Fire dept GD1 Installation guide

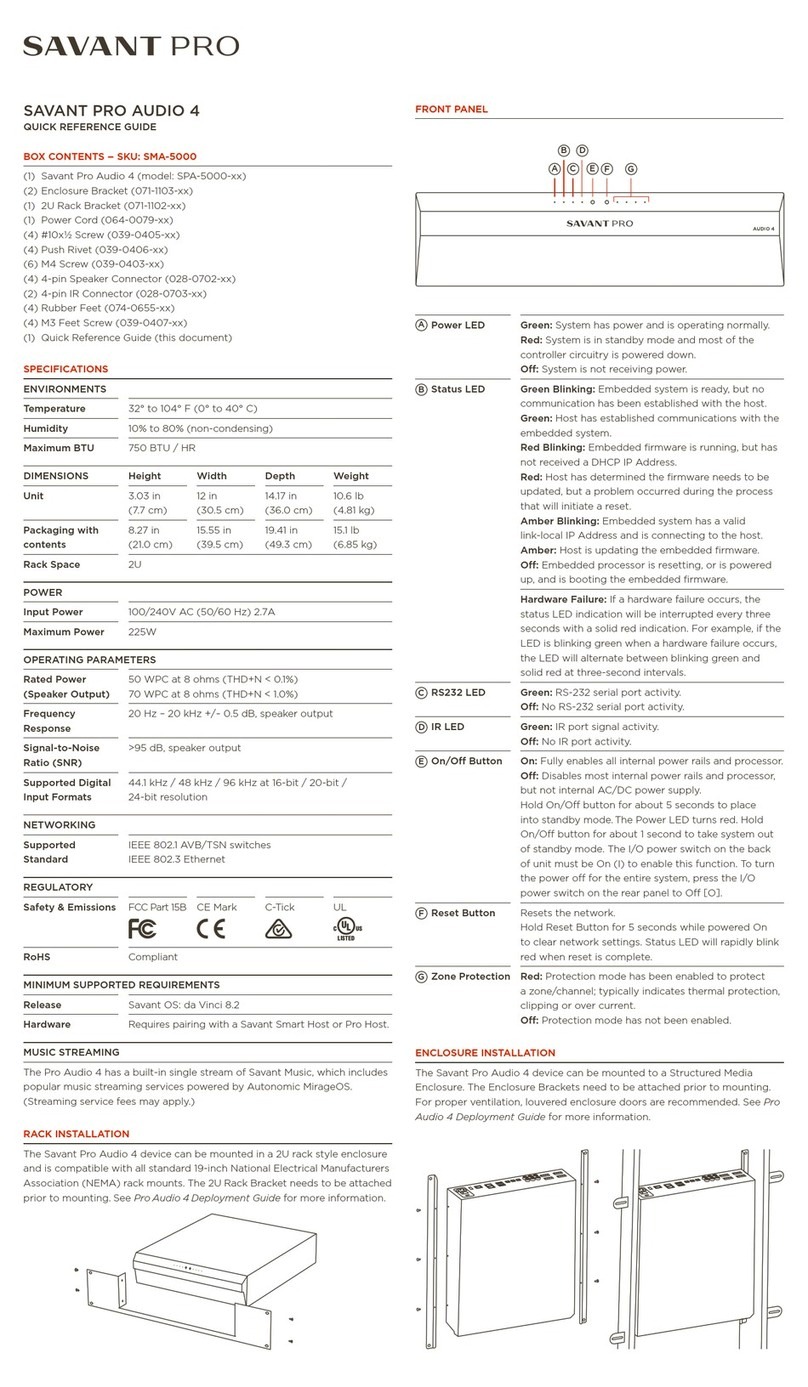

GD1 –Wall Switch

Installation Guide

Operating Instructions

Warranty

Version: July 2020 2

GD1 Installation Guide, Operating Instructions & Warranty

IMPORTANT!

This gas appliance must be installed to AS/NZS 5601.1:2013 by a qualified person and in accordance with

these instructions. Failure to install the appliance correctly will void your warranty and may cause a fire. This

appliance should not be modified under any circumstances.

Under no circumstances should any combustibles such as paper, wood or coal be used in this appliance.

It is recommended that you have this appliance serviced annually by a qualified technician.

Warranty repairs must be carried out by a ‘The Fire Dept.’ authorised technician.

