Toro 03200 Reelmaster 3100-D User manual

FormNo.3444-175RevA

27-inchVerticutter

Reelmaster®3100-DSeriesDPACuttingUnit

ModelNo.03203—SerialNo.408000000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3444-175*

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

Introduction

Theverticutterkitismountedonaride-onmachine

andisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarily

designedforverticuttinggrassonwell-maintained

lawnsinparks,sportselds,andoncommercial

grounds.Usingthisproductforpurposesotherthan

itsintendedusecouldprovedangeroustoyouand

bystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberplate(if

equipped)toaccesswarranty,parts,andother

productinformation.

g291194

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................3

BladeSafety.......................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................5

1InspectingtheVerticutter.................................5

2InstallingtheTransportRollers.........................5

3InstallingtheO-ringandtheGrease

Fitting..............................................................6

4AdjustingtheBladeDepth................................6

5AdjustingtheRearGrassShield.......................7

6AdjustingtheRollerScrapers...........................7

7AdjustingtheTransportRollers........................8

8MountingtheVerticutterReel...........................8

ProductOverview.....................................................9

Specications....................................................9

Attachments/Accessories...................................9

Operation..................................................................9

TrainingPeriod...................................................9

OperatingTips....................................................9

Maintenance...........................................................10

UsingtheKickstandWhenTippingthe

CuttingUnit...................................................10

LubricatingtheVerticutter.................................10

RemovingtheVerticutterBladesfromthe

Shaft..............................................................11

InstallingtheVerticutterBlades..........................11

OptionalBladeSpacing....................................12

ServicingtheRoller...........................................13

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395andANSIB71.4–2017.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Removealldebrisorotherobjectsthatmightbe

pickedupandthrownbythebladesofthecutting

unit.Keepallbystandersawayfromtheworking

area.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofanydischargeopening.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowerthecuttingunit(s).

–Disengagethedrives.

–Engagetheparkingbrake(ifequipped).

–Shutofftheengineandremovethekey.

–Waitforallmovementtostop.

–Iftheverticutterbladesstrikeasolidobjector

theunitvibratesabnormally,stopandshutoff

theengine.Checktheverticutterfordamaged

parts.Repairanydamagebeforestartingand

operatingtheverticutter.

–Ensurethattheverticuttersareinsafe

operatingconditionbykeepingallhardware

tight.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

CuttingUnitSafety

•Thecuttingunitisonlyacompletemachinewhen

installedonatractionunit.Readthetraction

unitOperator’sManualcarefullyforcomplete

instructionsonthesafeuseofthemachine.

•Stopthemachine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeinspecting

theattachmentafterstrikinganobjectorifthere

isanabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Useonlyaccessories,attachments,and

replacementpartsapprovedbyToro.

BladeSafety

Awornordamagedbladecanbreak,andapieceof

thebladecouldbethrowntowardyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

3

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal137-9706

137-9706

1.Cuttinghazardofthehandorfoot—shutofftheengine,

removethekeyordisconnectthesparkplug,waitforall

movingpartstostop,andreadtheOperator’sManual

beforeperformingmaintenance.

4

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Verticutter1Inspecttheverticutter.

Transportrollerassembly2

2Cotterpin2Installthetransportrollers.

O-ring1

3Greasetting1InstalltheO-ringandthegreasetting.

4Nopartsrequired–Adjustthebladedepth.

5Nopartsrequired–Adjustthereargrassshield.

6Nopartsrequired–Adjusttherollerscrapers.

7Nopartsrequired–Adjustthetransportrollers.

8Nopartsrequired–Mounttheverticutterreel.

MediaandAdditionalParts

DescriptionQty.Use

Operator'sManual1

PartsCatalog(notincluded)—refertothe

includedpostcardforinformationonobtaining

thePartsCatalog

–Reviewthematerialandsaveitinanappropriateplace.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

1

InspectingtheVerticutter

Partsneededforthisprocedure:

1Verticutter

Procedure

1.Checkeachendofthereelforgrease.Grease

shouldbevisiblyevidentintheinternalsplines

ofthereelshaft.

2.Ensurethatallnutsandboltsaresecurely

tightened.

2

InstallingtheTransport

Rollers

Partsneededforthisprocedure:

2Transportrollerassembly

2Cotterpin

Procedure

Secureatransportrollerbrackettoeachsideplatepin

withacotterpin(Figure3).

5

g195548

Figure3

1.Transportrollerassembly2.Cotterpin

Note:Positiontherollertotherearoftheverticutter.

