fivalco YS-300-FF User manual

Fivalco Ltd | info@fivalco.com | www.fivalco.com

Strainer

Fire Protection Products

YS-300-FF | YS-300-FG | YS-300-GG

Mechanical Services & HVAC Products

F73Y16 | F73Y25 | F73B16 | F73B25 |

V73Y16

This manual is also available online.

Fivalco Ltd | info@fivalco.com | www.fivalco.com

Fivalco Ltd | info@fivalco.com | www.fivalco.com

CONTENTS

Strainer

1 General .................................................................................................................................... 1

2 Unloading & Transportation.................................................................................................... 1

3 Storage.....................................................................................................................................1

4 Inspection Prior To Installation ................................................................................................ 1

5 Installation ................................................................................................................................ 2

6 Operation Of Strainer.............................................................................................................. 4

7 Maintenance........................................................................................................................... 4

8 Warnings................................................................................................................................... 4

Installation & Operation Manual

Strainer

1

Fivalco Ltd | info@fivalco.com | www.fivalco.com

STRAINER

1GENERAL

Strainer is a device installed in a pipeline system for mechanically removing unwanted debris

by means of a perforated screen or wire mesh straining element. They are used in pipelines

to protect expensive and critical downstream equipment such as pumps, meters, cooling /

heating coils, control valves, steam traps, regulators and other process equipment.

Strainers can be classified as Y-Type and T-Type or Basket Type, according to their body

configuration. Y-Strainer has the advantage of being able to be installed in either a horizontal

or vertical position. In both cases, the screening element must be pointing downward of the

strainer body so that the entrapped material can properly collect in it.

T-Strainer or Basket Type strainer can only be installed in horizontal pipelines, and for larger,

heavier basket strainers, the base of the strainer needs to be supported.

Y-strainer usually has a lower dirt holding capacity than basket type strainers, which means

that they require more frequent cleaning.

2UNLOADING &TRANSPORTATION

A vital consideration in handling strainers should be avoid damaging or scratching the

coating protection. Ensure that there are no heavy load and sharp objects are applied to

the strainers.

All strainers should be unloaded carefully. Each strainer should be carefully lowered from the

truck to the ground; it should not be dropped. In the case of larger strainers, forklifts or slings

around the body of the strainer or under the skids should be used for unloading. Only hoists

and slings with adequate load capacity to handle the weight of the strainer should be used.

Failure to carefully follow these recommendations is likely to result in damage to the strainer.

3STORAGE

Whenever practical, strainers should be stored indoors under dry, cool conditions, away from

corrosive or otherwise chemically active atmosphere. If outside storage is required, means

should be provided to protect the operating mechanism from weather elements.

4INSPECTION PRIOR TO INSTALLATION

Strainers should be inspected at the time of receipt for damage in shipment. The initial

inspection should be to verify compliance with specifications, type of end connections, etc.

Inspection personnel should look for dent or cracked parts, loose bolt, missing parts and

accessories, and any other evidence of mishandling during shipment.

Installation & Operation Manual

Strainer

2

Fivalco Ltd | info@fivalco.com | www.fivalco.com

5INSTALLATION

At the jobsite prior to installation, each strainer should be visually inspected and any foreign

material in the interior of the strainer should be removed.

Before being installed, the strainer needs to be cleaned so as to eliminate the dust caused

during the transportation and storage. The strainer’s cover should be removed and inspect

the interior for any loose or foreign materials that may have trapped in the screen during

transportation. After inspection, ensure sealing surfaces are clean prior to reinstalling the

gasket / O-ring and cover. Make sure the gasket / O-ring is seated correctly before tightening

the cover bolts. Confirm the type of connection and standard before starting the installation

work.

A strainer should always be installed ahead of pumps and other expensive, downstream

equipment to help ensure proper protection and trouble-free operation. This even holds true

for “clean lines” to protect against pipe scale and accidentally introduced items such as

gaskets or tools.

