Distech Controls GS-CDR20K Series Manual

Hardware Installation Guide

GS-CDR20K Series

Room Carbon Dioxide Detectors

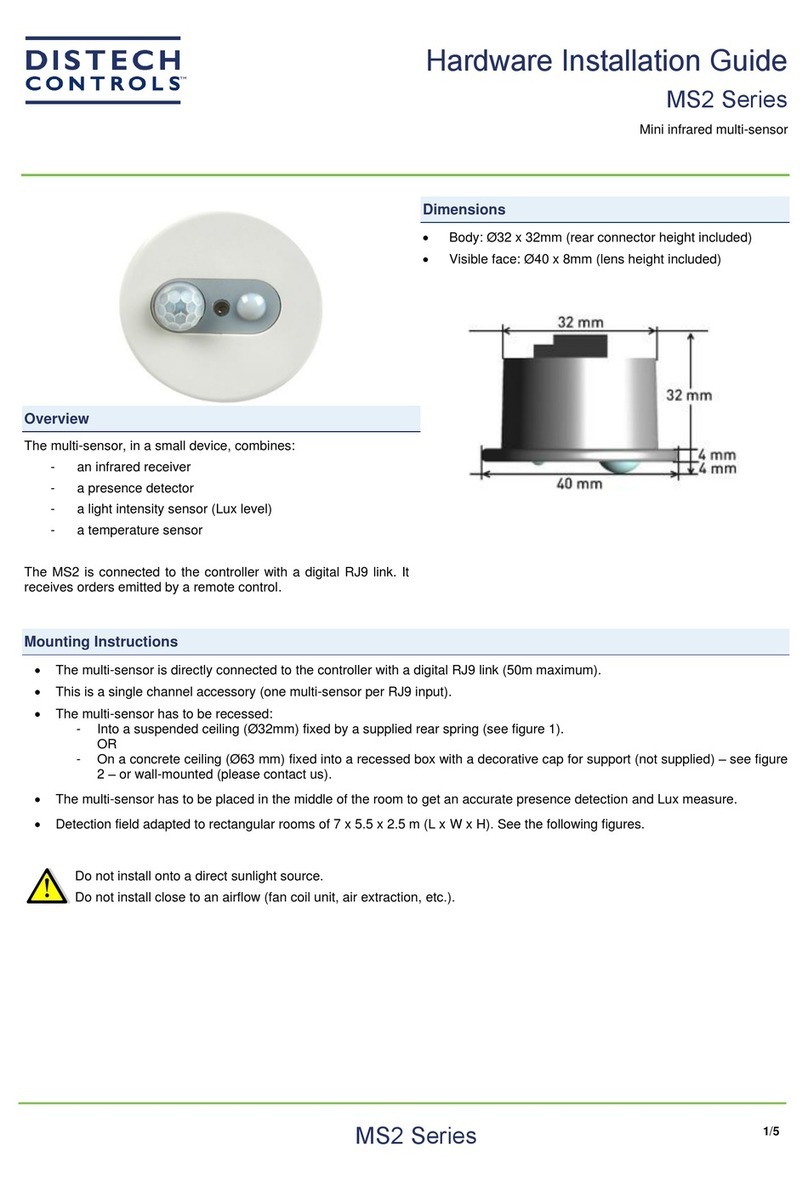

Figure 1: GS-CDR20K Series Room Carbon Dioxide Detectors

Product Description

The GS-CDR20K Series are room carbon dioxide gas detectors.

These devices provide precision measurement of CO2gas. The GS-

CDR20K series uses a highly accurate and reliable Non-dispersive

Infrared (NDIR) sensor combined with state-of-the-art digital

linearization and temperature compensated circuitry in an attractive,

low profile enclosure for room applications to monitor room CO2,

levels.

A linear analog signal output of 4-20 mA, 0-5 or 0-10 Vdc is provided

for connection to a building automation system. Optional features such

as temperature sensor, setpoint adjustment, manual override and

adjustable relay output are available.

