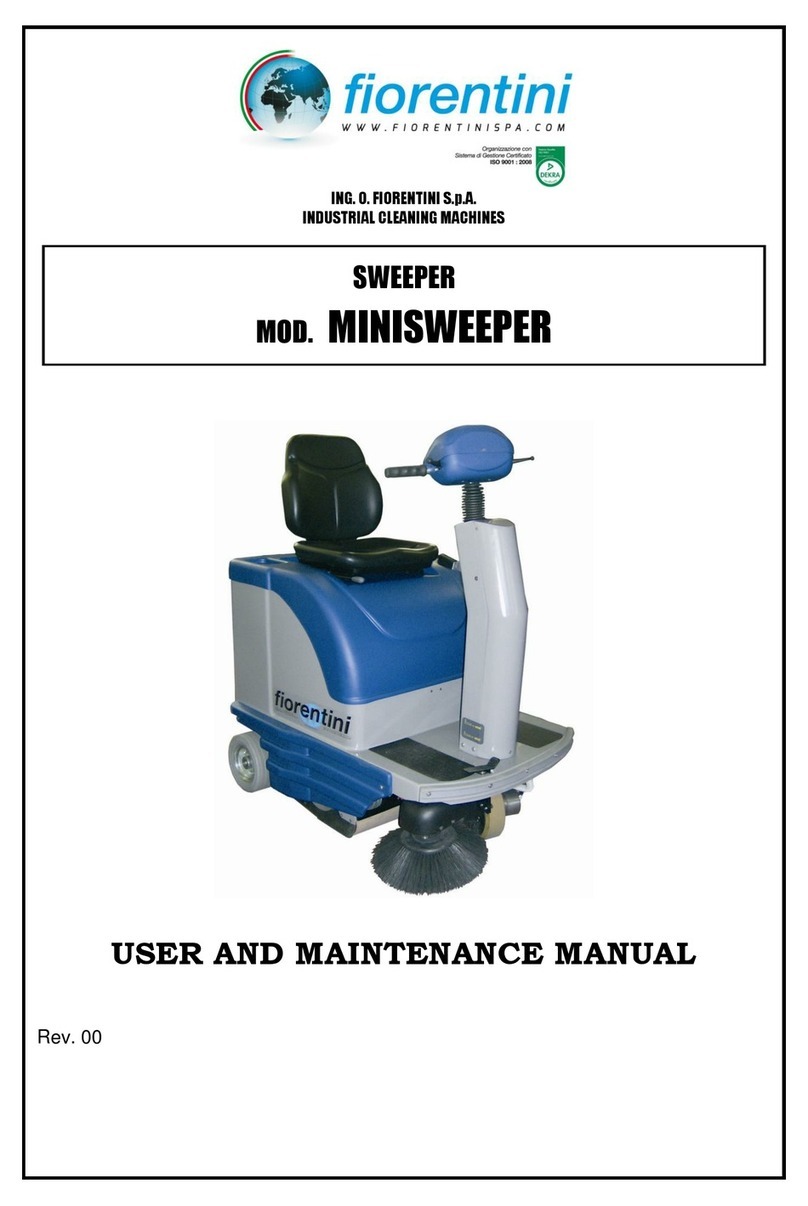

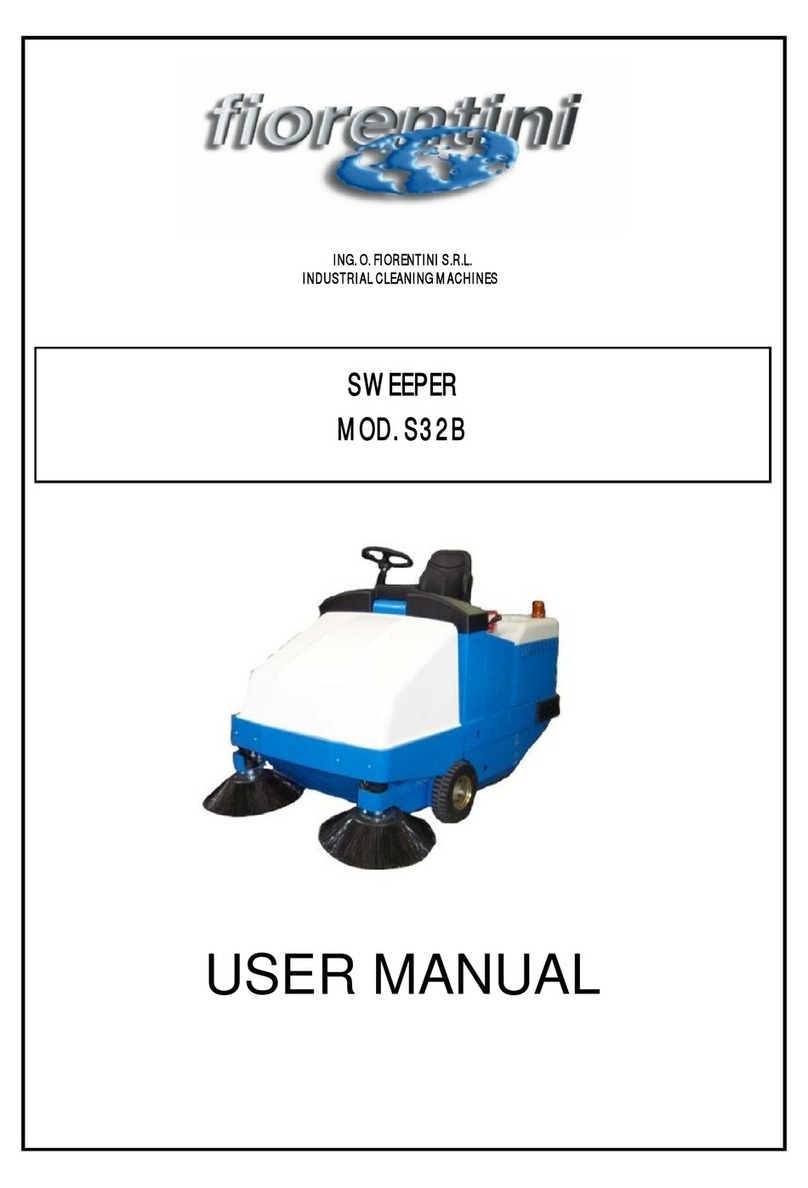

FIORENTINI SP500 NEW User manual

ING. O. FIORENTINI S.p.A.

INDUSTRIAL CLEANING MACHINES

WALK-BEHIND SWEEPER

MOD. SP500 NEW

OPERATING INSTRUCTIONS

AND MAINTENANCE

INDEX

1.

GENERAL INFORMATION

1.1. Used symbols…………………….…….........................……......……….page

4

1.2. Notes................................................…………...…………......……….......…...….........

4

1.3. Manual references......…………………………....…...………….....………….…………

4

1.4. Warranty..............................................................…….……...…………...….…...........

4

1.5. Conformity declaration......................................…………...........………….…...………

6

2.

SUPPORT FEATURES AND SPECIFICATIONS

2.1. Identification………………......…...............................….…………….….…….........….

8

2.2. Description and components……………...……………………………….…….…......…

8

2.3. Specifications................................…........……………………….....…........…………...

10

3.

SECURITY

3.1. Correct use…………..………....……………....…....……………….....…………......…..

11

3.2. Unproper use………………………………………………………..……………………

11

3.3. Recommended equipment…………………………………………………………………

11

3.4. Operators qualification....……………….......……………...………….............…………

12

3.5. Protection and alarm systems…………..................…...…………..........……………...

12

3.6. Safety devices...............................................…………..….…....…………………........

13

3.7. Residual dangers………………………………………….………………….……………

13

3.8. Safety signals……………………………..………………………………...………………

14

4.

INSTRUCTIONS FOR STARTING AND USE

4.1. Transport and handling.................….....................…....………….….….…......……….

16

4.2. Storage..............................................…………….…………..................………………

17

4.3. Instructions to unpack the machine...........................……………………........…...…..

17

4.4. Handle the unpacked machine….….…..........………………………..……........………

17

4.5. Installation…...............................................................………………..……...........…...

18

4.5.1 Battery installation………………………………………………………………………….

18

4.5.2 Motor installation…………………………………………………………………………

18

4.6. Regulations……………………………………………………………………………...

19

4.6.1. Regulation of the handle.………………………………………………………………

19

4.6.2. Regulation of central roller brush……………………………………………………….

19

4.7. Control devices…………………………………………………………………………..

20

4.7.1 Control board………………………………………………………………………………

20

Congratulations for your choice!

