FireClass FC400CH User manual

Product application & Design information Doc. version 1.0 14 February 2012 3

FireClass FC400CH Addressable carbon monoxide + heat detector

2.3.2 HEAT

Refer to Fig. 3.

The negative temperature coefficient thermistor produces an analogue output

which is fed to an analogue input on the communications interface.

2.4 COMMON CIRCUIT

Refer to Fig. 3.

Communications between the controller and detector uses the Frequency Shift

Keying (FSK) method. The ‘Discrimination Circuit’ filters the FSK signal from the

+ve line voltage and converts it to a digital square wave input for the ‘Communica-

tions ASIC’.The ‘Communications ASIC’ decodes the signal and when its own ad-

dress is decoded, the analogue inputs received from the carbon monoxide and

heat sensing elements are converted to corresponding digital values. These digital

values are then passed to the ‘Tx Driver Circuit/Current Sink’ which converts them

to FSK signals and applies them to the +ve line for transmission to the controller.

The Common Circuit is also used to:

ØControl Sounder and Relay bases via the ‘Functional Base Interface Circuit’

from controller commands.

ØControl the operation of the Remote LED via the ‘Remote LED Circuit’ from con-

troller commands.

2.5 WIRING

Loop cabling is connected to base terminals L (-ve) and L1 (+ve). A drive is pro-

vided for a remote indicator connected between loop positive and terminal R. Ter-

minal L2 (FUNCTIONAL BASE output) is for use with functional sounder base.

3. MECHANICAL CONSTRUCTION

The major components of the detector are:

ØBody Assembly

ØPrinted Circuit

ØCO Cell

ØScreening Can

ØCO Closure

ØThermistor

ØLight Pipe

ØOuter Cover

3.1 BODY ASSEMBLY

The body assembly consists of a plastic moulding which has four embedded de-

tector contacts which align with contacts in the base.The moulding incorporates

securing features to retain the detector in the base.

The CO cell is inserted onto the PCB followed by the screening can.

Four PCB mounted spring contacts provide electrical connection between the de-

tector contacts and the PCB.

The light pipe is slotted into the CO closure which is then clipped to the body. Fi-

nally, the outer cover is clipped to the body.

1. INTRODUCTION

The FC400CH carbon monoxide plus heat detector forms part of the 400 Series Ad-

dressable Fire detectors.

The detector is intended to plug into the following:

Ø5B 5” Universal Base.

ØFC450IB 5” Isolator Base.

ØFC430SB Low Power Sounder Base.

The detector is designed to transmit, to a remote FireClass fire controller, digital

signals which represent status of the carbon monoxide and heat elements of the

detector.

Software within the controller is used to interpret the returned carbon monoxide

and heat values to raise alarm or other appropriate response according to the type

of detector configured in FireClass Console.

The mode of the detector may be:

§Heat only detector (A1R or A2S).

§Carbon monoxide only detector (sensitivity: High, Normal or Low).

§Compensated carbon monoxide detector (sensitivity: High, Normal or Low).

§Compensated carbon monoxide (sensitivity: High or Normal) combined with

heat (A1R).

+Note:

ØThe heat detection grades are to EN54-5.

ØNormal and High sensitivity settings have been approved by the Loss Preven-

tion Council Board.

1.1 DAY/NIGHT SWITCHING

Two modes of detector operation are selectable from the list of possible modes as

follows:

Ø‘Normal’ mode, ie night time operation in which the detector will be evaluated

most of the time.

Ø‘Day’ mode in which the detector can be switched under certain circumstances,

eg during daytime when the building is occupied with people being able to de-

tect a fire manually. Switching to the ‘daytime’ mode can be done either by or

time driven.

1.3 SENSITIVITY SWITCHING

In addition to mode switching, the sensitivity can be changed within the actual

mode.This can be done either by PC programming or be time driven (eg,

day/night switching). Changing the sensitivity is done by shifting the sensitivity

up or down.

2. OPERATING PRINCIPLE

2.1 CARBON MONOXIDE

2.1.1 SENSING CELL

The CO element of the detector uses an electrochemical cell to detect the build up

of carbon monoxide generated by fires. The cell operates by oxidising carbon

monoxide on a platinum sensing electrode. Whilst on a corresponding counter

electrode the reduction half of the reaction takes place. The Sensing Cell is repre-

sented diagrammatically in Fig. 2.

