FLARING FC-500 User manual

1

Operation Manual

FC-500 Cutting Machine

2

Version

Due to product version upgrades or other reasons, the contents of this document are not regularly updated. Unless

otherwise agreed, this document is intended as a guide only and all statements, information and recommendations in this

document do not constitute any guarantee, expressed or implied.

The pictures in this document are for reference only. If the picture is different from the real one, then use the pictures for

guidance only.

Contents

Contents ....................................................................................................................................................... 2

1 Product brief introduction .......................................................................................................................... 3

1.1 Summarize ....................................................................................................................................... 3

1.2 Technical parameters .......................................................................................................................3

1.3 Accessories list ................................................................................................................................ 4

2 Installation instruction ................................................................................................................................4

2.1 Installation of Air Regulator ..............................................................................................................4

2.2 Air compressor connect to plasma cutter ........................................................................................5

2.3 Plasma Cutter Torch connect to machine ....................................................................................... 5

2.4 Cutting Torch explosive chart .......................................................................................................... 6

3 Operating instructions ............................................................................................................................... 6

3.1 Operation panel interface ................................................................................................................ 6

3.2 Cutting Operation instruction ...........................................................................................................7

3.3 Start Cutting ..................................................................................................................................... 8

3.4 Hand torch cutting Show ............................................................................................................... 10

4 Trouble shooting and fault finding ........................................................................................................... 11

5 Daily maintenance and checking ............................................................................................................12

5.1 Daily maintenance ......................................................................................................................... 12

5.2 Daily checking ................................................................................................................................12

5.3 Cutting problems and resolution ....................................................................................................13

6 Attention ...................................................................................................................................................14

6.1 Cutting environment and safety .....................................................................................................14

6.2 Symbol definition: .......................................................................................................................... 14

7 Service GUARANTEE .............................................................................................................................19

3

1 Product brief introduction

1.1 Summarize

Inverter

Technology

This device uses single tube IGBT inverter technology (the inverter frequency range is from

25-50KHz) to convert 50/60Hz alternating current (AC) to direct current (DC) and then to high

frequency and lower voltage rectification. The resulting pulse width modulation (PWM) output can

be used for the high-power DC power supply, Due to switching power inverter technology adopted,

the weight of the welder has been significantly decreased and the conversion efficiency of the whole

machine is increased by more than 30%.

Wide Voltage Our cutting machine is equipped with a power supply voltage compensation device,The power

supply voltage will work when the rated voltage is within 15% of requirements. When using

extension cords, in order to reduce voltage drop, use a heavy duty extension cord (10 or 12AWG or

greater) or use the recommended configuration length.

Easy to Use Piloting arc system can strike arc easily with principle of high frequency oscillation .It has functions

that it can supply gas ahead and turn off gas delayed.High frequency arc starting

Widely Used It is suitable for cutting stainless ,Steel, alloy steel, mild steel, copper and other color metal

materials.

Superior

Performance

1.Stabilizing 2.Reliability 3.Lightness 4.Energy-saving and no noise 5.High cutting speed 6.Cutting

smoothly and no polish demands

Attention Plasma cutter, the consumables are not on correctly, they are usually missing the white spacer. Air

regular not on it the correct direction(this will not give it enough flow).

Air leaking from the hose connections. Customers don't know they have to touch the metal to start

the arc.

1.2 Technical parameters

TYPE FC500

Input power voltage (V) AC220,50/60Hz

Rated input current (A) 17.2

Rated power capacity (KVA) 5.2

Current adjustment range (A) 20-50

Cutting thickness (mm)

