First Solar 6 Series User manual

First Solar Series 6™ Modules | USER GUIDE

PD-5-200-06

Global

REV 5.0

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE i of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

COPYRIGHT AND NOTICES

© Copyright 2020 First Solar, Inc. | | PD-5-200-06 Rev 5.0 | FIRST SOLAR SERIES 6 MODULE USER GUIDE.

All rights reserved. No part of this document may be reproduced in any form or by any electronic or

mechanical means, including information storage and retrieval systems, without permission in writing from

First Solar.

NOTICE

First Solar reserves the right to make changes in solar module design and/or specifications at any time

without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing

orders or finalizing system permitting and/or design. Information furnished by First Solar is believed to be

accurate and reliable. However, no responsibility is assumed by First Solar or its subsidiaries for its use; nor

for any infringements of patents or other rights of third parties, which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of First Solar or its subsidiaries.

CONTACT INFORMATION

For information regarding First Solar and its products, please visit www.firstsolar.com. First Solar has an

extensive library of supporting Application Notes that can be made available upon request from technical

support technicalsupport@firstsolar.com.

GLOBAL

First Solar, Inc.

P.O. Box 730

Toledo, OH USA 43697-0730

Tel: +1 (602) 414-9300

Fax: +1 (602) 414-9400

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE ii of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

TABLE OF CONTENTS

1INTRODUCTION 1

2SAFETY 2

3REGULATORY COMPLIANCE 4

4PRODUCT IDENTIFICATION & RATINGS 5

4.1 PRODUCT IDENTIFICATION & RATINGS 5

4.2 SYSTEM DERATING FACTORS 6

5HANDLING & STORAGE 7

6MECHANICAL SPECIFICATIONS 8

7INSTALLATION & MOUNTING 11

7.1 MOUNTING 11

7.2 MOUNTING LOCATIONS & LOAD RATINGS 11

7.3 SERIES 6 PLUS MODULES – REQUIRED ENGINEERING PRACTICES 13

7.4 TOP MOUNTING 14

7.5 SPEEDSLOT MOUNTING 15

7.6 MODULE ORIENTATION 16

7.7 MODULE SHADING CONSIDERATIONS 16

7.8 WIRE MANAGEMENT 17

7.9 ELECTRICAL INTERCONNECTION 19

7.10 INVERTER COMPATIBILITY 20

7.11 GROUNDING METHOD 21

8MAINTENANCE 23

8.1 MAINTENANCE 23

8.2 MODULE CLEANING GUIDANCE 24

8.3 MODULE DISPOSAL 25

9REVISION HISTORY 26

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 1 of 29

1INTRODUCTION

This document provides information on First Solar Series 6 Modules of model types FS-6XXX and FS-6XXXA

and First Solar Series 6 Plus Modules of model types FS-6XXX-P and FS-6XXXA-P for system designers,

installers, and maintenance personnel (“XXX” references the module power rating). Model types including

‘A’ contain an anti-reflective coating (ARC) on the front side surface. Series 6 Modules and Series 6 Plus

Modules are electrically compatible.

Note: This document will refer to Series 6 Modules and Series 6 Plus Modules as “Series 6 Modules”

unless specified otherwise.

Series 6 Modules are designed to have a long operating life and high energy yield when installed, operated,

and serviced in accordance with the instructions in this User Guide. Read this User Guide thoroughly before

beginning any work related to installation, operation, or maintenance.

Please refer to your First Solar Module Warranty Terms & Conditions for module warranty terms and product

return policies. Failure to follow this User Guide may void your warranty.

Keep this User Guide for future reference and provide to all subsequent owners or users of the

solar modules. Updates may be found at www.firstsolar.com.

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 2 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

2SAFETY

All instructions and safety information should be read and understood before attempting to handle, install,

or electrically connect First Solar modules. Failure to follow safety, installation, and handling instructions

may result in injury. Only qualified personnel should install, operate, or maintain PV modules or systems.

Series 6 Modules are designed for 1000 V systems at altitudes up to 5000 m (16404 ft) per IEC 61730

and 3000 m (9842 ft) per UL 61730. Series 6 Modules are designed for 1500 V systems at altitudes up to

3000 m (9842 ft) per IEC 61730 and 2000 m (6561 ft) per UL 61730.

Select installation locations and module support structures to ensure modules and connectors (open or

mated) are never submerged in standing water.

DANGER

Series 6 Modules may produce up to 280 Volts DC (VDC) and up to 4.0 Amps when exposed to

sunlight. The danger increases as modules are connected together in series and/or parallel.

