First Water FW-300-M User manual

Table of Contents

Operation Manual.....................................................................................1

1 Introduction ................................................................................................1

1.1 Style Conventions..............................................................................1

2 Unpacking ....................................................................................................2

2.1 Inventory .............................................................................................2

2.2 Storage ..................................................................................................3

3 Startup and Operation.............................................................................4

3.1 Water Source ......................................................................................4

3.2 Component Layout ...........................................................................5

3.4 Startup ..................................................................................................5

3.5 Operation.............................................................................................6

4 Post Operation Care .................................................................................8

4.1 Flushing System.................................................................................8

4.2 Removing Filters ...............................................................................8

4.3 Cleaning System.................................................................................8

4.4 Preparing for Storage......................................................................9

5 Special Procedures ................................................................................10

5.1 Maintenance Intervals .................................................................10

5.2 Replacing Filters ............................................................................10

5.3 Replacing UV Lamp........................................................................ 10

5.3 Replacing Quartz Sleeve .............................................................. 11

5.4 UV Lamp Disposal .......................................................................... 12

6 Troubleshooting ..................................................................................... 13

6.1 Pump will not move water.......................................................... 13

6.2 Water not flowing from Clean Water Hose ........................... 13

6.3 Water leaks from top of Canisters ...........................................13

6.4 Water leaks UV Chamber ............................................................13

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 1

1 Introduction

The Operator’s Manual has been prepared to acquaint the

owner/operator with this water filtration unit, its various controls,

maintenance, and safety instructions. It is valuable for the proper

use of The FW-300-M and should be kept with the unit at all times.

Make sure you read and understand the content of the Operator’s

Manual.

First Water Systems offers water treatment experts to assist you in

your water operation plans. You may contact us at any time to

discuss your needs. The FW-300-M is designed to provide

microbiologically safe water for human consumption from fresh

water sources.

Used in conjunction with the Supply Station, Filling Station and Aqua

Bags, The FW-300-M provides a complete water solution to a variety

of applications.

1.1 Style Conventions

The following style conventions will be used throughout this

operation manual.

Note: Notes present information that will enhance operator

experience.

Warning: Warnings present information that is critical to the safety

of the operator and equipment.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 2

2 Unpacking

Upon delivery of your FW-300-M, please inspect for damage and

inventory all components.

