SET UP AND ASSEMBLY continued

1- Remove all contents from the Hearth Kit shipping container.

( Box One )

2- Check the contents of the shipping container against the

shipping and packing list, or the parts list in this manual.

Report any missing or damaged parts to your retailer.

3- Remove any and all protective wrapping from the appliance.

TOOLS THAT YOU WILL NEED

2- Adjustable wrenches; at least one of which has a range

of 3/4" ( for gas fittings )

2- Adjustable Pipe Wrenches

1- 3/8” Nut Driver or socket ( for damper clamp )

1- TURN OFF THE GAS SUPPLY SYSTEM!

2- FOR VENTED APPLICATIONS: Place the fireplace damper

in the fully open position, and install the damper clamp over

the lip of the damper ( The damper must be in a fully open

position, any time that this appliance is in operation ).

Using a 3/8” nut driver or socket, and turning in a clockwise

direction, tighten the damper clamp bolt until the clamp is

secure. The damper clamp must be in place to maintain the

minimum permanent vent opening. See the chart “ MINIMUM

FIREPLACE DIMENSIONS “ on page 3 & 4, for correct

venting. ( SEE FIGURE 9, page 7 )

NOTE: The State of Massachusetts requires that the chimney

flue damper, when used with decorative gas log sets, be

welded open or completely removed.

3- Using two adjustable pipe wrenches ( one wrench on the gas

stub, and one wrench on the fitting ), remove the existing cap

or gas jet assembly from the gas stub in your fireplace, by

turning the wrench on the gas cap, in a counter-clockwise

direction.

4- Clean the pipe threads, on the gas stub, using either, a wire

brush or steel wool. Apply Teflon tape or pipe dope to the

steel fittings before making any connection.

NOTE: All gas connections ( except for brass to brass )

require Teflon tape or pipe dope.

5- Place the appliance into the fireplace ( unit is packaged as a

single burner assembly; grate, valve/regulator assembly, and

burner ). The unit should be centered from both side to side,

and front to back. The unit is shipped, ready for rear gas

connection only. ( SEE FIGURE 10 & 11 )

6- FOR UNVENTED APPLICATIONS: You must secure the

appliance to the floor of the fireplace. This must be done to

prevent movement of the appliance during adjustment of

controls. Movement of the appliance may cause a gas leak,

improper positioning of gas logs, and/or improper combustion

and sooting. ( SEE FIGURE 12 )

NOTE: Special care is required if you are installing the

appliance into a sunken fireplace. The fireplace floor must be

raised, using non-combustible materials, to allow access to

the controls. This will also insure proper air flow to the

appliance.

A) After centering the appliance correctly, and using the

grate leg fasteners as a guide, mark the hole positions on the

fireplace / firebox floor. Drill two ( 2 ) 5/32” diameter holes,

approximately 1 ½” deep for masonry screws ( not included ),

or 1/8” deep holes for sheet metal screws ( not included )

( SEE FIGURE 12 )

B) Affix the appliance to the fireplace / firebox floor using the

appropriate screws.

FIGURE 12

Proper installation of the appliance is essential to prevent

any movement of the gas logs and controls during

operation.