FIORENTINI S.p.A.. thanking you for the preference to our product, would like to remind you that

FIORENTINI’s S.p.A. production covers manufacture and marketing of industrial cleaning machines

and is currently a Leading industry in this sector .

Our tradition and competence guarantee technical quality of your choice; actually all our products are

being built first quality materials through criteria that can give reliability, solidity and functionality

satisfying every kind of customers. FIORENTINI has recently obtained the quality system certificate

conforming to the requirements of UNI EN ISO 9001:2000.

We wish therefore inviting you to contact us, unhesitatingly, for every kind of request, as technical or

commercial; we’ll be pleased to be at your disposal for any information you may need.

4.8 Functioning…………………………………………………………………………………

21

4.8.1. Leverage functions ………………………………………………………………………

21

4.8.2. Central brush replacement …………………………………………………………..

22

4.8.3. Side brush replacement………………………………………………………………..

22

4.8.4. Recovery tank emptying..……………………………………………………………..

23

4.8.5. Motor maintenance..……………………………………………………………..

23

4.8.6. Filter shaker motor maintenance……………………………………………………..

24

5.

MANUTENZIONE

5.1. Maintenance schedule…………..……………..................….....…..…………...........

25

5.2. Battery maintenance………………………………………………………………………..

25

5.2.1. Hydrometry…………………………………………………………………………………

26

5.2.2. Water Filling Up………………………………………………………………………...

26

5.2.3. Charge Limits……………………………………………………………………………

26

5.2.4. Off duty or inactive batteries ……………..…………………………………………...

26

5.2.5. Batteries disposal ………..……………………………………………………………..

26

5.3. Electrical equipment checking…………………………………………………………….

27

5.4. Tests and controls to be carried out …………..…………………………………………

27

5.5. Maintenance register………………………………………………………………………

28

6.

TECHNICAL ASSISTENCE

6.1. Servicing addresses…………….............…………..................……………..................

29

6.2. Verbal claim…….…………………………..…………...………………….…............

29

GENERAL INFORMATION

SP 500 NEW

Rev. 00

28/04/09

Pag. 4/31

1. GENERAL INFORMATION

1.1. USED SYMBOLS

This symbol is used to quote the attention of the operator on procedures or precautionsto

be followedto avoid damagestousersor to thesupport

This symbol is used to quote the attention of the operator on general information

1.2. NOTES

1.3. MANUAL REFERENCES

This manual deals exhaustively with all necessary arguments for easy and safe use of the machine, as

recommended by European Directives about product security.

Consequently we recommend to all authorized operators to use it of reading attentively this manual in every

part and carefully applying everything indicated, asking for explanations to FIORENTINI in case of doubt.

The manual must also be used as referring documentation each time it needs to remind a procedure or

operation or to train new operators.

For publishing reasons, pictures and drawings can look different from reality however without showing

meaning doubts.

Special symbols and bold type and/or sloping remind the attention of the reader on remarkable information,

particularly for safety.

Index of review is reported, each single page, at the bottom. List of revised pages can be found to the end of

the manual.

1.4. WARRANTY

Terms and conditions of warranty are stated to the following points if not differently specified in the order

confirmation.

OBJECT OF WARRANTY

The sweeper has been conceived and built for a long-term use without relevant problems; anyway, in case of

anomalies during the warranty period, FIORENTINI Co. is engaged to repair and/or substitute for free parts

which have shown early breakage or wear and tear caused by defective materials, working defects or

imperfect assembly.

Warrantyis not given for parts which earlybreakage or wear and tear are due to:

This manual is property of FIORENTINI S. p. A.

All rights reserved to copy, totally or in part, and transmission to third parties with

mechanic, electronic or whatever means, without permission of manufacturer. It’s been

made in one original copy unless differently specified in order place.

Manual is delivered with relative machine, of whom it constitutes integral part, and it has to be given in case

of transfer of the machine too. We remind to put it in a safe place and keep it for all the machine lifetime.

Purchaser is responsible to show it to qualified people. Incaseoflossaskfora duplicateto FIORENTINICo.

FIORENTINI decline every responsibility for any kind of possible damages caused by persons and/or things

due to non-observance of instructions in this manual.