Carbon Steel≤16.0

Stainless Steel≤16.0

Aluminum≤6.0

Copper≤5.0

Voltage adjustment range (V) 90V-110V

No-load voltage (V) 260±20

Rated duty cycle 60%

Efficiency (%) 80%

Power factor 0.7

Protection class IP21S

Insulation class F

Size (mm) 490*290*340

Weight (Kg) 9.6

Mode Type A=High Frequency Plasma Cutter

4

1.3 Accessories list

A B C

High Frequency Plasma Cutter*1 No Touch Pilot Arc High Frequency

Plasma Cutter*1

Non Touch Pilot Arc Low Frequency

Plasma Cutter*1

PT31 Plasma Cutter torch AG60 Plasma Cutter Torch*1 IPT60 Plasma Cutter torch * 1

Ground wire*1 Ground wire*1 Ground wire*1

2 Installation instruction

2.1 Installation of Air Regulator

(1) Wrap the copper gas nozzle around the

sealing tape and tighten it on the IN and

OUT ends;

(2) Wrap the meter head with the sealing tape

and tighten it on the meter head installation

position;

(3) Fix the connecting frame to the installation

position of the pressure reducing valve

behind the welder as shown in the figure;

(4) Unscrew the rubber nut and fix the pressure

reducing valve on the connecting frame as

shown in the figure;

(5) Turn on the air valve switch, lift up the

pressure regulating knob, adjust the air

pressure to the specified air pressure (turn to "+" to increase the air pressure, and to "-" to decrease the air

1

Pressure regulating knob

2Fixed connection frame

3Air outlet

4Air inlet

5Filter cylinder

6Drain out

7Pressure gauge

(what you see is A)

5

pressure), then Press down the pressure regulating knob;

(6) The scale position of the meter,suggest the indicated position is 60-70PSI(about 0.4Mpa) air pressure. When there is

too much water in the filter cylinder, the drain valve should be opened to drain the water.

2.2 Air compressor connect to plasma cutter

Air regulator is installed outside the machine Air regulator is installed inside the machine

2.3 Plasma Cutter Torch connect to machine

A=High Frequency Plasma

Cutter/PT31

B=No Touch Pilot Arc High Frequency

Plasma Cutter/AG60

C=Non Touch Pilot Arc Low

Frequency Plasma Cutter/IPT60

6

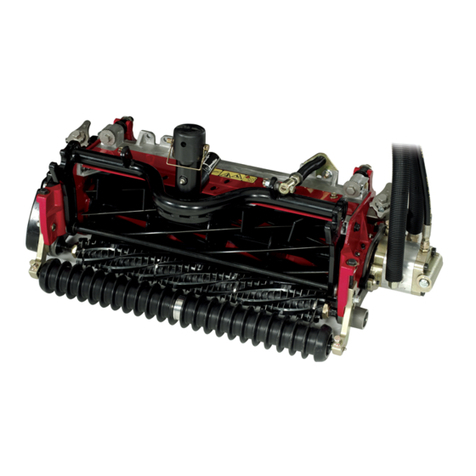

2.4 Cutting Torch explosive chart

A=PT31 Torch

1.Outside nozzle, 2.Extend tip,

3.Diffuser, 4.Electrode. These are

wear parts, among which the extend

tip and electrode are very easy to

wear, please keep it.

B=AG60 Torch

1.Spacer spring, 2.Outside nozzle,

3.Extend tip, 4.Electrode. These are

wear parts, among which the

extend tip and electrode are very

easy to wear, please keep it.

C=IPT60 Torch

1.Double pointed spacer, 2.Outside

nozzle, 3.Extend tip, 4.Diffuser,

5.Electrode. These are wear parts, among

which the extend tip and electrode are

very easy to wear, please keep it.

3 Operating instructions

3.1 Operation panel interface

1Current adjust knob

2Power light

When this light is on, it means that the power supply is normal.

3Over current or over heat protection light

When the cutting load is overloaded and the output current of the machine is too large, the internal temperature of

the machine is too high, and the machine fault light will be on. This is normal. The machine can recover after the

heat dissipation becomes normal. Please restart the power supply; When damaged, the fault light will be on, in

this case, the machine is abnormal and needs maintenance, please contact the supplier.

