FIORENTINI MINISWEEPER Operating instructions

ING. O. FIORENTINI S.p.A.

INDUSTRIAL CLEANING MACHINES

SWEEPER

MOD. MINISWEEPER

USER AND MAINTENANCE MANUAL

Rev. 00

INDEX

1.

GENERAL INFORMATION Pag.

4

1.1. Symbols…………….…………………….…….........................……......………………..

4

1.2. Warning….................................................…………...…………..............…...….........

4

1.3. Manual Consulting……….........…………………………....….........………….…………

4

1.4. Warranty..............................................................…………...…………...….…...........

4

1.5. Conformity Declaration…….........................................…...........………….…...………

6

2.

FEATURES AND TECHNICAL DATA OF THE MACHINE

8

2.1. Identifying the Machine……......…...............................….…………….….……...........

8

2.2. Description and Parts of the Machine……….…………………………….…….…........

8

2.3. Technical Data………..................................…........……………………….....…..........

10

3.

SAFETY

11

3.1. Right Use of the Machine……....……………....…....……………….....…………........

11

3.2. Wrong Use of the Machine…….……………………………………………..…………..

11

3.3. Suggested Equipment………..……………………………………………………………

11

3.4. Operator Qualify………...............……………….......……………...…………...............

12

3.5. Protection and Warning Devices……………………..................…...…………............

12

3.6. Safety Devices……................................................…………..….…....…………........

13

3.7. Safety Diagnostic sygnals……………….………………………………………………….

13

3.7.1 Other dangers………………….…………………………………………………….......

3.8 Safety signals……………………………………………………………………………......

15

16

4.

STARTING AND USE INSTRUCTIONS

18

4.1. Trasport and Handling……....................….....................…....………….….….…........

18

4.2. Storage……………...............................................…………….…………....................

19

4.3. Unpacking the Machine………………..........................……………………........….....

19

4.4. Handling the Unpacked Machine….….….…..........………………………..……..........

19

4.5. Installation……...............................................................………………..…….............

20

4.5.1. Batteries Installation……..........……..….......……………….…...….….........…......

20

4.6. Control Devices……………………………………………………………………………..

21

4.6.1. Dashboard……..…………………………………..……………………………………

21

4.7. Functioning…………………………………………………………………………………..

22

4.7.1. Levers and Pedals…………….…………………………….………………………….

22

4.7.2. Main Brush Replacement……………….………..………………………………..…..

23

4.7.3. Side Brush Replacement ………………………………………………………………

24

4.7.4. Waste Tank Emptying…………………………………………………………………..

24

4.7.5. Suction Engine Maintenance……..……………………………………………………

25

4.7.6. Filter Shaker Engine Maintenance…..……..…………………………………………

25

Congratulations for your choice!

FIORENTINI S.p.A. thanking you for the preference to our product, would like to remind you that

FIORENTINI’s S.p.A. production covers manufacture and marketing of industrial cleaning machines

and is currently a leading company in this sector.

Our tradition and competence guarantee technical quality of your choice; actually all our products are

being built first quality materials through criteria that can give reliability, solidity and functionality

satisfying every kind of customers. FIORENTINI has recently obtained the quality system certificate

conforming to the requirements of UNI EN ISO 9001:2000.

We wish therefore inviting you to contact us, unhesitatingly, for every kind of request, as technical or

commercial; we’ll be pleased to be at your disposal for any information you may need.

5.

MAINTENANCE

26

5.1. Periodical Maintenance …………..……………..................….....…..…………...........

26

5.2. Batteries Maintenance……………………………………………………………………..

26

5.2.1. Hydrometry………..…………………………………………………………………….

27

5.2.2. Water Filling Up………………………………………………………………………...

27

5.2.3. Charge Limits……………………………………………………………………………

27

5.2.4. Off duty or inactive batteries ……………..…………………………………………...

27

5.2.5. Batteries disposal ………..……………………………………………………………..

27

5.3. Electric System Control…………………………………………………………………….

28

5.4. Tests to be carried out ……..…………………..…………………………………………

28

5.5. Maintenance Register…..………………………………………………………………….

29

6.

SERVICE

31

6.1. Service Adresses……………….............…………..................……………..................

31

6.2. Claim Report……..……………………………..…………...………………….…............

31

GENERAL INFORMATION

MINISWEEPER

Rev. 00 del 05/07/04

4/33

1. GENERAL INFORMATION

1.1. SYMBOLS

This symbol is used to get the operator’s attention on procedures or precautions to be

followed inorder toavoiddamagestousersor tothe support

This symbol is used to get the operator’s attention on general information.

1.2. PREMISE

1.3. MANUAL CONSULTING

This manual deals exhaustively with all arguments that are necessary for an easy and safe use of the

machine as it is recommended by European Directives on product safety.

Therefore we suggest to all authorized operators to read carefully this manual contacting FIORENTINI S.p.A.

for any explanation. The manual has to be used every time the operator forgets a procedure or when new

operators have to be trained.

For publishing reasons, pictures and drawings can look different from the reality but without arising doubts.

Special symbols and bold type and/or sloping get the attention of the reader on remarkable information in

particular for safety.

The revision index is written on the left at the bottom of every page. The list of those pages that have been

updated has to be found at the end of the manual.

1.4. WARRANTY

Warranty conditions are stated as below when not differently specified in the order confirmation.

WARRANTY OBJECT

The machine has been designed and built for a long-lasting use without relevant problems. Anyway, if

problems arise during the warranty period, FIORENTINI S.r.l. is engaged to repair or substitute for free those

parts that are broken or damaged by defective materials, working defects or imperfect assembly.

