flakt woods FC102 User manual

AIR COMFORT

Content Page

Safety instructions 2

IT system 3x230VAC 2

Connections 3

Control unit (LCP) 4

Manual operation 4

Reverse the direction of rotation 4

More information 4

Wiring diagram 5

Basic configuration 6

PID regulation 7

AIR TREATMENT

9325 GB 2016.09.16

AIR COMFORT

» INSTALLATION AND MAINTENANCE

FREQUENCY CONVERTER

FC102 (QUICK GUIDE)

Installation and maintenance 2

Fläkt Woods 9325 GB 2016.09.16 Specifications are subject to change without further notice

FREQUENCY CONVERTER FC102 (QUICK GUIDE)

SAFETY INSTRUCTIONS

• Check that the frequency converter is correctly connected

to earth.

• Do not pull out the mains or motor contacts or other power

connections when the frequency converter is connected to

the power supply grid.

• Protect the user from mains voltage.

• Protect the motor against overload in accordance with

national and local regulations.

• The leakage currents to earth exceed 3.5 mA, see Design guide.

• The [Off] button is not an isolator switch. It does not discon-

nect the frequency converter from the mains.

WARNING!

Warning high voltage

The frequency converter is subject to highly

dangerous voltages when it is connected to

the mains. Incorrect installation of the motor

or frequency converter can lead to material

damage, serious personal injury or death.

Follow the instructions in this manual as well

as local and national provisions and safety

regulations.

WARNING!

Discharge time!

Frequency converters have DC bus capacitors

that can hold a charge even after the mains vol-

tage has been disconnected. Prevent electrical

hazards by disconnecting the mains voltage,

disconnecting permanent magnet motors and

DC bus supplies, including battery backup, UPS

and DC bus connections for other frequency

converters. Wait until the capacitors have fully

discharged before carrying out maintenance or

repairs. Read more about the discharge waiting

times in the table below. Starting to service or

repair the unit immediately after cutting the

power supply, without waiting for the specified

period, can lead to death or serious personal

injury.

TAKE CARE!

Residual current device:

This product can cause a direct current in

the protective earth conductor. When using a

residual current device as additional protec-

tion, use only a type B residual current device

(delayed) on the input side of this product. See

also Danfoss application note for the MN90G

RCD.

The protective earthing of the frequency

converter and the use of RCDs must always

follow national and local regulations.

TAKE CARE!

IT system (3x230VAC)

When installing the FC102 on an isolated

system (IT system, 3x230VAC) set parameter

14-50 to [0] Off.

Press [Main Menu] twice. Navigate using

the [▲] [▼] and [OK] buttons until parameter

14–50 is displayed (select 14–**, then 14–5*

and lastly 14–50). Set this parameter to [0] Off.

WARNING!

Installation at heights

For installation at height, contact Fläkt Woods

regarding PELV.

Voltage

(V)

Output range

(kW)

Minimum waiting

time (min)

200 – 240 1.1 – 3.7 4

200 – 240 5.5 – 45 15

380 – 480 1.1 – 7.5 4

380 – 480 11 – 90 15

Installation and maintenance

3

Fläkt Woods 9325 GB 2016.09.16 Specifications are subject to change without further notice

FREQUENCY CONVERTER FC102 (QUICK GUIDE)