FIORENTINI reserves the right to introduce in every moment and without notice all the technical and

commercial changes useful considered. Therefore data and information reported could have changes and/or

updating notes.

GENERAL INFORMATION

SP 500 NEW

Rev. 00

28/04/09

Pag. 5/31

Non-respect of instructions included in this manual;

Breaking and/or changes made up without FIORENTINI’s approval;

Not-use of genuine wear parts;

Interventions made up by unauthorized personnel;

Maintenance missing;

Natural calamities.

WARRANTY TERMS

Warranty is granted for a 12 months period since delivery date; this is a single warranty term, and extensions

cannot be given following to substitutions or reparations made in this period.

GOODS TO BE RETURNED

In case of goods to be returned for warranty replacement, it is necessary to have a written acceptance from

FIORENTINI technical department before sending them.

All defective parts must be carefully packed in order to avoid further damages during transport.

Goods must be shipped ex-warehouse and followed by :

serial number of the equipment where they were installed on;

item code of the defective part;

detailed description of the defect and of the conditions where it happened.

In case of defective electric or electronic goods,

please return them separately from other materials,

in order to help us in dividing dangerous waste goods

and recycle the (RAEE) as DER 2002/96/CEE LOW.

Components recognized under warranty are delivered ex works; those ones being substituted are property of

FIORENTINI Co..

EXCLUSIONS

Warranty does not cover normal wear parts and materials (brushes, squeegee blades, etc…), and those

parts of whom is impossible to define lifetime in advance.

GENERAL INFORMATION

SP 500 NEW

Rev. 00

28/04/09

Pag. 6/31

APPLICATION MODES

In order to establish anomalies causes, so that warranty could be applied, is necessary that defective

components must be sent to FIORENTINI. Repairing or substituting works under warranty will be, by

FIORENTINI’s opinion, made in its own workshop, or by third party on place. Works on place, are supplied

with customer’s energy sources and exceptional equipment to repairing if necessary.

INTERVENTION DEMANDS

Possible intervention demands have to be addressed to the technical assistance service of FIORENTINI Co.

in writing or by phone, just after a attentive analysis of fault and of causes, so that it would be necessary to

report to the agent the following data:

Machine model, get from the relative label (point 2.1.);

number, get from the relative label (point 2.1.);

detailed description of defect and the way it happened;

controls and/or regulations made;

code number and position of possible defective component, deduced from spare parts list

The relative label missing will involve the loss of any kind of warranty.

1.5. CONFORMITY DECLARATION

Conformity declaration is consigned with the support and the manual of operating and maintenance

instructions.

GENERAL INFORMATION

SP 500 NEW

Rev. 00

28/04/09

Pag. 7/31

SUPPORT FEATURES AND SPECIFICATIONS

SP 500 NEW

Rev. 00

28/04/09

Pag. 8/31

2. SUPPORT FEATURES AND SPECIFICATIONS

2.1. IDENTIFICATION

The sweeper SP500NEW is identified with an adhesive label put on the protection carter in the backside of

the machine which will clearly report the data referring to “CE” marking

The label has never to be removed and should be always kept legible. In case of

damaging it’s necessary to ask for a duplicate. The sweeper machine cannot be

commercialized without the label.

2.2. DESCRIPTION AND COMPONENTS

The sweeper machine SP500 NEW has been designed for treatment of flat areas by a sweeping process

that put the dust in a recovery tank in the back of the machine. The power is supplied by a battery

accumulator or by a petrol engine, which feed all motors and electric controls.

The machine is equipped with a front rotating brush that moves the dust to the center of the machine and the

main /central brush convey the dust in the tank, vacuumed by a fan motor. This machine must be utilized on

dry surfaces.

The dashboard controls some of the machine functions.

With the dashboard it is possible to activate the following functions:

switch on and off the machine;

start the machine traction;

start the filter shaker motor;

Ing. O.Fiorentini S.p.A.

MADE

50030 Piancaldoli (FI)

IN

ITALY

Mod

SP 500 NEW

S.N

2

0

0

9

V

Hz

Kg

A

W

IMAGE N° 2.1

SUPPORT FEATURES AND SPECIFICATIONS

SP 500 NEW

Rev. 00

28/04/09

Pag. 9/31

The main components of the machine are:

galvanized steel or stainells steel chassis;

right side nylon brush ;

central main roller brush;

vacuum and recovery system

2 driving wheels

1 castor wheel

FIORENTINI Co., taking care of new safety rules in CE community , has manufactured the machine following

safety and health rules of the CE normative. High quality material used, high technology and Fiorentini

experience allowed to have performing machine .