Warranty is not given for parts whose early breaking or wear and tear are due to:

FIORENTINI S. p. A. is the only owner of this manual.

The reproduction of all or part of the manual or the transmission to third parties with

mechanic or electronic devices are vorbidden without a written manufacturer’s

authorization. This manual is supplied to the customers in one original copy when

differently specified in the order.

This manual is supplied to the customer with the machine and it must be kept with it even when the machine

has to be transferred.

Please, keep the manual in a safe place and for all the machine lifetime. In case of loss ask for a duplicate to

FIORENTINI S.p.A.

FIORENTINI S.p.A. is not responsible for any kind of damages caused by people or things due to the non-

observance of the instructions dealt in this manual.

FIORENTINI reserves the right to add at any time and without notice all the technical and commercial

changes considered useful for the customer. Therefore data and information in this manual can be updated.

FEATURES AND TECHNICAL DATA OF THE MACHINE

MINISWEEPER

Rev. 00 del 05/07/04

5/33

Non-respect of instructions included in this manual;

Breaking and/or changes made up without FIORENTINI’s approval;

Not-use of genuine spare parts;

Interventions made up by unauthorised personnel;

Missing maintenance;

Natural calamities.

FIORENTINI S.p.A., its purchasers and its suppliers have the same warranty for the electric and expendable

materials that are sold by external suppliers.

WARRANTY CONDITIONS

Warranty is granted for 12 months since the delivery date of the machine. This is a single warranty term and

it cannot be extended.

RETURNED GOODS

Intervention demands must be sent to FIORENTINI Service Dpt. only after a careful analysis of the problem

and its causes. Following information have to be given to FIORENTINI’s agent:

Serial number you get it from the silver label sticked on the machine (§ 2.1.);

Code and position of the component taken from the spare parts list (§ 7.2.);

A detailed description of the problem and its causes.

The components considered under warranty are delivered ex factory. Those ones being substituted belong

to FIORENTINI Co..

Please send defected electric or electronic material separatly in order

to divide and recycle material with dangerous substances (see

directive about RAEE 2002/96/CEE).

EXCEPTIONS

Expandable materials like brushes, squeegee blades and materials whose lifetime cannot be predetermined

are not under warranty.

FEATURES AND TECHNICAL DATA OF THE MACHINE

MINISWEEPER

Rev. 00 del 05/07/04

6/33

APPLICATION MODALITY

Defective components must be sent back to FIORENTINI S.p.A. in order to establish the anomalies causes

and apply therefore the warranty. Repair and replacement under warranty will be done in FIORENTINI’s

workshop, by third parties or in loco. In case of repair or replacement in loco, energy sources and the use of

particular equipment have to be paid by the customer himself.

INTERVENTION DEMANDS

Intervention demands must be sent to FIORENTINI Service Dpt. only after a careful analysis of the problem

and its causes. Following information have to be given to FIORENTINI’s agent:

Serial number you get it from the silver label sticked on the machine (§ 2.1.);

Code and position of the component taken from the spare parts list (§ 7.2.);

A detailed description of the problem and its causes.

The components considered under warranty are delivered ex factory. Those ones being substituted belong

to FIORENTINI Co..

The warranty of the machine is no more available in case of the loss of the silver label.

1.5. CONFORMITY DECLARATION

Conformity declaration is released with the machine and the user manual.

FEATURES AND TECHNICAL DATA OF THE MACHINE

MINISWEEPER

Rev. 00 del 05/07/04

7/33

FEATURES AND TECHNICAL DATA OF THE MACHINE

MINISWEEPER

Rev. 00 del 05/07/04

8/33

2. FEATURES AND TECHNICAL DATA OF THE MACHINE

2.1. IDENTIFYING THE MACHINE

A silver label is sticked on the protection case of the steering column and clearly shows the data referring to

the “CE” brand.

The label has never to be removed and should always be kept readable. In case of

damage t is necessary to ask for a duplicate. The autoscrubber machine cannot be sold

without the label.

2.2. DESCRIPTION AND PARTS OF THE MACHINE

The machine Minisweeper is designed for the treatment of flat surfaces through the process of brushing and

the following process of collection of dirt in a sharps container. The system of power is supplied by a series

of accumulators batteries, which feed all the motors and the electric control.

By means of a rotating brush set in front of the machine, dirt is put in the middle of the machine. The main

brush takes dirt into the waste tank. This machine must be used on dry or at least humid surfaces.

By means of the dashboard, the operator can control the functioning of the machine through a signalling

system made of LEDs. The dashboard is equipped with a battery charger indicator, too.

Functions of the machine which can be operated from the dashboard:

select forward or riverse gear;

start the traction of the machine;

press the horn;

switch on or off the machine.

The machine frame is made of zinc-plated or stainless steel in order to avoid oxidation which could

compromise the reliability of the machine.

Ing. O.Fiorentini S.p.A.

MADE

50030 Piancaldoli (FI)

IN

ITALY

Mod

MINISWEEPER

S.N

2

0

0

9

V

Hz

Kg

A

W

FIGURA N° 2.1

FEATURES AND TECHNICAL DATA OF THE MACHINE

MINISWEEPER

Rev. 00 del 05/07/04

9/33

Thanks to the dashboard the operator can control all the machine functions, which are listed below:

zinc-plated or stainless steel frame;

right side brush;

main brush;

suction and collecting system;

driviing wheel;

two idle wheels;

seat.

FIORENTINI Co., taking the new CE safety rules under consideration, manufactures the machine following

the CE directives about safety and health. The materials high quality, the high technology and FIORENTINI’s

experience guarantee the performance and the reliability of this machine .