A single module or multiple interconnected modules can create a lethal shock hazard during

daylight hours, including periods of low light levels

.

DANGER

To avoid fire and/or injury

due to ground faults and associated electrical hazards:

►Do not unplug PV module connections while under load. Do not disconnect the module

connectors during daylight hours unless the module is in an open circuit condition.

►Replace modules with damaged wires immediately. Keep all array wiring out of reach of

non-qualified personnel.

►Do not concentrate light on the module in an attempt to increase power output.

►Never allow the PV array system voltage to exceed 1500 VDC under any condition.

►Replace broken modules immediately.

►Repair ground faults immediately.

►Do not work on modules or systems when the modules or wiring is wet.

►All building mounted PV systems should utilize Ground Fault Detector Interrupters (GFDI)

and ARC Fault Circuit Interrupters to minimize risk of electrical shocks and fires.

Series 6 Modules have a maximum series fuse rating of 5.0A as defined by UL 1703 and a maximum

overcurrent protection rating of 5.0A as defined by UL 61730/IEC 61730-1/IEC 61730-2. Series 6 Modules

have a maximum overcurrent protection rating of 5.0A as defined by UL 61730/IEC 61730-1/IEC 61730-2.

PV systems should be designed to comply with and provide module overcurrent protection consistent with

local codes.

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 3 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

The conditions necessary to trigger reverse current overload (RCOL) do not occur in typical operating modes

of a properly installed PV system. The system designer should ensure that modules are not subjected to

RCOL. The use of GFDI devices or other advanced fault monitoring techniques can significantly reduce the

likelihood of sustained ground faults. Properly selected and installed string fuses can increase protection

against RCOL.

DANGER

Reverse currents

higher than the rated values for a First Solar module, may result in module

failure, including module breakage due to RCOL. Extreme and continuous RCOL conditions may

cause a fire or create electrical shock hazards. To avoid RCOL:

►Maintain equivalent voltage in parallel strings by installing an equal number of modules

per string within the same source circuit. Failure to install modules with balanced voltage

in parallel strings can result in voltage imbalance.

►Incorporate measures to protect modules against RCOL for connections of parallel strings.

Modules damaged because of system-induced RCOL are not covered under the First Solar Module

Warranty. Module warranty eligibility is not affected by the presence, absence, or type of reverse current

protection used in a system design.

CAUTION

Wear safety glasses

and cut-resistant gloves when working with non-interconnected modules or

system components.

Wear electrically rated PPE

when working with interconnected modules or system components.

Select PPE based on work consistent with local and/or national standards.

WARNING

To avoid risk of fire, do NOT interconnect Series 6 Modules with other FS Series Modules (e.g.–

Series 4, Series 3, or Series 2) within the same interconnected string, inverter, or Maximum

Power Point Tracker.

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 4 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

3REGULATORY COMPLIANCE

It is the responsibility of the installer and/or system integrator to ensure compliance with all local structural

and electrical codes, which may be applicable to the installation and use of First Solar Series 6 Modules.

►For systems installed in Canada, installation shall be in accordance with CSA C22.1, Safety

Standard for Electrical Installations, Canadian Electrical Code, Part 1.

For systems installed in North America, First Solar Series 6 Modules are Listed by a Nationally Recognized

Test Laboratory (NRTL) to UL 1703 or UL 61730, the standard for Flat-Plate Photovoltaic Modules and

Panels. To maintain the modules’ application as a UL Listed product:

►Use only components that have been Recognized or Listed by Underwriters Laboratories (UL) for

their intended purpose.

►Ensure the PV array open-circuit voltage does not exceed 1500 VDC (1000 VDC for UL Canada).

►Install modules with mounting systems that have been evaluated for UL Listed application.

►Protect modules from reverse currents in excess of the 5.0A maximum series fuse rating.

►The module is considered to be in compliance with the applicable UL standard only when the

module is mounted in the manner specified by the mounting instructions in this User Guide.

►A module with exposed conductive parts is considered to be in compliance with the applicable UL

standard only when it is electrically grounded in accordance with this User Guide and the

requirements of the National Electrical Code, ANSI/NFPA 70.

Series 6 Modules are tested and certified per IEC 61730-1/IEC 61730-2 and meet Class II requirements for

1500 VDC systems.

Series 6 Modules are tested and certified per IEC 61215-1/IEC 61215-1-2/IEC 61215-2 for a maximum

system voltage of 1500 V.