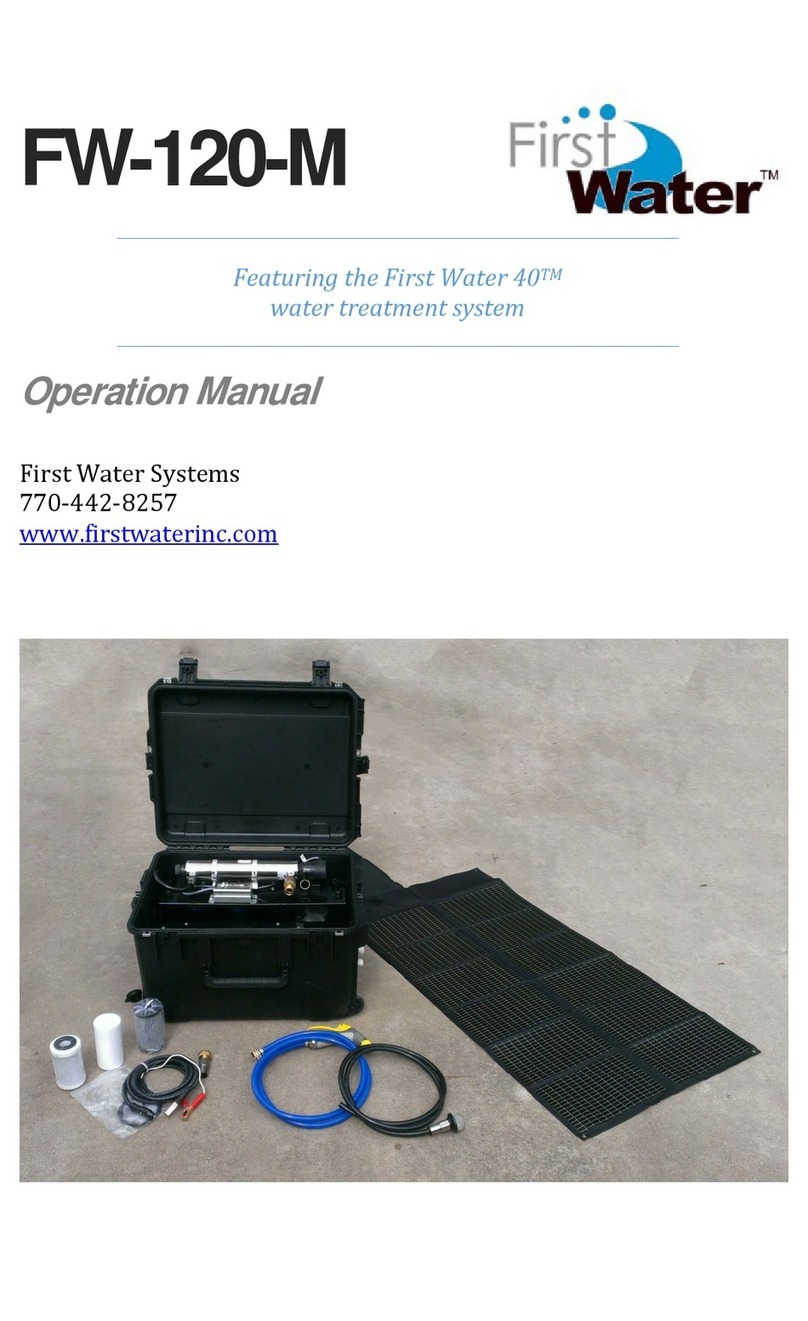

2.1 Inventory

The FW-300-M includes the following components:

(1) Water Purification Unit

(1) Operation Manual

(1) Maintenance Kit (0.5oz silicone grease & 3 x Canister O-

Rings)

(1) Filter Wrench

(1) Filter Set, installed in canisters

(1) Filter Set, spare

(2) UV/Quartz Sleeve sets, (1) installed/(1) spare

(1) Source Water Hose (black)

(1) Clean Water Hose (blue or white)

(1) Silt Screen

(1) Nozzle

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 3

2.2 Storage

The FW-300-M should be stored ready for deployment. The

following checklist will ensure that your FW-300-M is properly

stored.

Used filters discarded

New filters installed

Unit clean and dry

Canister O-Rings lubricated and in place

UV Lamp operational

Hoses and Accessories accounted for

Replacement filters re-ordered

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 4

3 Startup and Operation

3.1 Water Source

The FW-300-M produces microbiologically safe water from fresh

(non-saltwater) water sources. Zeonic virus media filtration utilizes

adsorption properties to remove microbiology and has been proven

against viruses as small as 0.019 microns. Microbiology removed

includes viruses, bacteria, and cysts.

Source water can come from a variety of locations. Ideal water

sources are free of sediment and turbidity and come from a

relatively known environment. As the scope of an event escalates,

less ideal water sources may be utilized.

Example water sources, from most ideal to least ideal:

1. Facility plumbing under boil water advisory.

2. Swimming or therapy pools.

3. Irrigation wells.

4. Shuttled water from fire trucks or tankers.

5. Rain water collected from roof runoff.

6. Surface water from retention ponds, lakes or streams.

The FW-300-M does not remove chemical contaminants from water

sources. Care should be taken in using a water source from

unknown locations or uncontrolled environments.

Water supplies with known chemical additives should never be used.