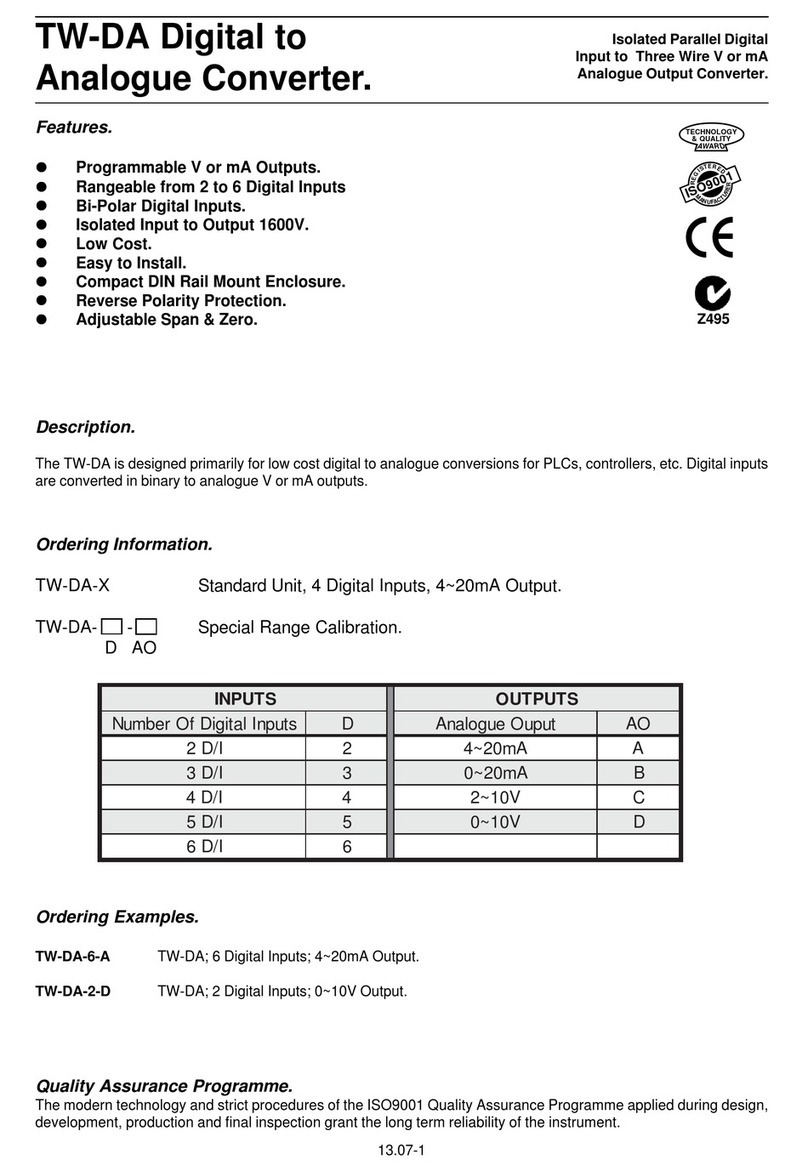

CONNECTIONS – PRINCIPLE IMAGE

1 Control unit (LCP)

2 RS 485 serial bus

3 Analogue I/O

4 LCP contact

5 Analogue switches

6 Cable support/ PE earth

7 Earthing plate

8 Earth clamp

9 Shielded cable earth clamp and cable

support

10 Motor connection

11 Relay 1

12 Relay 2

13 Brake and load distribution terminal

14 Mains connection

15 USB

16 Serial bus, terminal switch

17 Digital I/O and 24 V

18 Cover panel

1

23

4

5

6

7

8

9

10

11

12

13

14

8

15

16

17

18

130BB492.10

1

2

17

16

15

14

13

10

11

12

8

3

4

5

6

7

8

9

18

Installation and maintenance

4

Fläkt Woods 9325 GB 2016.09.16 Specifications are subject to change without further notice

FREQUENCY CONVERTER FC102 (QUICK GUIDE)

CONTROL UNIT (LCP)

A. Alphanumeric display

The information displayed in the control unit display (LCP) can

be customised. See parameters 0–20, 0–21, 0–22, 0–23 and

0–24. The factory settings display: motor rpm, motor current,

motor output, motor frequency and reference.

B. Menu buttons

Use the menu buttons to access the parameter settings, to

toggle between status display modes during normal operation

and to display fault log data.