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 5 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

4PRODUCT IDENTIFICATION & RATINGS

4.1 PRODUCT IDENTIFICATION & RATINGS

Each module is equipped with a product label on the back and laser-etched identification on the front glass.

The label identifies the model number, nameplate electrical ratings, and safety information.

The module Rated Power is denoted in the ‘XXX’ position of the base Model Number format of FS-6XXX.

(Example: FS-6440A has a Rated Power of 440W)

The ratings in Table 1 are UL Listed with a tolerance of ±10% unless otherwise noted.

Note: Electrical specifications are subject to change. See label for final electrical ratings.

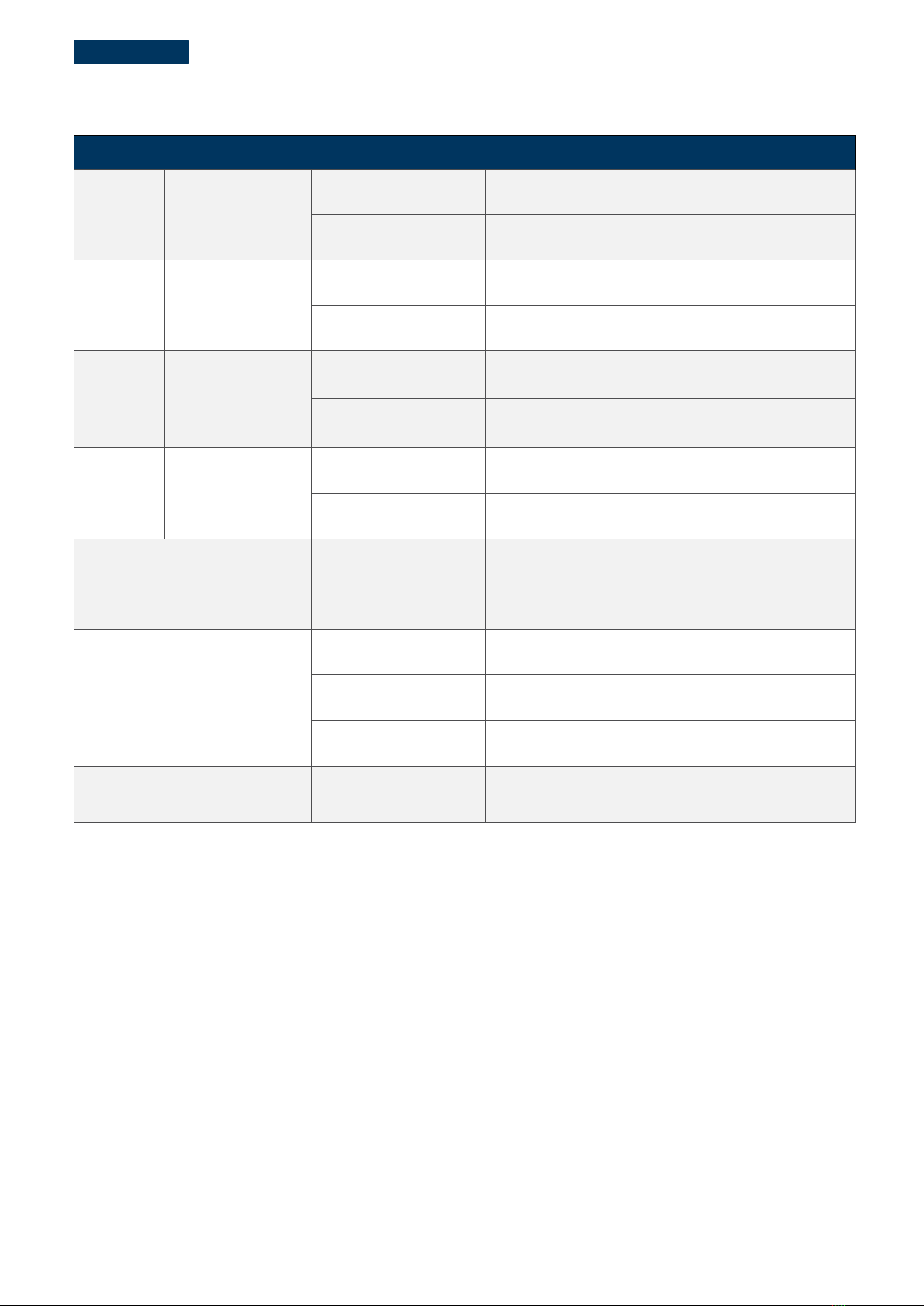

Table 1: Model Numbers & Ratings at Standard Test Conditions (STC1)