This appliance must ALWAYS terminate/flue outdoors.

Young children, elderly or infirm should be supervised to ensure that they are careful with the appliance.

Clothing and other flammable materials should never be placed near the appliance.

Never switch the appliance ON without the glass in place.

Please note that parts (near the flame) of this appliance, particularly the steel surrounding, glass panels to the

face or the door, become extremely hot during operation and can result in serious injury and burns if touched. It

is therefore recommended that a fireguard complying with BS 8423:2002 is used in the presence of young

children, the elderly or infirm.

The GD1 installation process consists of 8 steps Page

Step 1: Unpack and ensure all components are correct and undamaged 3

Step 2: Install plinth (if required) 3

Step 3: Install appliance into cavity 3

Glass removal process 4

Glass installation process 4

Burner Tray Removal Process 5

Burner Tray Installation Process 6

Step 4: Install flue, Air supply (duct and bracket) and connect to appliance 8

Step 5: Connect and test electrical supply 15

Step 6: Connect gas supply and commission 16

Step 7: Lay the firebed 18

How to lay Vermiculite 19

How to lay River Rocks Firebed –GD1 1200 21

How to lay River Rocks Firebed –GD1 1500 & 1600 22

How to lay Beach Driftwood Firebed –GD1 1200 23

How to lay Beach Driftwood Firebed –GD1 1500 & 1600 24

How to lay Forest Logs Firebed –GD1 1200 25

How to lay Forest Logs Firebed –GD1 1500 & 1600 26

Step 8: Show owner how to operate appliance 27

GD1 Operating instructions 28

Troubleshooting 28

Product warranty 29

Information in this installation guide may be subject to change without notice.

Please ensure that you have the current version before beginning installation.

If you have any queries, please contact ‘The Fire Dept.’on 0800 888 550

Version: July 2020 3

Step 1: Unpack and ensure all components are correct and undamaged

•Appliance

•Box of firebed mediums

•Flue kit

Step 2: Install plinth (if required)

•If the appliance is to sit on a plinth, ensure it is

capable of supporting a 200kg load.

•There is no clearance requirement for the base of

the appliance. It may safely sit directly upon

combustible (eg. timber) and non-combustible

(eg. concrete) materials.

Step 3: Install appliance into cavity

•Before installation, confirm all minimum

clearances from the outside surfaces of the

appliance to the surrounding enclosure are no

closer than 25mm from combustible materials

and 5mm from non-combustible materials.

•The exception to these minimum clearances is

the base, which can safely sit directly upon

combustible (eg. timber) and non-combustible

(eg. concrete) materials.

•If a gas supply pipe has already been run to the cavity, ensure 1000mm of 3/8 soft copper tube is available

at the lower left rear of the cavity, as this is where the copper tube with the gas supply enters the appliance.

•If an electrical supply cable has already been run to the cavity (must be a minimum of 1.0mm 5 core cable),

ensure that the cable reaches the lower left rear of the cavity, as this is where it will enter the appliance.

•In order to access the fixing slots in the base of the appliance, and the gas and electrical connections, it is

necessary to first remove the glass and the burner tray.

Version: July 2020 4

Glass removal process

•Note: Glass removal is best carried out by two people.

•Carefully remove glass, which is held in place by hooks at the top corners and powerful magnets in each

bottom corner.

•Place fingers at top and bottom corners of glass. Slide two

fingers outward behind bottom corners of glass until you feel the

2mm steel magnetic fixing brackets. You will need to apply

pressure to the back edge of the magnetic fixing brackets whilst

pressing thumbs against the appliance to break the magnetic

connections at bottom corners.

•Lift glass off top hooks and lay glass flat in a safe place with

insulating material facing down to protect glass.

Glass installation process

•Carefully re-install glass by simply reversing the glass removal process detailed above.

Version: July 2020 5

Burner Tray Removal Process

Cover and end cap removal

GD1 Burner end caps

This model has two end

cap covers, one at each

side of the burner.

•Remove the stainless steel burner end caps

(2 x screws on each cap) at either end of the

burner tray.

LPG

Natural Gas

GD1 1200

Input 18-28 MJ/h

One gas injector at the pilot

side of the burner tray.

•Remove the burner tray by carefully pushing

it away from the pilot and lift the pilot end of

the burner tray, lift the burner tray up and

away from the pilot in one movement.