C. Navigation and indication

[Back] returns to the previous step or menu list [Cancel]

Cancel the latest change or command [Info] Provides informa-

tion of the function displayed [▲] [▼] [▲] [▼] navigate and

increase/decrease [OK] Activate selection or access a

parameter group

• Green indication – power on

• Yellow indication – warning

• Red indication – alarm

D. Driftslägesknappar och återställning

[Hand/on] – Starting the motor for local control

[Off] – Stopping the motor

[Auto/on] – Allow control via control terminals or the commu-

nication bus

[Reset] – Resetting alarms

MANUAL OPERATION

• Press [Hand/on] to start

• Press the navigation buttons to set the desired speed

• Press [Off] to stop

• Press [Auto/on] to return to automatic operation

REVERSE THE DIRECTION OF ROTATION

If necessary the direction of rotation can be reversed using

parameter 1–06. When connection is correct 0=clockwise and

1=anti-clockwise.

MORE INFORMATION

This quick guide contains the basic information needed to

install and operate the frequency converter.

There is more information available in the attached docu-

mentation.

Auto

on Reset

Hand

on O

Status Quick

Menu

Main

Menu

Alarm

Log

Cancel

Info

Status 1(1)

1234rpm

Back

OK

43,5Hz

Run OK

43,5Hz

On

Alarm

Warn.

130BC362.10

a

b

c

d

1.0 A

a

b

c

d

Installation and maintenance

5

Fläkt Woods 9325 GB 2016.09.16 Specifications are subject to change without further notice

FREQUENCY CONVERTER FC102 (QUICK GUIDE)