RATED POWER2

(-0/+5%)

VOLTAGE AT

PMAX

CURRENT AT

PMAX

OPEN CIRCUIT

VOLTAGE

SHORT CIRCUIT

CURRENT

MAX SYSTEM

VOLTAGE

MAX SERIES

FUSE

P

MAX

(W)

V

MAX

(V)

IMAX(A)

VOC(V)

ISC(A)

V

SYS

(V)

ICF(A)

390.0 173.9 2.24 214.8 2.49

150035.0

395.0 175.0 2.26 215.4 2.50

400.0 176.1 2.27 216.1 2.51

405.0 177.2 2.29 216.8 2.52

410.0 178.3 2.30 217.4 2.52

415.0 179.3 2.31 218.1 2.53

420.0 180.4 2.33 218.5 2.54

425.0 181.5 2.34 218.9 2.54

430.0 182.6 2.36 219.2 2.54

435.0 183.6 2.37 219.6 2.55

440.0 184.7 2.38 220.0 2.55

445.0 185.7 2.40 220.4 2.56

450.0 186.8 2.41 221.2 2.57

455.0 187.7 2.42 222.0 2.58

460.0 188.8 2.44 222.9 2.59

1As received and stabilized ratings at STC (1000 W/m², AM 1.5 25±2°C Cell Temperature) ±10%

2Measurement uncertainty applies

3Model Types 1000 V Listed for UL Canada

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 6 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

Table 2: Temperature Characteristics

TEMPERATURE CHARACTERISTICS

Module Operating Temperature Range (°C) -40 to +85

Temperature Coefficient of PMAX

T

k

(P

MAX

)

-0.32%/°C (Temperature Range: 25°C to 75°C)

Temperature Coefficient of VOC

T

k

(V

OC

)

-0.28%/°C

Temperature Coefficient of ISC

T

k

(I

SC

)

+0.04%/°C

4.2 SYSTEM DERATING FACTORS

Under normal operation, a PV module may experience conditions that produce higher current and/or

voltage than reported at STC. Accordingly, the values of Isc and Voc listed for STC should be multiplied by a

factor of 1.25 when determining component voltage ratings, conductor current ratings, and size of controls

connected to the PV output. For UL installations, an additional 1.25 safety factor for short circuit current

may be applicable, reference the National Electric Code (NEC) Article 690 for further details. Specific site

conditions and local electric code requirements must be used for determining the maximum system

voltage.

When calculating module Voc at 125 mW/cm2, AM 1.5 spectrum, and cell temperature of -10°C,

multiply the specific model type STC listed Voc value by a factor of 1.109. When calculating module Isc

at 125 mW/cm2, AM 1.5 spectrum, and cell temperature of 75°C, multiply the specific model type STC

listed Isc value by a factor of 1.275.

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 7 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

5HANDLING & STORAGE

When handling packs using forklifts or other mechanical aids, ensure uniform pack support, and the forks

fully extend under the pallet. Packs can be lifted from either the short or long side of the pallet. Forklifts

must engage the pallet a minimum of 1.3 m (51 in) for long side engagement and a minimum of 1.5 m (60

in) for short side engagement. Failure to meet engagement lengths may damage pallet and modules on

bottom of pack.

Modules on a pack may lean or shift on a pallet during shipping. It is recommended to unload shifted packs

one at a time. If any damage is observed, use the Delivery Note to document affected pallets and contact

technicalsupport@firstsolar.com.

Only originally banded, fully intact and loaded packs may be stacked for storage up to two high for three

weeks on site or extended periods in a warehouse. Packs should not be stacked if rebanded on site, if any

corner braces or top cap material has been removed, or if any banding is broken from the pack.

►Do not transport stacked packs around project site.

►Do not attempt to transport the pack once the straps have been removed.

Please evaluate site conditions for safe pack storage as uneven or recently disturbed ground and moisture

may affect pack stability. Packs are not intended for long-term outdoor storage. Packs should not be

exposed to standing water higher than half the height of the pallet.

WARNING

Open the packaging with care. A single person should not attempt to lift a Series 6 Module. Lift the

modules from the pallet with two or more persons or with lift assist.

Do not attempt to lift multiple

modules off the stack at the same time.

During handling and installation, do not make abrasive contact with top glass surface to prevent

scratches of ARC film.

The pack’s cap includes two green markings for module orientation purposes. The long edge orientation

mark corresponds to the side of the module with the positive junction box cable.