•Stand the burner tray on its end and lean

against a stable surface.

•Remove the burner tray by carefully pushing it away from the

pilot and lift the pilot end of the burner tray, lift the burner tray

up and away from the pilot in one movement.

•Stand the burner tray on its end and lean against a stable

surface.

GD1 1500

Input 20-28 MJ/h

Two gas injectors one at the

right and one at left hand

sides of the burner tray.

GD1 1600

Input 30-38 MJ/h

Two gas injectors one at the

right and one at left

•Remove the burner tray by carefully pushing

it away from the pilot and lift the pilot end of

the burner tray, lift the burner tray up and

away from the pilot in one movement.

Ensure that the gas injector at the left hand

side is not damaged as the burner tray is

lifted out.

•Stand the burner tray on its end and lean

against a stable surface.

•On the pilot side gas injector, loosen and spin back the 12mm

brass nut away from the burner tray.

•On the non-pilot side injector, loosen both the 12mm brass

nuts all the way to the end of the injector. The injector will

need to be pushed away from the burner tray.

•Remove the burner tray by carefully pushing it away from the

pilot and lift the pilot end of the burner tray, lift the burner tray

up and away from the pilot in one movement.

•Stand the burner tray on its end and lean against a stable

surface.

Pilot side Gas Injector

Non-pilot side Gas Injector

Pilot burner end

cap

Non pilot burner end

cap

Version: July 2020 6

Burner Tray Installation Process

LPG

Natural Gas

GD1 1200

Input 18-26 MJ/h

One gas injector at the

pilot side of the burner tray.

•Install the burner tray by carefully lowering

the end opposite from the pilot meanwhile

holding up the pilot end, lower the burner

tray down and move towards the pilot in one

movement.

•Ensure the burner tray is located correctly

into the burner bracket and the jets are

aiming into the burner tube inlet holes.

•Install the burner tray by carefully lowering the end opposite

from the pilot meanwhile holding up the pilot end, lower the

burner tray down and move towards the pilot in one

movement.

•Ensure the burner tray is located correctly into the burner

bracket and the jets are aiming into the burner tube inlet holes.

•On the pilot side gas injector, gently tighten (do not over

tighten) the 12mm brass nut closest to the burner tray.

GD1 1500

Input 20-28 MJ/h

Two gas injectors one at the

right and one at left hand

sides of the burner tray.

GD1 1600

Input 30-38 MJ/h

Two gas injectors one at the

right and one at left hand

sides of the burner tray.

•Install the burner tray by carefully lowering

the end opposite from the pilot meanwhile

holding up the pilot end, lower the burner

tray down and move towards the pilot in one

movement.

•Ensure the burner tray is located correctly

into the burner bracket and the jets are

aiming into the burner tube inlet holes.

•Install the burner tray by carefully lowering the end opposite

from the pilot meanwhile holding up the pilot end, lower the

burner tray down and move towards the pilot in one

movement.

•Ensure the burner tray is located correctly into the burner

bracket and the jets are aiming into the burner tube inlet holes.

•On the non pilot side injector, gently tighten both the 12mm

brass nuts. The injector will pull towards the burner tray.

•On both the non-pilot and pilot side gas injectors, gently

tighten (do not over tighten) the 12mm brass nuts closest to

the burner tray.

Cover and end cap installation

GD1 Pilot ladder rope

This model has ladder rope

under the pilot end burner

end cap.

•Ensure the insulating material is glued to the

end cap fixing panel and runs behind the 3

way pilot, rectifier and sparker probes.

GD1 Burner end caps

This model has two end cap

covers, One at each side of

the burner

•Replace the stainless steel burner end caps

(2 x screws on each cap) at either end of

the burner.

Non-pilot side Gas Injector

Pilot side Gas Injector

Insulating material

Pilot burner end

cap

Non pilot burner end

cap

Version: July 2020 7

•Slide appliance into position and ensure that it complies with the minimum clearances required (25mm for

combustibles, 5mm for non-combustibles) to the surrounding enclosure.

•The exception to these minimum clearances is the base, which can safely sit directly upon combustible (eg.

timber) and non-combustible (eg. concrete) materials

•In order to provide maximum positioning flexibility, the base has four 30mm long slots.

•Mark out and drill fixing holes through the 30mm slots in the base. Ensure holes are drilled in the centre of

the slots to allow maximum positioning flexibility. Clear out any debris from drilling.

