulic circuit AGIP OSO-46

l

12

Tyres

Front dimensions

mm

2 x Ø260x85

Front wheel pressure

bar

Full rubber

Rear dimensions

--

8” – 3.50

Rear wheel pressure

bar

Full rubber

Suction System

Filtering surface standard version

m2

0.23

Filtering surface fine dust version

m2

3

Maximum negative pressure

hPa

22.5

Maximum flow rate

l/s

470

Environmental Conditions

Temperature

°C

0..40

Humidity, non-condensing

%

0..90

Steering Column Vibrations

m/s2

0.5

Suction Tube Vibrations

m/s2

0.2

Noise emission at 3 meters

dB(A)

87

ING. O. FIORENTINI S.p.A.

Via Piancaldoli 1896 Firenzuola 50033 Frazione Piancaldoli (FI) –Italy

Phone (+39) 055.81.73.610

Fax (+39) 055.81.71.44

E-mail: info@ingfiorentini.it

Website: www.ingfiorentini.it - www.fiorentinispa.com

Table of contents

Other FIORENTINI Blower manuals

FIORENTINI

FIORENTINI SP500 NEW User manual

FIORENTINI

FIORENTINI UBF 38 User manual

FIORENTINI

FIORENTINI S 150 User manual

FIORENTINI

FIORENTINI 650 Instructions for use

FIORENTINI

FIORENTINI UBF 28 NEW Operating instructions

FIORENTINI

FIORENTINI S32B User manual

FIORENTINI

FIORENTINI MINISWEEPER Operating instructions

FIORENTINI

FIORENTINI GENIUS-14 User manual

FIORENTINI

FIORENTINI GENIUS-18 User manual