Each machine is tested during the manufacturing process and the final check is done before the machine is

shipped out.

FEATURES AND TECHNICAL DATA OF THE MACHINE

MINISWEEPER

Rev. 00 del 05/07/04

10/33

2.3. TECHNICAL DATA

MAIN TECHNICAL DATA

MINI SWEEPER

SWEEPING WIDTH

728 mm

CLEANING CAPACITY UP TO m²h

3640 m²/h

BATTERY AUTONOMY

4 h

WASTE TANK CAPACITY

40 l

FILTERING SURFACE m²

3 m²

GENERAL TECHNICAL DATA

MECHANICAL DRIVE

REAR

MECHANICAL DRIVE (type)

DRIVING WHEEL

FORWARD SPEED Km/h

0-5 km/h

MAX SLOPE

8 %

NOISE LEVEL

65 dB

TURNING RADIUS

1750 mm

ELECTRIC SYSTEM

POWER

24 V

VACUUM MOTOR

TO WHIRLF

CENTRAL MOTOR BRUSHE

1 x 650W/24V

LATERAL MOTOR BRUSHE

1 x 60W/24V

TRACTION MOTOR

200W/24V

VOLTAGE

2 x 12V-157A/h

DIMENSIONS AND WEIGHT

LENGTH

1040 mm

WIDTH

690 mm

HEIGHT

1200 mm

CENTRAL BRUSHES

Ø260 x 590 mm

LATERAL BRUSHES

Ø200 mm

WEIGHT (without batteries)

110 Kg

WEIGHT (with batteries)

2x 26 Kg

The above mentioned characteristics are not binding for the manufacturer; they can be

changed without any notice . ING.O.FIORENTINI Co. is always at disposal for any

information (par.6.1.).

MEASUREMENT UNITS CONVERSION

Length

1 inch = 1” = 25,4 mm

Power

1 kW = 1,36 CV = 1,34 BHP

Temperature

T (K) = t (°C) + 273 / t (°F) = 1,8 t (°C) + 32

Pressure

1 bar =100 kPa = 14,5 psi

SAFETY

MINISWEEPER

Rev. 00 del 05/07/04

11/33

3. SAFETY

3.1. RIGHT USE OF THE MACHINE

This sweeper has been designed for an industrial use. It can sweep on flat surface or

with a max. 8% slope.

3.2. WRONG USE OF THE MACHINE

the sweeper cannot be driver by non authorized personnel;

this machine cannot work on surfaces with holes;

this machine cannot sweep on sloping surfaces;

The machine cannot sweep sloping surfaces whose gradient is higher than 8%;

The machine cannot be used in places with dangerous substances and in

particular with explosive atmospheres or with a bad microclimate;

The machine cannot clean surfaces with inflammable products;

The machine cannot be used as a means of transport for people or other means

of transport;

The protection devices of the machine cannot be modified or tampered;

Batteries must be recharged in a fanned room;

The operator have always to respect safety rules;

The operator cannot use equipments or devices that can create problems to the

machine working;

The machine components cannot be modified without FIORENTINI’s

authorization;

The operator cannot use acids that can damage the machine;

The operator has always to respect the rules written in the user manual.

Please read carefully and do not cover the labels sticked on the machine. FIORENTINI

S.p.A. is not responsible for a wrong use of the machine.

3.3. SUGGESTED EQUIPMENT

In order to use the machine in a proper way, we suggest to use the FIORENTINI’s equipment and original

spare parts.

FIORENTINI S.p.A. Technical Dept. is always at your disposal to design components or parts for a particular

use of machine as requested by the customer.

SAFETY

MINISWEEPER

Rev. 00 del 05/07/04

12/33

3.4. OPERATORS’ QUALIFY

The below specs shows the qualify requested from the operators depending on the kind of maintenance to

be done on the machine.

OPERATION

OPERATORS’ QUALIFY

Driving/control of the machine

Trained operator

Installation/ disinstallation

Fiorentini technician

Mechanical parts maintenance

Fiorentini technician

Electric parts maintenance

Fiorentini technician

Cleaning maintenance

Trained operator

Dismantling and demolition

Fiorentini technician

FIORENTINI S.r.l. suggests to train the operator before using the machine. The operator also must be

trained about safety rules and carefully read this manual.

FIORENTINI S.p.A. is not responsible for any possible damage to people and/or things caused by

the non-observance of the instructions dealt within this manual.

3.5. PROTECTION AND WARNING DEVICES

It is absolutely forbidden to tamper or disconnect safety and warning devices while

the machine is working;

It is important to check periodically safety and warning devices

Central brush

protection

Fiorentini Minisweeper is equipped with a central nylon brush which rotates

when the machine is working. The central brush is protected on both sides by

a stainless steel panel and two cases which avoid the contact with dangerous

components. These protection devices can be only willingly removed from the

machine.