When this reaction takes place the potential across the cell tries to change and this

causes a current to flow within the circuit around the cell. The current is mirrored

into a current to voltage conversion circuit with the resulting output directly propor-

tional to the carbon monoxide concentration.

The cell itself has a diffusion limiting component to ensure that all carbon monox-

ide in the area proximate to the sensing electrode is continuously oxidised. This

means that the rate of transport of carbon monoxide to the cell is directly propor-

tional to the external concentration and independent of air-speed.

2.2 HEAT DETECTOR

The heat element of the detector uses a single thermistor to produce an output propor-

tional to temperature. Rate of change of temperature is determined by the controller by

using differences between consecutive temperature values returned to the controller.

2.3 CIRCUIT DESCRIPTIONS

2.3.1 CARBON MONOXIDE

Refer to Fig.3.

The current through the cell circuit is added to a fixed baseline voltage and mir-

rored by the current mirror. This is fed to a current to voltage converter amplifier

which buffers and scales the signal. The resultant voltage is fed to an analogue in-

put on the common circuit.

ENGLISH

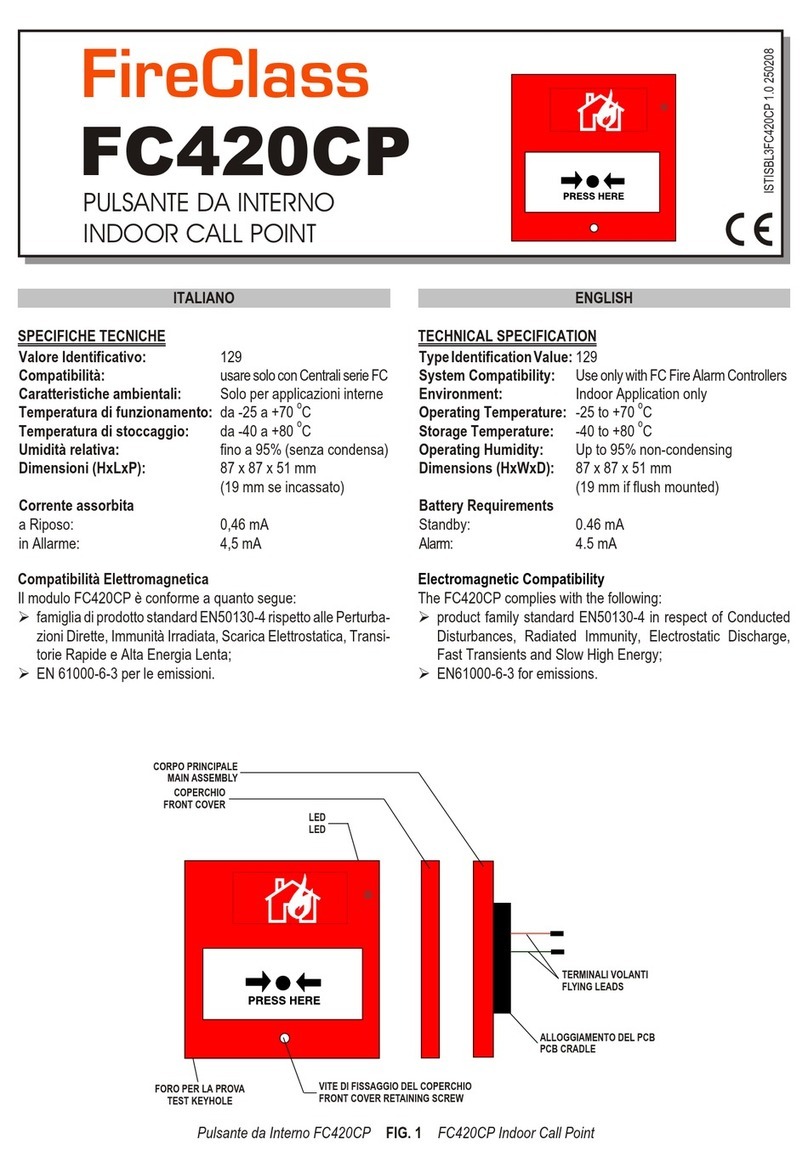

FC400CH Addressable Carbon Monoxide + Heat DetectorFIG.1

4 Product application & Design information Doc. version 1.0 14 February 2012

FC400CH Addressable carbon monoxide + heat detector FireClass

4.5.1.2 EFFECT OF AIRFLOW ON SENSITIVITY

The signal status of the FC400CH detector has been specifically designedto be in-

sensitive to abnormal air velocities. The effect of normal air velocities upon sensi-

tivity is negligible.