•Ensure the appliance is level and pack up corners to suit where necessary. Fix bolts / screws into floor.

Check and ensure unit is levelled.

•If the electrician and/or gas fitter is available at this stage the electrical supply and gas supply can be

connected and tested/commissioned (see steps 5 & 6).

•Install the burner tray. The burner tray installation process depends upon the model and type of gas to be

used. Refer to table above.

Version: July 2020 8

Step 4: Install flue, Air supply (duct and bracket) and connect to appliance

•Flue installation must meet the requirements of AS/NZS 5601.1:2013 must comply with all local

council requirements and be installed and certified by a suitably qualified person.

•Refer to appropriate Fire Dept product specification for specific minimum requirements.

•Only follow the ‘Wall cowl assembly details’in this guide if the flue is required to terminate through the

wall.

•A 25mm clearance from combustible materials, 75mm clearance from wiring and plastic pipes and a

minimum of 5mm from non-combustible materials is required when installing a flue system for any appliance

supplied by The Fire Dept.

•The flue installation requires a restriction free cavity from the top of the firebox (flue spigot) to the outside

atmosphere.

•For the In-Line fan installation follow the ‘In-Line Fan assembly details’in this guide.

•For all other Cowl Termination options refer to ‘Air supply duct options for the different cowl

terminations’ in this guide.

•Air flow must be unobstructed from the appliance to the inner flue and from the heat shield to outer casing

allowing air to circulate from the appliance to the flue casings to the atmosphere.

•Connect the Air supply duct bracket to the flue / wall spigot at the flue penetration to termination.

•Run the 100mm Aluminium Semi-Rigid Ducting from the Air supply duct bracket to the 100mm air

supply spigot on the top of the appliance. Refer to appropriate Fire Dept product specification for specific

fixing requirements.

•The 100mm Aluminium Semi-Rigid Ducting will require a joint if the flue run is over 6 meters. Refer to

appropriate Fire Dept product specification for specific fixing requirements.

Version: July 2020 9

Flow from the In-Line Fan to termination

In-Line Fan

Casing slip

In-Line Fan assembly details

Step 1:

Connect the flue and outer casing to the appliance

1. Make sure the In-line Fan has adequate access for future maintenance.

2. Run the flue from the appliance to the location of the In-line Fan.

3. Run the outer casing from the appliance to finish 90mm shorter than the flue.

Note: The outer casing must have the crimped end removed.

Step 2:

Connect the In-Line Fan to the flue and outer casing

1. Fit the Casing slip over the outer casing.

2. Fit the flue over the inlet spigot to the In-Line Fan.

3. Fix the flue to the inlet spigot at the In-Line Fan.

Step 3

Complete the flue installation

1. Slide the casing slip up the outer casing and over the outer casing spigot

at the In-Line Fan.

2. Fix the casing slip to the outer casing and the In-Line fan

3. Complete the flue installation. Refer to appropriate Fire Dept product

specification for fixing details and specific minimum requirements.

Version: July 2020 10

Air supply duct options for the different cowl terminations

Option 1: Wall cowl fan (horizontal exit)

Wall cowl fan: Horizontal exit

100mm Semi-Rigid Duct. 3m or 6m

Wall cowl

100mm Semi-

Rigid Duct

Flue system

F74 –3.6m Flue Wall cowl fan shown

Version: July 2020 11

Option 2: Cowl fan (vertical exit)

Cowl fan: Vertical exit

100mm Semi-Rigid Duct. 3m or 6m

100mm Semi-

Rigid Duct

Flue system

Cowl fan

F75 –3.6m Flue Cowl fan shown

Version: July 2020 12

Option 3A: In-Line Fan (vertical exit)

In-line fan

100mm Semi-Rigid Duct. 3m or 6m

Vertical exit

100mm Semi-

Rigid Duct

Flue system

Vertical exit

In-Line Fan

F76 –3.6m Flue In-Line Fan shown

Version: July 2020 13

Option 3B: In-Line Fan (horizontal exit)

In-line fan

100mm Semi-Rigid Duct. 3m or 6m

Horizontal exit

100mm Semi-

Rigid Duct

Flue system

In-Line Fan

Wall cowl

F77 –3.6m Flue In-Line Fan shown

Version: July 2020 14

Wall cowl assembly details

(for wall cowl + wall cowl fan installation)

Step 4:

Fit the front

panel

To fit the front

panel reverse

steps 1 to 3

Step 1:

Remove 5mm cap screw

Step 2:

Lift front panel

The front panel is hung on hocks

Step 3:

Remove the front panel

Fit Wall cowl into position

Step 1:

Timber framing

Set-up timber framing to suit

wall cowl.