SAFETY

MINISWEEPER

Rev. 00 del 05/07/04

13/33

3.6 SAFETY DEVICES

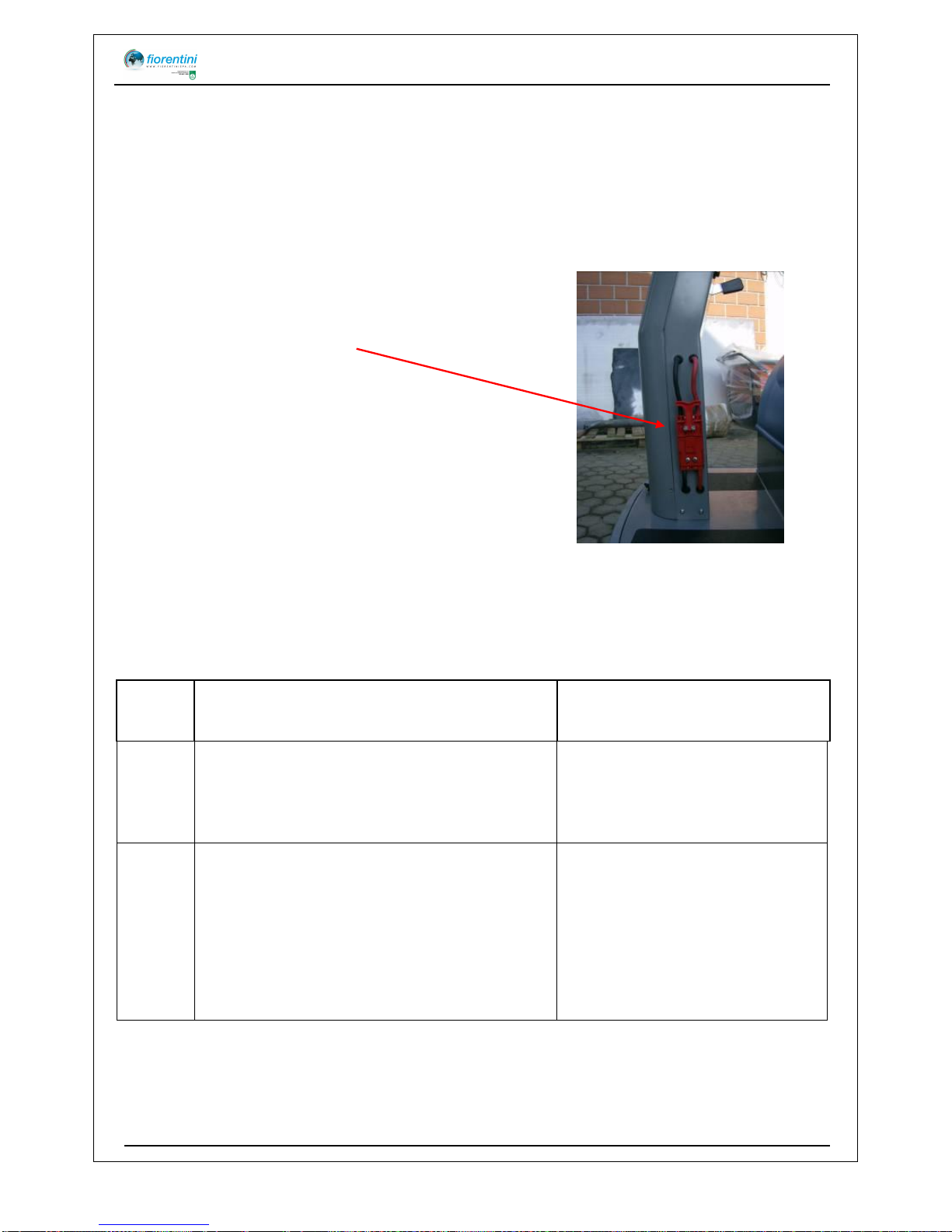

The machine is equipped with the following safety devices.

Socket (picture 3.1), the same socket used for the battery charger. In case of emergency, this

socket must be taken away from the plug by means of its handle.

The operator must be trained about safety rules. Do never restore this safety system before the

problem has been sorted out. If it is necessary ask for the technician help.

Disconnect in case of emergency

3.7 SAFETY DIAGNOSTIC SYGNALS

The Mini Sweeper is equipped with a system that shows all errors noticed from the electronic cards, that

controls all machine functions. These errors are displayed on the battery charge indicator, placed on the

dashboard, in the form of rapid flashes.

No. of

flashes

Description

Solution

1

Forward command already active when switching on

the machine: the start key has been turned on with the

forward command already entered.

Release the forward commande in

order to stop this sygnal. If this does not

stop it might be necessary to set the

acceleration system again.

2

Battery too low or under tension, caused by a short

circuit on the power. It means that the tension read

from the system is lower than the minimum threshold

needed for the correct machine functioning and that

the version of system is not compatible with the

battery installed. In different case, replace the system.

Verify that the battery is not too low, if

so, recharge it.

Alternatively, check that all electric

connections are well fixed. If the

problem is not solved it might be

necessary to replace the complete

system.

PICTURE 3.1

SAFETY

MINISWEEPER

Rev. 00 del 05/07/04

14/33

3

Not used

4

Motor not connected or false contact on the motor

circuit. It happens for example if the motor brushes

are not touching properly on the armature or if there

are loose cables.

Check the connections of the motor, its

functionality and integrity.

5

Fault inside the controller or mass on the engine.

There may be a negative dispersion on

the motor circuit; as alternative, it is

necessary to check the regulator.

6

Fault potentiometer; it is displayed when there is no

negative potentiometer. This signal indicates that the

voltage read by the system is higher than that

provided for the speed command and it occurs, for

example, if there is no connection to the negative of

the speed command

Check the wiring of the potentiometer

and the integrity of it.

7

Temperature of the power circuit is too high; it occurs

when the temperature of the mosfets is over 75 ° C +/-

5 ° C, that is, if the machine has worked in overload

conditions, for example on high slopes for long period

or at ambient temperatures above 40 ° C. It may

happen even in case of damage to the motor

windings, which causes an abnormal current

absorption.

Wait for the temperature to fall down.