4Current display meter,Display preset current and actual current during operation

7

3.2 Cutting Operation instruction

On display

After open the power supply,the power light is light,current meter display the preset current.

Preparation

Input cable connection

Every machine has been disposed a power cable which must be connected to coordinated voltage class in

compliance according to input voltage of cutting machine .If cutting machine whose power voltage is 230V is

connected wrong to AC 400V, that will cause components of inter-machine are burned up.

Make sure power cable is connected to power switch reliably and prevent from oxidizing. Make sure power voltage is

inside the waved range.

Connect Air compressor

Make sure tube of pressed air is connected to copper connector by high-pressure rubber tube firmly.

Connect one end of the trachea to the gas in of the machine and the other end to the air compressor.(Refer to 2.2)

Output cable connection

Earth cable is connected to positive terminal of front panel then tighten it.

Make sure copper screw of another end of torch is connected to gas-electrify integration terminal then tighten them

clockwise relation (prevent from leaking gas). (Refer to 2.3)

Operation

(1) Open the power switch; make the power switch is in “on” position . Screen will show the current volume.

(2) Adjust the gas pressure and make it is adequate to machine, open the valve of pressed air.

(3) Make sure cutting current is adequate to machine according to thickness of cutting piece.

(4) Press the control knob of torch, electromagnetic valve is starting, it can be heard and burner of torch should flow out

gas (Burner of low frequency cutting machines or pilote-arc cutter should spurt fire)

(5) It is 1mm from copper tip to work piece (if it is arc-supporting cutter.),It is 3-5mm from copper tip to work piece (if it is

burner of low frequency cutting machines or pilote-arc cutter ).knob of torch and burn and strike arc,sparks of HF arc

striking will diminished immediately. User can begin to cut.

Adjust air pressure and Current

1

Input 220V 20Amps 35Amps 40Amps 45Amps 50Amps

Air pressure(PSI) 60-70 60-70 60-70 60-70 60-70

Thickness (Fe) 5mm 8mm 10mm 12mm 16mm

Thickness (Ss) 5mm 8mm 10mm 12mm 16mm

Thickness (Al) 1mm 3mm 4mm 5mm 6mm

Thickness (Cu) 2mm 3mm 4mm 5mm

8

3.3 Start Cutting

3.3.1 Edge cutting

Touch No Touch Remarks

1 Keep the torch vertical at the edge of the

workpiece. Keep your wrist steady and ready to

start cutting

2 Pull the trigger to start the arc ,The cutting arc

will initiate when the torch tip is close enough to

the work Piece. Start cutting on the edge until

the Arc has cut completely through.

3 During the cutting process, it is necessary to

control the speed. Too fast speed will lead to

incomplete cutting, and arc blowback is easy to

damage the device. Too slow speed will lead to

excessive scum and cutting gap.

Touch:A=High Frequency Plasma Cutter/PT31

No Touch:B=No Touch Pilot Arc High Frequency Plasma Cutter/AG60

C=Non Touch Pilot Arc Low Frequency Plasma Cutter/IPT60

3.3.2 Piercing Cutting

Touch No Touch Remarks

1 Hold the torch at an angle to the work piece, pull

the trigger to start the arc and slowly rotate it to

an upright position.

2 Pull the trigger to start the arc ,The cutting arc

will initiate when the torch tip is close enough to

the work Piece. Start cutting on the edge until

the Arc has cut completely through.

3 When the pierce is complete, Control the cutting

speed and adjust the angle and position of the

cutting torch to continue the cutting

operation.Too fast speed will lead to incomplete

cutting, and arc blowback is easy to damage the

device. Too slow speed will lead to excessive

scum and cutting gap.