3

InstallingtheO-ringand

theGreaseFitting

Partsneededforthisprocedure:

1O-ring

1Greasetting

Procedure

Installthegreasettingonthereelmotorsideofthe

verticutter.Usethefollowingdiagramtodeterminethe

positionofeachreelmotor(Figure4).

g196714

Figure4

1.Verticutter14.Weight

2.Verticutter25.Reelmotor

3.Verticutter3

1.Removeanddiscardthesetscrewonthe

reel-motorsideplate(Figure5).

g028407

Figure5

1.Bolts3.Setscrew(removeand

discard)

2.Straightgreasetting

(install)

2.Installthestraightgreasetting(Figure5).

3.Fortheverticutter3location(Figure4),move

theendweighttotheoppositesideofthecutting

unit.

4.Iftherearenoboltsonthereel-motorsideplate,

installthem(Figure5).

5.InstalltheO-ringonthereelmotor(Figure6).

g191072

Figure6

1.O-ring

6

4

AdjustingtheBladeDepth

NoPartsRequired

Procedure

Note:Themaximumrecommendedblade

penetrationdepthis6mm(1/4inch).

1.Placetheverticutterreelonalevelsurface.

2.Place2gaugebars,whichhavethedesired

depthofbladepenetrationbelowtheground,

underthefrontandrearrollersoftheverticutter

reel(oneachendofthereel)(Figure7).

g012693

Figure7

1.Gaugebar2.Adjustingbolt

Note:Theverticutterbladesmustnottouchthe

gaugebars.

3.Turntheadjustingboltoneachheight-of-cut

bracket(Figure7)sothatthereelbladescome

incontactwiththelevelsurfaceonbothends.

Note:Astheverticutterbladeswear,the

diameterofthereeldecreasesandthedepth

settingchanges.Checkthedepthsetting

periodicallytoensurethatthedesiredsettingis

achieved.

5

AdjustingtheRearGrass

Shield

NoPartsRequired

Procedure

Note:Whenoperatinginturfconditionswheremuch

debrisorunusuallyheavythatchisencountered,open

thereardischargeshieldtohelpallowthedebristo

dischargefromthereel.

1.Loosentheboltsonthepivotofthegrassshield

(Figure8).

g196703

Figure8

1.Reargrassshield2.Pivotbolt

2.Rotatethegrassshieldtothedesiredsetting,

andtightenthebolts(Figure8).

CAUTION

Donotopentherearshieldsothatitishigher

thanleveltoground.

Throwndebriscouldcausepersonalinjury.

7

6

AdjustingtheRoller

Scrapers

NoPartsRequired

Procedure

1.Loosentheangenutsthatsecuretheroller

scrapers(Figure9).

g012271

Figure9

1.Frontrollerscraper3.Transportroller

2.Rearrollerscraper4.Cotterpin

2.Movethescraperrodsinorouttoattain0.0to

0.75mm(0.0to0.03inch)clearancebetween

thescraperandroller.

3.Ensurethatthescraperrodisparalleltothe

rollerandtothelevelsurface.

4.Tightentheangenutstolocktheadjustment.

7

AdjustingtheTransport

Rollers

NoPartsRequired

Procedure

Beforetheverticuttersareloweredtotheshopoor

orremovedfromthetractionunit,lowerthetransport

rollers(Figure9)toprotectthebladesfromhard

surfacecontact.

1.Removethecotterpinthatsecuresthetransport

rollerbrackettothesideplatepin.

2.Positionthetransportrollerasfollows:

•Lowertherollerbracketbeforetheverticutter

isloweredtotheshopoor.

•Raisetherollerbracketaftertheverticutteris

raisedtotheoperatingposition.

3.Securethetransportrollerbrackettotheside

platepinwiththecotterpin.

4.Repeattheprocedureontheoppositeendof

theverticutter.

8

MountingtheVerticutter

Reel

NoPartsRequired

Procedure

Important:Whenloweringtheverticutterreels,

takecaretopreventdamagetothereelbladesdue

tocontactwithaconcreteoororapavedsurface.

Lowerthetransportrollersbeforeloweringthe

verticuttierstoaconcreteoororapavedsurface.

Figure10showstheorientationofthehydraulicdrive

motorforeachofthelocations.

Verticutterreelsaremountedtotractionunitthe

samewaycuttingunitsare.Refertothetractionunit

Operator'sManualformountinginstructions.

g196714

Figure10

1.Verticutter14.Weight

2.Verticutter25.Reelmotor

3.Verticutter3

8

ProductOverview

Specications

Netweight56kg(124lb)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedToro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

Operation

TrainingPeriod

Beforeoperatingtheverticutterreels,evaluatethe

performanceofthereelatthedesiredsetting.Operate

inaclear,unusedareatodetermineifthedesired

resultsareachieved.Adjustasdesired.