8

Segnala che si sta tentando di avviare la macchina

quando questa (o il motore) è già in movimento.

Engine already rotating when starting. It indicates that

somebody is trying to start the machine when this (or

the engine) is already working.

Stop the vehicle first and then repeat.

9

Anomaly to the microcontroller software or hardware

problem. It occurs in case of failure to circuits for

measuring the current and the load.

Try to turn off the vehicle. If the error

still appears check the controller.

SAFETY

MINISWEEPER

Rev. 00 del 05/07/04

15/33

3.7.1 OTHER DANGERS

FIORENTINI S.p.A. realyzes –starting from the design of the machine - all the dangers that can occur while

the machine is operating in order to prevent or at least low the operator’s accidents. Thanks to a series of

signals on the machine the operator can avoid many risks that can occur.

This kind of ranger can occur:

during the brushes regulation;

during the batteries maintenance.

Whilst regulating the side brushes, the central brush and the central washing brushes the ignition

key must be kept away from the dashboard in order to avoid the casual starting of the machine.

Whilst the batteries recharge, the operator must pay attention that any parts of his/her body enter the

batteries room.

Special labels sticked on the cartes of the brushes or on the recovery tank prevent dangers

to the operator (see § 3.7.).

TURNOVER

This kind of ranger can occur:

- during the normal operating of the machine when you exceed sloping limits as specified in the

manual and you use the machine to clean disconnected surfaces or with holes and high

depressions.

Do not use the machine to wash sloping surfaces higher than 10% or surfaces with

holes or depressions which might compromise the stability of the machine.

FIORENTINI is not responsible for accidents occurred to people or things provoked by a

wrong use of the machine, i.e. using the machine on surfaces which can compromise its

stability.

The purchaser must stick proper labels on the machine to show the operator its right use.

SQUASHING DANGER

SAFETY

MINISWEEPER

Rev. 00 del 05/07/04

16/33

3.8. SAFETY SIGNALS

Among safety signals there are:

DANGERS

Dangers’ signals are triangular with black

pictures on a yellow background

PROHIBITIONS

Prohibitions’ signals are round with black

pictures and a red stripe

The purchaser must replace danger signals on the machine if they are damaged. It is

absolutely forbidden to remove or temper danger signals.

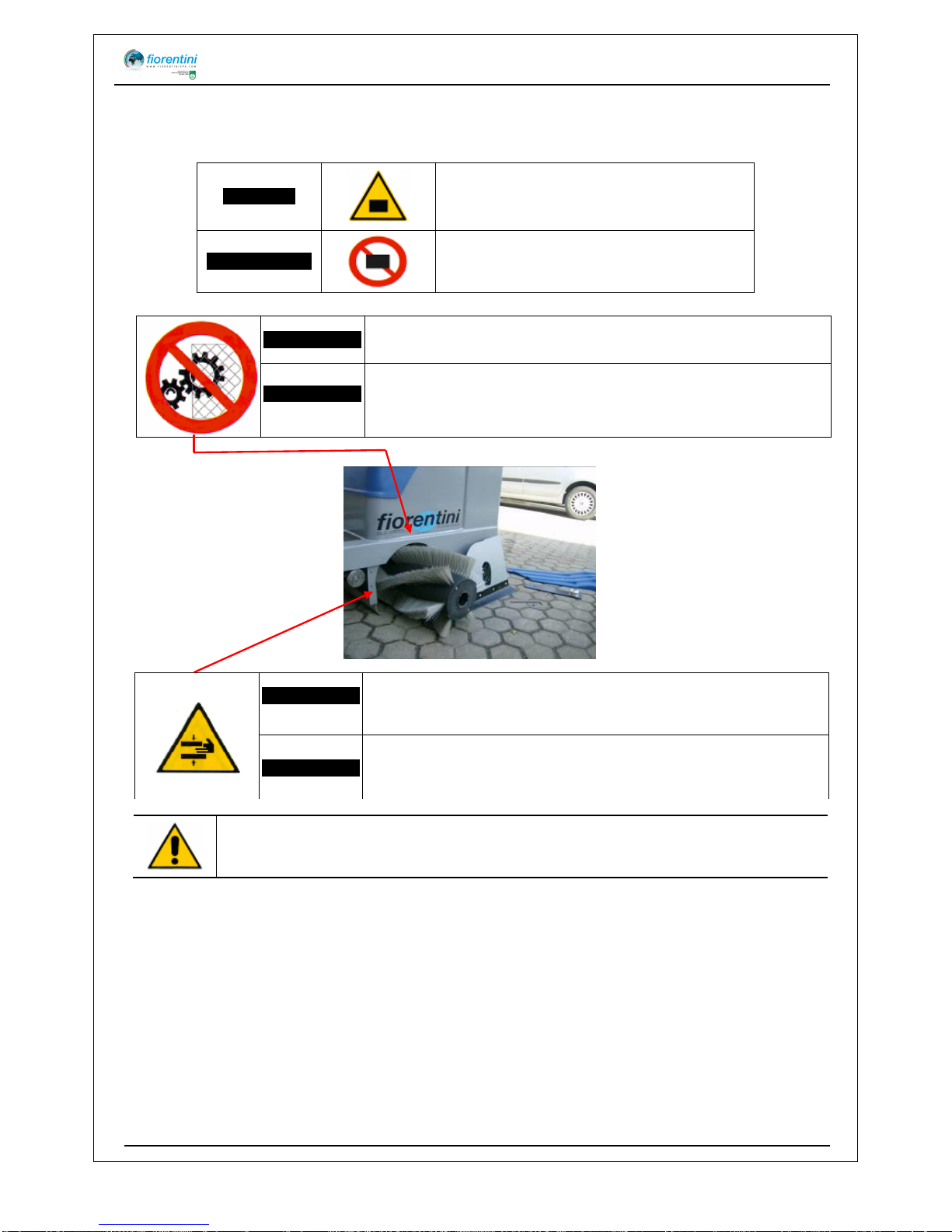

What is it?