Step 2:

Fit wall cowl into position

Fix will cowl into position

through the angle surround.

Step 3:

Flash wall cowl

Fit flashing in

accordance with NZBC.

Step 4:

Complete wall cladding

Fit wall cladding in accordance

with NZBC

Fit wall cladding into Wall cowl front panel (optional)

Step 1:

Remove front hot panel

1. Hot panel is fixed to back

panel with 4 x 5mm

counter-sunk cap screws.

Step 2:

Fix sub-straight into wall cowl

1. Cut sub-straight to suit (sub-straight not supplied)

2. The 4 x 5mm counter-sunk cap screws can be

used to hold the sub-straight in place.

Step 3:

Fix cladding into wall cowl

1. Adequately fix the cladding into the

wall cowl.

Version: July 2020 15

Step 5: Connect and test electrical supply

•All electrical connections must meet the requirements of AS/NZS 3000 standards and be installed

and certified by a suitably qualified person.

•In order to access the electricals, it is necessary to first remove the glass and the burner tray.

•Follow the ‘Glass installation process‘ in this guide.

•Lift glass away from the appliance and lay flat in a safe place with insulating material facing down.

•Remove the burner tray by following the ‘Burner Tray Removal Process’in this guide.

•With the burner tray removed the electrical connections between the appliance and the wall isolation switch

can be seen, use 5 core (minimum 1mm) cable from the wall isolation switch.

•Following these connection details, using the 5 core cable that has been run at site, connect the wall

isolation switch to the appliance

•IMPORTANT: Before testing, ensure the gas valve is

turned OFF.

•The GD1 models have a safety switch, behind the glass

panel. The safety switch turns the appliance off if the glass

is not in the right position. The safety switch will need to

be held back to complete electrical testing. It is

recommended that masking tape is used to hold the safety

switch back.

•Test electrical functions by switching the bottom High/Low switch to LOW, then switch the appliance ON

using the top On/Off switch.

•The fan will start and after approximately five seconds, the pilot will spark. Because the gas supply is turned

off, the pilot will spark for approximately five seconds then automatically switch off. The fan will continue to

operate.

•NOTE: GD1 1200 models have one fan which operate in both LOW and HIGH settings. GD1 1500 & GD1

1600 models have two fans which operate in both LOW and HIGH settings..

•Switch to HIGH setting. Ensure that a red light appears on electrical controller and the fan is operating.

•Switch the appliance OFF. Electrical testing is complete.

•Install the burner tray by following the ‘Burner tray installation process’ in this guide.

•NOTE: The masking tape must be removed once testing is completed.

•Carefully install glass by following the ‘Glass installation process‘ in this guide.

Safety switch

Version: July 2020 16

Fan for GD1 1500 & 1600

Thermal switch for

GD1 1500 & 1600

Version: July 2020 17

Step 6: Connect gas supply and commission

•Gas installation, connection and commissioning must meet the requirements of AS/NZS 5601.1:2013

and be installed and certified by a suitably qualified person.

•In order to access the gas supply and testing area, it is necessary to first remove the glass and the burner

tray.

•Follow the ‘Glass installation process‘ in this guide.

•Remove the burner tray by following the ‘Burner tray

removal process’in this guide.

•Connect 3/8 soft copper pipe to main valve.

•Leak test all joints.

•The GD1 models have a safety switch, behind the glass

panel. The safety switch turns the appliance off if the

glass is not in the right position. The safety switch will

need to be held back to complete electrical testing. It is

recommended that masking tape is used to hold the

safety switch back.

•Switch the appliance ON.

•Test / adjust high pressure first (using the outer brass nut)

and then the low pressures against rating plate

specifications.

•In the unlikely event that the rating plate is not attached, Do Not commission the appliance and contact The

Fire Dept immediately.

•Switch the appliance OFF.

•Install the burner tray by following the ‘Burner Tray Installation Process’ in this guide.

•Switch the appliance ON.