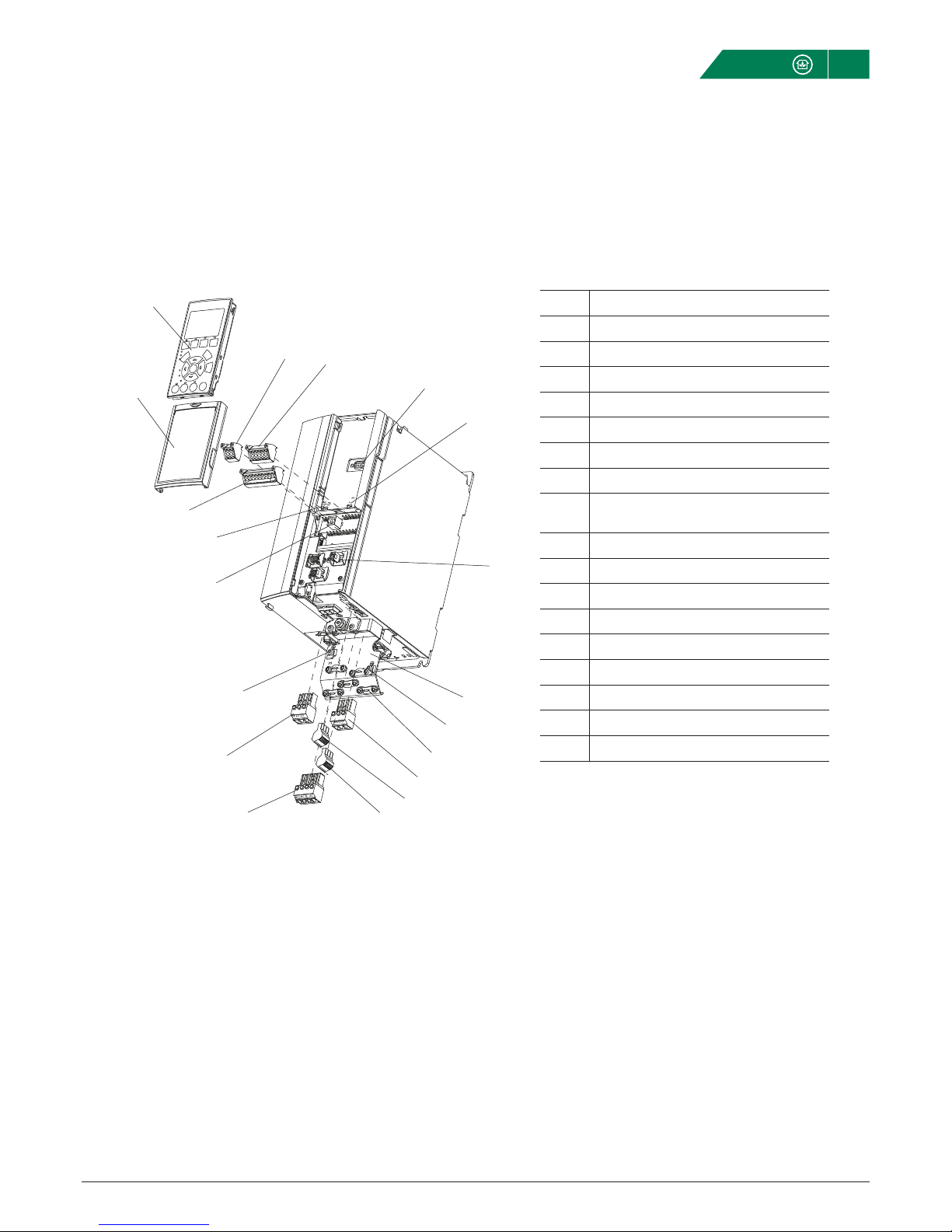

WIRING DIAGRAM

SIGNALS

Designation Type Terminal block

Start Potential-free closure 12-18

Control signal 0...10VDC 53

Pressure/ow sensor 0...10VDC (4...20mA) 54

COM For analogue in (Terminal blocks 53, 54) 55

Alarm R1 NO/NC 01, 02, 03

Operation R2 NO/NC 04, 05, 06

Relay output 0

Alarm NO/NC (Param. 5-40.0)

Relay output 1

Run Indicator NO/NC (Param. 5-40.1)

Start

Reference 0…10VDC (FW standard)

Actual value PID regulation

Start

+

-

+

-

Danfoss FC102

+24V 12

+24V 13

DIG IN 18

DIG IN 19

COM 20

DIG IN 27

DIG IN 29

DIG IN 32

DIG IN 33

DIG IN 37

+10V 50

A IN 53

A IN 54

COM 55

A OUT 42

COM 39

01

02

03

04

05

06

RS-485 com 61

RS-485 + 68

RS-485 - 69

R2 R1

91 92 93 95

L1 L2 L3 PE

U V W PE

96 97 98 99

L1

F1

L2

L3

N

PE

Analog switches

ON = 0-20m

OFF = 0-10VDC

A54

A53

ON

12

ON

12

M

The basic configuration (Fläkt Woods standard) relates to 0...10 VDC control via terminal block 53.

To activate the internal PID regulator see page 6. The sensor is connected to terminal block 54.

Installation and maintenance 6

Fläkt Woods 9325 GB 2016.09.16 Specifications are subject to change without further notice

FREQUENCY CONVERTER FC102 (QUICK GUIDE)

