1

Table of Contents

1. Introduction................................................................................................................ 3

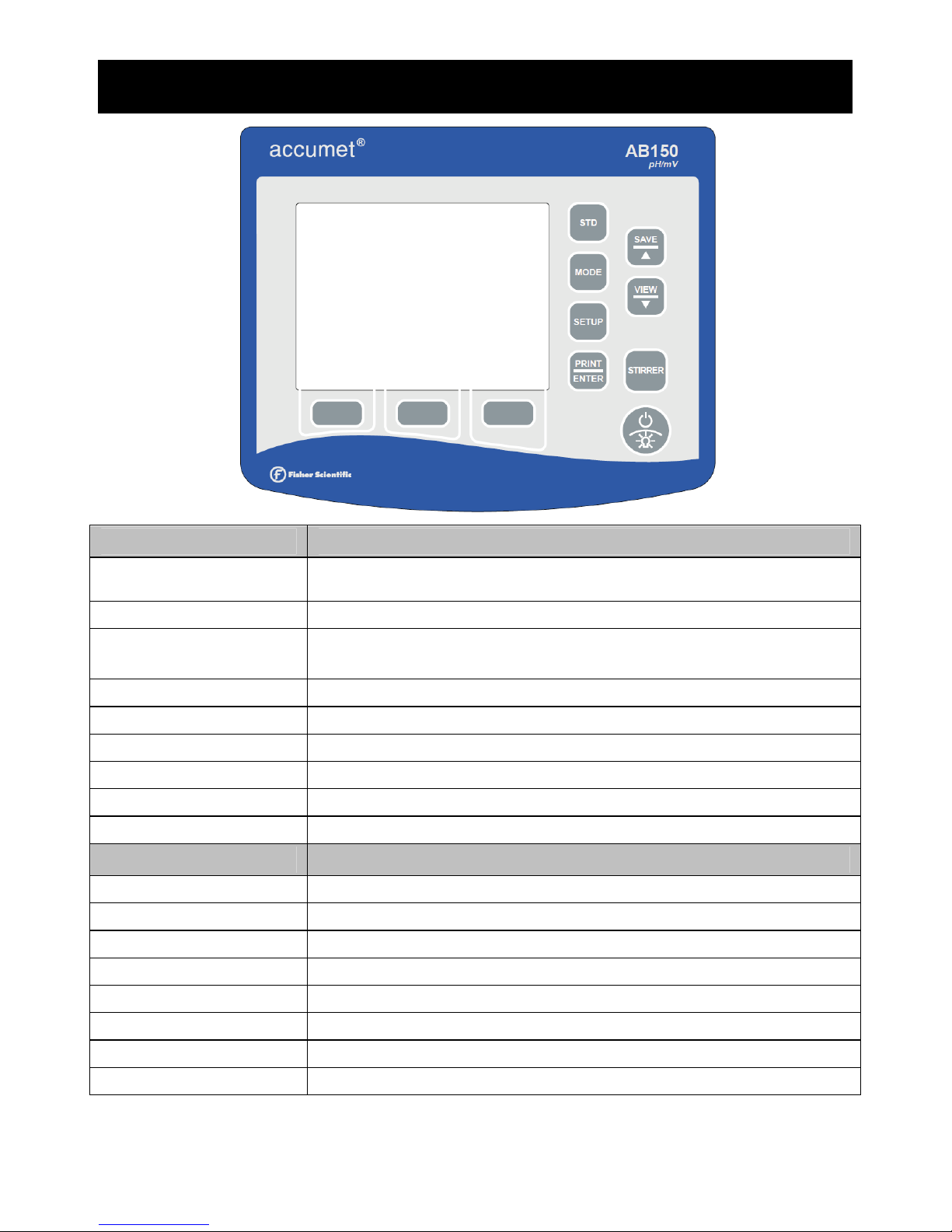

2. Keypad & Display....................................................................................................... 4

