flakt woods EQKR ReCOOLER HP Guide

Content Page

EQKR ReCOOLER HP

Heat-pump with heat recovery 1

Safety directions 2

Technical data 3

Product description 4

Description of the functions 5

Safety instructions 6

Operating and care 6

User interface 7

Maintenance 8

Heat-pump with heat recovery

AIR COMFORT

AIR TREATMENT

9568 GB 2015.08.11

AIR COMFORT EQKR ReCOOLER HP

» MAINTENANCE

Maintenance 2

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

EQKR ReCOOLER HP

SAFETY DIRECTIONS

Important!

– The unit must NOT be used for purposes

other than as a reversible heat pump unit.

– The unit’s Operating & Maintenance

Instructions must be studied carefully

before starting/operating/servicing/

maintaining/scrapping the unit.

Keep these instructions in a safe place

for future reference!

– All service and maintenance must be

carried out by certified personnel.

Service/maintenance of the refrigerant

system must only be carried out by an

accredited company and certified

personnel wearing required protective

equipment (gloves and protective eye-

glasses).

– Lock and tag the heat pump prior to

performing service on the unit.

– Do NOT stand on the heat-pump unit!

– Use only genuine spare parts for

maintenance!

– Installation of units with split casing is

to be performed only by certified refri-

gerant technicians.

Failure to comply with above terms and conditions can

result in serious injury and will void the warranty.

COMPULSORY DECLARATION AND RECURRING

INSPECTION

Compulsory declaration

This product contains refrigerant R410A which is a flourinated

greenhouse gas. The European Union is committed to reducing

emissions of such gases. Ensure that you are fully aware of

your local regulations and that they are complied with.

Recurring inspection

Recurring inspection, i.e. leakage inspection of the refrigerant

system must be carried out at least once annually by certified

personnel (normally a refrigeration service company), see

“Maintenance”.

Maintenance 3

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

EQKR ReCOOLER HP

TECHNICAL DATA EQKR ReCOOLER HP

Table above shows data for current ratings and refrigerant quantities for ReCooler HP delivered with eQ Master.

eQ size 3x400 VAC Operating current (A)

(without electric heater)

3x400 VAC Operating current (A)

(with electric coil)

Refrigerant charge (kg) Oil / Circuit

Circuit 1 Circuit 2 Circuit 3 Total (l)

8 22,1 22,1 4,9 4,9 0,9

11 14,3 18,7 6,9 6,9 1,9

18 17,1 26,2 9,8 9,8 1,9

23 20,9 32,4 16,4 16,4 1,9

32 21,1 39,9 21,5 21,5 1,9

41 33,8 53,7 13 13 26 1,9

50 41,7 65,4 14,3 19,5 33,8 1,9

72 61,8 93 13,5 13,5 13,5 44,5 1,9

Maintenance 4

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

EQKR ReCOOLER HP

PRODUCT DESCRIPTION

The EQKR ReCooler is an integrated reversible heat pump

providing both heating and cooling. It consists of a rotary heat

exchanger and a Heat-pump unit. The ReCooler Heat-pump

has an independent control unit with heating-, cooling- and

thermal wheel demand supplied via an external control

source.

REFRIGERATION SYSTEM

The Reversible Heat-pump unit in the ReCooler is designed for

external air temperatures:

• Cooling+20to+40°C

• Heating,withelectricalheater+20to-20°C

• Heatingwithoutelectricalheater+20to-15°C

ROTOR UNIT

The rotor unit in the ReCooler is designed for heating and cool-

ing air by utilising the temperature differences in the outdoor

air and extract air. The rotor operates to recover energy from

the extract air in combination with the heat pump unit.

OPTIONAL ELECTRIC DEFROSTING COIL

The defrost electrical heater is mainly used to shorten defrost

cycle time. It’s also used as an additional heater when evapo-

rationtemperatureislow(<-21°C).Theelectricalheaterinclu-

des two thermal protectors:

• Anautoreset

• Amanualreset

1. Outdoor air

2. Supply air

3. Extract air

4. Exhaust air

5. Rotary heat exchanger - service hatch

6. Compressor

7. Frequency inverter for compressor

8. Drainage

9. Control system for the ReCooler

10. 4-way valve in wrong position

11. Main switch disconnector

12. Optional – Electrical heater

13. Cable glands

14. Electronic expansion valves

15. Handheld terminal for the ReCooler

3

5

13

11

14

14

10

12

15

1

2

4

6

7

9

8

8

Maintenance 5

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

EQKR ReCOOLER HP

DESCRIPTION OF THE FUNCTIONS

Size 008-032 1 circuit

Size 041-050 2 circuits

Size 072 3 circuits

Pos Total Component

1:1-3 1 Supply air coil

2:1-3 1 Exhaust air coil

3:1-3 1 4 way valve

4:1-3 1 Compressor

5:1-3 1 Liquid separator

6:1-3 1 Reciever

7:1-3 1 Filter dryer

9:1-3 1 EEV 2

10:1-3 1 EEV 1

11:1-3 1 High pressure sensor

12:1-3 1 Low pressure sensor

13:1-3 1 Suction gas sensor

14:1-3 1 Liquid temperature sensor

15:1-3 1 Discharge gas sensor

16:1-3 1 Low pressure service connector

17:1-3 1 High pressure service connector

18 1 Defrosting pressure sensor

19 1 Rotor

20 1 Electrical heater

GT6 1 Automatic thermal protection

GT7 1 Manual thermal protection

18

18

Room

Cooling mode

Heating mode

20

19

VVX

GT6 GT7

2:1-3

1:1-3

3:1-3

15:1-3

GT12:1-3

GT13:1-3

GT16:1-3

4:1-3

5:1-3 9:1-3

7:1-3

14:1-311:1-317:1-3

6:1-3

10:1-3

Room

Maintenance 6

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

EQKR ReCOOLER HP

SAFETY INSTRUCTIONS

LIFTING

Because of its design, the centre of gravity is offset towards

the inspection side. This must be taken into account when

lifting the unit. The unit should first be lifted slightly, and then

inspected to ascertain that it does not tilt or appear unstable

before being lifted higher.

DUTY OF NOTIFICATION AND IN-SERVICE

INSPECTION

Duty of notification

If the amount of refrigerant in a unit exceeds 10 kg the

supervisory authorities, generally the environmental health

department, must be informed. This information must be

provided well in advance of installation. More information

about this is contained in local refrigerant legislation.

Leak tracing during installation and in-service inspection

A leakage inspection must be carried out yearly on EQKR

008-072. This conforms to the EU regulation on fluorinated

greenhouse gases 517/2014.

Important!

The unit must be commissioned by

authorised personnel.

Important!

The unit’s centre of gravity is not in

the middle of the unit.

OPERATING AND CARE

MAIN COMPONENTS

A control panel is installed in the service section of the cooling

unit and includes the following components:

– Main electrical panel disconnect switch

– Miniature circuit breaker

– Control unit with display

COMPONENT DESCRIPTION

Control unit (KR1).

Microprocessor-based, programmable electronic controller.

MINIATURE CIRCUIT BREAKER

Automatically operated electrical switch designed to protect

an electrical circuit from damage caused overload or short

circuit.

MAIN ELECTRICAL PANEL DISCONNECT SWITCH

The disconnect switch is used to turn on/off power to the Re-

Cooler heat pump unit.

Always lock and tag the unit prior to performing any mainte-

nance or servicing work.

ELECTRICAL CONNECTIONS

Check the electrical schematics for additonal information with

regards to external connections (page 10).

Important!

Always read the safety directions on page 2

prior to beginning any work!

Warning!

The circuit breaker does NOT isolate

the power supply to the entire cooling unit!

Therefore always open and lock the main

switch before you begin any work on

the cooling unit.

Maintenance 7

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

EQKR ReCOOLER HP

PGD1 HUMAN MACHINE INTERFACE

The ENTER button is used to scroll through the list of

available languages and the ESC button is used to

confirm the users selection.

The home screen shows the following information:

– Circuit that the display is connected to

– Operating mode (Cooling/Heating)

Status:

– Standby

– Start phase

– Unit running

– Start delay

– Defrost

– Alarm

& etc.

The current example shows:

– Compressor speed demand sent from external

control system: 75 %

– Current rotation speed of the compressor: 35 %

– Current speed of Rotary Heat Exchanger: 100 %

This screen displays information related to the current

status (operation mode) of the coils (condensing/eva-

porating) and whether the AHU is configured with

supply air in the upper or lower level.