General Installation Requirements

For proper installation and subsequent operation of each device, pay

special attention to the following recommendations:

- Upon unpacking the product, inspect the contents of the carton for

shipping damages. Do not install damaged device.

- Avoid areas where corroding, deteriorating or explosive vapors,

fumes or gases may be present.

- Ensure that all equipment is installed according to local, regional,

and national regulations.

Personal injury or loss of life may occur if you do not follow a

procedure as specified.

Equipment damage or loss of data may occur if you do not

follow a procedure as specified.

Do not use in an explosive or hazardous environment, with

combustible or flammable gases, as a safety or emergency

stop device or in any other application where failure of the

product could result in personal injury.

Take reasonable precautions to prevent electrostatic

discharges to the controller when installing, servicing or

operating the controller. Discharge accumulated static

electricity by touching one’s hand to a well-grounded object

before working with the controller.

Mounting Instructions

The room type sensor installs directly on a standard electrical box and

should be mounted five feet from the floor of the area to be controlled.

Do not mount the sensor near doors, opening windows, supply air

diffusers or other known air disturbances. Avoid areas where the

detector is exposed to vibrations or rapid temperature changes.

The cover is hooked to the base at the top edge and must be removed

from the bottom edge first. Use a small screwdriver to carefully pry

each bottom corner if necessary. If a security screw is installed on the

bottom edge, then it may have to be loosened or removed also. Tip the

cover away from the base and set it aside.

The PCB must be removed from the base to access the mounting

holes. Follow usual anti-static procedures when handling the PCB and

be careful not to touch the sensors. The PCB is removed by pressing

the enclosure base to unsnap the latch near the bottom edge, then the

PCB can be lifted out of the base. Set the PCB aside until the base is

mounted on the wall.

2/5

After the base is screwed to an electrical box or the wall using the

appropriate holes, pull the wires through the wiring hole in the center of

the PCB and then reinstall it in the enclosure base. Ensure the PCB is

snapped into the base securely and correctly.

The mounting hole locations are shown in the following drawings:

Figure 2. Mounting Hole Locations

Wiring

Deactivate the 24 Vac/dc power supply until all connections are made

to the device to prevent electrical shock or equipment damage. Follow

proper electrostatic discharge (ESD) handling procedures when

installing the device or equipment damage may occur. Use 22 AWG

shielded wiring for all connections and do not locate the device wires in

the same conduit with wiring used to supply inductive loads such as

motors. Make all connections in accordance with national and local

codes.

This is a 3-wire sourcing device. Connect the plus DC or the AC

voltage hot side to the PWR terminal. The supply common is

connected to the COM terminal. The device is reverse voltage

protected and will not operate if connected backwards. It has a half-

wave power supply so the supply common is the same as the signal

common. Several devices may be connected to one power supply and

the output signals all share the same common.

Use caution when grounding the secondary of a transformer

or when wiring multiple devices to ensure the ground point is

the same on all devices and the controller.

The analog output is available on the CO2terminal. This signal is

switch selectable for either voltage or 4-20 mA active output. In voltage

mode the output is selectable for either 0-5 or 0-10 Vdc via the menu

(the factory default is 0-5 Vdc). The current output operates in the

active mode and does not require a loop power supply (the signal

current is generated by the transmitter and must not be connected to a

powered input or device damage will result). Check the controller

Analog Input to determine the proper connection before applying

power. Both current and voltage signals are referenced to the COM

terminal. The analog output signal is typically connected directly to the

Building Automation System (B.A.S.) and used as a control parameter

or for logging purposes.

The optional relay output is on the N.O. RELAY terminals. The relay

output is completely isolated and has a Normally Open (NO) signal.

This signal can be used to directly control an alarm or ventilation fan.

The optional override switch is a two-wire dry contact normally open

switch contact. The slide pot is a two-wire resistive signal that can vary

from 0-10K ohms (for example) with left-to-right slide pot action. Other

resistive values are available on request and the slide pot may be

configured as normal or reverse acting. These options share a single

common labelled S. COM and this is not connected to the power

supply COM.

