Rev. A 7/2023

Page 1 of 2

FIS CABLE JETTER KIT

Fiber Instrument Sales | 161 Clear Road • Oriskany, NY 13424

Tel: 315.736.2206 • 1.800.5000.FIS (347) • Fax: 315.736.2285 | berinstrumentsales.com • info@berinstrumentsales.com

SPECIFICATIONS

Cable Types:

2-3mm Cable Diameters

1-12 ber Distribution Style Cable Available

Mechanical Drive:

15 ft per/min

Power Supply for Jetter:

24v from wall plug

Pneumatic Projectile:

Foam cylinder secured with

connection pin

Microduct Size:

Limited to 3/8”I.D. - ½”O.D.

(9.5mm - 12.7mm)

Compressor: (Includes 50ft x 1/4”Air Hose)

Portable 6-gallon pancake compressor option available (2.6 scfm @ 90 PSI)

Larger compressors are able to be used but a max of 80 PSI is advised

• Quick connect system to

attach to 3/8”I.D. conduit

• Air hookup with air shuto

valve

• Nylon pull string spool holder

• Mechanical drive to push ber

thru conduit when needed

FEATURES OF

CABLE JETTER

F1JETTERKIT

(Full Kit Pictured Below)

Patent Pending

Microduct is an excellent way to physically protect ber cable.

Microduct also allows for the cable to be installed by air forcing

or mechanically pushing the cable using the Cable Jetting

equipment.

The Cable Jetter Kit is a complete kit enabling the user to air

blow and mechanically push up to 3mm diameter ber optic

cable, to install 60-pound nylon line as a pull string, or as and

aid to install mule tape. Installation of cables up to 250’long

can be easily achieved. The ability to mechanically push the

cable helps move the cable past bends. Longer distances can

be achieved with the nylon pull string line option. The portable

90 PSI compressor can be purchased as a kit, or you can use

your air source; it is not recommended to exceed 80 PSI.

ORDERING INFORMATION

• Cable Jetter Kit (F1JETTERKIT)

• 6 Gal 165 PSI Compressor & 50ft Air Hose (F1JETTERC)

• Consumable rell kit (6 projectiles) (F1JETTERRFK6)

• Consumable rell kit (24 projectiles) (F1JETTERRFK24)

• Microduct – 3/8”I.D. – 1/2“ O.D. (9.5mm - 12.7mm) (KDI12101)

• Nylon Pull String Rell (JETTERFLREFILL)

Cable Types:

9/125µm - OS2 SINGLEMODE

• S09-MD2-CZNPY20 (2 Fiber, Plenum,Yellow)

• S09-MD12-CZNPY20 (12 Fiber, Plenum,Yellow)

50/125µm - OM3 MULTIMODE

• M50-MD02-CGNPA20 (2 Fiber, Plenum, Aqua)

• M50-MD12-CGNPA20 (12 Fiber, Plenum, Aqua)

50/125µm - OM4 MULTIMODE

• M50-MD02-C4NPA20 (2 Fiber, Plenum, Aqua)

• M50-MD12-C4NPA20 (12 Fiber, Plenum, Aqua)

50/125µm - OM3 MULTIMODE 10 Gig

• M50-SX01-CGNRA (3.0mm, Simplex, Riser, Aqua)

• M50-SX01-CGNPA (3.0mm, Simplex, Plenum, Aqua)

• M50-SX01-CGNRA20 (2.0mm, Simplex, Riser, Aqua)

• M50-SX01-CGNPA20 (2.0mm, Simplex, Plenum, Aqua)

OM1 / OM2 Fiber Cable

Available

CABLE JETTER KIT CONTENTS

• Cable Jetter with Nylon Pull String

• Threaded Nozzle

• Quick Connect (2 Qty)

• Blowing Projectile (6 Qty)

• Pre-cut Nylon Pull String

• Mini Pulling Eye (6 Qty)

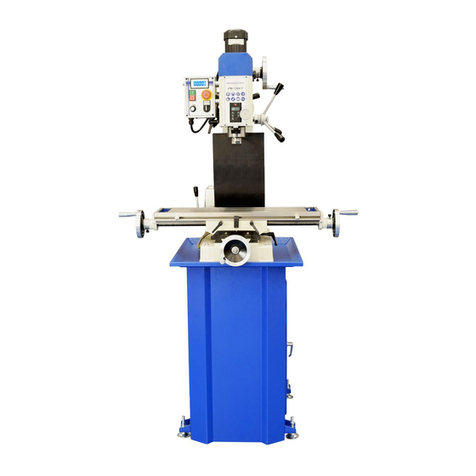

CABLE JETTER Figure 1)

Mini Pulling Eye

Microduct Suppliers

• Fiber Instrument Sales

• Duraline

• Knet

• Blue Diamond Industries

Quick connect

for 1 /2” O .D .

tubing

“Threaded

Nozzle”

Blowing

Projectile

Pre-Cut

Nylon Pull

String