4.5.1.3 EFFECT OF TEMPERATURE ON SENSITIVITY

The carbon monoxide detector incorporates temperature compensation and its

condition current will be substantially constant over its specified operating range.

4.5.1.4 EFFECT OF ATMOSPHERIC PRESSURE ON SENSITIVITY

The sensitivity of the detector is not effected by changes in atmospheric pressure

unless they happen very quickly ie explosions.

4.5.2 RESPONSE TO FIRE TESTS

The response of the FC400CH carbon monoxide detection element of the detector

to real or large-scale test fires will be dependent on the detection mode chosen

and the sensitivity set in the control unit.

Other factors however, such as the rate of development of the fire, and relative ox-

ygen supply are also important. The fire tests defined in prEN54 pt. 7 which are in-

tended for ionisation and optical detectors are less appropriate for carbon

monoxide fire detectors as their design means that they produce significant levels

of carbon monoxide only in their later stages.

However, the FC400CH using compensated carbon monoxide combined with

A1R heat (sensitivity High and Normal) mode, pass all tests laid down in prEN54 pt

7 including the fire tests.

4.5.3 HEAT DETECTOR

4.5.3.1 GENERAL

The performance of heat detectors is defined in European Standard prEN54-5.

5. DETECTOR ADDRESS

The loop address of the detector is held in internal E2PROM which is pro-

grammed from the FC490ST Address Programmer.

+Note: this device use one address only on the loop.

6. ADDRESS FLAG

Refer to Fig.6. The address flag is used to identify the address and zone of the de-

tector.The address flags are supplied in one of two packs (address 1 - 127 or

128-255 , with a different colour for each loop) and are ordered separately from the

detector.The address flag is fitted to the bottom of the detector. When the detector

is fitted to the base and turned until fully located the address flag is then transferred

to the base. If the detector is removed from the base, the address flag remains with

the base.

7. ORDERING INFORMATION

FC400CH Carbon Monoxide + Heat detector.

Address Flag Labels - Loop A (White).

Address Flag Labels - Loop B (Yellow).

8. RECYCLING INFORMATION

Customers are recommended to dispose of their used equipments(panels, detec-

tors, sirens, and other devices) in an environmentally sound manner. Potential

methods include reuse of parts or whole products and recycling of products, com-

ponents, and/or materials.

9. WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE)

DIRECTIVE

In the European Union, this label indicates that this product should

NOT be disposed of with household waste. It should be deposited at

an appropriate facility to enable recovery and recycling.

The manufacturer reserves the right to change the technical specifications of this

product without prior notice.

4. TECHNICAL SPECIFICATION

4.1 MECHANICAL

Dimensions: The overall dimensions are shown in

Fig.5 ( less base ).

Materials

Body,cover, and closure: FR110 ‘BAYBLEND’ flame retardant.

Weight

Detector: 0.088kg

Detector + Base: 0.152kg

4.2 ENVIRONMENTAL

Temperature

Operating: -0oCto+55

oC

Storage: -20oCto+55

oC

+The detector may be operated for short periods between the limits of 0oCto

-20oC but with reduced performance.

+The detector may be operated for short periods between the limits +55oCto

+70oC, prolonged use between these limits will degrade the performance and

shorten the life of the detector.

Relative Humidity: 95% ( non-condensing )

Shock:

Vibration: prEN54 Pts. 5 and 7

Impact:

Corrosion: prEN54 Pts.5 and 7

The detectors comply with Lloyd’s Register Test Specification Number 1 (1996).

Environmental Category ENV2 plus Salt Mist test.