The two-wire temperature sensor output is available with various RTDs

and thermistors to suit all control applications and is available on the

TEMP terminals.

Figure 3. Typical 4-20 mA wiring with 24 Vdc and all options

Figure 4. Typical 0-5 Vdc wiring with 24 Vac for CO2only

3/5

Start-Up

Verify the device is properly wired and connections are tight. Ensure

the V/I switch is set for the correct signal type. Apply power and the

LCD will indicate the software version number, the output signal type,

the relay setpoint (if installed), the CO2measurement range and then

the sensor will begin reading the CO2level, output the correct analog

signal and display the value on the LCD.

Output

The CO2output is scaled such that 4-20 mA (or 0-5/0-10 Vdc) equals 0

to Out_High. The factory default is 0-20,000 ppm. Out_High can be

changed in the Setup Menu and the output is scaled accordingly. If

using voltage output type, the default is 0-5 Vdc (0-10 can be selected

in the menu).

Operation

The output signal is available on the CO2terminal and is connected to

the BAS analog input which reads the signal and calculates the CO2

ppm value using correct scaling for the range and signal type. The CO2

value is used to control output ventilation devices or initiate alarms.

The CO2value is also displayed locally on the optional LCD.

If a relay is installed it can control a small fan or alarm by setting the

trip value and hysteresis to appropriate values.

If a temperature sensor is installed it will be wired to an analog input of

the BAS that is set for the specific resistance type. This could be a 10

KΩthermistor, a 1000 ohm RTD or other sensor values. The BAS

reads the resistance signal and converts it to a temperature value.

The override switch provides a dry contact closure to a digital input of

the BAS. The slide pot can be connected to another analog input and

will provide a linear signal such as 0-10 KΩto be used as a setpoint

control.

Calibration

Calibration with gas requires a field calibration kit with pressure

regulator, necessary tubing and appropriate bottles of CO2gas

The GS-CDR20K series dual-channel sensors with extended range

requires a 3-point calibration with 0, 1000 and 20,000 ppm gas (in

order).

0 PPM Calibration

1. Turn the regulator knob off and attach it to the Nitrogen gas bottle

and hand tighten.

2. Remove the cover of the unit to be calibrated to expose the gas

sensor chamber.

3. The tubing from the gas bottle can be connected to either port on

the chamber after the plastic cap is removed.

4. Gently remove one cap and connect the tubing. Note that strong

shock or vibration can affect calibration.

5. Ensure the device has been operating normally for at least five

minutes before applying gas.

6. Turn the valve knob on the regulator to start the gas flow. The

regulator will restrict the flow rate to the specified 100 ml/min.

7. After a brief period the gas will flow into the chamber. Wait 1 to 2

minutes until the CO2stabilizes.

8. Enter the Setup menu and use the <MENU> key to advance to

Calibrat 0 PPM.

9. Press and hold the <SAVE> key for 2 seconds and the display will

change to Waiting Calibrat then to Waiting 5 minute to indicate

that the process of setting the internal calibration is taking place.

10. This takes about 5 minutes while the LCD counts down. Do not

disturb the unit or the gas flow. When complete the unit will

display the ppm value and Cal Done.

11. Press the <SAVE> key to return to normal operation and shut the

gas off.

1000 PPM Calibration

1. Connect the 1000 ppm CO2gas bottle and apply the gas as before.

The CO2reading on the LCD will begin to approach 1000 ppm. Wait

1 to 2 minutes until the CO2reading stabilizes.

2. Enter the Setup menu and use the <MENU> key to advance to

Calibrat 1000 PPM.

3. Press and hold the <SAVE> key for 2 seconds and the display will

change to Waiting Calibrat then to Waiting 5 minute to indicate

that the device is calibrating. Again, this process takes about 5

minutes. When calibration is complete the unit will display the

ppm and Cal Done.

4. Press the <SAVE> key to return to normal operation and shut the

gas off.

20,000 PPM Calibration

1. Connect the 20,000 ppm CO2and apply the gas as before. The

LCD will begin to approach 20,000 ppm. Wait 1 to 2 minutes until

the CO2reading stabilizes.