Each machine is inspected during the manufacturing time and the final check is done before shipping out the

machine.

SUPPORT FEATURES AND SPECIFICATIONS

SP 500 NEW

Rev. 00

28/04/09

Pag. 10/31

2.3. TECHNICAL SPECIFICATIONS:

SP500 NEW

Battery version

SP500 NEW

Petrol version

MAIN SPECIFICATIONS

SWEEPING WIDTH

650 mm

WORKING CAPACITY UP TO.

3200 m²/h

AUTONOMY

3.5 h

/

DUST TANK CAPACITY

35 l

FILTER

Cartridge

FILTERING SURFACE

2 m²

GENERAL SPECIFICATIONS

TRACTION (front/rear)

With rear belt

FORWARDING SPEED

0-5 km/h

MAXIMUM SLOPE

8 %

NOISE LEVEL (for operator)

60 dB

75dB

VACUUM

Free flow turbine

ELECTRIC SYSTEM

TENSION

12V 500W

2600rpm 10A/h

/

BRUSH TRACTION

With belt

MOTOR

/

Honda motor 3 hp

BATTERY

2x 6V 240A/h

/

WEIGHT AND DIMENSIONS

LENGTH

1200 mm

WIDTH

620 mm

HEIGHT

910 mm

CENTRAL BRUSH

Ø260x500 mm

SIDE BRUSH

Ø200 mm

WEIGHT (empty machine)

50 kg

BATTERY WEIGHT

13.4 kg

/

The above characteristics are not a must for the manufacturer so they can be changed

without any notice .In any case ING.O.FIORENTINI Co. Is always at disposal for any

information ( 7.1.).

MEASUREMENT UNITS CONVERSION

Lenght

1 inch = 1” = 25,4 mm

Power

1 kW = 1,36 CV = 1,34 BHP

Temperature

T (K) = t (°C) + 273 / t (°F) = 1,8 t (°C) + 32

Pressure

1 bar =100 kPa = 14,5 psi

SAFETY

SP 500 NEW

Rev. 00

28/04/09

Pag. 11/31

3. SAFETY

3.1. CORRECT USE

The machine is a sweeper machine and has been studied and manufactured to be

used to clean flat floors or with maximum slop of 8%.

3.2. UNPROPER USE

Not authorized operator uses;

Not regular floors cleaning

Cleaning of surfaces with more than 8% slope

To use the machine in place with dangerous products

Floor cleaning with inflammable products;

To use the machine as transport vehicle of person or goods;

Modify or removing protection device;

Charging the batteries in places with no suction or with good ventilation;

No respect of safety rules from the operators;

Any modification that can modify the correct machine function;

Any modification not authorized by Fiorentini Co.

Use of acid products that can damage the machine

Not respect of what mentioned in the operator’s manual.

Read carefully the information labels stuck on the machine , don’t cover them for any

reason.

FIORENTINI is not responsible for the machine use not in a correct way .

3.3. RECOMMENDED EQUIPMENT

In order to use in a better way the machine characteristics it is suggested to use the original parts and spare

parts studied by Fiorentini Co.. In any case the Technical department is at customers disposal in order to

satisfy any needs .

SAFETY

SP 500 NEW

Rev. 00

28/04/09

Pag. 12/31

3.4. OPERATOR QUALIFICATION

Follow the request operator qualification for different uses

OPERATION TYPE

OPERATOR QUALIFICATION

Use /Inspection

Taught operator

Installation / disinstallation

Specialized technician

Mechanical parts maintenance

Specialized technician

Electrical parts maintenance

Specialized technician

Ordinary maintenance

Taught operator

Dismantling and demolition

Specialized technician

We recommend to teach the personnel the correct use of the machine, especially for what concerns safety

aspects ; particularly operators must read and understand this manual.

FIORENTINI decline every responsibility for accidents to persons or things from using the

machine by non-authorized or unqualified operators.

3.5. PROTECTION AND ALARM SYSTEMS

It is absolutely forbidden to tamper these devices, keep them out or disconnect

during the functioning of the machine.