Before placing the strainer into place, support the existing pipeline with pipe supports near

the inlet and outlet connections.

Y-Strainer can be installed in either a horizontal or vertical pipe line depending on its

application. Every strainer has an arrow marked on the body to shows the flow direction of

the media. Please make sure the installation of the strainer is following the direction of the

arrow.

The installer shall provide sufficient space for strainers for easy installation, operation,

maintenance, inspection and replacement.

The strainer screen is manually cleaned by shutting down the line and removing the strainer

cap. For applications with heavier dirt loading, strainers can be fitted with a blow-off / drain

plug connection that permits the screen to be cleaned at a higher frequency without

removing it from the strainer body.

During installation, it is essential to ensure an accurate centering between flanges and in a

well aligned position so that the stress would not be acting on the strainer body. Inspect all

sealing surfaces to ensure gasket surfaces are free of defects (no nicks or cuts).

To provide for easier maintenance, the strainer should be located where the drain plug can

be removed. Additionally, ensure the drain or blow-off is located at the lowest position when

installed. If installed in the vertical position, the wye side of the strainer must be pointing

downward. If there is any space constraint on the installation on horizontal pipe line, where

the drain plug and cover not able to directly facing downward, turning the strainer clockwise

or counter clockwise is possible, within and not more than 45 degree from the right angle

downward. Ensure there is ample space at the wye side of the strainer for screen removal.

After installation and before pressurization of the system, the installation should be inspected

for adequate tightness to prevent leakage. Proper inspection at this time will minimize the

possibility of leaks after pressurization of the piping system.

On completion of the installation, strainer location, size, make, type, date of installation, and

other information deemed pertinent should be entered on permanent records.

