FIXATOR LM500+ User manual

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 1/16

Version : 44/16

INSTALLATION – USE

MAINTENANCE

Monitoring of updates

Date Description

03/11/2016 Creation

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 2/16

Version : 44/16

SUMMARY / PLAN

1

GENERALITIES ............................................................................................................................................................... 3

1.1

D

ESCRIPTION OF THE MACHINE

.................................................................................................................................... 3

1.2

G

ENERAL DESCRIPTION

. ............................................................................................................................................... 3

1.3

C

OMPLIANCE WITH GUIDELINES AND STANDARDS

;

COMMISSIONING

..................................................................................... 3

1.4

S

PECIFICATIONS

......................................................................................................................................................... 4

1.5

M

ACHINE LOGBOOK

, .................................................................................................................................................. 4

1.6

R

ECOMMENDATIONS FOR USE AND GENERAL SAFETY

......................................................................................................... 4

1.

A

NCHORING

.............................................................................................................................................................. 5

2

INSTALLATION AND USE ............................................................................................................................................... 5

2.1

I

NSTRUCTIONS FOR INSTALLATION

,

ASSEMBLY

,

COMMISSIONING AND USE

-

TRAINING

.............................................................. 5

2.1.1

Suspended installation............................................................................................................................................ 5

2.1.2

Installation with deflection ..................................................................................................................................... 5

2.1.3

Installation support on a basis ............................................................................................................................... 6

2.1.4

Reeving for lifting of load ....................................................................................................................................... 7

2.1.5

ower ...................................................................................................................................................................... 7

2.1.5.1

Hoist connection ............................................................................................................................................................. 8

2.1.5.2

Commissioning ................................................................................................................................................................ 8

2.1.6

Installation of cables for lifting ............................................................................................................................... 8

2.2

D

IAGRAMS AND SAFETY EXPLANATIONS

.......................................................................................................................... 9

2.2.1

Main dimensions .................................................................................................................................................... 9

2.2.2

Safety devices ....................................................................................................................................................... 10

2.3

D

ESCRIPTION OF THE WORK OR CONTROL STATION

.......................................................................................................... 10

2.4

N

ORMAL USE

.......................................................................................................................................................... 10

2.5

D

ECOMMISSIONING

.................................................................................................................................................. 11

2.6

W

ARNINGS ABOUT CONTRAINDICATIONS

...................................................................................................................... 11

2.

R

ESIDUAL RISKS

....................................................................................................................................................... 11

2.8

T

RANSPORTATION

,

HANDLING

,

STORAGE

...................................................................................................................... 11

3

MAINTENANCE - SETTINGS ......................................................................................................................................... 11

3.1

M

AINTENANCE OPERATIONS

...................................................................................................................................... 11

3.1.1

reventive maintenance ....................................................................................................................................... 11

3.1.2

Adjusting of the brake .......................................................................................................................................... 12

3.1.3

Lubricating a hoist cable ....................................................................................................................................... 12

3.2

T

ROUBLESHOOTING

.................................................................................................................................................. 13

3.3

S

PARE PARTS

........................................................................................................................................................... 13

3.4

D

ISPOSAL

............................................................................................................................................................... 14

3.5

N

OISE EMISSION

...................................................................................................................................................... 14

4

APENDICES .................................................................................................................................................................. 14

The original of this document is in French. No translation can replace the original.

Thank you for purchasing a FIXATOR product. In the following pages we give you details of instructions

allowing you to safely use and maintain your equipment in good working condition. Please read these

instructions prior to commissioning the equipment: no installation operation, use and maintenance should

be performed until this document has been fully understood. These operations must also be carried out by

clearly designated personnel suitably trained.

The following symbol will alert you to hazards to watch out for: .

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 3/16

Version : 44/16

1Generalities

This notice covers the use of winches LM type 461.

1.1 Description of the machine

The LM is a portable electric reeving hoist for

unlimited hoisting cable movement (check

instructions on the hoist plate: "Type 461").