Touch:A=High Frequency Plasma Cutter

No Touch:B=No Touch Pilot Arc High Frequency Plasma Cutter,C=Non Touch Pilot Arc Low Frequency Plasma

Cutter

9

3.3.3 Cutting performance

1 Amperage Standard rule of thumb is the thicker the material the more amperage required. On thick material, set

the machine to full output and vary your travel speed. On thinner material, you need to turn down the

amperage and change to a lower-amperage tip to maintain a narrow kerf. The kerf is the width of the

cut material that is removed during cutting.

2 Speed Amperage and speed are critical to producing a good quality cut. visually follow the arc that is coming

from the bottom of the cut. The arc should exit the material at a slight angle away from the direction of

travel. If it's going straight down, that means the speed is too slow, and IT will have an unnecessary

buildup of dross or slag. If the speed is too fast, it will start spraying back onto the surface of the

materia without cutting the workpiece completely. Because the arc trails at an angle, at the end of a

cut, slow your cutting speed and angle the torch in to cut through the last bit of metal.

3 Direction It is easier to pull the torch towards you than push it. The plasma stream swirls as it exits the tip, biting

one side and finishing off on the other leaving a bevelled edge and a straight edge. The bevel cut effect

is more noticeable on thicker material and needs to taken into consideration before starting your cut as

you want the straight side of the cut to be on the finished piece you keep.

4 Torch tip

height &

position

The distance and position of the plasma torch cutting tip has an affect on the quality of the cut and the

extent of the bevel of the cut. The easiest way to reduce bevel is by cutting at the proper speed and

height for the material and amperage that is being cut.

5 Tip size

and

condition

The tip orifices focus the plasma stream to the work piece. It is important to use the correct size tip for

the amperage being used,for example a tip with a 3/64" orifice is good for 0-40 amps whereas a 1/16"

orifice is better for 40-80 amps.

The low-amp tip has a smaller orifice which maintains a narrow plasma stream at lower settings for use

on thin-gauge material. Using a 25 amp tip at an 60 amp setting will blow out and distort the tip orifice

and require replacement.

Conversely, using an 80-amp tip on the lower settings will not allow you to focus the plasma stream as

well and creates a wide kerf.The condition of the tip orifice is critical to the quality of the cut result, a

worn or damaged tip orifice will produce a distorted plasma stream resulting in a poor cut quality.

6 Electrode

condition

A fixed gap is established between the electrode and the inside of the cutting tip. Electrons arc across

the gap, ionizing and super heating the air creating the plasma stream. The electrode contains an

insert in the end made of a highly conductive material called hafnium. This insert erodes with use and

develops a pit in the end of the electrode, when the pit becomes too much poor quality cuts will result

and necessitate replacement of the electrode.

7 Air quality,

Air

pressure

and

volume

Compressors take in air at atmospheric pressure and increase the pressure and store it in a tank.

Moisture that forms in air lines has a tendency to condense into larger drops when the air pressure

decreases as it is entering the plasma torch. When these droplets enter into the high temperatures in

the plenum of the torch, they immediately break down into oxygen and hydrogen, which alters the

normal chemical content of air in the torch. These elements will then dramatically change the plasma

arc which causes the torch consumable parts to wear very quickly, alters the shape of the nozzle

orifice, dramatically affecting cut quality in terms of edge squareness, dross formation, and edge

smoothness.Air pressure, flow rate and air quality are critical to quality plasma cutting and consumable

life span.Usually air pressure is preset at 60 psi . The volume capacity of your compressor is important,

If you are doing a lot of cutting, cutting thick plate (same air consumption but slower cut speeds =

longer cut time) then choose a compressor at 1.5 to 2 times the plasma system requirement.

10

3.4 Hand torch cutting Show

Torch tip height & position

①②③④

①The correct torch height and right angle shall be consistent with the minimum slope and equal slope of the material, so

as to ensure good cutting effect and prolong the service life of consumables.

②Torch angled to the material unequal bevel, one side may be excessively beveled.

③Torch height too high, plasma stream may not cut all the way through the material.

④Torch height too low. Tip may contact the work piece and short out or damage the tip.