We recommend to verify periodically their efficiency

Brush cover

The sweeper SP500NEW is equipped a central nylon brush, which rotates

when the machine works. Plastic covers prevent the accessibility to the

dangerous areas. Only specialized technicians can remove these parts.

SAFETY

SP 500 NEW

Rev. 00

28/04/09

Pag. 13/31

3.6 SAFETY DEVICES

This machine is provided of the following safety systems (battery version).

Electric plug (image 3.6), the same used for the battery charter. In case of emergency, this socket

can be immediately removed from the plug in order to immediately stop every machine operation.

Before using the machine, the operator must learn how to use this safety system. Do not restore the

safety system if the problem is not solved. If necessary call a specialized technician. To disconnect

the plug it is necessary to lift the battery protection cover and pull the plug handle.

Disconnect in case of emergency

3.7 RESIDUAL DANGERS

La FIORENTINI ha analizzato tutti i pericoli correlati all’uso della macchina allo scopo di eliminare, o

perlomeno ridurre, il rischio di infortunio per gli operatori, fin dalla fase progettuale. Per ridurre il rischio

associato ai pericoli residui si è provveduto informando gli operatori mediante segnaletica e indicando i

mezzi e le procedure antinfortunistiche da adottare.

Crushing danger may happen:

When setting the brushes

During maintenance of motor/batteries

All the maintenance operations must be do with the machine turned off.

The danger is indicated by proper signals on the machine in order the remember the operator.

OVERTURNING DANGER

Overturning danger may happen:

During the normal use when the machine overpass the gradient limit specified in this manual

or when the machine is used on not regular surface with holes.

CRUSHING DANGER

IMAGE 3.6

SAFETY

SP 500 NEW

Rev. 00

28/04/09

Pag. 14/31

Don’t use the machine to clean up areas exceeding 8% slope or presenting holes

and depressions, which might compromise the stability of the machine.

FIORENTINI decline every responsibility for accidents to persons or things using the machine

on surfaces that can compromise the stability of the same one. The operator has to follow

recommendations about areas conditions on which he has to work.

3.8. SAFETY SIGNALS

Safety signals include :

DANGERS

Signals are triangular shaped with black

colored pictograms in yellow field

PROHIBITIONS

Signals are circular shaped with black colored

pictograms in white field red-crossed

What is it ?

This signal shows the prohibition to remove covers in which members

are still moving.

What to do ?

In phase of installation/maintenance we recommend, to remove

mobile protections, to disconnect the ignition key from the control

board. When the machine is in action not enter with body’s parts and

make sure that all covers are well fixed.

In case of wear and tear, the purchaser must re-establish similar signals of danger.

It’s absolutely forbidden to keep out or to temper with these signals.

What is it ?

This signal shows crushing dangers due to moving parts of the

machine.

What to do?

In phase of installation/maintenance we recommend to keep away

the ignition key from the control board.

SAFETY

SP 500 NEW

Rev. 00

28/04/09

Pag. 15/31

What is it ?

This signal shows crushing dangers due to moving parts of the

machine.

What to do?

In phase of installation/maintenance we recommend to keep away

the ignition key from the control board and not introduce any part of

body inside the machine.

In case of wear and tear the purchaser must re-establish similar signals of danger.

It’s absolutely forbidden to keep out or to temper with these signals.

What is it ?

This signal indicate the risk of explosion due to hydrogenous exhaled

during the battery charge (battery version).

What to do ?

During the batteries charge make sure that the machine is under a

vacuum chimney or in a ventilated area. Keep clear from the heat and

corrosive environment.

INSTRUCTIONS FOR STARTING AND USE

SP 500 NEW

Rev. 00

28/04/09

Pag. 16/31

4. INSTRUCTIONS FOR STARTING AND USE

4.1. TRANSPORT AND HANDLING

This sweeper is delivered to the purchaser in a special package, which features are well showed in picture

4.1, completely assembled. The package shows the barycentre position indicated with a black arrow. The

forks of the truck or transpallet must be placed in such a way as the black arrow is at the center of them. The

package has to be moved carefully. We recommend not to place packages one on the top of the other. As

agreed with purchaser, the machine can be delivered without package, placed on a bed and blocked with

bands.

At the moment of delivery we suggest to check the machine about accidental damages

while transported and about have received all material indicated in coverings ; in case of

damages or missing parts, please inform the forwarder and the manufacturer that will soon

as possible provide to the mishap.