The standard equipment includes:

- the unit with its carrying handle and the safety

hook; engine with main brake and protected by

thermal probe

- 2 travel end stopper

- 1 pendant control station (2,5 m) double insulation

IP 65 3 buttons: ascent, descent and emergency stop

(extension: 200 m maximum)

- male/female plug and cable power (0.50m)

- 1 manual

The LM winch cannot be used to lift or move

people.

1.2 General description.

Diagram of typical installation:

This winch is designed for the lifting and traction of

loads. It is intended for professionals involved for

work, such as in an elevator shaft or on building

facades. The winch uses one steel cable (hoisting

cable).

The drive system consists of a pulley whose throat

has a special profile, and in which the cable is tight

under the effect of the load by two articulated

rollers. This allows an unlimited run of the hoisting

cable.

This technical design ensures a great security

provided you follow the instructions given in this

manual.

Each device carries labels information and

instructions. Constantly make sure that all these

labels are in place and legible.

The LM winch must be used exclusively with

special lifting cable, to fully ensure the safety and

efficiency.

Before its expedition by Fixator, each hoist is tested

to 110% of its capacity.

Additional kits exist:

ref : 540155

ref : 461021

Extensions to the pendant control station (5G1) :

-15m : ref 540134

-30m : ref 540136

1.3 Compliance with guidelines and standards;

commissioning

This machine complies with the European

Machinery Directive 2006/42/EC.

It is manufactured under a quality process according

to EN-ISO 9001: 2015.

A test prior to initial commissioning and after each

maintenance or dismantle must be performed with a

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 4/16

Version : 44/16

static test coefficient of 1.25xWLL and a dynamic

test coefficient of 1.1xWLL.

1.4 Specifications

The LM500 winch has a working load limit of

500kg (WLL). It is displayed on the winch plate.

Type

070781

CMU / WLL (kg) 500 (1100lbs)

Motor P (kW) 1.1

Voltage (V) 230V-50/60Hz

I Nominal / start (A) @50Hz 7/21A

I Nominal / start (A) @60Hz 9/21A

Weight (kg) 32 (70lbs)

Dimensions (mm) 255x240x809

T° for use (° C) -10°C / +55°C *

Operating Speed (m/s) @50Hz 0.12 (7m/mn)

Operating Speed (m/s) @60Hz 0.14 (8m/mn)

Wire rope Ø and type Ø6.5 à 6.8 - 6x19

synthetic core

Minimum breaking load (kg) 2500 (5500lbs)

Upper limit switch Yes

Lower limit switch Yes

Service factor S3 60% 30cy/h

* Use between -20° and -10°C is possible

providing a gradual and uniform preheating

unloaded operation is carried out, then the load can

be applied as soon as the hoist reaches a T ° - 10°C.

1.5 Machine logbook,

The contents of the logbook of this machine are not

provided; it is up to the owner to create or acquire

one in which the following is noted:

- the name of the person in charge of

equipment

- operator names and dates / periods of use

- serial numbers of components

- the number of hours of use,

- the characteristics of the cables used

- the number of hours the cables are used,

- a record of incidents and actions taken to

remedy them

- forecast dates of periodic inspections and

record of actual dates of inspections

1.6 Recommendations for use and general

safety

Before using this equipment, ensure:

-that you read and understand this entire

manual

-that no obstacles will obstruct the required

motion

-that the periodic inspection has been

performed and recorded,

-that the electrical installation is designed and

protected according to current regulations

-that your material is stable and aligned, freely

with the load

-the load or machine movements will not trap

or crush you or other people; signal and block

access to the area under the load

-you can communicate with help in case of

need,

-that you have adequate lighting

ensure :

-every day the correct operation of the

mechanisms, brakes, and emergency stop

-periodically the electrical cables, limit

switches, structural elements and wire ropes

-regularly the presence of travel end stopper,

the presence of plates and safety instructions

(and their readability),

-safety of the suspension structure

-there is no accumulation of snow, ice, debris

or materials on the winch,

-that there are no obstructions on the façade or

in the shaft

-at the end of work, that the deactivation is

complete.