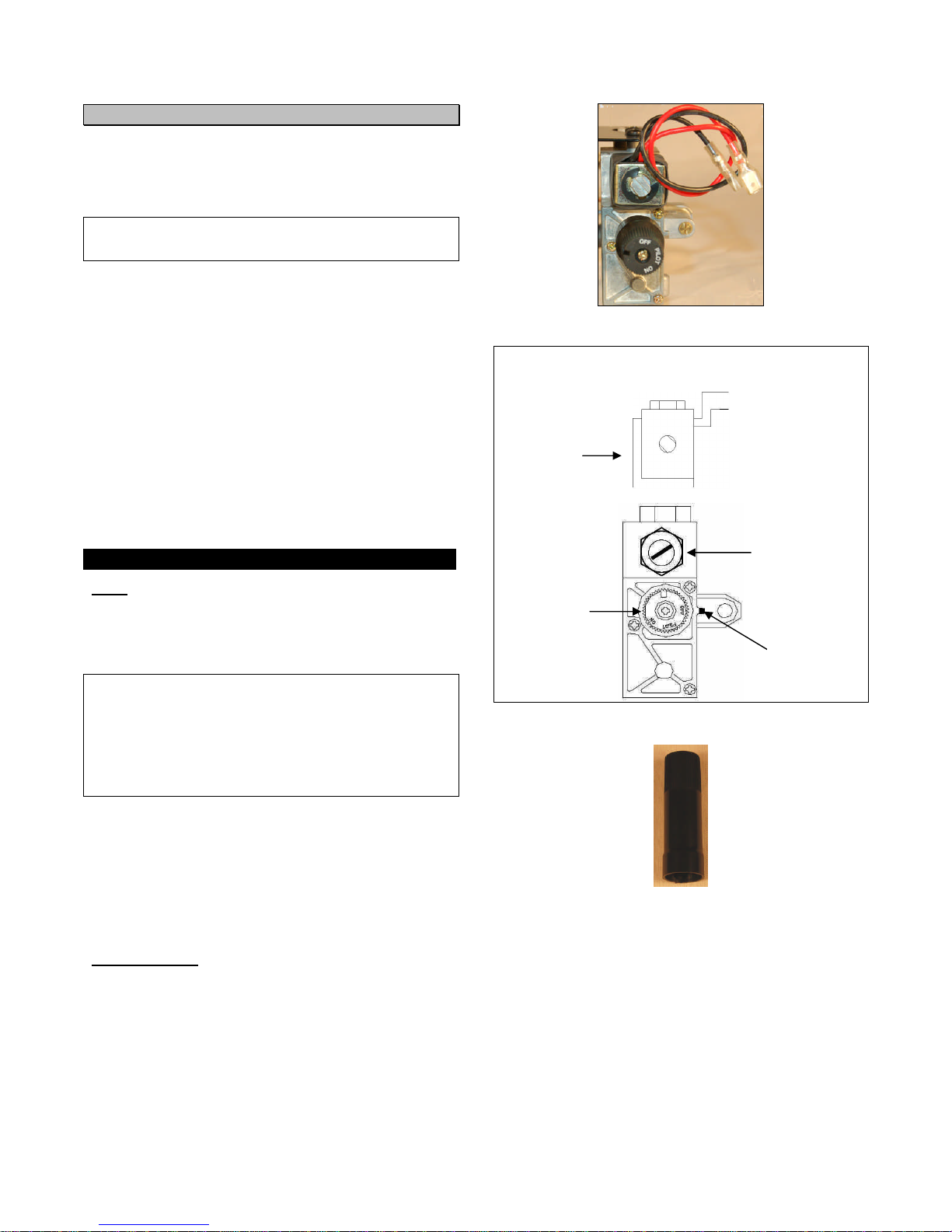

7- Bend a 3/8” gas line, with two ( 2 ) 3/8” brass, female flare

fittings ( not included ), to facilitate the gas connection,

between the valve/regulator assembly, and the gas stub.

BE CAREFUL! Gas lines are easily kinked if bent too sharply.

8- Using an adjustable wrench, and turning in a clockwise

direction, attach a 1/2” Female Flare X 3/8” Male Flare Brass

Reducer Fitting ( not included ), to the gas stub.

9- Using two adjustable wrenches, and turning in a clockwise

direction, attach one end of the gas line, to the brass reducer

fitting that you have just installed on the gas stub. ( One

wrench on the brass gas line fitting, and one wrench on the

brass reducer fitting )

10- Using two adjustable wrenches, and turning in a clockwise

direction, attach the other end of the gas line to the brass

fitting on the valve/regulator assembly. ( One wrench on the

gas line fitting, and one wrench on the brass fitting on the rear

of the regulator for LP units, and on the valve for NG units )

BE CAREFUL! Make sure all gas connections are snug, but DO

NOT over tighten!

11- It is our recommendation that, at this point of the

installation, lighting the pilot, and test ignition should

take place, before attempting to set up the logs.

See “UNITS WITH REMOTE SYSTEMS” section, on page 11,

and “LIGHTING INSTRUCTIONS” on page 15.

12- CHECK FOR LEAKS! Apply soapy water to each connection

and watch for bubbles. If bubbles are seen, turn off the gas

supply; retighten the connections, and CHECK AGAIN! DO

NOT use a lighted match to check for leaks. Repeat this

procedure until you are sure that there are no leaks in the gas

connections.

13- When you are assured that there are no gas leaks present,

you may proceed to “ FINAL SET UP “ on page 12.