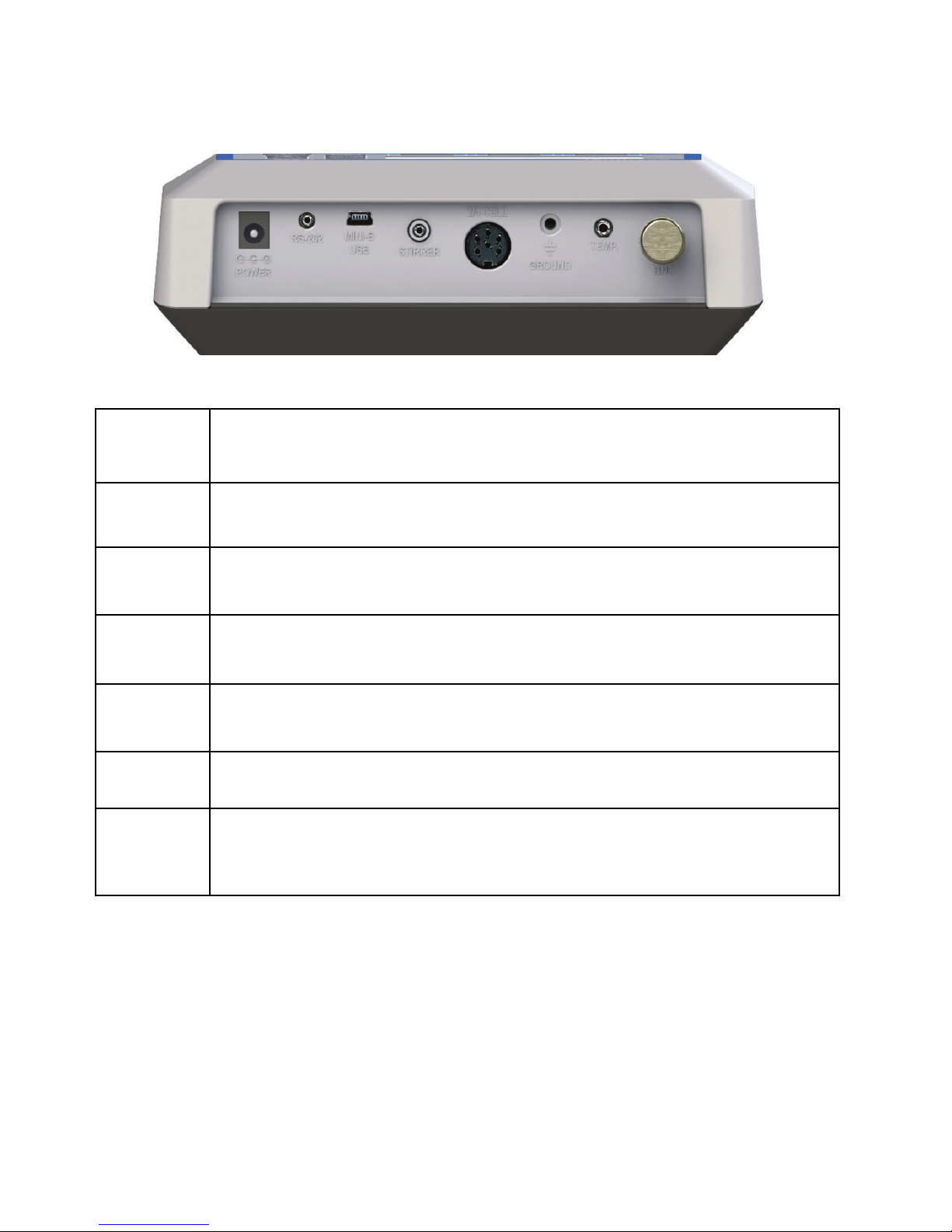

Connections: ............................................................................................................................... 6

3. System Setup & Configuration................................................................................. 7

STABILITY .................................................................................................................................. 7

EXPORT DATA........................................................................................................................... 7

DATE & TIME.............................................................................................................................. 8

PASSWORD ............................................................................................................................... 8

FACT RESET.............................................................................................................................. 9

CONTRAST................................................................................................................................. 9

STIRRER..................................................................................................................................... 9

SAMPLE ID ................................................................................................................................. 9

LANGUAGE ................................................................................................................................ 9

BEEP........................................................................................................................................... 9

4. Setup pH & mV........................................................................................................... 10

BUFFER (pH Only) ..................................................................................................................... 10

RESOLUTION (pH Only) ............................................................................................................ 10

ALARM........................................................................................................................................ 10

STD DUE (pH Only) .................................................................................................................... 10

5. pH Standardization (With Preset Buffer Group)...................................................... 11

6. pH Standardization (With Custom Buffers)............................................................. 12

7. mV Standardization (Offset Adjustment)................................................................. 13

8. Temperature Setup .................................................................................................... 13

9. Temperature Standardization ................................................................................... 14

10. Conductivity, TDS, Salinity, & Resistivity Setup..................................................... 15

STD METHOD (Conductivity Mode Only)................................................................................... 15

STD POINTS............................................................................................................................... 15

PURE WAT COEF (Pure Water Coefficient) .............................................................................. 16

TEMP COEFFICIENT (Linear).................................................................................................... 16

NORMALIZATION TEMPERATURE (ºC) ................................................................................... 16

TDS FACTOR (TDS Mode Only) ................................................................................................ 16

CELL CONST (Cell Constant)..................................................................................................... 16

ALARM........................................................................................................................................ 17

STD DUE..................................................................................................................................... 17