7www.broddson.com

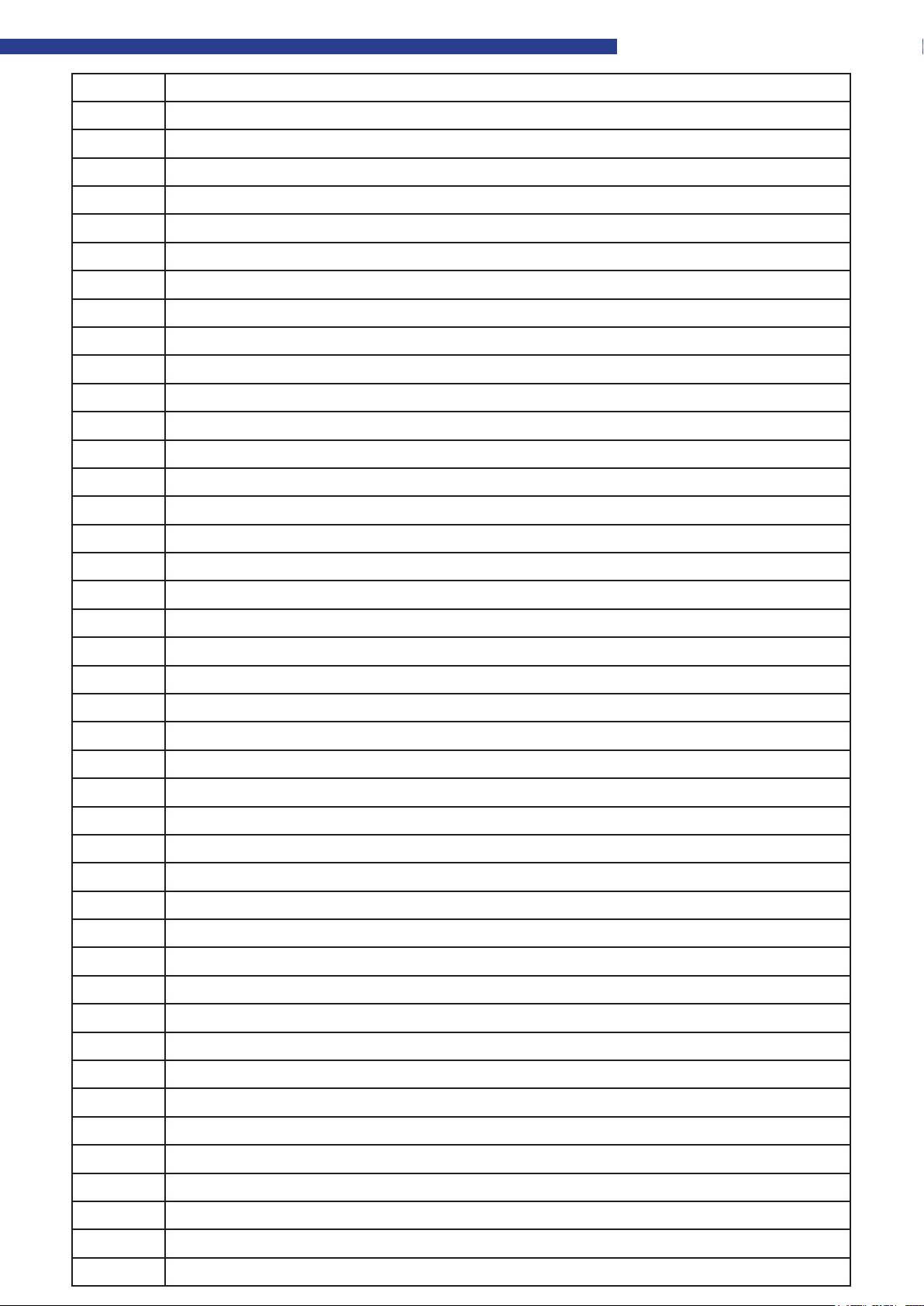

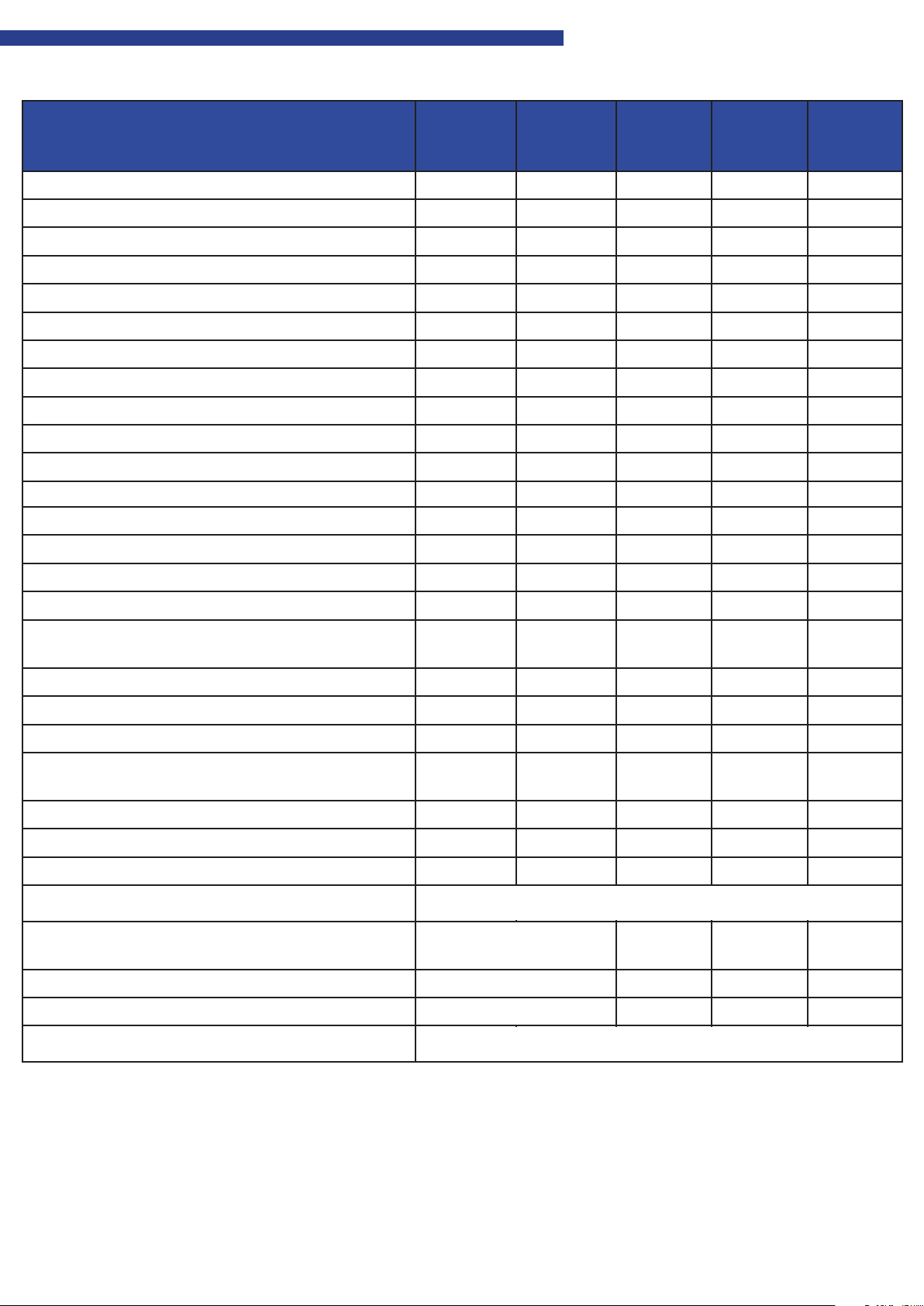

MAINTENANCE OVERVIEW

To see more about each service interval, look further in the book

Maintenance overview Daily Weekly After 250

working

hours

Each

500

hours

Each

750

hours

Cleaning the machine √

Visual inspection of tyres √

Check fuel level, refuel if necessary √

Check the fan belt √

Check the conveyor rubber mat tension √

Engine service due to supplier´s regulations √

Check oil level in engine, add if necessary √

Check coolant level, add if necessary √

Draining water separator √

Change of oil in air lter (cyclone lter) √

Check the brushes, change if necessary √

Re-tighten elevator rake nuts √

Cleaning of water lter √ √ √

Check water nozzles, clean if necessary √ √ √ √

Lubrication due to lubrication scheme √ √ √ √ √

Cleaning of air cleaner element (clean plastic tank) √ √ √ √ √

Cleaning of radiator, blow with compressed air

only if necessary √ √ √ √ √

Check hydraulic oil level, add if necessary √ √ √ √

Replacement of hydraulic lter cartridge √

Replacement of hydraulic breathing lter √ √ √

Check for leakage on cooler and cooler hoses,

defect or porous hoses are to be changed out √ √ √

Check tension of elevator belts √ √ √

Check wheel bearings on wheel axle √ √ √

Function control √ √ √

Recharging of battery

Visual inspection of oil leakage on hydraulic

system, tighten if necessary √ √ √

Check wheel nuts, tighten if necessary (460 Nm) √ √ √

Check pressure in tyres (675 kPa) √ √ √

Replacement of hydraulic oil

Aer instruction

Aer instruction

Aer instruction

Every two years

If necessary