-If a charge is to be raised by multiple devices,

the installation of these must be preceded by a

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 5/16

Version : 44/16

technical review by a competent technician

and then conducted according to this study,

including to ensure the constant distribution

of the load in suitable conditions.

During the operations of lifting, up and down,

the user must constantly observe the load and the

free end of the cable to prevent any risk of collision.

The load must be constantly guided (EN14492-2) ;

otherwise the use of rotation-resistant wire rope is

necessary.

Check and apply local regulations concerning

the installation, use, maintenance and control of

lifting devices.

See also contraindications §2.6

1.7 Anchoring

Verify that the anchoring point is strong enough for

the effort to apply.

If the anchoring is not provided by FIXATOR each

anchor must withstand, without any deformation, up

to 2.5 times the WLL of the winch, that is 1250 kg,

and remain stable when subjected to this load.

(special case of reeving 2:1, the resistance must be

of 5 times the WLL, that is 2500kg ; see §2.1.4)

If the fixing of the unit must be in a dangerous place

for the operator, the safety precautions provided for

by the work’s regulation must be taken to exclude

any risk uncontrolled in this operation. It is perhaps

better in this case to implement the hoisting cable

into the device before the anchoring operation.

2Installation and Use

2.1 Instructions for installation, assembly,

commissioning and use - training

Installation and use operations must be performed

by personnel specially trained by the manufacturer

or its dealers, duly authorized by their employer.

Depending on your country, regulatory inspections

may be necessary.

Make sure you have:

- a sufficient length of special cable Ø6.5-6.8

mm

- an adequate length of supply cable and

suitable number of wires with suitable cable

section,

- Accessories you may wish to use

2.1.1 Suspended installation

It's the simplest mounting and the most common.

Device in suspension and direct traction or lifting.

The anchoring of the device must be done

exclusively by its hook and never by its handle.

There is no way to anchor the hook of the cable to

the fixed point to get the device moving on the

cable.

The hook of the machine must be placed in the

body of the attachment

point, so that this body is at

bottom of hook. The pawl

of safety of the hook must

close completely.

If a gene appears in the

articulation of the

apparatus with the body of

fixing hook, it is necessary

to interpose a sling of

appropriate capacity.

Check each element

of connection capabilities

to ensure your safety.

2.1.2 Installation with deflection

- Device suspended ; indirect traction or lifting.

This case requires a deflection pulley anchored to a

fixed point.

- Device on ground and lifting through a deflection

pulley.

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 6/16

Version : 44/16

The resistance of the pulley and its

anchorage must be calculated for a double effort of

the load.

2.1.3 Installation support on a basis

Use the optional ref 461021.

This type of installation requires special

precautions:

-The bearing surface on which the unit is

placed must be flat and horizontal.

-This surface must have a minimum Ø120mm

orifice for the passage of the two strands of

cable,

-The device must be positioned so that the

lifting wire rope, under load, does not rub

against the walls of the hole, and so that the

travel end stoppers on the wire rope can come

in contact with the switch levers.

-The device must be propped so that it will not

move on the support. (4 drillings Ø13

available)

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 7/16

Version : 44/16

-The surface on which the unit is placed in

support must have the necessary stability and

strength in regard of the safety of the

operation.

-The load must be in free suspension.

With this arrangement, never lift the load

without having placed it beforehand at the vertical

of the hoist.

2.1.4 Reeving for lifting of load

Use the reeving kit ref 540155.

This assembly allows you to double the capacity

(working load 990 Kg) of the device. In return, the

speed is decreased by half.

The LM must not be otherwise than with this

reeving kit assembled. Additional system must not

be added.

The reeving kit consists of an anchor carrier strand

and a reeving block with a hook and a spring.

The user should note that when reeving, the

required length of wire rope is at least twice the lift

height, plus at least 1 meter of apparent slack

strand.