FS-6XXX/ FS6XXXA / FS-6XXX-P / FS6XXXA-P

FS-6XXX-P-I / FS6XXXA-P-I

Figure 1: Model Type Pack Identification

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 8 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

6MECHANICAL SPECIFICATIONS

Figure 2: Series 6 Module Mechanical Drawing

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 9 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

Table 3: Series 6 Module Mechanical Specifications

DIMENSION

SPECIFICATION

MODEL TYPE

DETAILS

A Length

FS-6XXX / FS-6XXXA 2009 mm +3/-1 mm (79.1 +0.11 / -0.04 in)

FS-6XXX-P / FS-6XXX-P

FS-6XXX-P-I / FS-6XXXA-P-I 2024 mm +3/-1 mm (79.7 +0.11/-0.04 in)

B Width

FS-6XXX / FS-6XXXA 1232 mm ± 2 mm (48.5 ± 0.08 in)

FS-6XXX-P / FS-6XXXA-P

FS-6XXX-P-I / FS-6XXXA-P-I 1245 mm ± 2 mm (49.0 ± 0.08 in)

C Height

FS-6XXX / FS-6XXXA

FS-6XXX-P / FS-6XXXA-P 49 mm ± 1 mm (1.9 ± 0.04 in)

FS-6XXX-P-I / FS-6XXXA-P-I 45.5 mm ± 1 mm (1.8 ± 0.04 in)

D Junction Box

Lead Wire4

FS-6XXX / FS-6XXXA 2.5 mm² (14 AWG)

720 mm (28.35 in) (+) & Bulkhead (-)

FS-6XXX-P / FS-6XXX-P

FS-6XXX-P-I / FS-6XXXA-P-I

2.5 mm² (14 AWG)

733 mm (28.86 in) (+) & Bulkhead (-)

Total Area

FS-6XXX / FS-6XXXA 2.47 m² (26.5 ft²)

FS-6XXX-P / FS-6XXXA-P

FS-6XXX-P-I / FS-6XXXA-P-I 2.52 m² (27.1 ft²)

Module Weight5

FS-6XXX / FS-6XXXA 34.5 ± 1 kg (76 ± 2.2 lbs)

FS-6XXX-P / FS-6XXXA-P 34.9 ± 1 kg (76.9 ± 2.2 lbs)

FS-6XXX-P-I / FS-6XXXA-P-I 34.2 ± 1 kg (75.4 ± 2.2 lbs)

Fire Performance6

FS-6XXX / FS-6XXXA

FS-6XXX-P / FS-6XXXA-P

FS-6XXX-P-I / FS-6XXXA-P-I

Type 19: Class A Spread of Flame /

Class C Burning Brand

4Length from junction box exit to connector mating surface

5When designing structure components for systems with mixed model types (mixed ‘-P’ and ‘-P-I’ model suffixes) the larger nominal

weight should be used to enable flexibility to utilize ‘-P’ modules universally in any array mounting position.

6Module UL 1703 fire rating is valid only when mounted in the manner specified in this User Guide. Roof mounted fire rating is

established by assessing rack and module as a unit. External fire source resistance has not been evaluated.

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 10 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

For Model Types FS-6XXX / FS-6XXXA

For Model Types FS-6XXX-P / FS-6XXXA-P / FS-6XXX-P-I / FS-6XXXA-P-I

Figure 3: Grounding Hole & Wire Management Hole Detail from Frame Center

Figure 4: Long Edge Frame Detail with SpeedSlotTM Dimensions

FS-6XXX / FS-6XXXA / FS-6XXX-P / FS-6XXXA-P

FS-6XXX-P-I / FS-6XXXA-P-I

Figure 5: Long Edge Frame Detail by Model Type

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 11 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

7INSTALLATION & MOUNTING

7.1 MOUNTING

It is best practice to complete heavy construction and trenching prior to module installation to minimize

module exposure to dust. Ensure any site preparation or maintenance chemicals (soil binding agents or

chemicals used for on-site dust control or weed control) do not spray, splash, or drift onto the surface of the

modules or its associated components.

It is the responsibility of the qualified engineer and/or qualified installer to ensure the system and its

components meet applicable structural and electrical code requirements for the product application’s

jurisdiction. First Solar is not responsible for bonding failure, breakage, damage, wear, corrosion, or module

performance issues that are deemed to be caused by design or installation practices that do not comply

with this User Guide.

CAUTION

Safety hazards or potentially unsafe practices:

►Do not install the modules during high wind or wet conditions.

►Handle modules with care during installation, as heavy impact to the front, back, or

edges could result in damage to the module. Do not impact module with hammer to

aid installation process.