Maintenance 8

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

PGD1 HUMAN MACHINE INTERFACE

EQKR ReCOOLER HP

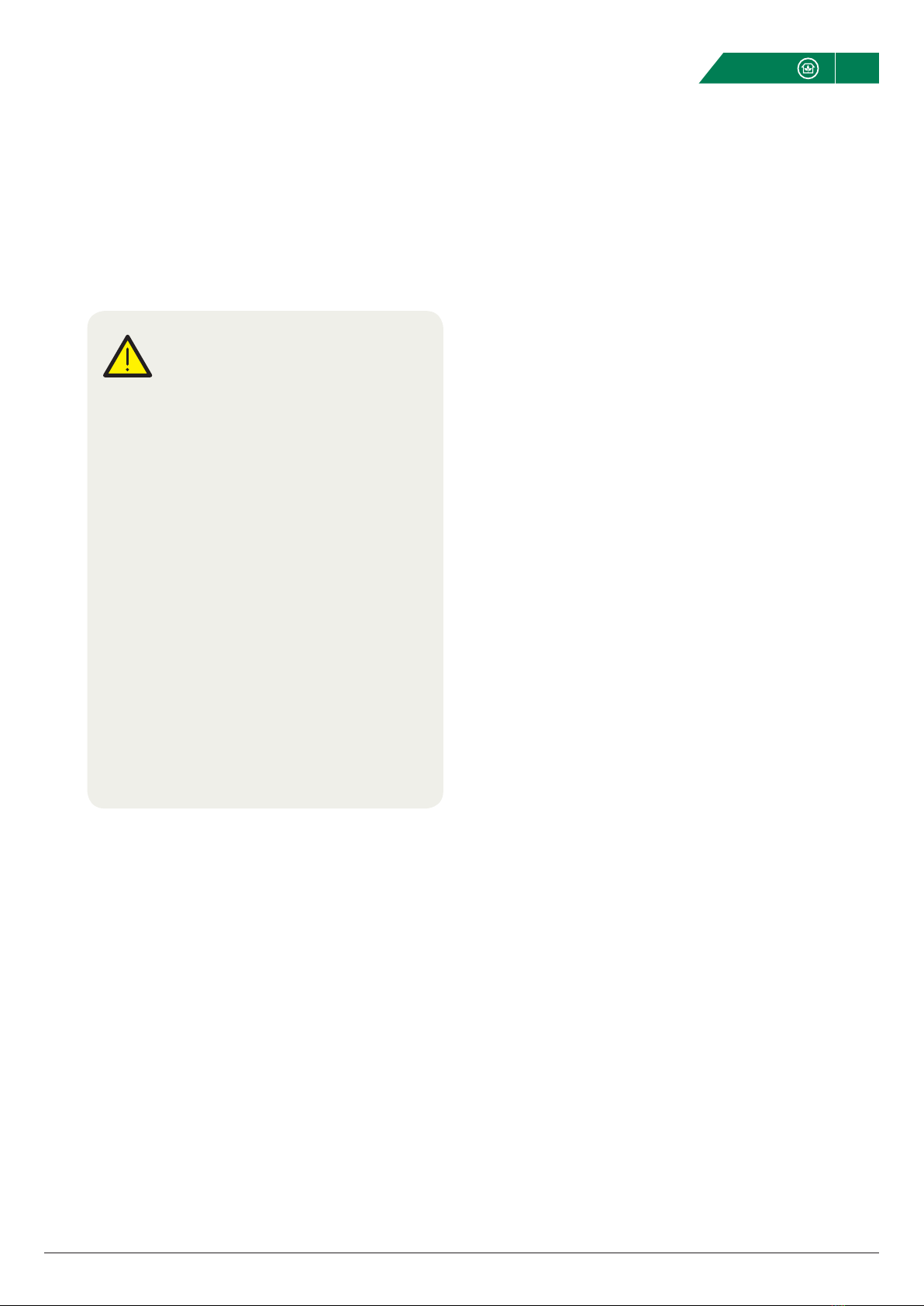

Temperature and pressure values.

Superheat and sub-cooling.