OperatingTips

1.Operatethetractionunitatfullthrottle,fullreel

speed(setting11)andbetween5to8km/h(3

to5mph).

2.Themaximumrecommendedsettingis6mm

(1/4inch)deepbladepenetration.

3.Thepowerrequirementstooperatethe

verticutterreelsvarywithturfandsoilconditions.

Travelspeedmayneedtobereducedinsome

conditions.

4.Whenoperatinginturfconditionswheremuch

debrisisencountered,orunusuallyheavy

thatch,openthefrontandreardischargeshields

tohelpallowthedebristodischargefromthe

reel.

CAUTION

Throwndebriscouldcausepersonal

injury.

Donotopentherearshieldsothatitis

higherthanleveltotheground.

9

Maintenance

UsingtheKickstandWhen

TippingtheCuttingUnit

Note:Whenevertheverticutterhastobetipped

toexposetheverticutterblades,usethekickstand

(suppliedwithtractionunit)(Figure11).

g196702

Figure11

1.Kickstand

LubricatingtheVerticutter

Eachverticutterhas5greasettings(Figure12)that

mustbelubricatedweeklywithNo.2lithiumgrease.

Thelubricationpointsarethefrontroller(2),therear

roller(2),andthereelmotorsplines(1).

Important:Lubricatingthecuttingunits

immediatelyafterwashinghelpspurgewaterout

ofthebearingsandincreasesbearinglife.

1.Wipeeachgreasettingwithacleanrag.

2.Applygreaseuntilyouseecleangreasecoming

outoftherollersealsandthebearingreliefvalve

(Figure12).

g029271

Figure12

1.Reliefvalve

3.Wipeanyexcessgreaseaway.

10

RemovingtheVerticutter

BladesfromtheShaft

1.Securetheendoftheverticuttershaft,which

hasonlyonewasherandnut,inavise.

2.Onotherendofshaft,rotatethenut

counter-clockwiseandremovethenut.

CAUTION

Thebladesareextremelysharpandmay

haveburrsthatcancutyourhands.

Usecautionwhenremovingtheblades

fromtheshaft.

3.Removethesmallspacer,thewasher,the

bladesandthelargespacers.Cleanand

lubricatethesquareshaftwithalightcoatingof

greasetosimplifytheassembly(Figure13).

g010889

Figure13

1.Shaft4.Smallspacer

2.Nut5.Blade(19)

3.Washer6.Largespacer(18)

Important:Donotinverttheverticutter

reelblades.Theorderofdisassemblyis

extremelyimportant.Donotinvertthe

verticutterreelbladeswhendisassembling

orreversetheorderwhenassemblingthem.

Notetheverticutterbladesindexhole.The

indexholeisprovidedforassemblyinorder

toobtaintheproperhelixfortheverticutter

reel.

InstallingtheVerticutter

Blades

1.Assembleareelblade(Figure14).

2.Assemblealargespacer.

3.Donotinvertthereelbladeswhenassembling

themontothereelshaft.

Note:Ifthebladesareinverted,thebladesthat

areinuse(rounded)mixwiththesharpends

ofthepreviouslyunusedblades;thiscauses

unsatisfactoryverticutterperformance.

4.Installthenextbladeclockwisesothattheindex

referencehole(Figure14)isnotalignedwiththe

rstbladeholebyoneatoftheshaft.

g010890

Figure14

1.Indexreferencehole

5.Continuetoinstallspacersandbladesinthis

manneruntilthefullcomplementofbladeshas

beeninstalled.

Note:Whenproperlyassembled,theblades

arestaggeredinsuchamannerastoappear

likeahelix.

6.Installthesmallspacertotheshaft.

7.ApplyBlueLoctite242tothenut.Installthenut

ontotheshaft(machinedsideofthenuttoward

thespacer)andtightenitto109to135N∙m(80

to100ft-lb).

11

OptionalBladeSpacing

Changingthecongurationoftheverticutterfromthestandardspacing(1.20inches)totheoptionalspacing

(0.94inch)requiresanadditional23spacers(PartNo.140-5532)andanadditional5carbide-tipblades(Part

No.106-8625)asshowninFigure15.