4.3 ELECTROMAGNETIC COMPATIBILITY

The detector complies with the following:

Øproduct family standard EN50130-4 in respect of Conducted Disturbances, Radi-

ated Immunity, Electrostatic Discharge, Fast Transients and Slow High Energy;

ØEN50081-1 for Emissions.

4.4 ELECTRICAL CHARACTERISTICS

The following characteristics (Table 1) apply at 25oC and nominal supply voltage of

37.5V unless otherwise specified.

Table 1: Electrical Characteristics

Characteristic Min. Typ. Max. Unit

Loop Voltage 20.0 - 40 V

Quiescent Current - 275 305 µA

Alarm Current* 3 3.3 mA

* No remote indicator fitted

Addressable circuit voltage:

40V dc max. with addressable waveform (polarity conscious).

4.5 PERFORMANCE CHARACTERISTICS

4.5.1 CARBON MONOXIDE

The FC400CH carbon monoxide sensing element with base, forms an address-

able detector which transmits, to remote equipment, signals representing the state

of the sensing cell. The control equipment evaluates these signals against prede-

termined criteria and decides when an alarm condition should be signalled.The in-

formation given below therefore relates to the performance of the carbon

monoxide element of the detector simply as a transducer, since the system alarm

response is determined by the control unit.

4.5.1.1 RESPONSE TO CARBON MONOXIDE

The response to carbon monoxide will vary from detector to detector. For this rea-

son each detector is characterised on manufacture and calibration values are

stored in the internal detector memory. The controller will then normalise the out-

put signal from the detector such that the output is equivalent to 2.5 bits/ppm car-

bon monoxide above a threshold of 20 bits. Carbon monoxide may be present in

some environments under certain circumstances (high values of pollution or ex-

treme environmental conditions). However, the deviation is unlikely to be signifi-

cant compared with the alarm threshold level.