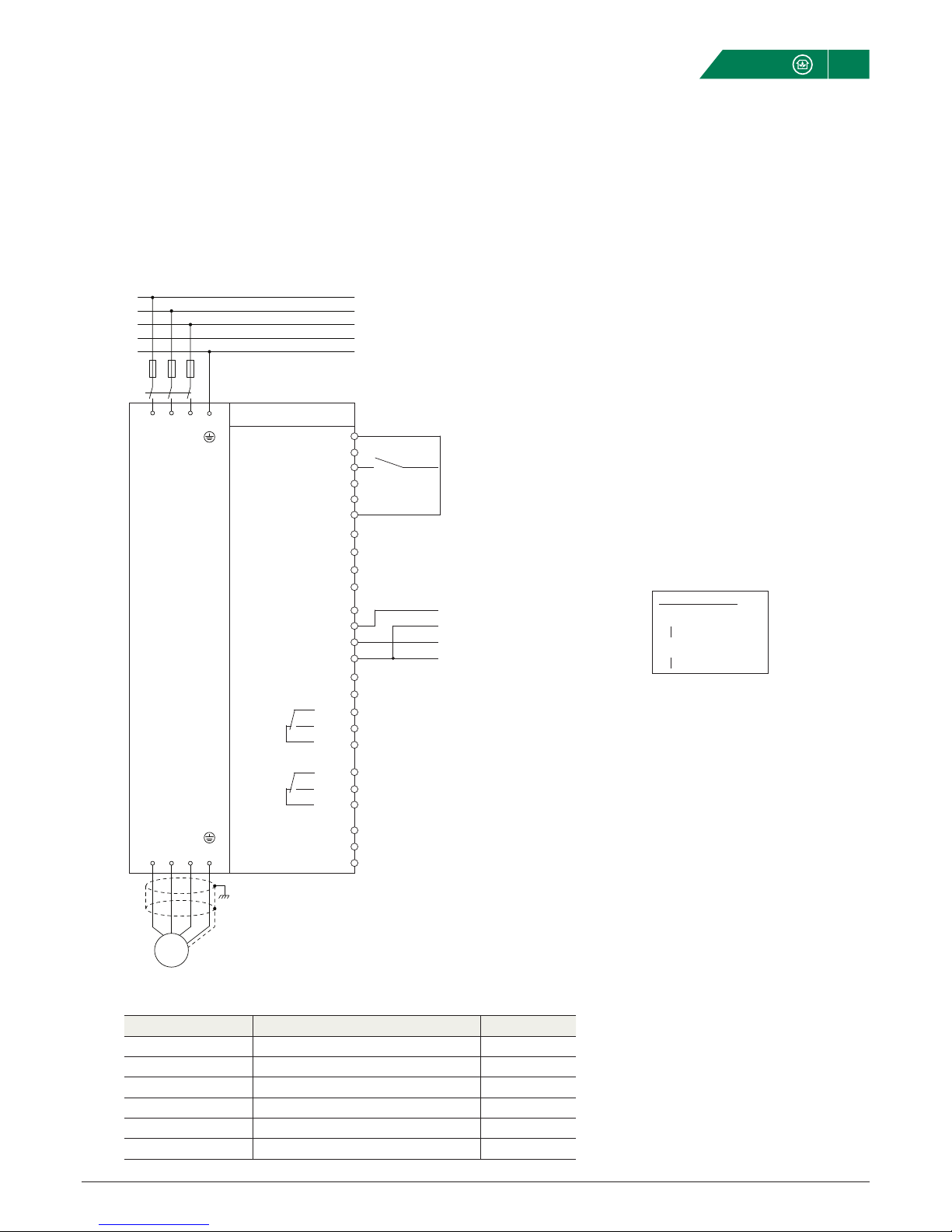

BASIC CONFIGURATION FOR ASYNCHRONOUS MACHINES (FLÄKT WOODS STANDARD)

When the frequency converter is energized for the first time the language can be selected. Obviously this can be changed later.

After Smart Start is started for 0...10VDC control by pressing [▼], followed by pressing [OK].

See motor

plate

See motor

plate

≥30s

≥40s

Step Description TF FF

1 Language English English

2 Select Q3 Function Setups Asynchronous Asynchronous

3 Number of motors 1 1

4 Thermal motor protection ETR 1 ETR 1

5 Motor Power [kW] _________________ _________________

6 Motor Voltage _________________ _________________

7 Motor Current _________________ _________________

8 Motor Frequency _________________ _________________

9 Motor Nominal Speed _____ _____

10 Minimum Reference 0 Hz 0 Hz

11 Maximum Reference ______________Hz ______________Hz

12 Apply on terminal block 53 Yes Yes

13 Application Fan Fan

14 Autom Energy Optimisation ❏ Yes (2, 4-pon) ❏ Yes (2, 4-pin)

❏ No (other) ❏ No (other)

15 AMA Yes Yes

16 Confi rm AMA OK OK

17 Press [Main Menu] twice

18 Select 3-** Reference / Ramps

19 Select 3-4* Ramp 1

20 [3-41] Ramp 1, Ramp Up Time _________________ _________________

21 [3-42] Ramp 1, Ramp Down Time _________________ _________________

When the frequency converter is energized for the first time the language can be selected. Obviously this can be changed later.