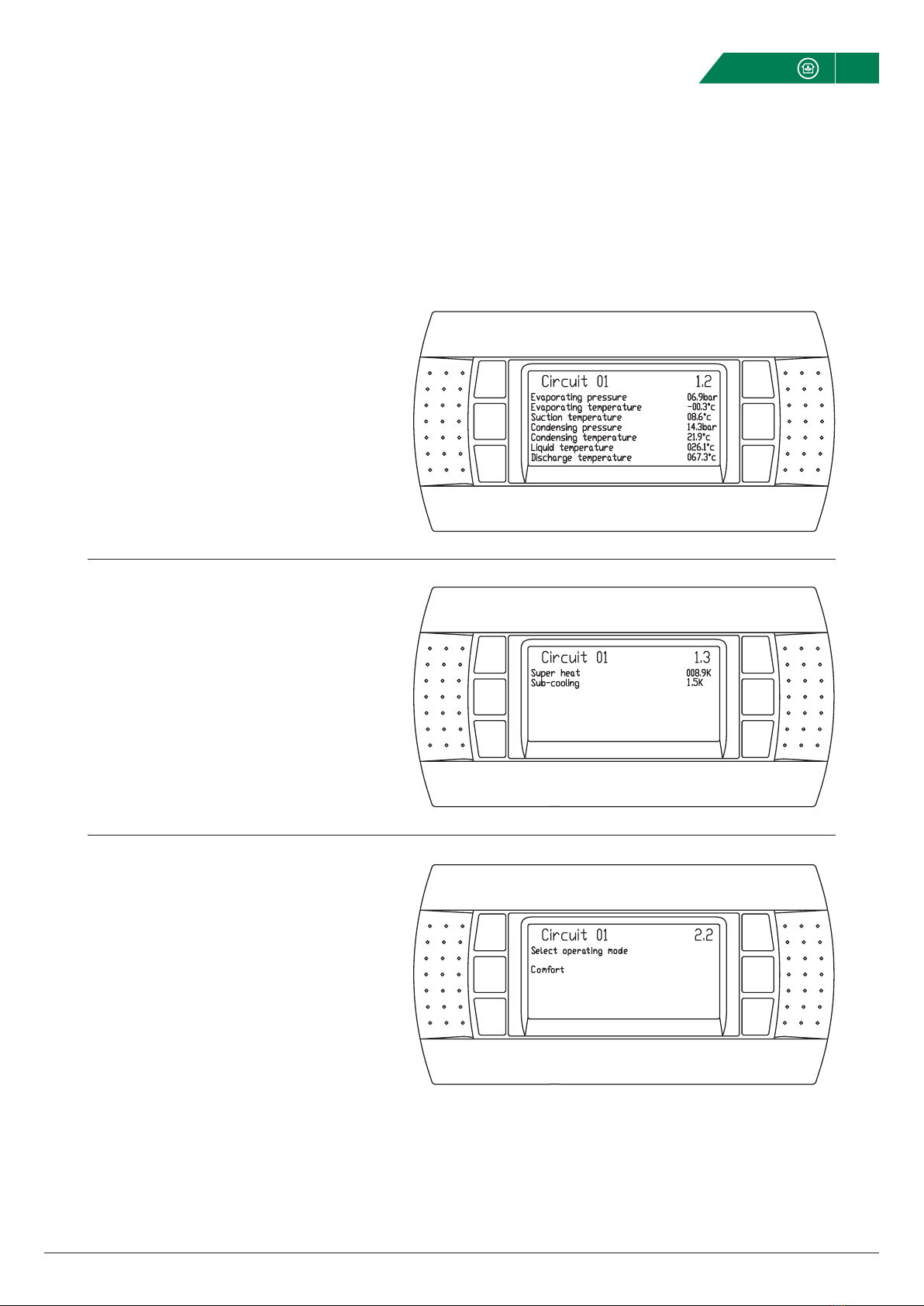

This function is activated ONLY when the heat pump is

controlled via Analog control.

Default setting of the ReCooler HP unit.

1. At start-up, the rotating heat exchanger speed will

decelerate when the demand compressor speed is

less than the actual compressor speed.

2. With low demand and the compressor at its lowest

speed, the rotating heat exchanger will decelerate.