2. Enter the Setup menu and use the <MENU> key to advance to

Calibrat 20,000 PPM.

3. Press and hold the <SAVE> key for 2 seconds and the display will

change to Waiting Calibrat then to Waiting 5 minute.

4. Again, wait 5 minutes and when calibration is complete the unit

will display the ppm and Cal Done.

5. Press the <SAVE> key to return to normal operation and shut the

gas off.

6. Disconnect the tubing and replace the cap on the sensor chamber

as calibration is complete.

Setup Menu

The menu has several items shown below. Some items change

depending on the hardware configuration and the CO2sensor.

To enter the menu, press and release the <MENU> key while in

normal operation.

This will enter the SETUP menu step 1, pressing the <MENU> key

again advances to step 2.

Each press of <MENU> advances the menu item. No values are saved

or changed by using <MENU>.

The <ROLL> key is used to make changes to program variables by

scrolling through the available options. When a value is changed, use

the <SAVE> key to save it to memory and advance to the next menu

item.

1. Press and release the <MENU> key to enter the SETUP menu.

- If the 20,000 ppm CO2range is installed (GS-CDR20K models)

a) Out High: The default CO2range is 0-20,000 ppm. The

span can be changed from 2000 to 20,000 ppm in

increments of 500. Use the <ROLL> key to change the

value and <SAVE> to save. The factory default is 20,000

ppm.

2. Altitude: The default is 0 feet. Change by using the <ROLL> key

from 0 to 5000 feet in 500 feet increments. Change for CO2local

altitude correction and press <SAVE> to save a change.

Items 3, 4 and 5 are only available if the Relay Option is installed,

otherwise the menu skips directly to step 6.

3. Relay SP: The relay trip setpoint default is 1000 ppm. It can be

changed from 500 to 15,000 ppm. Save changes by using the

<SAVE> key.

4. Relay Hy: The relay hysteresis default is 50 ppm. This can be

changed from 25 to 500 ppm. Use <SAVE> to save any change.

5. Relay: Use the <ROLL> key to toggle the relay ON or OFF for

testing purposes. Press either <SAVE> or <MENU> to turn the

relay off and advance to the next item.

6. Out Type: For voltage, the factory default output type is 0-5 Vdc.

Use the <ROLL> key to change the value to 0-10 Vdc if

necessary. Press the <SAVE> key to save. If the switch is set to

mA, then 4-20 mA is displayed.

4/5

7. Output: Use the <ROLL> key to toggle the output OFF (normal

operation), MIN (minimum output) or MAX (maximum output) for

testing purposes. Press either <SAVE> or <MENU> to set it back

to OFF and advance to the next item.

8. Calibrat: This item is used for 0 ppm gas calibration and is

explained in the Calibration section.

9. Calibrat: This item is used for 1000 ppm gas calibration and is

explained in the Calibration section.

10. Calibrat: This item is used for 20,000 ppm gas calibration and is

explained in the Calibration section.

Item 12 is only available if the cover is equipped with a viewable LCD,

otherwise the menu skips directly to step 13.

11. BackLite: Use the <ROLL> key to enable or disable the LCD

backlight. When enabled the backlight is always on, when

disabled it never lights. Press the <SAVE> key to save the

setting. The factory default is Enable.

12. Restore: Press the <SAVE> key to restore calibration to original

factory settings.

13. Menu: Press <SAVE> to exit the menu and return to normal

operation or <MENU> to repeat the menu.

Product Components

Figure 5. Product Components

©, Distech Controls Inc. 2022 All rights reserved.

Distech Controls is not responsible for damages or claims arising out of improper or careless installation or handling of its products. Persons using this manual are assumed to be trained

HVAC specialist / installers and are responsible for using the correct wiring procedures and maintaining safe working conditions with fail-safe environments.

Global Head Office - 4205 place de Java, Brossard, QC, Canada, J4Y 0C4 - EU Head Office - ZAC de Sacuny, 558 avenue Marcel Mérieux, 69530 Brignais, France

5/5 GS-CDR20K_IG_10_EN

Dimensions

Figure 6. GS-CDR20K Series Dimensions shown in inches (millimeters).