After Smart Start is started for 0...10VDC control by pressing [▼], followed by pressing [OK].

Confi guration carried out by __________________________________________________ Date ________________________________

Smart Start can be reactivated at any time. First press [Quick Menus]. Then navigate using the [▲] and [▼] buttons until the

cursor is on Q4 Smart Start. Then press [OK].

Danfoss factory reset

Press [Main Menu] twice. Navigate using the [▲] [▼] and [OK] buttons until parameter 14–22 is displayed (select 14–**,

then 14–2* and lastly 14–22). Set this parameter to [2] and then switch off the mains voltage.

When the frequency converter is re-energised the parameters will have returned to their factory settings.

Installation and maintenance 7

Fläkt Woods 9325 GB 2016.09.16 Specifications are subject to change without further notice

FREQUENCY CONVERTER FC102 (QUICK GUIDE)

ACTIVATING PID REGULATION

See sensor

See sensor

Setpoint

Adjust if

necessary

Step Description TF FF

1 Press [Quick menus]

2 Press [Quick menus]

3 Select Q3-3 Closed Loop Settings

4 Select Q3-30 Single Zone Int.Setpoint

5 1-00 Confi guration Mode [3] Closed Loop [3] Closed Loop

6 20-12 Reference/Feedback Unit [72] Pa [72] Pa

7 20-13 Minimum Reference/Feedb. 0 Pa 0 Pa

8 20-14 Maximum Reference/Feedb. ______________Pa ______________Pa

9 Press [▼] once

10 6-24 Terminal 54 Low Ref./Feedb. 0 Pa 0 Pa

11 6-25 Terminal 54 High Ref./Feedb. ______________Pa ______________Pa

13 6-26 Terminal 54 Filter Time Const ≥1 s ≥1 s

14 Press [▼] four times

15 20-21 Setpoint 1 ______________Pa ______________Pa

16 20-81 PID Normal/Inverse Control [0] Normal [0] Normal

17 Press [▼] twice

18 20-93 PID Start Speed 2.0 2.0

19 20-94 PID Proportional Gain 30.0s 30.0s

20 Press [Main Menu] twice

21 Select 0–** Operation / Display

22 Select 0–2* LCP Display

23 0–20 Display Line 1.1 Small [1654] Feedback 1 [1654] Feedback 1

Confi guration carried out by __________________________________________________ Date ________________________________

Installation and maintenance

8

Fläkt Woods 9325 GB 2016.09.16 Specifications are subject to change without further notice

FREQUENCY CONVERTER FC102 (QUICK GUIDE)

MODBUS RTU IN EQ

If Modbus RTU is used in eQ AHU for controlling drives, they

must be set according to the table below.

Configuration

Parameter Description Value

8-30 Protocol [2] Modbus RTU

8-31 Address Supply fan: 60

Exhaust fan: 70

8-32 Baudrate [2] 9600

8-33 Parity / Stop bits [2] No parity, 1 Stop bit

Parameter Description TF FF

6-50 Function, terminal block 42 4-20mA 4-20mA

Parameter Description TF FF

6-14 Output frequency

equivalent to 4mA 0 Hz 0 Hz

6-15 Output frequency

equivalent to 20mA ____Hz ____Hz

PARALLEL OPERATION

When two frequency converters are to operate in parallel, one

must be configured as master and the other as slave.

After this, connect the two frequency converters together as

indicated below.

Configuration, master

Configuration, slave

Set switch A53 (located under the display) to position I.

The power to the converter must be switched off.

Connection

Master Slave

42

39

53

55

Table of contents

Popular Media Converter manuals by other brands

SIIG

SIIG RS-232 to Multi-Mode Fiber Optic Quick installation guide

Omnitron Systems

Omnitron Systems OmniConverter FPoE/SL user manual

Repotec

Repotec RP-IMC811FP user manual

CYP

CYP SY-300H-4K22 operating manual

Schumacher Electric

Schumacher Electric PC-6 owner's manual

Chiayo

Chiayo GMC-60 Operation manual