The limit spring mounted on the lower pulley is

intended to replace the high limit stop.

A stop may still be placed on the loose strand to

serve as low end stopper.

In case of reeving, double the maximum load

to be taken into account for the calculations of

security.

NOTA : take care to mount the pulley block so that

its limit spring is located on the cable between the

pulley and the entry in the hoist (see figure).

Check the triggering of your travel limit

switch before use; a repositioning of the stoppers

may be necessary depending on the configuration of

job.

Check the capacity of the anchoring points.

When operating with the reeving system, especially

the operator will ensure that the load is not turning

on itself, to avoid tangling the three strands of the

cable (two strands loaded and the slack side).

Stop immediately if the loose strand comes to

tangle with the other strands.

2.1.5 Power

The installer must ensure that the power supply is

compatible with the specification of the winch.

The power supply must be protected

upstream by a 30 mA differential switch. The

installation must be in accordance with EN 60204-

1. Power outlets must be calibrated to 16A.

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 8/16

Version : 44/16

The power cable to the Liftho control box must be

flexible cable (Class 5). Beyond 30m, it must be

held in place by a suitable anchorage clamp.

EXTENSION SECTION (mm²) at 230V

Type : 0-50m 50-80m 80-

140m 140-

200m

3 wires

P+N+T 2.5²

13AWG

4.0²

11AWG

6.0²

9AWG 10.0²

7AWG

If the LM winch is powered by a generator, check

that it delivers at least the voltage and power

required at the start of the winch (min 6kVA).

2.1.5.1 Hoist connection

-Connect the button box to the socket on the

winch.

-Connect the main power plug.

2.1.5.2 Commissioning

-Unlock the emergency stop if

necessary

-Press the UP button to lift or pull the

load

-Press the DOWN button to lower the

load

At any time, in case of imminent danger or

need, press the Punch red button to stop any

movement of your hoist.

2.1.6 Installation of cables for lifting

Use protective gloves when handling wire

rope.

Check the condition of the cable and its length

(working height + 2m).

Check the condition of the hook and safety latch.

Avoid the formation of loops when unwinding..

The end of the cable should be clean and sharp.

pour votre sécurité, n’utiliser que des câbles

FIXATOR

Put the end stopper on the wire rope (the spring

being directed to the winch). Block with an Allen

key.

Insert the end of the wire rope through the bottom

opening A. press the UP button on the pendant

control while pushing the wire rope so that it

engages in the throat of the pulley.

When the rope come out through hole B, continue

the movement so as to obtain a sufficient length of

wire rope.

PS : a second stopper is provided to stop the

descent; position the spring on the side of the

winch:

A B

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 9/16

Version : 44/16

Check the operation of the limit switches of the

winch.

For your safety, use only FIXATOR cables.

Ensure that the cable above the hoist (taut) does not

touch surfaces or angles.

Ensure that the outgoing winch cable (slack) is free.

Do not let the loaded rope become slack if the load

is not stable, resting on a strong enough support.

2.2 Diagrams and safety explanations

Installation and use operations must be

performed by personnel specially trained by the

manufacturer or its dealers, duly authorised by their

employer.

The maximum capacity of the hoist (WLL) should

be the basis for calculations of anchor strength.

2.2.1 Main dimensions

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 10/16

Version : 44/16

2.2.2 Safety devices

-A main brake acts on the engine in case of

power supply failure

-An upper limit switch sensor stops lifting

when the spring touches the plate.

-A lower limit switch sensor stops lowering

when the spring touches the plate.

-An electrical emergency stop placed on

pendant control acts immediately and stops

the winch to the ascent and the descent.

-Mechanical locking prohibiting the

simultaneous action of the up and down

commands.

-Electrical protection of the pendant control :

class 2.

-Fuse protecting the command, in the electrical

box.

-Hooks with safety latch.