•Note: due to lack of firebed and glass, it may be necessary to manually light burners.

•Switch the appliance OFF

•Lay firebed in accordance with instructions in Step 7 of this guide.

•NOTE: The masking tape must be removed once testing is completed.

•Carefully install glass by following the ‘Glass installation process‘ in this guide.

•Send gas certificate to appropriate person.

Safety switch

Version: July 2020 18

Step 7: Lay the firebed

•The GD1 has three firebed options: River Rocks, Beach Driftwood & Forest Logs.

•Particular care should be taken when placing the chosen firebed mediums into the burner tray. Failure to

place the medium correctly may result in the appliance performing inefficiently.

•Open the firebed cardboard box and identify firebox mediums.

River Rocks option has two firebed mediums:

Vermiculite –2 or 3 bags

White rocks –large and small

GD1 1200

GD1 1500 & 1600

Beach Driftwood option has three firebed mediums:

Vermiculite –2 or 3 bags

White rocks –large and small

Driftwood –large and small

GD1 1200

GD1 1500 & 1600

Forest Logs option has three firebed mediums:

Vermiculite –2 or 3 bags

White rocks –large and small

Logs –large and small

GD1 1200

GD1 1500 & 1600

Version: July 2020 19

How to lay Vermiculite

•In order to access the burner tray, it is necessary to first remove the glass.

•Note: glass removal is best carried out by two people.

•Follow the ‘Glass installation process‘ in this guide.

•Lift glass away from appliance and lay flat in a safe place with insulating material facing down.

•Beginning in the middle at the back of the burner,

carefully empty the bags of vermiculite into the

burner tray.

•Ensure not to spill any vermiculite in cavities

in front of and behind burner tray.

•Do not pour vermiculite directly into burner slots.

•Fill area behind burner up to top of burner tray.

Use hand to spread out and push under burner.

•Fill up area in front of burner and gently pat

down vermiculite to ensure it is spread evenly

throughout the burner tray.

•Using a small Allen key (or similar), remove any

vermiculite that may have fallen into burner slots.

Version: July 2020 20

•If natural gas is being used, leave burner slots

slightly exposed.

•If LPG is being used, lightly cover burner slots

in a thin layer of vermiculite by adding at back

of burner tray and gently sweeping forward.

•If LPG is being used, small burner slots should

be just visible.

•Vermiculite layer complete.

Table of contents

Popular Switch manuals by other brands

CrimeStopper

CrimeStopper VSMC-1000 installation manual

Quintum

Quintum BX Series BX204 Specifications

NETGEAR

NETGEAR GSM7328Sv1 - ProSafe 24+4 Gigabit Ethernet L3 Managed Stackable... Cli manual

