General operation

Seite/Page 10 - Kaptitel/Chapter 2: General operation 10.5.17

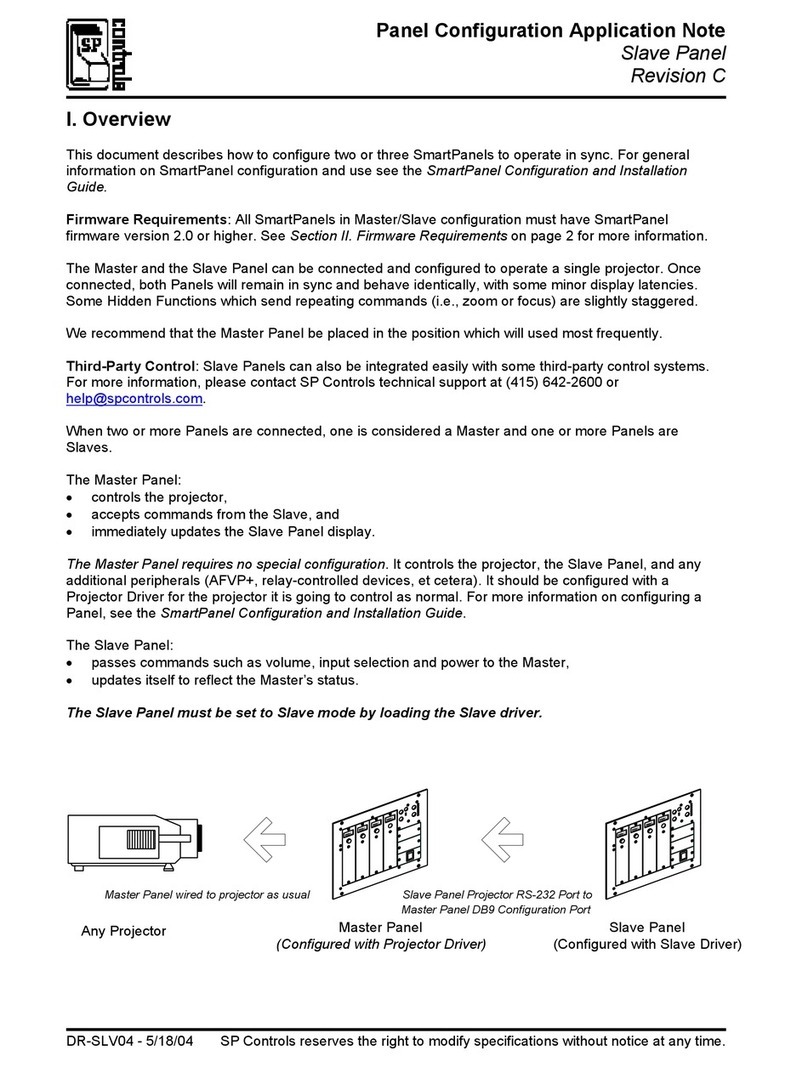

2.3 Installation of the remote control panel

2.3.1 Placement.

Install the remote control panel at a dry, good accessible and shady place.

Connect the remote control panel to the standard 12 core cable at the generator. (1:1)