The 230V single-phase motor is protected against

excessive warm-ups by a probe inserted into the

coil. This probe prohibits operation by interrupting

the control circuit as long as the temperature of the

coil is not back to an acceptable value. In case of

intensive work or high duty, we suggest to allow a

15 minutes break every 45 minutes of work to avoid

overheating.

2.3 Description of the work or control station

"Up" and "down" hoist movements are controlled

from the pendant control.

Never stand under the load.

In case of a command error, wait for a complete

stop of motion before performing another

command. The control buttons are held type

buttons.

Limit stops are not operating devices but safety

devices. They should therefore not be used

voluntarily but only serve as shutoff devices in case

of involuntary exceedance of the expected travel.

Never stay or work under load. If necessary, have a

barrier of security on the floor around the area at the

vertical of the load.

Avoid heavy slipping: Wait for a complete

stop of your installation before resuming

movement.

Check regularly that no obstacle is located along the

path of movement (above and below the load).

2.4 Normal use

This hoist is designed for lifting loads.

It is designed for professionals involved,

for example, in work in elevator shafts or

on façades.

Press on «» to lift and on «» to lower.

Release the buttons to stop the movement.

If it is not stopped, press the Emergency

Stop. If it is not working, remove the main

plug and have your hoist maintained.

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 11/16

Version : 44/16

2.5 Decommissioning

After work, or during an prolonged shutdown, or if

preventive maintenance tests (see §3) are not

satisfactory, put your load on the floor or a secure

access level. Disconnect the hook from the load

when it is resting stable on a fixed and solid

support.

The device can remain attached provided that it is

protected from the weather and in a dry place.

Snap your emergency stop.

Unplug and store your pendant control box.

Store your power supply cable.

2.6 Warnings about contraindications

It is forbidden to use this product:

-if you are not a trained professional

-to exert a force or lift a load greater than

500kg if it is not described in this manual,

-to lift people,

-in harsh conditions (extreme or corrosive

environment, high magnetic fields, etc.)

-in potentially explosive atmospheres

-to perform work on energized power lines,

-to carry loads themselves dangerous (molten

metals, acids, bases, radioactive material,

fragile loads etc)

-in combination with other lifting equipment if

it is not listed in this instruction manual,

-with loads with a wind surface area >2 m² if it

is not listed in this manual,

-with a wireless remote control system not

mentioned in this manual

-in the event of specific risks (wind> 14 m / s,

T ° <-10 ° C or> 55 ° C, storms etc)

-with worn or deformed cables

-with lubricated cables with products

containing bisulphite or MoS2 (Molykote ®,

etc)

-To apply a load on the loose strand of the

hoist.

-To use the wire rope as a means to sling the

load

2.7 Residual risks

The use of cable damaged or not suited to the

device is the major risk of accident and failure.

Check that your equipment has not been

subject to vandalism, theft, or damage.

Never disable the safety features.

Never swing a load voluntarily.

Do not block a control.

In case of continuous operation for more

than 30 ', the surface temperature of the motor can

begin to rise significantly.

2.8 Transportation, handling, storage

To transport your machine from one site to another,

remove the cables from your hoist.

Store the various components of your equipment in

a clean and dry place.

3Maintenance - Settings

Maintenance operations must be performed

by personnel specially trained by the manufacturer

or its dealers.

3.1 Maintenance operations

LM hoists must be reviewed at least once a year and

every 100h. In harsh environments (sandblasting,

marine, back and forth operation at full load, doubts

about the proper use etc) a higher frequency of

verifications may be required.

Load lifting winches are intended for a limited

lifetime; beyond that, a return to factory is

imperative.

For the hoist LM type 461, the ranking is A2.

In some countries, periodic audits and reviews of

commissioning are mandatory.

3.1.1 Preventive maintenance

These operations must be performed by a

competent person trained by FIXATOR or its

dealers. The FIX022 manual details these annual or

control operations.

Check:

Daily :

The quality of your anchors and of the 2 hooks

(latch).

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 12/16

Version : 44/16

The good clamping of the travel end stoppers on

your cable.