Crushing danger: it can be due to parts in movement of the machine.

What to do

During the installation or the maintenance make sure that the ignition

key is not in the dashboard before removing the mobile protections.

What is it?

This signal forbids to remove the protection of pieces in movement.

What to do

During the installation or the maintenance make sure that the ignition

key is not in the dashboard before removing the mobile protections.

While the machine is operating make sure that all covers are well

fixed.

SAFETY

MINISWEEPER

Rev. 00 del 05/07/04

17/33

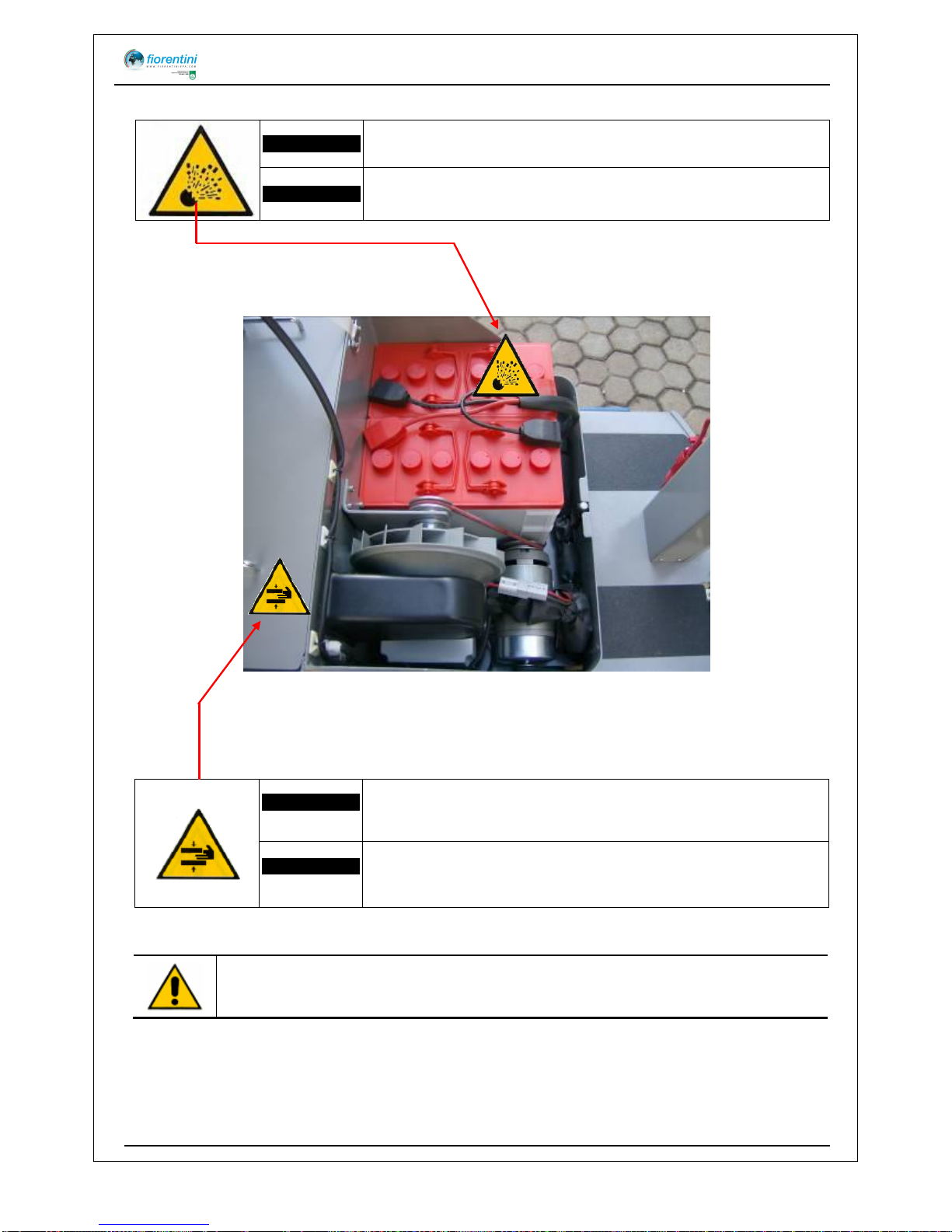

The purchaser must replace danger signals on the machine if they are damaged. It is

absolutely forbidden to remove or temper danger signals.

What is it?

Risk of crushing due to overturning of the recovery tank.

What to do

Whilst recharging the batteries, please make sure that any parts of

your body got in contact with the batteries room.

What is it?

Explosion danger: it may occur while recharging the batteries because

of hydrogen spread.

What to do

During the batteries recharge, please place the machine under a

suction chemney or in a ventilated area and keep it away from heat

and corrosive substances.