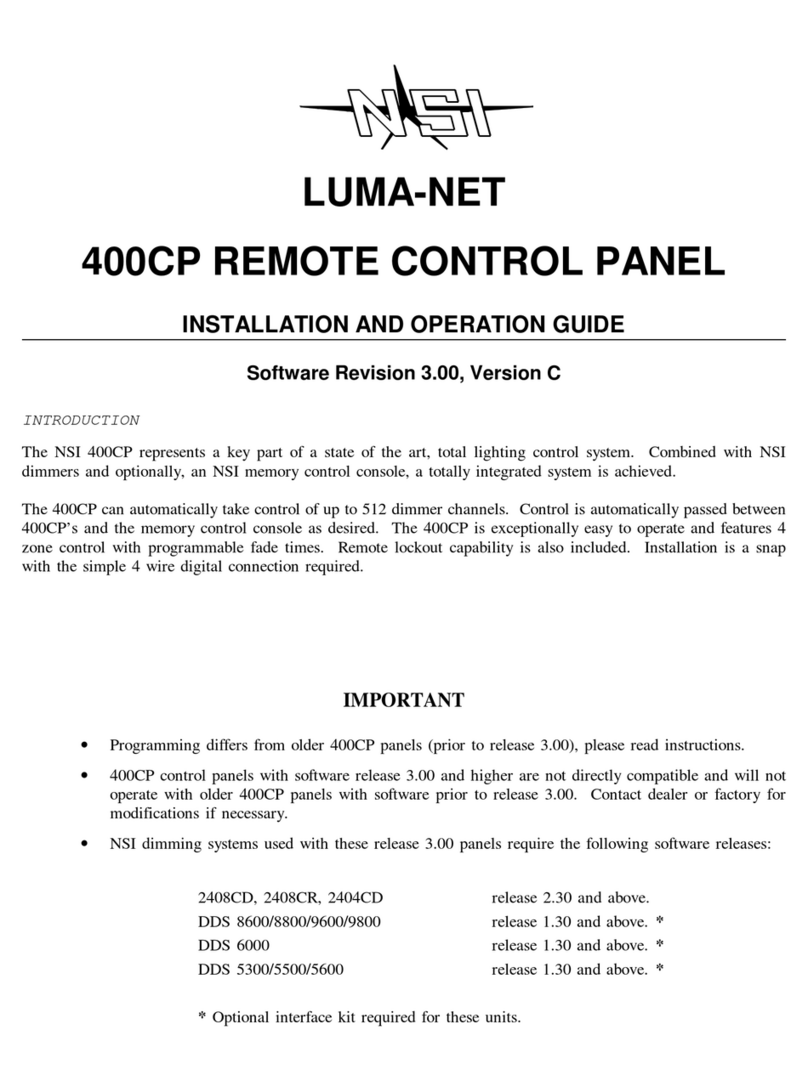

2.3.2 Terminal connections

Standard for NC temperature switch configured i.e. in case of failure „open“.

Fig. 2.3.2-1: Terminal connections

Clamp no. Clamp name IN / OUT Description

1 Vbat IN power supply + 12 V (or optional 24 V, must be adjusted by jumper)

2 GND IN power supply -

3 T-Engine IN Error “coolant temperature”. Input for thermo-switch to GND. The input is adjustable for NC/NO (N

= no error) (must be adjusted by solder Jumper). The input loads the switch with 22 mA to +12 V

(with 24 V-operated internally generated). The occurrence of an error is delayed, for analysis and

displayed, around 100ms. Omission not. The in/out status is indicated with red LED.

4 Water leak

(Replace air filter) IN Error “water leak”. Input for sensor switch to GND. The input is adjustable for NC/NO (N = no error)

(must be adjusted by solder Jumper). The input loads the switch with 10 mA to +12 V (with 24 V-

operated internally generated). The occurrence of an error is delayed, for analysis and displayed,

around 100 ms. Omission not. The input status is indicated with red LED.

The input can be used alternatively for the signal “Replace air filter” (must be adjusted by solder

Jumper). Then the signal does not lead to switching off and is indicated with yellow LED.

5 Oil-Press IN Error “oil pressure“. Input for oil pressure switches to GND. The input is adjustable for NC/NO (N

= no error) (must be adjusted by solder Jumper). The input loads the switch with 22 mA to +12 V

(with 24 V-operated internally generated). The occurrence of an error is delayed, for analysis and

displayed, around 1s. Omission not. The input status is indicated with red LED.

6 DC-Control IN / OUT Load control display. Input for signal of the dynamo. The input is adjustable for GND = OK or 12 V/

24 V = OK (must be adjusted by solder Jumper). The input loads the signal with 5 mA at 12 V and

10 mA at 24 V. The input status is indicated with red and green LED.

The connection can supply an energizing current for the dynamo over a fixed resistor with 68R.

Either with the control panel switched on or with “Fuel pump” switched on (must be adjusted by

solder Jumper). This function is available only in 12 V-operation.

7 AC-Control IN AC control display. Input for NC-open-collector-sensor-switch to GND (N = OK). The input loads

the switch with 2,5 mA to +12 V (with 24 V-operated internally generated). The input status is

indicated with red and green LED´s.

8 Heat OUT Output for pre-glow relays. The output isso long active,as the button “Heat” ispressed. Theoutput

supplies, if active, the voltage of clamp 1. Additionally the output can be operated via the button

“start” (must be adjusted by solder Jumper). Consider (notes 1-4).

9 Fuel-Pump OUT Output for fuel pump relay. The output is active, if no error is present (inputs 3, 4, 5, 11 and 12, if

configured accordingly). The button “start” suppresses the error analysis and the output is then

also active in the case of error, if the button “start” is pressed. The output supplies, if active, the

voltage of clamp 1. Consider (notes 1-4).

10 Start OUT Output for starting relay. The output is active, as long as the button “start” is pressed. The output

supplies, if active, the voltage of clamp 1. Consider (notes 1-4).

11 AC-Fault (Fuel

Level) [former T-

Oil]

IN Error generator AC input for NC-open-collector-sensor-switch to GND (N = no error). The input

loads theswitchwith2,5 mA to +12 V. (with 24 V-operated internally generated).Theoccurrence

of an error is delayed, for analysis and displayed, around 100ms. Omission not. The input status

is indicated with red LED.

The input can be used alternatively for the signal “Fuel level” (must be adjusted by solder Jumper).

The signal does not lead to switching off and is indicated with yellow LED.

The input can be used alternatively for the signal “error oil-temperature”. The input is adjustable

for NC/NO (N = no error) (must be adjusted by solder Jumper). The load of the sensor switch is

adjustable to 10 mA by +12 V (must be adjusted by solder Jumper).