The good general condition.

Monthly :

The proper functioning of the safety devices

(emergency stop, limit switches, brake).

The overall proper functioning by performing a full

movement at the rated load.

Every year and every 100h :

Check the groove pulley.

Check the bearings, rudder, gear...

Check the motor brake.

Control each security (cf §2.2.2) at the rated load.

Clean and grease the gears (e.g. BIMO EP or

Kluberplex AG11-462)

3.1.2 Adjusting of the brake

Remove the cap (5) that is on the ventilator lid (1).

Increasing the braking: turn the brake screw (6)

progressively counter clockwise and check that the

brake does not slide during the lowering.

Decreasing the braking : turn clockwise.

TO RELEASE THE BRAKE SYSTEM:

If necessary, it is possible to unlock the brake

manually, by pressing the (8) pivot. After each

operation, a load test must be performed.

FIXATOR or its dealers can train your staff for the

maintenance of your winches.

For your safety and to benefit from the full

guarantee of the manufacturer, use only original

FIXATOR parts (ask the complete list of spare

parts).

3.1.3 Lubricating a hoist cable

The hoisting cable must be regularly greased or

lubricated with Teflon.

For this, use for example:

- IGOL SHP 50 grease

- A lubricant spray PRO-LUBE Teflon.

Never use products containing bisulphite or MoS2

(Molikote).

Only cables recommended by FIXATOR provide

safe hoist operation. The removal’s criteria to

follow are those of the ISO4309.

The diameter should not be reduced by more than

10% (for wire rope Ø 6.5-6.8 mm) : min 6.1mm

The cables must be replaced in the following cases:

-More than 10 wires broken over a length of

20 cm for wire rope Ø 6.5-6.8 mm.

-“Basket” deformation or rupture of one of the

cable strands.

-Cable crushed, unravelling.

-Considerable oxidation

When using a plastic return pulley, they must be

replaced once they have been used with cables

having at least one broken wire.

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 13/16

Version : 44/16

3.2 Troubleshooting

Faults

observed Potential causes of the fault Remedies

The motor

does not rotate The temperature sensor is activated

The motor has a mechanical fault

The contactor in the hoist is out of order or

disconnected

The limit switch is activated

Fault in the control circuit

Fault in the power circuit

Power supply fault

Current escape to earth

Batteries of the remote control out-of-order

Wait for a drop in temperature

Check the motor

Reconnect or replace it

To be checked by a competent person

Check

The hoist does

not lift The grooved pulley is worn or dirty

The condenser is disconnected or out of

order

The temperature sensor is activated

The motor is blocked

The contactor on the hoist is out of order or

disconnected

The limit switch is activated

Fault in the control circuit

Fault in the power circuit

Verification

Verification

Wait for a drop in temperature

Verification (maintenance)

Reconnect or replace it

To be checked by a competent person

The hoist does

not lower The temperature sensor is activated

The motor is blocked

The contactors in the hoist are off or

disconnected

Error in the control circuit

Error in the power circuit

Wait until it cools

Check the motor

Reconnect or change

To be checked by a competent person

The motor is

powered but

stops (snoring

sound)

The capacitor is disconnected or out of

service (for single phase hoist only)

The motor is blocked

Power cable section too thin

Verification

Verification (maintenance)

Replace the power cable

The hoist does

not lift the

load

The groove pulley is worn or dirty

The capacitor is disconnected or out of

service (for single phase hoist only)

The temperature sensor is activated

Power cable section too thin

The wire rope is inserted in wrong way

Verification

Verification

Wait until it cools

Replace the power cable

Verification

Current too

high The brake is out of service

The capacitor is disconnected or out of

service (mono phase hoist only)

The motor is blocked

Verification

Reconnect the capacitor or change it

Verification (maintenance)

Slow slide The groove pulley is worn or dirty

The brake is worn

The adhesion system is worn or dirty

Verification

Adjust the brake

Verification

3.3 Spare parts

Use only FIXATOR original spare parts.