Water sources with high turbidity, sediment or tannin levels will

cause filters to be expended more rapidly. There is no impact on the

quality of clean water produced.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 5

3.2 Component Layout

Arrange components in the following order, flowing from source

water to water outlet:

1Water Source

2Source Water Hose with Silt Screen attached (black)

3Pump

4Water Purification Unit

5UV Chamber

6Clean Water Hose (blue or white)

7Clean water distribution

3.4 Startup

Place Source Water hose in water source

Attach Clean Water hose to system outlet

Plug unit into 120 volt power source

Turn system on

Confirm that UV Lamp is operating by inspecting UV

indicator light

Power must be supplied through a Ground Fault Circuit Interrupter

(GFCI) that is properly grounded.

Allow the system to run for 5 to 10 minutes prior to distributing

clean water. This will ensure all carbon particles are flushed and the

UV lamp has the proper contact time with water.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 6

Water coming from the Outlet is clean, but any down stream

distribution components may be compromised. Any components

beyond the FW-300-M should be cleaned with a 3:1 bleach solution

or other appropriate disinfectant then thoroughly rinsed before

clean water is distributed.

3.5 Operation

Once water is flowing, very little maintenance is required. Someone

should be present to monitor the following:

Source water does not deplete.

Clean water storage does not overflow.

Water flow does not stop.

Filters needing to be changed.

Pausing Operation

The FW-300-M may be turned off and on throughout an event. To

stop the flow of water, turn any downstream valves to the off

position. The pump will automatically stop. If desired, you may turn

off the power to the Filtration Unit to shut off the UV Lamp.

If the system will be down for more than 4 hours, flush with clean

water for 1 minute before turning off. Do not leave standing water in

the unit for more than 36 hours.

Resuming Operation

After a pause in operation, the system may be restarted by turning

all power back on and opening downstream valves.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 7

Filter Maintenance During Operation

Filter life will vary greatly based on the turbidity of source water.

Under optimal water conditions, a complete filter set should be

replaced every 25,000 gallons. Optimal water conditions are defined

as micro-biologically contaminated water sources with low levels of

sediment, turbidity or tannins. Increased levels of sediment,

turbidity or tannins will require more frequent changes of the

sediment filter identified by observable drops in water flow. When

you notice the flow rate decrease, follow the steps below to check

filters:

Disconnect all power from the unit.

Check Silt Screen for debris.

Replace the Sediment Filter in housing #1.

Restart unit and observe flow rate. If flow rate has not

improved, replace the Virus Media Filters.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 8

4 Post Operation Care

4.1 Flushing System

As soon as possible after an event, flush the system by

pumping clean water for at least 5 minutes.

Remove the Source Water Hose from the source and allow

the system to pump until no water is flowing.

Disconnect all power from the Filtration Unit.

4.2 Removing Filters

Remove Filter Housings from the case.

Unscrew each Canister, using the Filter Wrench where

necessary.

Retain Canister O-Ring.

Remove and discard used Filters.

Drain water from Canisters and dry.

4.3 Cleaning System

Follow instructions above to flush and drain the system.

If sediment remains in the system, replace empty Canisters

and flush with clean water from a garden hose.

Follow steps above to remove and dry filter canisters.

Drain the UV Chamber by tilting unit slightly and allowing

water to flow from the Outlet.

Remove and drain all hoses.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 9

Discard used filters.

Rinse and dry all components.

Leaving Canisters open, allow system to air dry for at least 8

hours, longer if necessary to ensure the unit is completely

dry.

4.4 Preparing for Storage

Visually inspect the UV Bulb and Quartz Sleeve.

Inspect and lubricate each (3) Canister O-Rings with Silicone

Grease or other food grade lubricant.

Place new filters in each Canister and screw the Canisters

back on the unit.

oTighten Canisters hand tight only.

Coil and store all hoses and accessories.

The FW-300-M should be stored ready for deployment. The

following checklist will ensure that your FW-300-M is properly

stored.

