www.Fisher.com

Fisher™2506 and 2516 Receiver/Controllers

Contents

Introduction 2.................................

Scope of Manual 2.............................

Description 2.................................

Specifications 2...............................

Educational Services 4.........................

Installation 5..................................

Mounting the Controller 5......................

Actuator Yoke Mounting 6..................

Wall Mounting 6...........................

Actuator Diaphragm Case Mounting 7........

Pipestand Mounting 8......................

2500 Controller/Transmitter and

2506/2516 Receiver/Controller Mounting 9.

Connections 11...............................

Supply Connection 12......................

Output Connections 12.....................

Instrument Connection 12..................

Vents 12.................................

Remote Set Point Connection 13.............

Startup 13.....................................

Adjustments 14................................

Set Point Adjustment 14........................

Remote Set Point Adjustment 15................

Proportional Band Adjustment 15................

Reset Adjustment

(2516 Receiver/Controller Only) 15............

Anti‐Reset Windup Valve Adjustment

(2516F Receiver/Controller Only) 15...........

Calibration 16..................................

Principle of Operation 17........................

2506 Receiver/Controllers 17...................

2516, 2516F Receiver/Controllers 18.............

Maintenance 19................................

Changing Controller Action 19..................

Troubleshooting 20............................

Testing Relay Deadband 21.....................

Replacing Receiver/Controller Parts 21............

Bellows Replacement 21....................

Changing the Relay 22......................

Changing Proportional or Reset Valve 22......

Parts Ordering 22...............................

Parts Kits 23...................................

Parts List 23...................................

Receiver/Controller Common Parts 23............

Anti‐Reset Windup Valve for 2516F Only 26.......

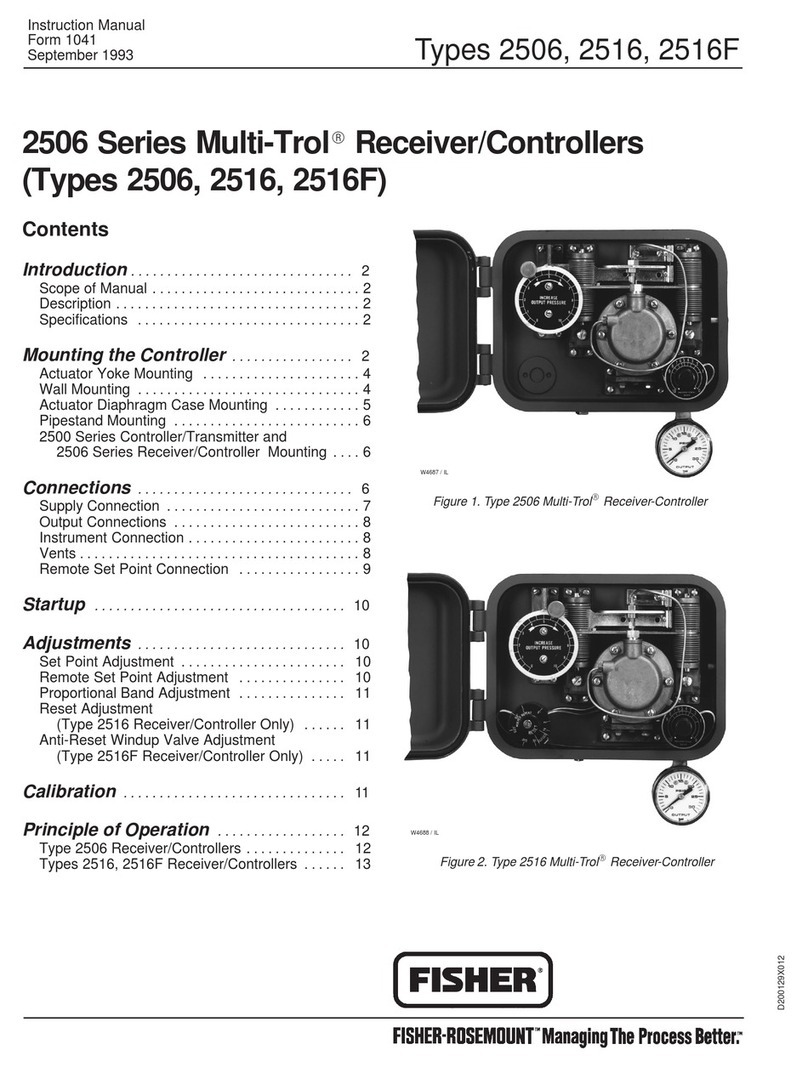

Figure 1. Fisher 2506 Receiver‐Controller

W4687

Figure 2. Fisher 2516 Receiver‐Controller

W4688

2516F Reset and Anti‐Reset Windup

Valve Assembly 26..........................

Mounting Parts 27.............................

Yoke Mounting 27.........................

Wall Mounting 27..........................

Case Mounting 27.........................

Pipestand Mounting 27.....................

2500 Controller/Transmitter and 2506/2516

Receiver/Controller Mounting 27..........

Instruction Manual

D200129X012

2506/2516 Receiver/Controller

June 2017