►Do not walk, stand, or sit on modules.

►Do not carry multiple modules on top of one another after removal from pack.

►Do not lift or pull on modules using lead wire or junction boxes.

►Do not rest objects (such as tools, etc.) on module glass.

Modules must have adequate ventilation and airflow to prevent operating temperatures above 85°C.

For rooftop mounting, mount modules over a fire resistant roof covering rated for the application. The

recommended minimum standoff height is 8 cm (3.15 in). Series 6 Modules may be installed at an

installation angle up to 60°.

7.2 MOUNTING LOCATIONS & LOAD RATINGS

The interface of the mounting structure to the module frame must meet the technical requirements

specified in this User Guide. The mounting system design must provide adequate support for the module to

prevent load damage from occurring based on the loading requirements for the given application and the

chosen mounting locations. Structures must not come into direct contact with the surface or edges of the

module glass or center cross brace(s).

Modules can be secured to the support structure with top (front side) mounting clamps or by frame slots,

known as SpeedSlots.

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 12 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

Series 6 Modules have been evaluated to operate in an ambient air temperature range of -40°C to +40°C

and have been tested to wind/snow loads as detailed in Tables 4.1 and 4.2. Test loads include a safety

factor of 1.5 above the design loads.

Series 6 Modules meet the following load ratings when mounted as specified in this User Guide and

evaluated according to the listed standard in Tables 4.1 and 4.2.

Table 4.1: Series 6 Module Load Ratings

Model

Types

Mount

Config

Symmetrical

Four-point

Mount

Location

IEC 61215 / IEC 61730

UL 1703

UL 61730

Design

Load

Test Load

Design

Load

Test Load

Design

Load

Test Load

FS-6XXX

FS-6XXXA A

Top Mount:

Range of

400mm to 1200

mm (C/C)

SpeedSlot

Mount:

400 mm

800 mm

1200 mm

± 1600 Pa

(± 33.4

lb/ft2)

± 2400 Pa

(± 50.1

lb/ft2)

± 1436 Pa

(± 30 lb/ft2)

± 2154 Pa

(± 45 lb/ft2)

± 1600 Pa

(± 33.4

lb/ft2)

± 2400 Pa

(± 50.1

lb/ft2)

Table 5.2: Series 6 Plus Module Load Ratings

Model

Types

Mount

Config.

Symmetrical

Four-point

Mount

Location

IEC 61215 / IEC 61730

UL 61730

Design Load

Test Load

Design Load

Test Load

FS-6XXX-P

FS-6XXXA-P A

Top Mount:

Range of

400mm to

1200 mm (C/C)

SpeedSlot

Mount:

400 mm

800 mm

1200 mm

± 1600 Pa

(± 33.4 lb/ft2)

± 2400 Pa

(± 50.1 lb/ft2)

± 1600 Pa

(± 33.4 lb/ft2)

± 2400 Pa

(± 50.1 lb/ft2)

FS-6XXX-P-I

FS-6XXXA-P-I

B7

Top Mount:

1200 mm (C/C)

SpeedSlot

Mount:

1200 mm

± 1600 Pa

(± 33.4 lb/ft2)

± 2400 Pa

(± 50.1 lb/ft2)

± 1600 Pa

(± 33.4 lb/ft2)

± 2400 Pa

(± 50.1 lb/ft2)

C

Top Mount:

Range of

400mm to

1000 mm (C/C)

SpeedSlot

Mount:

400 mm

800 mm

+1300 Pa / -900 Pa

(+27.2 / -18.8 lb/ft2)

+1950 Pa / -1350 Pa

(+40.7 / -28.2 lb/ft2)

Symmetrically secure the module using a minimum of four frame contact points regardless if mounted with

top clamps or with SpeedSlot clamps. Other mounting solutions not discussed in this User Guide (Such as -

asymmetric mounting, higher load ratings, alternative clamp geometry, etc.) may be permitted, but require

7FS-6XXX-P-I / FS-6XXXA-P-I Model Types are IEC 61215/IEC 61730 certified at Mounting Configuration B only when supplemented

with additional interface point(s). Consult First Solar for supplemental documentation.

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 13 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

evaluation by First Solar (technicalsupport@firstsolar.com). First Solar reserves the right to reasonable

access to validate proper installation.

►The modules shall have a minimum spacing gap of 6 mm (0.24 in) between each other. Usable

junction box lead wire lengths accommodate spacing up to 245 mm (9.65 in) (assuming no

substructure interference).

►Do not use module short edge frame sides or center cross braces for mounting unless specifically

evaluated and approved by First Solar in writing.

