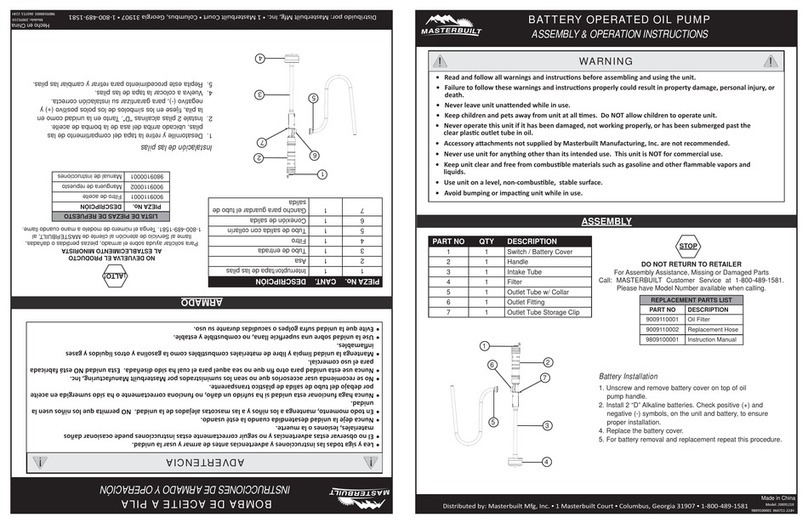

TYPE MIN. PRIMING

LEVEL

MIN. DRAINAGE

LEVEL

START LEVEL STOP LEVEL WEIGHT

Kg.

Picture

BIOX® 200/8

BIOX® 300/10

BIOX® 400/12

A

123mm

123mm

123mm

B

45mm

45mm

45mm

C

370mm

400mm

400mm

D

250mm

300mm

300mm

8,5

9

10

Pump with less than 10 mt. supply cord cannot be used in open spaces.

The min. priming level refers to completely submerged outlet. (See Pict. 1)

Single phase version

Single phase pumps are equipped with double ground contact plug at top end of supply cord ; in this case grounding is done when plugging

in.

Three phase version

In this case the ground wire ( yellow-green cable ) of supply cord must be connected to ground wire of electric current network.

Ensure connection to electric current network by using an omnipolar-sectionned magneto thermic circuit-breaker.

This will ensure effective disconnection from electric current network.

Electric shock risk

DANGER

Electric shock risk

DANGER Installer must make sure that electric current network

has ground wire conforming to current laws.

Ensure tension and frequency of pump ( read motor

plate ) and supply network are same.

REMARK

Make sure that electric current network is provided with a

high-sensitivity circuit-breaker

=30 mA (DIN VDE 0100T739)

Please refer to Fig. 1

The linear meausures in chart are in millimeters

CHAP. 3 INSTALLATION

When installing, please ensure pump is disconnected

from electric current network.

CHAP. 4 ELECTRIC CONNECTION

DANGER

Electric shock risk

Please use handlebar to remove or lift pump up.

Please use a non-return valve in case pump is connected to fixed installation with rigid piping; this will avoid liquid circulating when

pump has been turned off; use of a pipe fitting will allow easy disconnection of pump for maintenance.

Dimensions of drain well must allow max. 30 on/off cycles/hour. ( See USE AND HIS LIMITATIONS )

Please use flexible pipe connected to pump by means of plastic fitting in case of temporary use of pump.

Use a rope to immerse pump and fasten it to pump's handlebar.

BIOX®aut is equipped with a pre-rated float switch ( See Pict. 1); please increase or decrease the free piece of float switch cable

by making it sliding through the proper seat on the handlebar, when modifying the rating of float switch.

Pumps used besides or inside swimming pools, garden ponds or similar places may have special requirements.

Make sure that float switch turns

off pump, when at min. level of liquid.

Make sure no obstacles stand in the way of

float switch, during up/down swinging.

REMARK

REMARK

5

GB