INTERFACCIA

COMUNICAZIONE ASIC

COMMUNICATIONS

ASIC INTERFACE

KOMMUNIKATIONS ASIC

LOGICA

DI ELABORAZIONE

DELL’INDIRIZZO

ADDRESS SET/LATCH

SIGNAL PROCESSING

LOGIC

ADRESS-SPEICHER

SIGNAL-VER-

ARBEITUNG

SET/LATCH

CIRCUITO COMUNE

COMMON CIRCUIT

BASISSCHALTKREIS

ELEMENTO CO

CO ELEMENT

TEST AUTOMATICO

SELF TEST

SELBST-TEST

REGOLATORE

REGULATOR

REGLER STABILIZZATORE DI TENSIONE

VOLTAGE REGULATOR

SPANNUNGS-REGLER

CIRCUITO DISCRIMINATORE

DISCRIMINATION CIRCUIT

DISCRIMINATOR-SCHALTKREIS

FSKIN

FSKOUT

CIRCUITO Tx DRIVER/

ASSORBIMENTO CORRENTE

Tx DRIVER CIRCUIT/

CURRENT SINK

SENDE-

SCHALTUNG STROMSENKE

LED ALLARME

ALARM LED

-VE LINEA IN/OUT

-VE LINE IN/OUT

+VE LINEA IN/OUT

+VE LINE IN/OUT

BASE

BASE

SOCKEL

CIRCUITO LED REMOTO

REMOTE LED CIRCUIT

TREIBER FÜR HINWEISLEUCHTE

CIRCUITO D’INTERFACCIA

DELLA BASE FUNZIONALE

FUNCTIONAL BASE

INTERFACE CIRCUIT

TREIBER FÜR FUNKTIONS-

SOCKEL

ELEMENTO TERMOSENSIBILE

HEAT ELEMENT

TEMPERATUR-

ELEMENT

ELEVATORE L BASE

BASELINE LIFT

VOR-SPANNUNG

SPECCHIO DI

CORRENTE

CURRENT MIRROR

STROM-SPIEGEL

CONVERTITORE I / V

‘I’ TO ‘V’CONVERTER

I/UKONVERTER

CELLA

CELL

MESSZELLE

Schema a blocchi semplificato del rilevatore

Simplified Block Schematic Diagram of detector

FIG.3

Vereinfachte Block-Schemadarstellung des Melders FC400CH

ELETTROLITA

ELECTROLYTE

ELEKTROLYT

ELETTRODO CONTATORE

COUNTER ELECTRODE

GEGENELEKTRODE

ELETTRODO ATTIVO

SENSING ELECTRODE

MESSELEKTRODE

BARRIERA DI DIFFUSIONE

DIFFUSION BARRIER

DIFFUSE BARRIERE

CONTATTI

CONTACT PINS

ANSCHLUSSSTIFTE

Schema del sensore

Representational Diagram of CO Sensing Cell

FIG.2

Diagramm der CO-Messzelle