STARTING AND USE INSTRUCTIONS

MINISWEEPER

Rev. 00 del 05/07/04

18/33

4. STARTING AND USE INSTRUCTIONS

4.1. TRANSPORT AND HANDLING

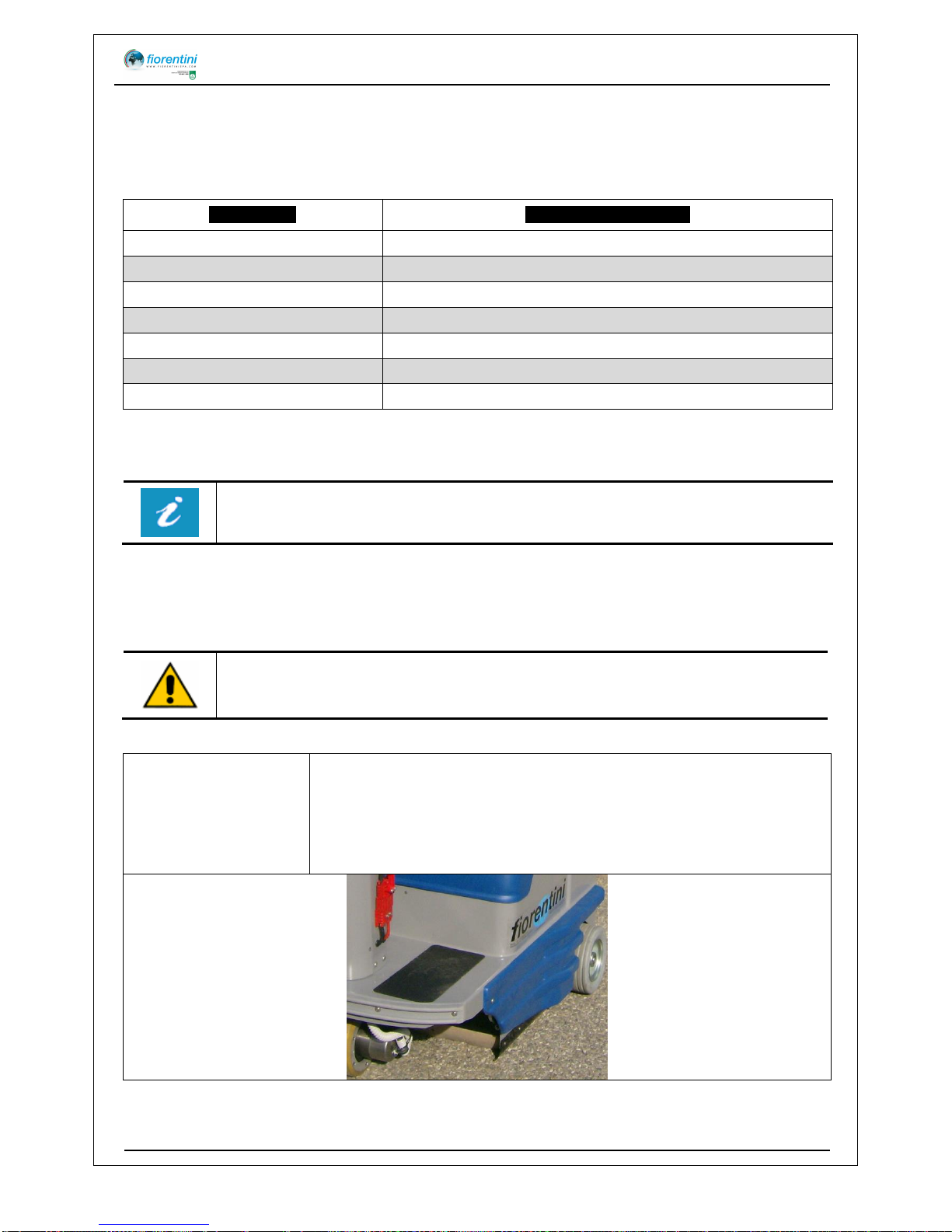

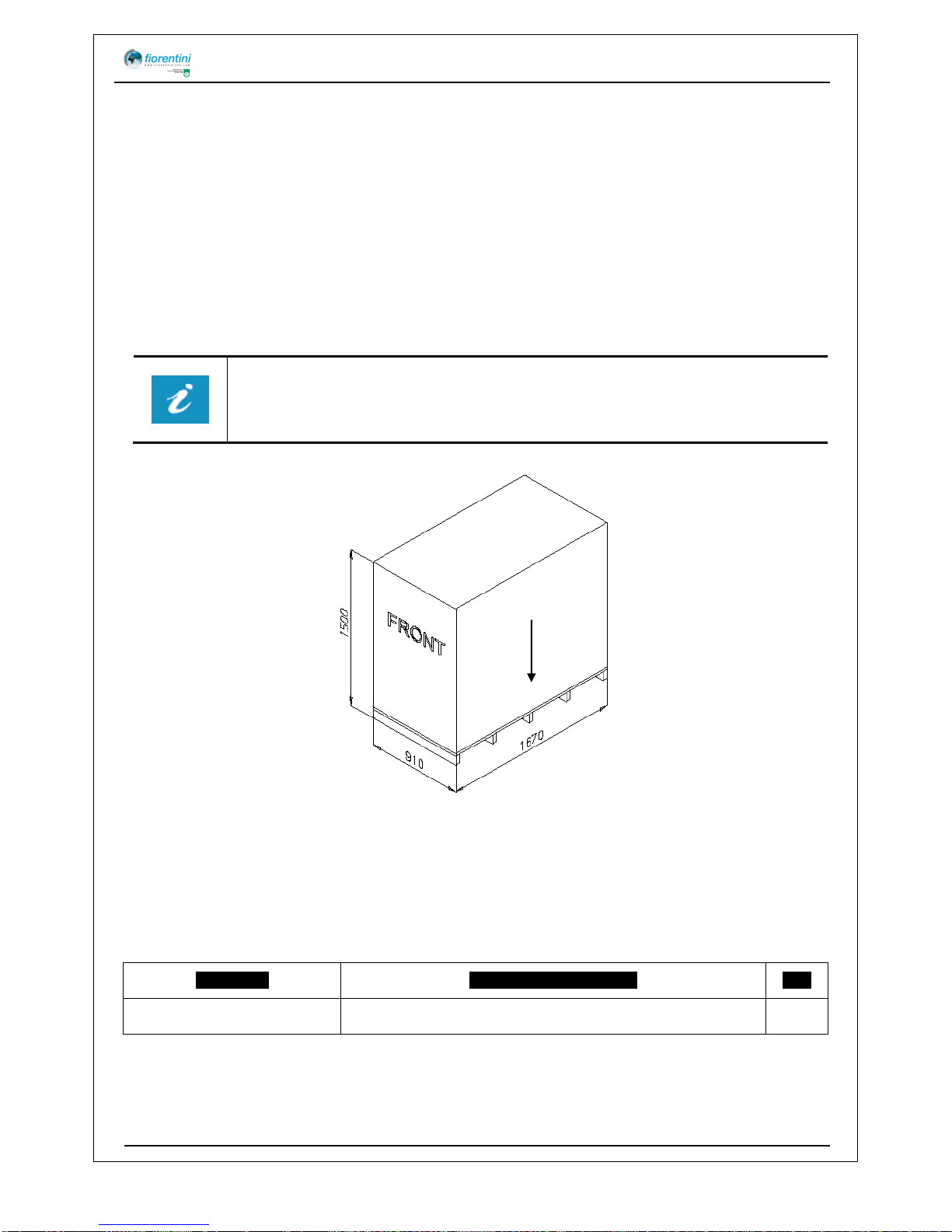

The machine is delivered to the purchaser in a proper package (see picture 4.1 below). A black arrow on the

package indicates the barycentre. This arrow must be in the middle of the elevator or transpallet forks. The

package must be carefully handled. Do not place one package on another one. If agreed with the purchaser,

the machine can be delivered without package, placed on a pallet and fixed by means of straps.

The purchaser must make sure that the machine has not been damaged during the

transport and that all papers are on the machine. Otherwise, the purchaser must

immediately contact FIORENTINI in order to sort out the problem.

The purchaser is responsible for the transport of the machine if not differently agreed with

FIORENTINI.

The machine must be handled with proper devices as stated in the scheme below.

Make always sure that the black arrow on the package is in the middle of the elevator forks or the straps.

Anchorage and/or strapping points are set up in order to keep the machine on balance during the transport.

PACKAGE

HANDLING EQUIPMENT

PIC.

Carton box or plywood box on a

pallet

Fork elevator

Nr. 4.2

PICTURE 4.1

STARTING AND USE INSTRUCTIONS

MINISWEEPER

Rev. 00 del 05/07/04

19/33

Bands used for lifting the machine up must have the same loading capacity as the

machine load. Handling operations must be done without causing a loss of stability

of the machine. Otherwise, the machine can be damaged or the operator can de in

danger.

FIORENTINI suggest to use authorized personnel (see § 2.3.) to handle the machine.

LOADING SYSTEM

4.2. STORAGE

The machine must be stored in a closed and dry place if not immediately installed in order to keep every part

safe.

Relative humidity must be lower than 80% and the storage temperature must be between 3°C t + 45 °C.

4.3. HOW TO UNPACK THE MACHINE