Speed and Amperage

Touch No Touch

1

When cutting, select the appropriate current and pushing speed according to the material and thickness of the workpiece

to ensure that the spark are exiting from the bottom of the workpiece

2

If the spark comes out from the top of the workpiece, it means that the workpiece has not been completely cut, because

the torch moves too fast or the current is set too low.

3

If the spark passes vertically through the workpiece, it indicates that the workpiece has been completely cut off and the

torch is cutting air because the torch moves too slowly or the current setting is too large

11

4 Trouble shooting and fault finding

Notes: The following operations must be performed by qualified electricians with valid certifications. Before maintenance,

you are suggested to contact local distributor to verify qualification.

Faults Resolvable Methods

Switch indicator is on,fan is not working,

control knob is out of work.

Over voltage protection is working. Close machine then

Open it again after several minutes.

Switch indicator is lit,fan is working.

press control knob of torch, there is no HF

arc-striking sound and electromagnetic valve is not

working.

Check if torch is open circuit.

Check if control knob of torch is damaged.

Part of assistant power of top board is damaged and there is

no DC 24V output.

Switch indicator is lit,

fan is working.

press control knob of torch, there is no HF arc striking

sound and inter red diode is lit.

Check if MOS or IGBT of top board is damaged (driver

mould is damaged).

Rising transformer of bottom board is damaged.

Control mould is damaged.

Switch indicator is lit,

fan and electromagnetic valve are working,

there is no sound of HF

arc-striking and inter red diode is not lit.

here is some trouble in part of arc-striking, such as:

It is too far between discharge tip or there is adhesion in

discharge tip.

Primary coil of arc-striking transformer is damaged or poor

contact.

Check if four times voltage rectifier diode is stricken.

Check if HF electric capacity 102/10KV is leaking.

Relay is damaged.

Other of machine is normal, but arc is not be stricken

when it is be operating.

Input voltage is too low.

Pressure of air compressor is too high or too low .

Even the machine comes up with abnormal phenomenon such as cutting unable, arc unstable or bad welding effect, it is

still early to judge that there is malfunction on the machine.

The above-mentioned abnormal phenomenon may be caused by some reasons.

For example:

tight parts loosen,forgetting to switch on, wrong set up, cable broken and gas rubber pipe cracked, etc. Therefore, please

test and inspect these factors before deliver it back to the factory because a large number of troubles may be easily

solved probably.

12

5 Daily maintenance and checking

5.1 Daily maintenance

Remove dust regularly with dry compressed air. If the cutting machine is used in surroundings with heavy smoke and

polluted air, it is necessary to remove dust at least one time one month.

The pressure of compressed air shall fall to required level to prevent damage to small components in the machine.

Examine inside electric joints and ensure perfect contact (Especially plugs and sockets). Fasten the loosing joints. In

case of oxidation, remove oxide film with sand paper and connect again.

Prevent water from entering into the machine and prevent the machine from getting moist. If any, blow and dry.

Measure the insulation with megohmmeter to make sure it is qualified to use.

If the cutting machine is not used for a long time, pack the machine in original package and store in dry surroundings.

All the maintenance and testing must be carried out when the power supply is totally

cut off. Please make sure the power is off before opening the closure.

5.2 Daily checking

POWER SUPPLY

Position Checking keys Remarks

Control panel

Operation,conversion and installation of the switch

Check the state of the power indicator light

Lead to unstable arc and wire

sending

Cooling fan Check if the fan state and the sound is normal or not Clean the residue and check the

reason and solve it

Power part

Check if there is abnormal liberation and sound when the

power is on

Check if there is smell when the power is on

Whether the outside color change or get warm

Outer parts

The connector is loosen

Whether the outer shell or other connect parts are loosen

CABLE

Position Checking keys Remarks

Output cable

Wearing-out of the cable insulated

material

Cable connecting head naked (insulation

damage), or loosen (the end of power

supply, and cable of main material

connecting point)

For life security and stable cutting, adopt

suitable method to check according to

working place

Simple check daily

Careful and in-depth check on fixed period

Input cable

If the connection between the plug and the

power socket is firm

If the power input end cable fixed

If the input cable is worn out and bares the

conductor In case of leakage and to ensure safety, please do

perform daily checking

Earth cable If the earth cable that connects the main part is

broken and connects tightly

13

CUTTING TORCH

Position Checking keys Remarks

Switch

Press the torch switch, no gas comes out. Check switch.