►Do not modify the module frame in any way. This includes drilling additional holes, altering mounting

features (slots), or otherwise cutting, trimming, or shaping any part of the module frame.

►Module mounting structure support under clamps must maintain a minimum bearing area length of

35 mm (1.38 in) and maintain full frame bottom flange engagement under load.

►Module attachment hardware (i.e. clamps, bolts, etc.) must not contact the module glass.

►Install clamps to the torque stated by the mounting hardware manufacturer.

►Mounting clamps certified/designed to electrically bond and/or ground the module frame are

allowed when used in accordance with the clamp manufacturer’s instructions.

►The maximum clamp force shall not exceed 5500 N for either top or SpeedSlot clamps.

►Minor clamp deformation under load may be acceptable as long as clamping force is maintained

and the deformation does not contribute to a weakening of the clamp or dislodgement of the

module.

7.3 SERIES 6 PLUS MODULES – REQUIRED ENGINEERING PRACTICES

Series 6 Plus Modules of model types of FS-6XXX-P-I / FS-6XXXA-P-I have a reduced mechanical design load

as allowed under its UL 61730 listing and depicted in Table 4.2. These modules are identified by “Reduced

mechanical design load” wording on the module nameplate label.

CAUTION

Model types FS-6XXX-P-I / FS-6XXXA-P-I shall not be used on rooftop systems and

may only be deployed in engineered PV systems, where the following conditions are

met:

•UL 61730 is the applicable certification standard (in any instance where a

module mounting method results in a <1600 Pa load capability per Table

4.2 or otherwise documented by First Solar.)

•The racking vendor has reviewed the project’s design conditions and

subsequently has issued a Module Pressure Zones document, indicating the

required module design pressures, both upward and downward, based on

the module’s location with the PV array.

•The project’s Structural Engineer of Record (SEOR) has reviewed the Module

Pressure Zones document, aligned it with the eligible installation locations

on the Site Layout, and verified that the design load ratings exceed the

design load ratings required.

Many project designs will choose to incorporate Series 6 Plus model types FS-6XXX-P-I / FS-6XXXA-P-I either

in full, or in zoned portions of an array combined with Series 6 Plus model types FS-6XXX-P / FS-6XXXA-P in

other zones. For these mixed design cases, the SpeedSlot mounting interface with universally consistent

interface dimensions for all Series 6 Plus Modules, is preferred in order to avoid managing the different top

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 14 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

clamp height dimensions between the different Series 6 Plus model types (See Figure 5). Also for these

mixed design cases, the Structural Engineer of Record must utilize the weight specification of the FS-6XXX-P

/ FS-6XXXA-P model types from Table 3 for structural racking design, top-of-pile calculations, and post

design calculations for all array positions. It is recommended all array positions be designed to

mechanically accommodate the FS-6XXX-P / FS-6XXXA-P model types, given their ability to be utilized in all

array zones. For the same reason, First Solar will typically provide these FS-6XXX-P / FS-6XXXA-P model

types as spares and/or warranty replacements.

7.4 TOP MOUNTING

Center each clamp +/- 12 mm (0.48 in) within mounting range or location (detailed in Tables 4.1 and 4.2)

to meet documented load ratings based on model type. Top mounting clamps must have a uniform frame

engagement area of 9 mm (0.35 in) minimum width on the top ledge and 30 mm (1.18 in) minimum length

as depicted below in Figure 6. Clamps that do not meet the minimum requirements may not preserve

module certifications or warranty and must be evaluated by First Solar (technicalsupport@firstsolar.com).

Figure 6: Shared Top Clamp Detail on Series 6 Modules

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 15 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

7.5 SPEEDSLOT MOUNTING

The Series 6 Module frames include six SpeedSlots on each side, as shown in Figure 7. SpeedSlot clamps

must either extend 10 mm (0.39 in) beyond the inner edge of the frame, or have a retention feature to

prevent module frame dislodgement under load. SpeedSlot clamps must be at least 12 mm (0.47 in) wide

from attachment point through the 10 mm (0.39 in) extension or until point of retention feature, shown in

Figure 8. Clamps should rest on the flat surface of the SpeedSlot.

Figure 7: SpeedSlot Detail on Series 6 Module Long Edge Frame

Figure 8: Shared SpeedSlot Clamp Detail on Series 6 Modules

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 16 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

7.6 MODULE ORIENTATION

PV performance modeling software, such as PlantPredict (http://www.plantpredict.com), should be used to

determine the optimum orientation and tilt angle for each location.