120.415.966 Doc. version 1.0 Sheet 1 14.February 12 – Subject to change without notice. ISTSUBL3FC400CH 1.0 140212 V10

INCAVI DI BLOCCAGGIO

RETAINING DEPRESSIONS

RIENTRANZA DI MONTAGGIO

MOUNTING RECESS

PARTE SAGOMATA A ´D`

´D` SHAPED PART

CANALE SAGOMATO A ´U`

´U` SHAPED CHANNEL

SPORGENZE DI BLOCCAGGIO

RETAINING PIMPLES

Inserimento della linguetta indirizzoFIG.6

Fitting Address Label Carrier

Dimensioni generali del rilevatore FC400CH

Overall Dimensions of FC400CH detector

FIG.5

Abmessungen des Melders FC400CH

Sezione e vista superiore del rilevatore

Sectioned and Top View of the detector

FIG.4

Schnittdarstellung und Ansicht von oben

© FireClass

Via Gabbiano 22, Z. Ind. S. Scolastica

64013 Corropoli (TE), Italy

Hillcrest Business Park Cinderbank Dudley West Midlands

DY2 9AP United Kingdom

www.fireclass.co.uk

Other FireClass Security Sensor manuals

Popular Security Sensor manuals by other brands

Riken Keiki

Riken Keiki SD-D58-AC operating manual

Elk

Elk ELK-6051 instructions

Velleman

Velleman VTTEST18 user manual

Polymer Laboratories

Polymer Laboratories PL-ELS 2100 Service manual

Distech Controls

Distech Controls GS-CDR20K Series Hardware installation guide

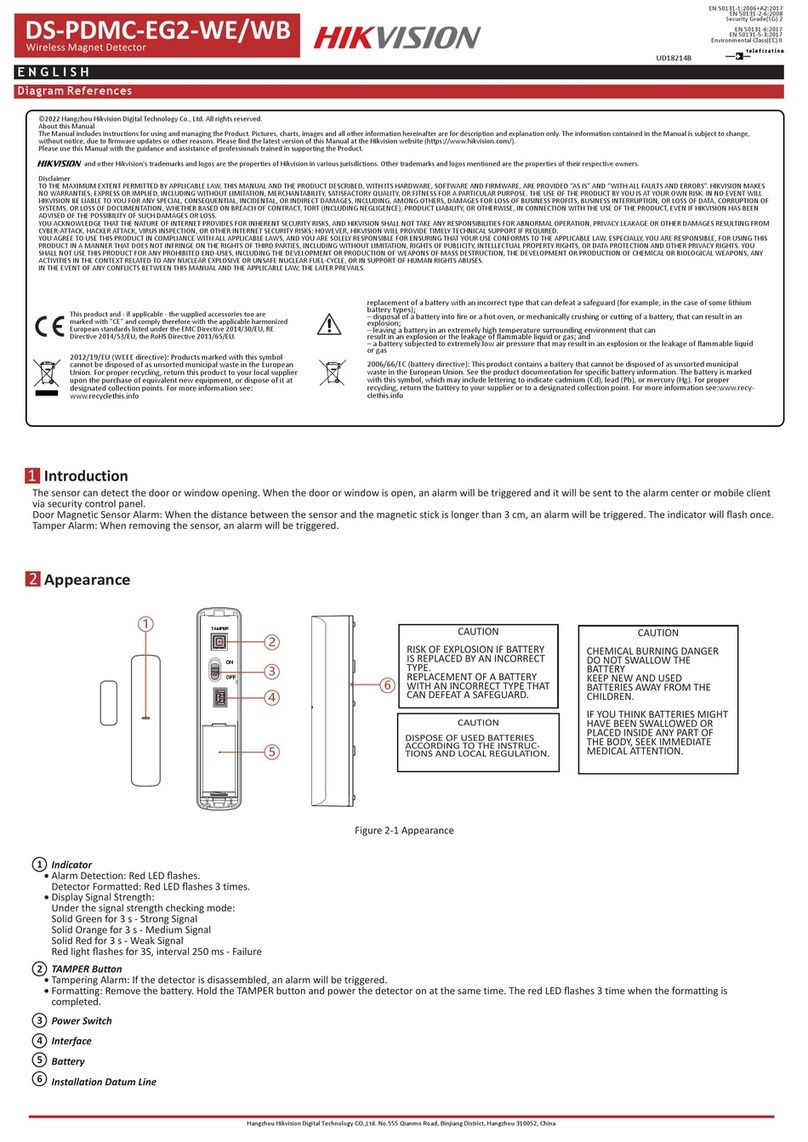

HIK VISION

HIK VISION DS-PDMC-EG2-WE quick start guide

C.P. Electronics

C.P. Electronics MWS3A-PRM-2CH installation guide

Paradox

Paradox SR230 installation manual

Resolution

Resolution CryptiX RE110P install guide

HIK VISION

HIK VISION Door Station quick start guide

HIK VISION

HIK VISION DS-PDBG8-EG2-WB user manual

Maxouttech

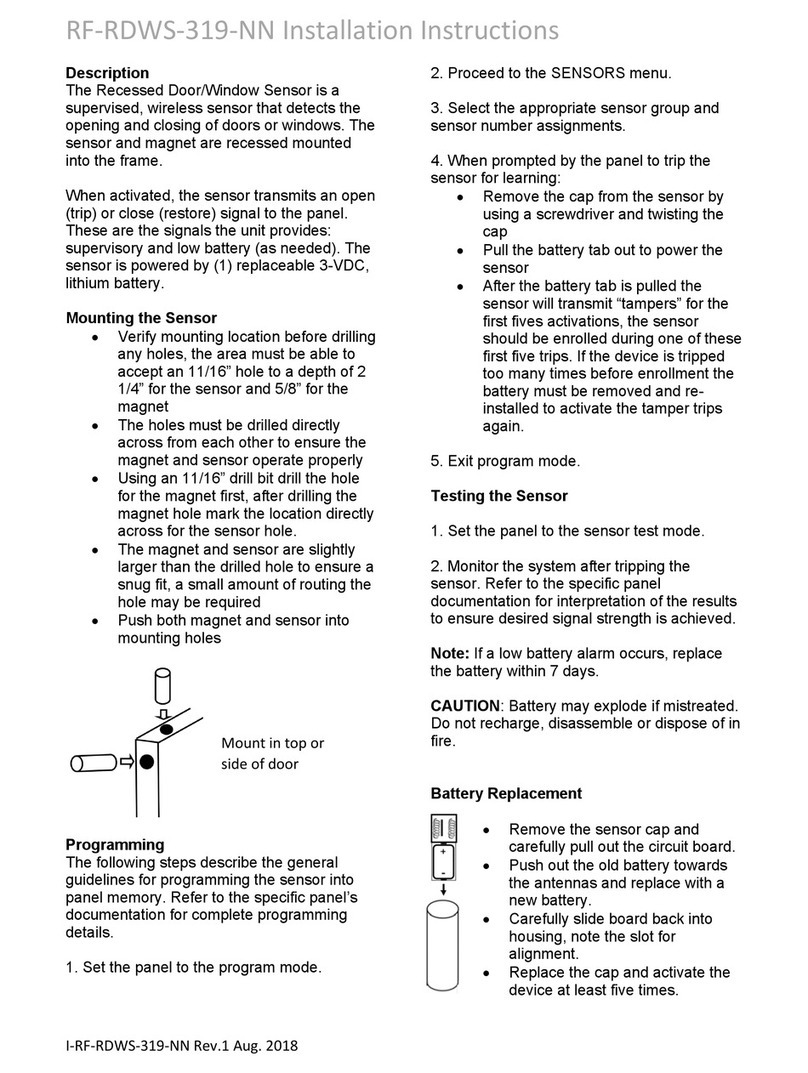

Maxouttech RF-RDWS-319-NN installation instructions