Note and send the information listed on the plate

shown below before requesting parts.

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 14/16

Version : 44/16

Main wear parts and estimated replacement

frequency (highly dependent on actual usage) :

Grooved pulley ref 462001 100h

S/A Travel limit ref 461022 400h

Pinion shaft ref 461024 /

Pressure system ref 461023 500h

Travel end stopper ref 462030 /

Capacitor ref 540144 /

Pendant control ref 462020 /

Motor cap ref 462021 /

Fuse ref 244612 /

3.4 Disposal

Disassembly and disposal of the hoist must be in

accordance with the current regulations in force.

Electrical components, gear oils, greases, etc ...

should be separated and sent to the appropriate

treatment locations.

3.5 Noise emission

The A weighted sound pressure levels at

workstations is less than or equal to 70 dB (A)

4Apendices

Installation examples, wiring diagrams, component

instructions …

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 15/16

Version : 44/16

INSTRUCTION MANUAL

Electrical winches LM500+

Réf

:

181300020

4

Page : 16/16

Version : 44/16

The original of this document is in French, no translation can replace it.

P.A. 8, rue du Bois Rinier - B.P. 10041 – 49181 ST BARTHELEMY D’ANJOU (France)

TEL : + 33 (0) 2 41 31 17 00 – FAX : + 33 (0) 2 41 31 17 10

Other manuals for LM500+

1

Table of contents

Popular Chain Hoist manuals by other brands

HADEF

HADEF 20/94 AFR manual

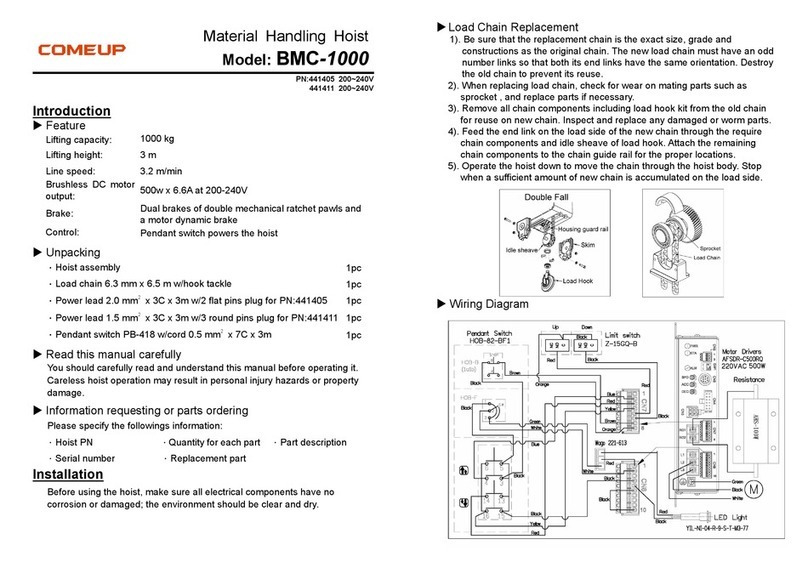

Comeup

Comeup BMC-1000 quick start guide

Stagemaker

Stagemaker SR05 user manual

Sievert Crane & Hoist

Sievert Crane & Hoist CM BANDIT Operating, Maintenance & Parts Manual

IMER

IMER ES 150 Operating, maintenance, spare parts manual

J. D. NEUHAUS

J. D. NEUHAUS PROFI 6 Ti Customer's operating and assembly instructions

Ingersoll-Rand

Ingersoll-Rand 7700-E Series Operator's manual

MODE

MODE M4 user manual

J. D. NEUHAUS

J. D. NEUHAUS PROFI 25TI Original operation and assembly instructions

Verlinde

Verlinde STAGEMAKER SL10 508 M2 A D8+ manual

Gude

Gude 55103 Translation of original operating instructions

SKF

SKF LINCOLN 84827 Series User and maintenance instructions