Cut the straps paying attention to the back spring.

Remove clips that join pallet and carton;

in case of plywood box, please remove clips from both sides and basis of each panel:

Cut the strips that hold the machine.

Lay the machine on the floor.

4.4 HANDLING THE UNPACKED MACHINE

Check the machine and install the batteries if not already installed.

For a brief transport of the machine, please disconnect the batteries cables and remove brushes; for

a longer transport, please use the original package of the machine.

PICTURE N° 4.2

STARTING AND USE INSTRUCTIONS

MINISWEEPER

Rev. 00 del 05/07/04

20/33

4.5. INSTALLATION

Installation must be carried out by authorized personnel after reading this manual..

4.5.1 BATTERIES INSTALLATION

Please follow the instructions below to install the batteries:

the batteries room is under the operator’s seat protected by a cover;

lift the cover of the batteries room up (picture no. 4.4 detail 2);

install the batteries in their room (picture 4.4 detail 2 and make sure the batteries boxes are not

broken;

do never add distilled water after batteries recharge;

clean the surfaces for the cables connections;

use the handles on the batteries to move them.

PICTURE N° 4.4

1

2

Table of contents

Other FIORENTINI Blower manuals

FIORENTINI

FIORENTINI UBF 38 User manual

FIORENTINI

FIORENTINI GENIUS-18 User manual

FIORENTINI

FIORENTINI ASPIRIK-P User manual

FIORENTINI

FIORENTINI 650 Instructions for use

FIORENTINI

FIORENTINI S32B User manual

FIORENTINI

FIORENTINI SP500 NEW User manual

FIORENTINI

FIORENTINI UBF 28 NEW Operating instructions

FIORENTINI

FIORENTINI S 150 User manual

FIORENTINI

FIORENTINI GENIUS-14 User manual

Popular Blower manuals by other brands

Grizzly

Grizzly BLS 30 Translation of the original instructions for use

Shark

Shark V1725BL user guide

Makita

Makita DUB183 instruction manual

Makita

Makita DUB362 instruction manual

Kraftixx

Kraftixx KX-ALB 1821 Li Kit Original operating instructions

CARNES

CARNES VDBA Series Installation, operating and maintenance instructions