Maintenance 9

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

PGD1 HUMAN MACHINE INTERFACE

EQKR ReCOOLER HP

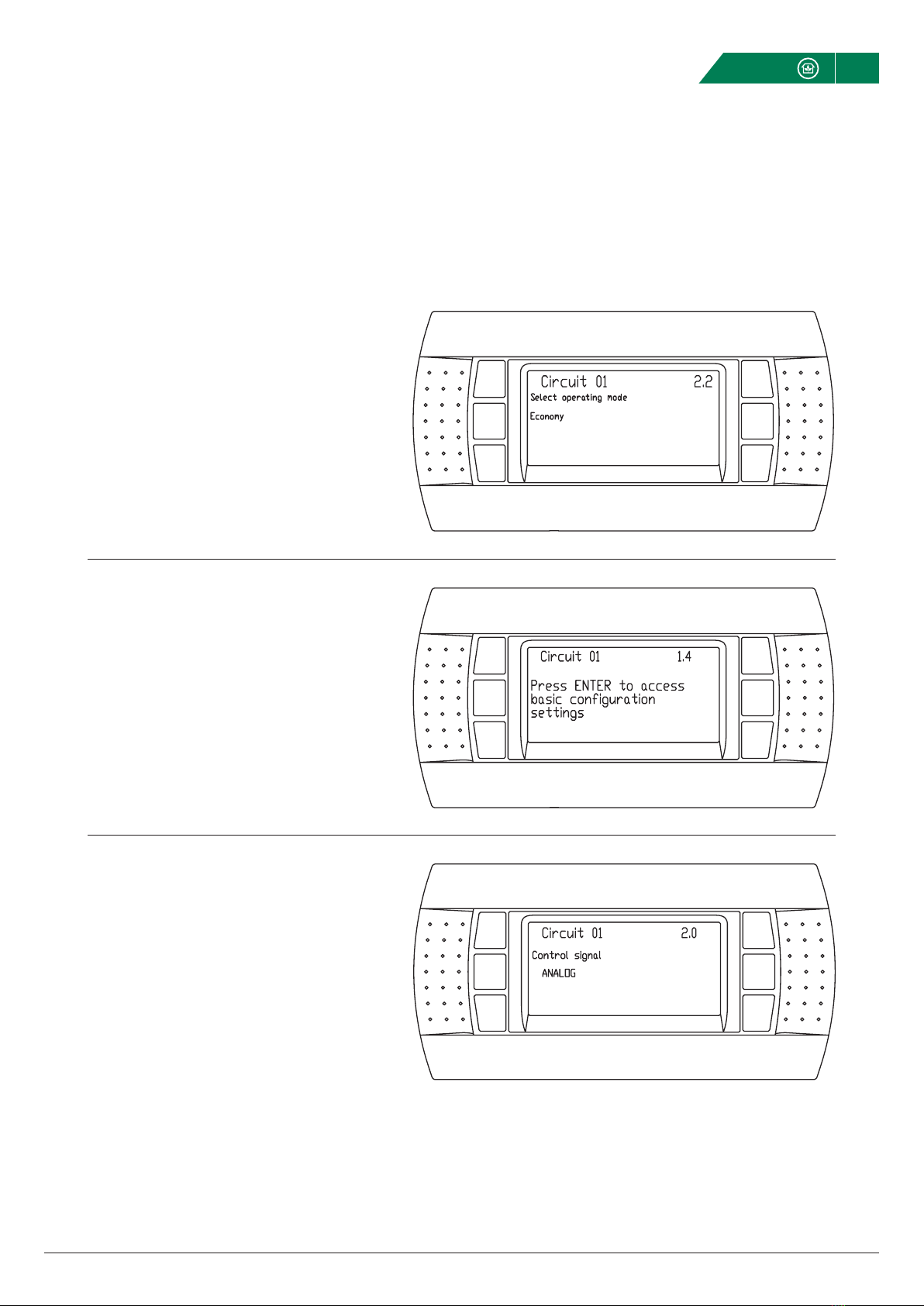

When the unit is running in economy mode, the rotating

heat exchanger is always first in the heating sequence and

only begins to decelerate when the compressor is off.

Access to additional basic configuration settings.

Used to select the heat pump control method

(Analog/Modbus),

Maintenance 10

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

EQKR ReCOOLER HP

PGD1 HUMAN MACHINE INTERFACE

Activating quick start will bypass the normal

compressor start up sequence.

Software information of the system.

Maintenance 11

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

EQKR ReCOOLER HP

MAINTENANCE

INSPECTION/MAINTENANCE

Regular inspection and maintenace in accordance with legi-

slation in force must be carried out by a certified refrigeration

technician.

INSPECTION

To be carried out by the owner/user once a week.

Check the following:

1. Indicated alarms

2. Abnormal noise/vibrations

3. Leakage

4. Corrosion, wear and tear

5. The interior of the unit, light fittings

MAINTENANCE

To be carried out by a certified refrigeration technician at least

once each year.

Check the following:

1. Evaporation/condensation temperature

2. Discharge temperature

3. Expansion valves

4. Safety equipment

5. Cooling and heating capacity

6. Unit system test

7. Electrical equipment

8. Coils, drip tray and the drainage system

9. Air filter

Important!

Always read the safety directions on page 2

prior to beginning any work!

RECURRING CHECKS

Must only be carried out by a certified refrigeration technician.

Inspect the system at least once every 12 months and maintain

a journal.

Check the following wherever applicable:

1. Piping

2. Inspection to detect refrigerant leakage

3. Check for abnormal vibrations

4. Check to detect possible corrosion

5. Whether filling with additional refrigerant is needed

6. Check to detect possible oil leakage

7. Safety equipment

8. Connection joints/Seals

DISMANTLING

When dismantling (scrapping) this type of unit, the refrigerant

and compressor oil must unconditionally be collected and

contained for destruction/recycling.

SPARE PARTS

Spare parts can be bought via local cooling suppliers. Contact

your local Fläkt Woods office for information regarding com-

ponents that need to be replaced.

Table of contents