Press the torch switch, arc cannot be

started. Check switch.

Extend tip,

Electrode

Cutting power is reduced. Replace.

5.3 Cutting problems and resolution

The phenomenon listed below may happen due to relevant accessories used, cutting material, surroundings and power

supply. Pleas improve surroundings and avoid these problems.

Arc starting difficulty. Arc interruption happens easily:

Examine whether grounding wire clamp contacts with the work pieces well.

Examine whether each joint has improper contact.

The output current fails to reach rated value:

The deviation of power voltage from rated value may cause that the output current does no accord with adjusted value.

When the power voltage is lower than rated value, the maximum output current may be lower than rated value.

The current can not keep stable during operation:

This situation may relate to the following factors:

The voltage of electric power network changes;

Serious interference from electric power network or other electric facilities.

14

6 Attention

The safety notes listed in this manual is to ensure correct use of the machine and to keep you and other people from being

hurt.

The design and manufacture of cutting machine considers safety. Please refer to the safety warning listed in the manual to

avoid accidents.

Different damage would be caused by wrong operation of the equipment as follows. Please read the user manual carefully

to reduce such damage.

6.1 Cutting environment and safety

Working surroundings

(1) Cutting should be carried out in dry surroundings. The air humidity level should not be higher than 90%.

(2) The temperature should be between -10C to 40C.

(3) Don’t use the cutting machines in sunshine or rain. Keep it off water.

(4) Don't use the machines in the places of dust or corrosive air.

(5) Cutter machine should not be carried out in places with quick air flow.

Safety norms

Protection circuit of over-voltage, over-current and over-heat circuits are designed in the cutting machines. It will stop

working automatically when the input voltage, output current or internal temperature exceed the rated value. But if the

machines are excessively used, such as with input voltage higher than the rated, the machine might be damage. Please

pay close attention to the following matters.

Keep good ventilation!!

The cutting machines work with high cutting voltage. Nature air flow can’t reach the requirement of heat dissipation. So

the fans are installed as cooling system to ensure stable performance.

Make sure the ventilation windows are not covered or blocked. The distance between the machines and things around

should not be less than 0.3m. Good ventilation is good for cutting performance and operational life.

Never over load!

Check the maximum rated current (according to the Duty Cycle chosen). Make sure the cutting current is never higher

than the rated value. Over current running will obviously shorten the operation life, even damage the machine.

Never over voltage!

The Input Voltage could be found in Technical data diagram. The auto-compensation function will keep the cutting current

in the rated range. If the input voltage exceed the permissible value, the machine would be damaged. Users should take

protective measures in advance to avoid it.

Make sure earth connected before operation.

On the rear panel of cutting machine, a screw for earth connecting would be found. It must be ground connected with

cable whose section is bigger than 6mm2 before operation, to avoid accidents caused by static or electricity leak.

6.2 Symbol definition:

The safety notes listed in this manual is to ensure correct use of the machine and to keep you and other people from being

hurt.The design and manufacture of cutting machine considers safety. Please refer to the safety warning listed in the

manual to avoid accidents. Different damage would be caused by wrong operation of the equipment as follows. Please

15

read the user manual carefully to reduce such damage.

This Manual contains symbols as blow, please refer to their means expressed

Symbol Description

Any contact of electric parts may cause fatal electric shock or burnt.

Gas and fumes are harmful to health.

Operation in narrow space may cause choke.