Mount modules in portrait orientation for applications where row-to-row shading could occur. Landscape

orientation is permitted only in flat mount applications where the module long edge is not completely

shaded and when compliant with Section 7.7 Module Shading Considerations.

7.7 MODULE SHADING CONSIDERATIONS

Specific shading patterns can cause damage to module cells

due to the creation of localized areas of reverse bias. Reverse

bias is generated by one or more series-connected cells being

shaded while the rest of the cells are fully illuminated. When

at-risk shading patterns occur, damage can occur in short

durations (seconds to minutes) and a wide range of irradiance

(as low as 160 W/m²).

There is no risk of module damage due to shading that occurs

while modules are in open circuit. Shading that occurs at a

distance greater than 2 m (6.6 ft), also known as diffuse

shading, carries minimal risk and should be avoided where

possible. Row-to-row shading of modules installed in portrait

orientation is acceptable.

There is a low risk of module damage due to shading from repeatedly walking or standing in front of

operating modules or from repeatedly parking or driving vehicles in front of operating modules during

illuminated times. It is best practice to stay close to the backside of the adjacent rack as one travels down a

row of operating modules.

Do not subject modules to high risk shading instances listed below:

►Resting or adhering slender objects (tools, brooms, clothing, wires, tape) on front-side of operating

modules, or when within ~1.5 to 2 m (~4.9 to 6.6 ft) above operating modules, especially when the

shadow is oriented parallel to cells

►Fixed objects within ~1.5 to 2 m (~4.9 to 6.6 ft) above operating modules that cast a shadow over

the long dimension of the cells. Close objects (posts, ropes, fences, etc.) can begin to increase risk

of partial shading of full cells when within ~1.5 to 2 m (~4.9 to 6.6 ft) from the front-side of

operating module

►A support frame or mounting method on the long edge(s) of modules that fully shades the entire

length of a cell (either partially or completely)

►Cleaning robots or other mechanisms that traverse the module while the system is operating

►Row-to-row shading when the modules are installed in landscape orientation

►Closely “stair-stepped” trackers on northerly slopes (northern hemisphere), or southerly slopes

(southern hemisphere).

Figure 9: Example of at-risk Shading

Patterns

FIRST SOLAR First Solar Series 6™ Modules | USER GUIDE 17 of 29

© FIRST SOLAR, INC. | PD-5-200-06 REV 5.0

7.8 WIRE MANAGEMENT

All wire management shall comply with the applicable NEC/IEC codes and standards for maintaining and

managing wires, as well as any applicable local requirements determined by local authorities having

jurisdiction. This document includes evaluation of general wire management requirements based on

interpretation of the following codes and standards and does not substitute for a comprehensive evaluation

of applicable requirements:

►NEC 2017

o300.3(C)(2) – Conductors of Different Systems

o334.30 – Support and Securement Spacing

o338.24 – Cable Bend Radius Requirements for Type USE cable

►IEC

o62548:2016, 7.3.7.3 – Erection Method

o62548:2106, 7.3.8 – Segregation of AC and DC Circuits

o60364-5-52:2009, 522.8.3 – Cable Bend Radius

Below is a list of best practices that applies to the majority of wire management scenarios:

►The connectors, X/T joints, and in-line fuses should not be in direct contact with the metal frame or

structure. It is recommended that insulated cables do not come in direct contact with the metal

frame or structure, unless unavoidable, to minimize stresses on components.

►The installation of harnesses, harness jumpers, harness whips, and PV array cables (or “Homerun”

cables) should not subject the connectors, X/T joints, and in-line fuses to tensile loads.

►Cable ties should be a minimum distance of 25mm (1 in) from connectors, X/T joints, and in-line

fuses.

►Cables should not maintain constant contact with the edges of glass-to-glass solar module

laminates.

►Cable ties should be tensioned such that there is at least 13mm (0.5 in) (two-finger-gap) between

the top of the cable bundle and the bottom of the frame.

Other manuals for 6 Series

1

Table of contents

Other First Solar Control Unit manuals

Popular Control Unit manuals by other brands

Siemens

Siemens FCA2018-U1 installation instructions

GEM

GEM 620 Series Assembly instructions

Victaulic

Victaulic FireLock NXT 764 Series Installation, Maintenance, and Testing Manual

National Instruments

National Instruments PXIe-8267 Getting started guide

ABB

ABB FCAN-01 Quick installation and start-up guide

ZURN

ZURN AquaSense ZER-W2 Series Installation, operation, maintenance and parts manual