DOMUS LINE

DOMUS LINE SMART TOUCH MIRROR installation manual

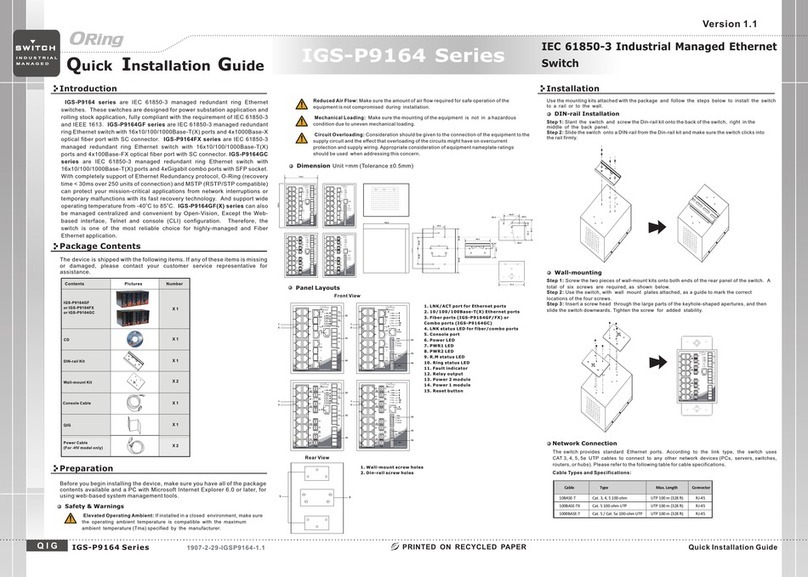

ORiNG

ORiNG IGS-P9164 Series Quick installation guide

Hama

Hama 00053180 operating instructions

Eterna

Eterna TLS1440 installation instructions

Lutron Electronics

Lutron Electronics Sunnata ST-6ANS quick start guide

Edge-Core

Edge-Core ECS3510-26P installation guide

Cisco

Cisco Nexus 93180YC-FX3 Hardware installation guide

TP-Link

TP-Link JetStream T3700G-52TQ Cli reference guide

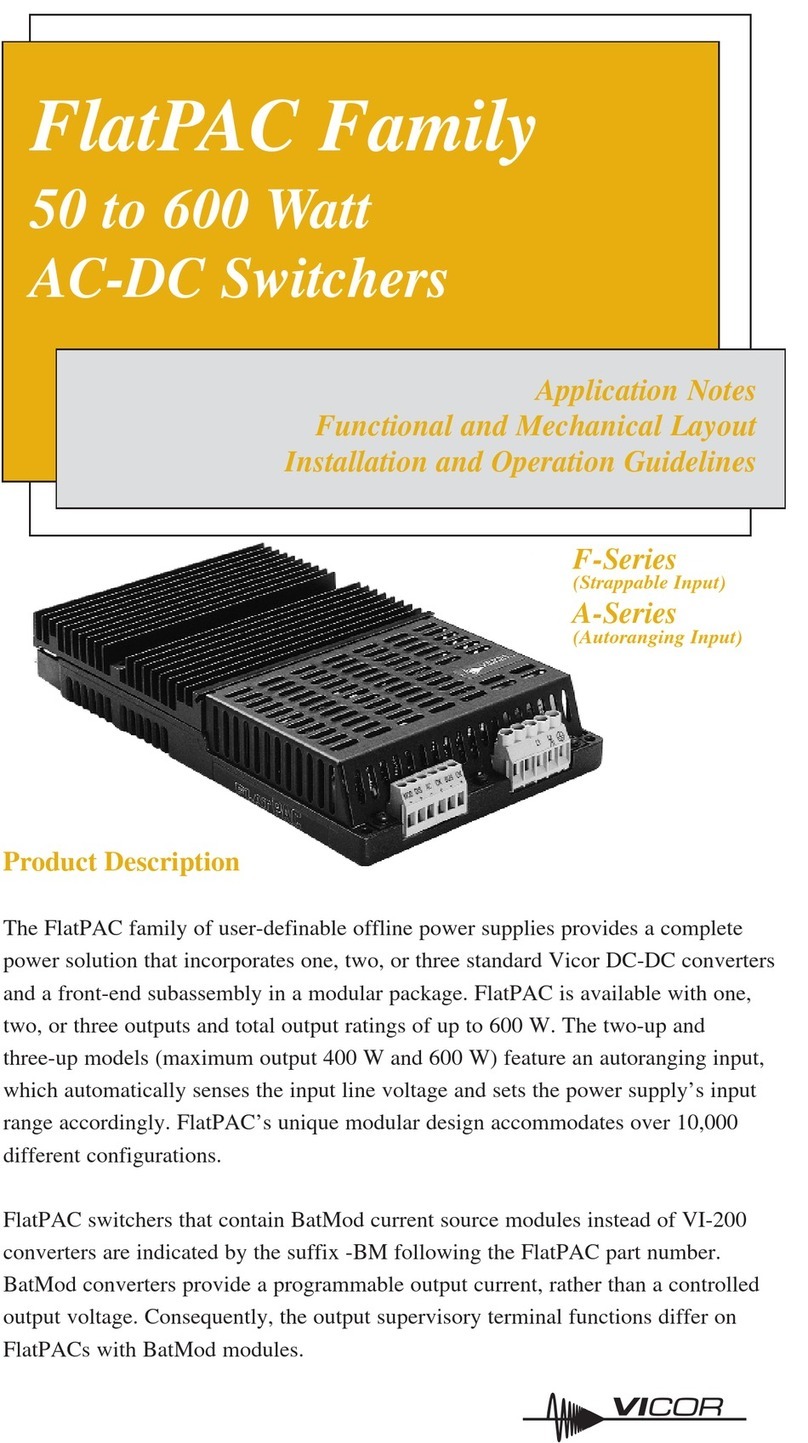

VICOR

VICOR AC-DC Application notes