Spark and hot workpiece after cutting may cause fire.

Bad connected cable may cause fire.

Incompletion connection of workpiece side circuit may cause fire.

Never cut on the case of tinder stuff, or it may cause explode.

Never cut airtight containers such as slot, pipe etc., or it may break.

Arc ray may cause eye inflammation or skin burnt.

Spark and residue will burn your eyes and skin.

Toppling over of the gas cylinder will cause body hurt.

Wrong use of the gas cylinder will lead to high-pressure gas eruption and cause human hurt.

Never let fingers, hair, clothes or etc. near the moving parts such as the fan.

The arc shoot out of the torch may stab eyes, face and other naked parts.

Never stand in front of the swing equipment or under it, or it may fall and cause injury.

Please follow the rules below to avoid heavy accidents.

Never use the equipment to do other things but cutting.

Follow related regulations for the construction of the input-driven power source, choice of place, usage of

high-pressure gas, storage, configuration, safe-keeping of workpiece after cutting and disposal of waste, etc.

Nonessential do not enter the cutting area.

People using heart pacemaker is not allowed to get close to the cutting machine or area without doctor’s permission.

Symbol Definition

The words after this sign means there is great potential danger, which may cause major

accident, damage or even death, if it is not followed.

The words after this sign means there is some potential danger, which may cause hurt or

property lose, if it is not followed.

The words after this sign means there is potential risk, which may cause equipment fault

or break, if it is not followed.

16

The magnetism created by energizing the cutting machine can have a bad effect to the pacemaker.

Install, operation, check and maintain the equipment by profession personnel.

Understanding the contents of the user manual for safety.

Please follow the rules below to avoid electric shock。

Keep away from any electric parts.

Earth the machine and workpiece by professional personnel.

Cut off the power before installation or checking, and restart 5 minutes later. The capacitance is chargeable device.

Please ensure it has no voltage before start again even if the power source is cut off.

Do not use wire with inadequate section surface or damage insulation sleeve or even exposed conductor.

Do ensure well isolation of wire connection.

Never use the device when the enclosure is removed.

Never use broken or wet insulation gloves.

Use firenet when work at high position.

Check and maintain regularly, don’t use it until the broken parts are fixed well.

Turn off the power when not in used.

Follow the national or local related standard and regulations when using the AC cutting machine at narrow or high

position.

Please follow the below notes to avoid fire and explode, etc.

No combustible in cutting area.

Keep off combustible when cutting.

Keep hot workpiece after cutting away from flammable gas.

Do move away the combustible around when cut the dooryard, ground and wall,.

The wire connection of base metal should be as close to the cutting place as possible.

Never cut those facilities with gas pipe or airtight slot.

Put fire extinguisher around the cutting area to prevent fire.

The gas and fumes are harmful to health, please wear protective device according to

regulations.

Wear exhaust equipment and breathe preventive facilities to prevent gas poisoning or choke.

Use suggested part exhaust equipment and breathe preventive facilities to prevent hurt or poisoning by gas and

other powder, please.

To prevent oxygen-deficiency, air out the gas-filled room which is full of CO2 and argon on the bottom, When

operating on trunks, boilers, cabins, etc.

Please accept the supervisor’s inspection when operating in narrow space. Air the room and wear breathe

preventive facilities.

Never operate in degrease, washing or spray space.

Using breathe preventive facilities when cut shielded steel for it will cause poisonous dust and gas.

17

The arc, spark, residue and noise are harmful to health, please wear protective appliance.

Eye protection against arc is recommended when cutting or supervise cutting.

Please wear preventive spectacles.

Welder’s gloves, welder’s goggles, long sleeve clothes, leather apron, and other standard protection equipment

must be worn for cutting operation.

A screen to protect other people against the arc must be set in the cutting place.

Please follow the notes below to avoid gas cylinder toppling over or broken.

Use the gas cylinder correctly.

Use the equipped or recommended gaseous regulator.