Missing particular agreements, the goods travel at the purchaser’s risk.

Handling of the machine has to be carried out with suitable lifting apparatus, as showed below. Take always

care about the elevator forks, or the sling bands, that have to be placed with the black arrow, as drawn on

the package, has to be put at the center of the lifting system. Anchorage or slinging points are prepared for

having a good balanced position when lifting up the machine.

PACKAGE TYPE

LIFTING APPARATUS

PIC.

Cartoon or plywood with bed

Elevator with forks

N° 4.1

PIC. 4.1.

INSTRUCTIONS FOR STARTING AND USE

SP 500 NEW

Rev. 00

28/04/09

Pag. 17/31

Bands to be used must be suitable for the effective loading. Operations must be

executed slowly avoiding oscillations or upsetting. The incorrect way of operating

can damage the support or expose to dangers.

Machine dimensions and mass are explained at point 2.3. We strongly recommend

authorized personnel for lifting operations.

LOADING DIAGRAM

4.2. STORAGE

In case the machine is not immediately installed, it has to be preserved in a dry and closed

Place to grant a perfect conservation and efficiency of its body parts. Humidity must be lesser than 80 % and

storage temperature between 3° C t + 45 °C.

4.3. INSTRUCTIONS TO UNPACK THE MACHINE

Cut off the bands being careful of the elastic reversion

Take away on the base of the cartoon the clips that keep it together with the pallet.

Where plywood is take away the clips at both sides and at the base of each panel.

Cut off the clips that stop the machine.

Put the machine at round level.

4.4 HANDLE THE UNPACKED MACHINE

Check the machine and mount the batteries if not installed.

To displace it, after use, take off the battery cables, the brushes and the squeegee; to displace it

through a longer space pack the machine once again in its own package.

FIGURA N° 4.2

INSTRUCTIONS FOR STARTING AND USE

SP 500 NEW

Rev. 00

28/04/09

Pag. 18/31

4.5. INSTALLATION

The installation must be done by authorized personnel after reading this manual.

4.5.1 BATTERY INSTALLATION

Follow the below instructions to install the batteries:

the battery box is under the protection cover

(detail 1 image 4.5.1);

Lift the cover by mean of the proper handles

(detail 2 image 4.4);

Install the batteries in their specific place and make

sure that all battery cells are intact

Do never add distilled water after having

charged the batteries

Clean the connecting surfaces

use the battery handles to move them more easily

4.5.2 MOTOR INSTALLATION

Follow the below instructions to prepare the petrol engine ready for use.

Open the protection cover;

Check the oil level (detail 1 image 4.5.2);

Fill the tank with fuel (detail 2);

Move the lever (detail 3)

To the right to give air to the motor;

Switch the motor on by using the handle (detail 4)

IMAGE N° 4.5.1

1

2

3 4 2

1

IMAGE N° 4.5.2

INSTRUCTIONS FOR STARTING AND USE

SP 500 NEW

Rev. 00

28/04/09

Pag. 19/31

4.6 REGULATIONS

4.6.1 REGULATION OF THE HANDLE

Turn the knobs at the base of the handle in order to set it according to the operator’s needs.

When loosen, it is possible to change the handle height.

Strengthen the knows again to fix the handle position.

4.6.2 REGULATION OF CENTRAL ROLLER BRUSH

Turn the pins at both machine sides to set the central brush (see red arrow on image 4.6.2).

The brush height can be changed by unscrewing the pin, in order to reach the ideal position for a satisfying

sweeping.

IMAGE N° 4.6.1

IMAGE N° 4.6.2

INSTRUCTIONS FOR STARTING AND USE

SP 500 NEW

Rev. 00

28/04/09

Pag. 20/31

4.7. CONTROL DEVICES

4.7.1. CONTROL BOARD

The control board is composed by some switches which control the main functions of the machine. Here

below there is the scheme that resumes all control board main functions ( image. N° 4.7.1).

POS.