Used filters discarded

New filters installed

Unit clean and dry

Canister O-Rings lubricated and in place

UV Lamp operational

Hoses and Accessories accounted for

Replacement filters re-ordered

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 10

5 Special Procedures

5.1 Maintenance Intervals

During Operation

oClean Silt Screen as needed.

oReplace Sediment Filter as needed.

oReplace Filter Set every 25,000 gallons, or as needed

based on flow rate.

During Storage

oEvery 6 Months: Visually inspect UV Lamp operation.

oEvery 6 Months: Open Canisters to ensure unit is

stored dry.

5.2 Replacing Filters

Disconnect power from the filtration unit and remove filter

housings from the case.

Unscrew each Canister, using the Filter Wrench where

necessary.

Retain Canister O-Rings.

Remove and discard used Filters.

Insert new Filters into Canisters.

oCanister 1: White, Sediment Filter, no end caps.

oCanister 2 and 3: Silver, Zeonic Virus Media Filter,

black end caps.

Inspect and lubricate each (3) Canister O-Rings with Silicone

Grease or other food grade lubricant.

Tighten Canisters hand tight only

5.3 Replacing UV Lamp

Disconnect power from the Filtration Unit.

Remove UV Canister from brackets.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 11

Pull the retention pin located on the rubber UV boot.

Slide UV lamp from the chamber and disconnect socket.

Reinstall Lamp in reverse order.

Lamp and Quartz Sleeve are easily damaged. Exercise care when

removing or replacing lamp.

Never look directly at an illuminated UV Lamp.

5.3 Replacing Quartz Sleeve

Disconnect power from the Filtration Unit.

Shut off water supply.

Follow steps in “Replacing the UV Lamp” to remove lamp.

Unscrew Chamber Cap from each end of Chamber.

Remove Washer from both ends of the Quartz Sleeve.

Carefully remove Quartz Sleeve from Chamber. NOTE: It is

advisable to support the quartz sleeve on the opposite end

with your finger so that it does not drop to the bottom of the

chamber as it slides into the chamber.

If removing a broken Quartz Sleeve, follow the steps below:

oCarefully remove as much of the broken quartz sleeve

as possible, from each end of the chamber.

oTo remove fragments of quartz sleeve, position the

UV Chamber vertically and shake. The quartz

fragments will break and drop out of the Chamber.

oFlush water through chamber being careful to

remove all quartz fragments from the interior of the

chamber

Once the quartz sleeve is removed, clean with alcohol or a

mild, non-abrasive detergent. Stubborn stains usually can be

removed with a diluted hydrochloric acid.

Reassemble in reverse order. Make sure the quartz sleeve

protrudes an equal distance past each threaded nipple.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 12

Tighten End Caps firmly by hand only, DO NOT USE HAND

TOOLS. Tightening with hand tools is likely to cause Quartz

Sleeve to break.

Slowly restore water supply and check for leaks.

If no leaks occur, reinstall lamp.

5.4 UV Lamp Disposal

Germicidal ultraviolet lamps, like standard fluorescent lamps contain

small amounts of mercury. Mercury added lamps should not be

placed in the trash. Dispose of properly.

For further information regarding the disposal and recycling of

lamps containing mercury, along with Federal and State

requirements visit http://www.lamprecycle.org.

Operation Manual FW-1200-M

© 2012 First Water Systems, Inc pg. 13

6 Troubleshooting

6.1 Pump will not move water

Check the 120 volt power source

Check the Silt Screen for debris

6.2 Water not flowing from Clean Water Hose

Follow troubleshooting steps for “Pump will not move water”

Check that downstream valves are open

Check power source to Purification Unit

Check Silt Screen for excessive debris

Check filters

6.3 Water leaks from top of Canisters

Check that each Canister O-Ring is in place and lubricated

Hand tighten Canister

A small, dripping leak is not abnormal

6.4 Water leaks UV Chamber

Inspect Quartz Sleeve for damage

Inspect Quarts Sleeve O-Rings and Washers (See “Replacing

Quartz Sleeve”)

Tighten UV Canister End Cap

Table of contents

Other First Water Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual