Type 304 & 304L

8

Parts Ordering

Whenever corresponding with the Fisher sales office

or sales representative about this equipment, always

mention the position switch serial number. When or-

dering replacement parts, refer to the 11-character

part number of each required part as found in the fol-

lowing parts list.

Parts

List

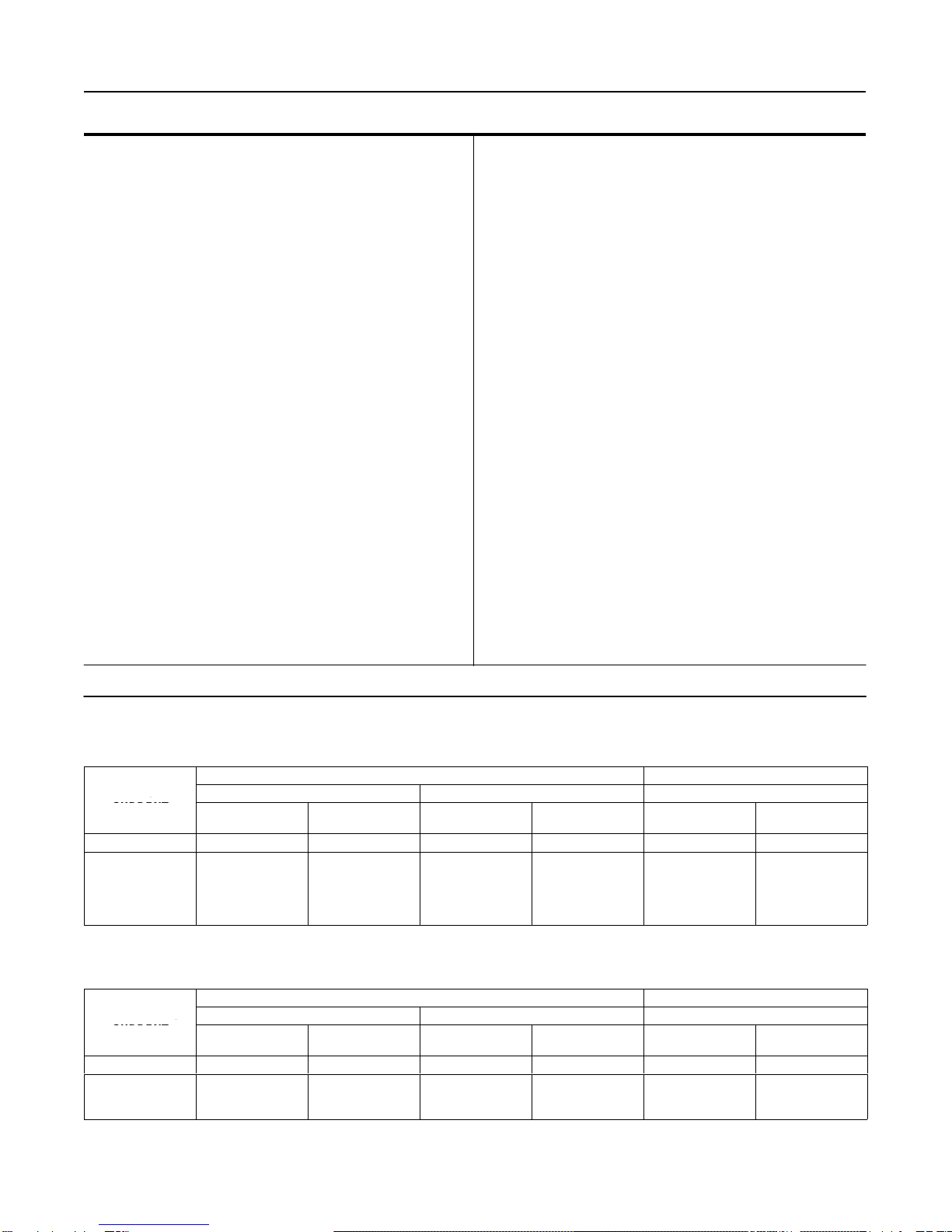

Position Switch Common Parts (figure 6)

Key Description Part Number

1 Base assembly, aluminum 11A8584X012

2 Cover assembly, aluminum

2 switch unit 19A8070X012

6 switch unit 29A8069X012

4 Switch post, pl steel (3 req’d)

2 switch unit 1N251024502

6 switch unit 1N251124502

5* Switch (1 to 6 req’d) 1P123299012

6 Switch insulator (2 to 7 req’d) 1N251606992

7 Spring washer, pl steel (2 req’d per switch) 1P271028992

8 Lockwasher, pl steel (3 req’d) 1H267128982

9 End plate, pl steel 1N251728992

10 Hex nut, pl steel (4 req’d) 1A330328982

11 Cam rod, stainless steel

2 switch unit 1U868135032

6 switch unit 1N807535032

12 Cam, stainless steel (1 req’d per switch) 1P129636032

13 Hex Nut, pl steel (1 req’d per switch) 1A946324122

14 Gear, pl steel (1 req’d per switch) 1P270924592

15 Washer, pl steel (1 req’d per switch) 10B2660X012

16 E-ring, pl steel (2 req’d) 1H153828982

17 Washer, pl steel (2 req’d) 1C332928982

18 Switch spacer, pl steel

2 switch unit

1 switch (2 req’d) 1N252924102

2 switches (none req’d) - - -

6 switch unit

1 switch (10 req’d) 1N252924102

2 switches (8 req’d) 1N252924102

3 switches (6 req’d) 1N252924102

4 switches (4 req’d) 1N252924102

5 switches (2 req’d) 1N252924102

6 switches (none req’d) - - -

21 Nameplate, aluminum

for switch with no approval 14A2115X0A2

22 Machine screw, pl steel 1P426928982

23 Spacer plate, pl steel (not shown)

(none required with terminal strip) 1P129525022

24* O-Ring, nitrile 1H862106992

25 Seal retainer, stainless steel 1V5834X0012

26* O-ring, nitrile 1C853806992

107

Wire retainer

16A2821X012

115 Lubricant, Lubriplate Mag-1 (not furnished with switch)

116 Adhesive, Loctite, #609 (not furnished with switch)

Key Description Part Number

Terminal Strip Assembly (figure 6)

30 Screw, pl steel

2 switch unit

1 switch (4 req’d) 1D677628992

2 switches (8 req’d) 1D677628992

6 switch unit (8 req’d) 1D677628992

31 Bracket, pl steel

2 switch unit 24A2116X012

6 switch unit 24A2109X012

32 Terminal strip

2 switch unit

1 switch (1 req’d) 1J304299012

2 switches (2 req’d) 1J304299012

6 switch unit (2 req’d) 1H767499012

33 Marker Strip 1

2 switch unit 1U872106992

6 switch unit 1U830906992

34 Marker Strip 2

2 switch unit

1 switch (none req’d) - - -

2 switches (1 req’d) 1U872206992

6 switch unit (1 req’d) 1U830806992

35 Red wire assembly

(1 req’d per switch) (not shown) 14A0758X012

36 Blue wire assembly

(1 req’d per switch) (not shown) 14A0759X012

37 Black wire assembly

(1 req’d per switch) (not shown) 14A0760X012

Position Switch Mounting Parts

Note

In this section, the letters ‘‘MO’’ (means manual opera-

tor) following a type number or size indicate that the

actuator has a manual handwheel.

Type 329 Actuators

See section covering Type 329, 1051, 1052,

1061, and 1069 actuators below.

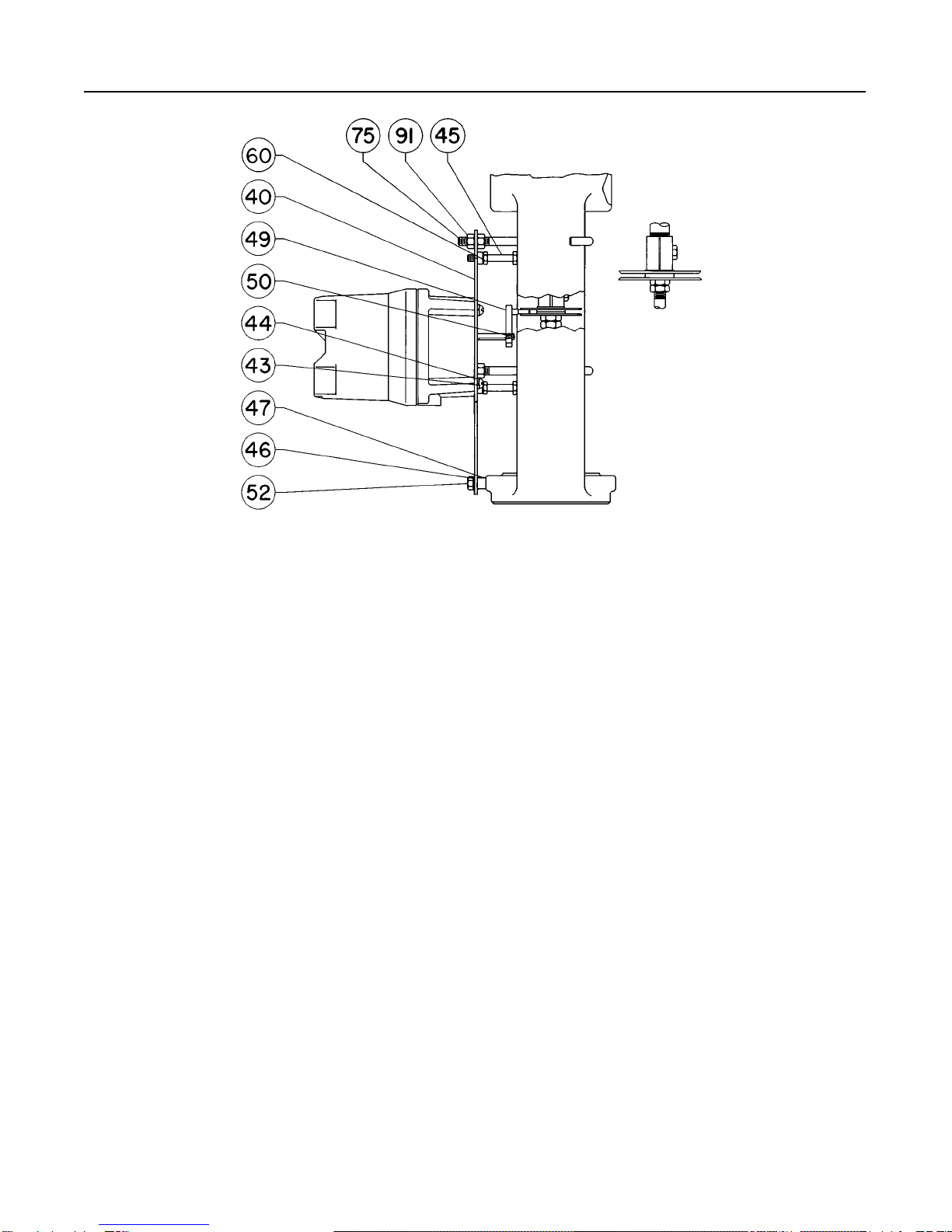

Type 350 and 350MO Actuators (figure 7)

40 Mounting plate, assembly, steel

Type 350 and 350MO

2-13/16 (71 mm) boss 10A8524X012

3-9/16 (90 mm) boss 12A2348X012

43 Machine screw, pl steel (4 req’d) 1C582428982

44 Lockwasher, pl steel (4 req’d) 1C225628982

45 Cap screw, pl steel (2 req’d)

Type 350

2-13/16 (71 mm) and 3-9/16 (90 mm) boss 1A352524052

Type 350MO

2-13/16 (71 mm) boss 1A352524052

3-9/16 (90 mm) boss 1C870224052

46 Lockwasher, pl steel 1C225728982

47 Spacer, pl steel

Type 350

2-13/16 in. (71 mm) boss 1N254324102

3-9/16 in (90 mm) boss (none req’d) - - -

Type 350MO

2-13/16 in. (71 mm) boss 1N254324102

3-9/16 (90 mm) boss 1N466124102

*Recommended spare parts