Installation & Operation Manual

Strainer

3

Fivalco Ltd | info@fivalco.com | www.fivalco.com

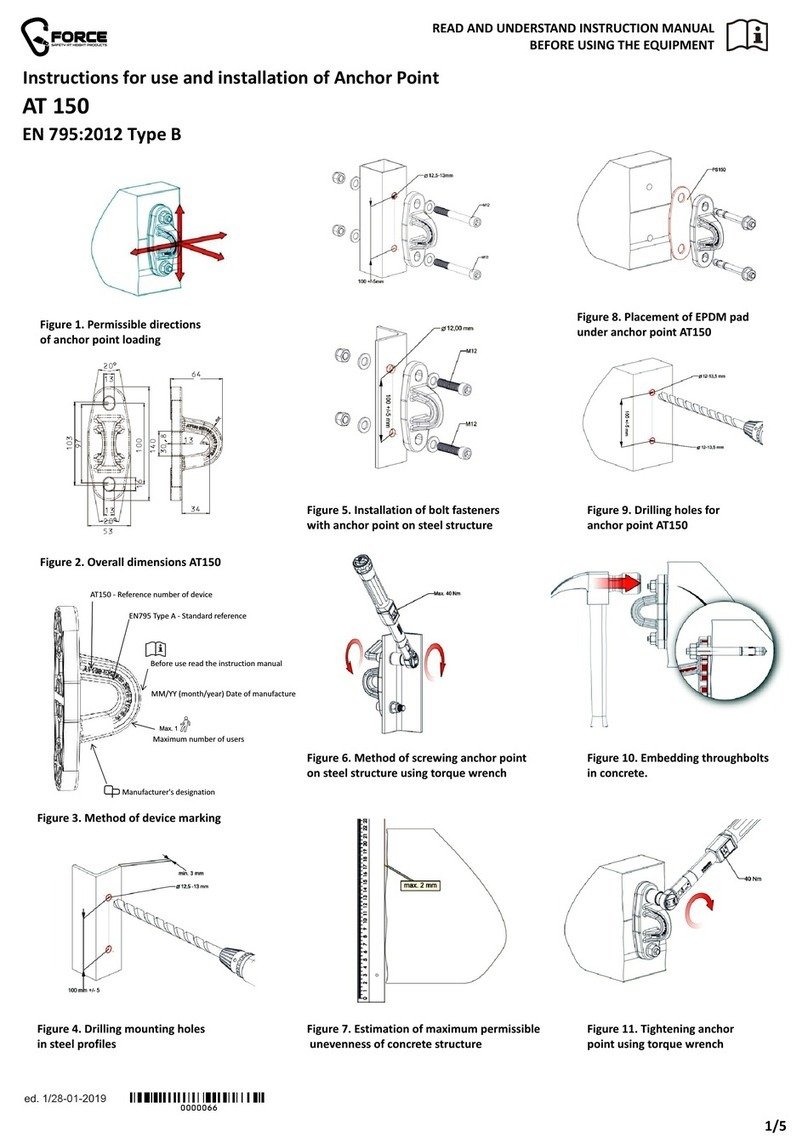

Mounting Position of a Strainer

Figure 1: Mounting position of a strainer. The drain plug of the strainer should be at the lowest position.

Bolts must be tightening in a crosswise pattern (see figure 2). Installer should ensure that the

flanges are well aligned and an even pressure on the gasket surface is applied.

Figure 2: Crosswise pattern for tightening or loosening bolts.

Installation & Operation Manual

Strainer

4

Fivalco Ltd | info@fivalco.com | www.fivalco.com

6OPERATION OF STRAINER

During normal use, the screen will become clogged with foreign matter, causing the

differential pressure to increase. Once the differential pressure has increased to an

unacceptable value, typically by 5 psi to 10 psi, it is time to clean or replace the screen. It is

not advisable to let the differential pressure increase beyond 10 psi. For maximum efficiency,

to determine when the screen needs to be replaced is to install pressure gauges on the inlet

and outlet side of the Strainer. The maximum acceptable pressure drop across the strainer

will indicate when the screen needs to be replaced. Screen size and construction determine

the maximum pressure drop a strainer screen can withstand.

7MAINTENANCE

If the strainer is installed according to our standard procedures, it is maintenance free.

The pressure differential across the strainer should be checked periodically to determine if

the screen needs to be cleaned or replaced. If the pressure differential goes unchecked and

the screen becomes completely clogged, the screen will break and require replacing.

Before removing the strainer’s cover, ensure that the media that is flowing in the pipeline is

known and any special handling precautions are understood. The pressure inside the vessel

must be reduced to atmospheric via suction or venting. Failure to do so may result in serious

bodily injury. Once the pressure is relief, remove the cover so that the screen can be removed

for cleaning. Avoid banging or hitting the screen to remove stubborn debris. It is

recommended to use high pressure water or air stream to clean the screen for perforated

screen. If the strainer is use for fuel, oil or other chemicals, solvent may be required.

For every 4-5 years, we recommend that you carry out a routine check of the strainer for

leaks at the sealing surface or the gasket. All seals will in the course of time be influenced by

air and sunshine, frequent and careful checks can reveal leaks.

8WARNINGS

The working pressure, temperature, suitable media of strainers must be accord with the

regulation of the illumination, or that maybe dangerous.

Prior to any maintenance work that requires disassembly make sure that the pressurized line

involved is isolated, depressurized and drained before starting any dissembled. Failure to do

so may result in sudden pressure release and subsequent severe injury or death.

If the pressure exceed regulation, the strainer maybe leak and the body maybe explode of

craze.

If the temperature is too high, the material maybe invalidation and the valve may be broken.

If the media does not accord with the regulation of the illumination, it may rot the body or

break the gasket / O-ring, the body may corrode and craze, the media may be leaked.

Installation & Operation Manual

Strainer

5

Fivalco Ltd | info@fivalco.com | www.fivalco.com

This manual suits for next models

7

Table of contents

Other fivalco Safety Equipment manuals