Table of contents

Other Distech Controls Security Sensor manuals

Popular Security Sensor manuals by other brands

Tyco

Tyco BLAZEMASTER CPVC manual

bolid

bolid S2000-IP-03 user manual

Telefunken

Telefunken HVMM LICHT MAL 31550xTF Mounting instructions

elobau

elobau 153 Series Translation of the original operating instructions

mcmurdo

mcmurdo Fastfind Plus owner's manual

Dahua Technology

Dahua Technology DHI-ARD323-W2 user manual

mothercare

mothercare wood effect corner cushions user guide

Tunstall

Tunstall Fall Detector 66000/01 User instructions

Pentatech

Pentatech CO30 Operating instructions and safety instructions

HomeMatic

HomeMatic HM-Sec-MDIR-2 Installation and operating manual

ParTech

ParTech 715 Operator's manual

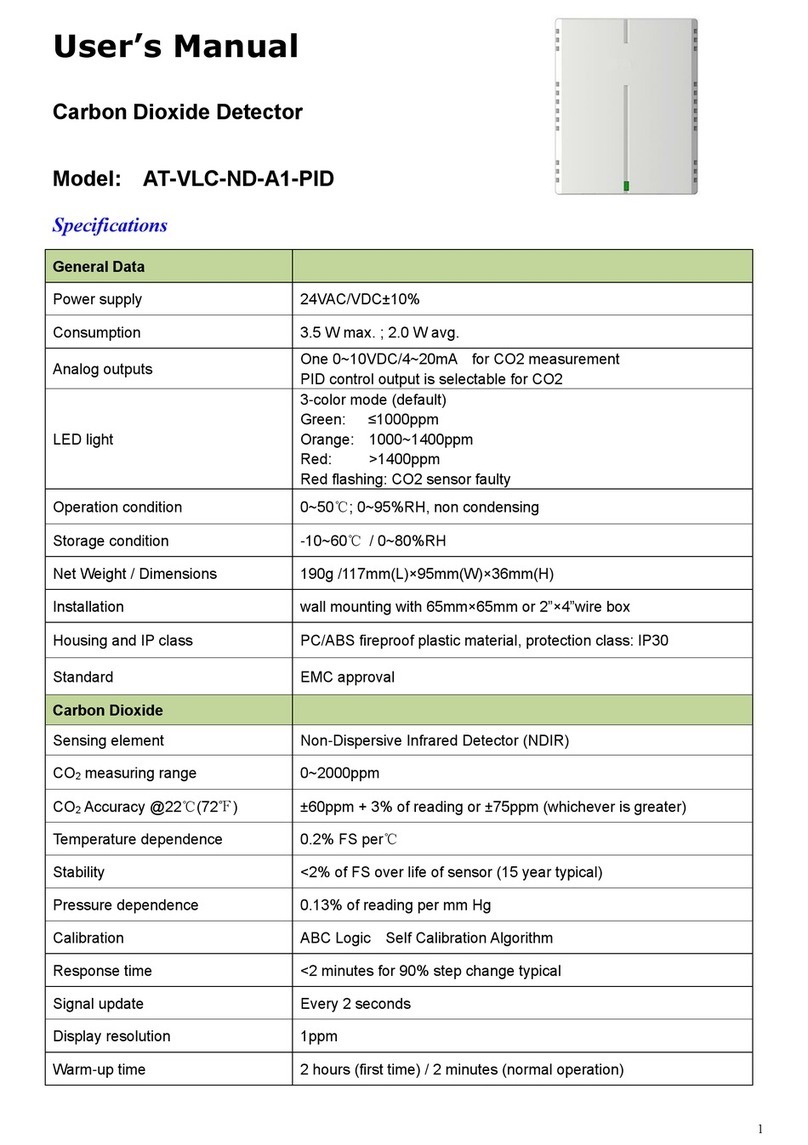

Atal

Atal AT-VLC-ND-A1-PID user manual