FUNCTION

1

KEY SWITCH

2

TRACTION LEVER

3

FILTER SHAKER LEVER

4

DUST TANK UNHOOKING PIN

5

SIDE BRUSH LOWERING PEDAL

IMAGE N° 4.7.1

3

5

4

1

2

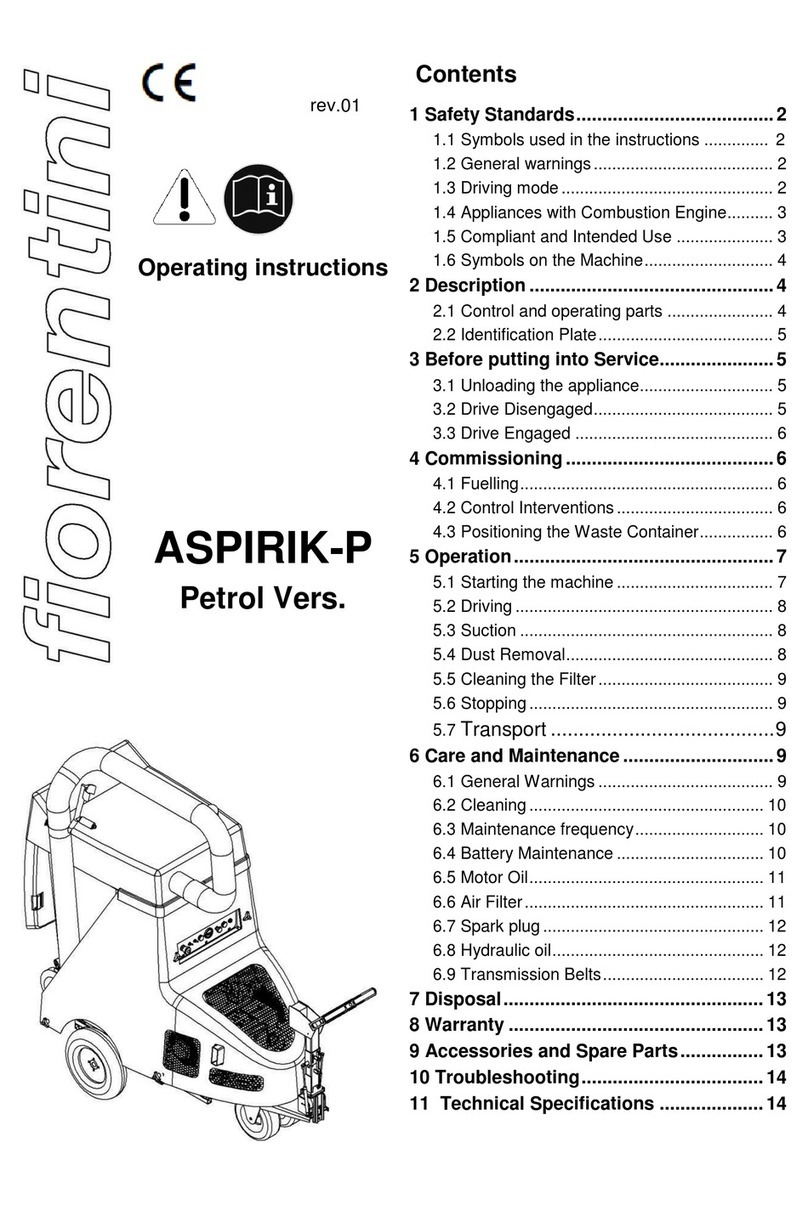

Table of contents

Other FIORENTINI Blower manuals

FIORENTINI

FIORENTINI S 150 User manual

FIORENTINI

FIORENTINI MINISWEEPER Operating instructions

FIORENTINI

FIORENTINI UBF 28 NEW Operating instructions

FIORENTINI

FIORENTINI ASPIRIK-P User manual

FIORENTINI

FIORENTINI UBF 38 User manual

FIORENTINI

FIORENTINI S32B User manual

FIORENTINI

FIORENTINI 650 Instructions for use

FIORENTINI

FIORENTINI GENIUS-18 User manual

FIORENTINI

FIORENTINI GENIUS-14 User manual

Popular Blower manuals by other brands

Lithium Earthwise

Lithium Earthwise LB20024 Operator's manual

EINHELL

EINHELL GE-CL 36 Li E Original operating instructions

EINHELL

EINHELL VENTURRO 18/210 operating instructions

Troy-Bilt

Troy-Bilt 657 Operator's manual

Weed Eater

Weed Eater VS2000BV instruction manual

KRAUSMANN

KRAUSMANN U37020-00 Operation manual