Read the manual of gaseous regulator carefully before using it, and pay attention to the safety notes.

Fix the gas cylinder with appropriative holder and other relative parts.

Never put the cylinder under high temperature or sunshine environment.

Keep your face away from the gas cylinder exit when opening it.

Put on the gas shield when it is not used.

Never put the torch on the gas cylinder. The electrode can not meet the gas cylinder.

Any touch of the switch part will cause injury, please note the following.

Never use the machine when the enclosure is off.

Install, operate, check and maintain the machine by professional person.

Keep your fingers, hair, clothes etc. away from the switch parts such as the fan.

The wire end may deal damage, please note the following.

Never look into the electric conduction hole when checking the wire feeding is normal or not, , or the shooting wire

may stab your eyes and face.

Keep your eyes, face or other naked parts away from the end of torch when feeding the wire manually or pressing

the switch.

For better work efficiency and power source maintenance, please note the following.

Precautions against toppling over.

Never use the cutting equipment for pipe thawing.

Lift the power source from side when use the up-down forklift truck to avoid toppling over.

When using the crane for lift, tie the rope to the ears with an angle no more than φ15 to the vertical direction.

When lifting the cutting machine which equipped with gas cylinder and wire feeder, download them from the power

source and ensure the horizontal of the machine. Do fix the gas cylinder with belt or chain when moving it to avoid

body hurt.

Ensure fastness and insulation when lifting the wire feeder through the swing ring for cutting.

18

Electromagnetic interference needing attention.

It may need extra preventive measures when the equipment is used in particular location.

Before the installation, please estimate the potential electromagnetism problems of the environment as follows.

(1) Upper and lower parts of the cutting equipment and other nearby power cable, control cable, signal cable and phone

cable.

(2) Wireless electric as well as TV radiation and reception equipment.

(3) Computer and other control equipment.

(4) Safety-recognition equipment etc. Such as supervise of industrial equipment.

(5) Health of people around. Such as personnel using the heart pacemaker or audiphone.

(6) Equipment for adjustment and measurement.

(7) Anti-disturb capability of other used equipment .Users should ensure these equipment and the environment are

compatible, which may need extra preventive measures.

(8) Practical state of the cutting and other activities.

Users should observe the following dos and don’t to decrease radiation interference.

(1) Connect the cutting equipment to the power supply lines.

(2) Maintain the cutting equipment regularly.

(3) The cable should be short enough to be close to each other and the ground.

(4) Ensure the safety of all the cutting metal parts and other parts nearby.

(5) The workpiece should be well earth.

(6) Shield or protect the other cable and equipment to decrease the effects of disturbances. The cutting equipment can

be complete shielded in some special conditions.

Users are responsible for interference due to cutting.

19

7 Service GUARANTEE

This product is made of high quality material and great care has been taken in its manufacture.It is designed to give good

performance provided it is properly operated and maintained.The product is sold subject to the understanding that if any

defect in manufacture or material shall appear within 12 months from date of consumer sale,if any defect in main parts

over 12 months,the warranty period is subject to country Consumer Law , Our Service will arrange for such defect to be

rectified without change under the following warranty items and conditions.

Warranty Terms and Conditions:

The defect is not due to use of the product for other than domestic purposes , or an incorrect voltage, or use of improper

accessories,or contrary to operating instructions,or to accidental damage, misuse, neglect or inexpert repair, or incorrect

installation, or the product is excessively used for improper purposes other than daily consumption, or accessories

belonging to the product,transportation.

Thank you for choosing our products. Please feel free to give your precious suggestions, we will make efforts to

perfect our products and service.

Warranty period from the purchase date :

1、One year warranty for welding and cutting machine.

2、1 month warranty for welding accessories.

3、The warranty does not cover faults resulting from operation

careless handing or not following instructions.

Customer:[email protected]

Whatsapp:+86 18926400145

Table of contents

Other FLARING Cutter manuals