g349402

Figure15

1.1.20-inchbladespacing(default)2.0.94-inchbladespacing

12

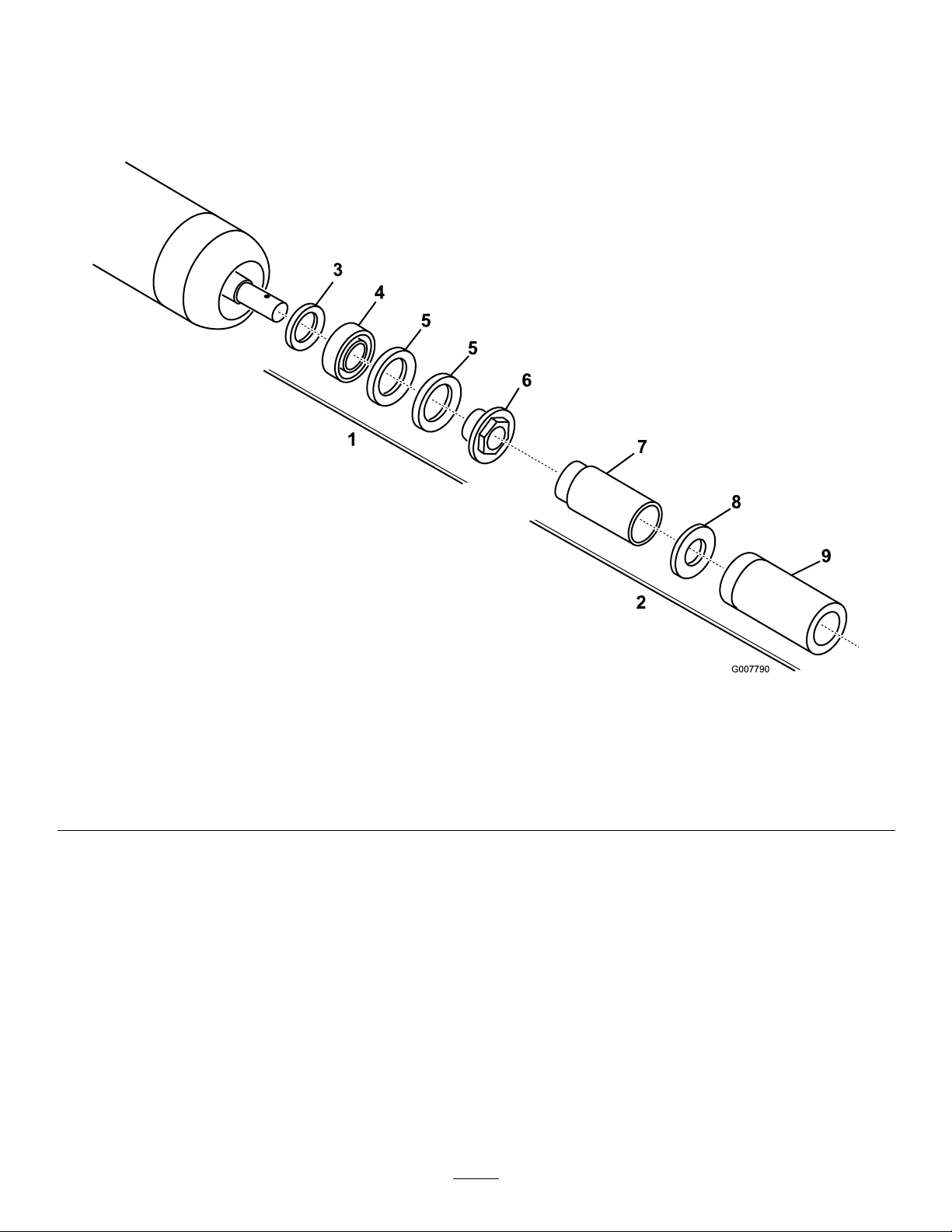

ServicingtheRoller

TheRollerRebuildKit(PartNo.114-5430)andthe

RollerRebuildToolKit(PartNo.115-0803)(Figure

16)areavailableforservicingtheroller.TheRoller

RebuildKitincludesallthebearings,bearingnuts,

innerseals,andoutersealstorebuildaroller.

TheRollerRebuildToolKitincludesallthetoolsand

theinstallationinstructionsrequiredtorebuildaroller

withtherollerrebuildkit.Refertoyourpartscatalogor

contactyourauthorizedTorodistributorforassistance.

g007790

Figure16

1.RollerRebuildKit(PartNo.114-5430)6.Bearingnut

2.RollerRebuildToolkit(PartNo.115-0803)7.Innersealtool

3.Innerseal8.Washer

4.Bearing9.Bearing/outer-sealtool

5.Outerseal

13

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

03203408000000andUp

27-inchVerticutter,

Reelmaster3100-DSeries

DPACuttingUnit

RM310027IN

VERTICUTTERCUVerticutter2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

JohnHeckel

EngineeringDirector

8111LyndaleAve.South

Bloomington,MN55420,USA

February15,2021

EEA/UKPrivacyNotice

Toro’sUseofYourPersonalInformation

TheToroCompany(“T oro”)respectsyourprivacy.Whenyoupurchaseourproducts,wemaycollectcertainpersonalinformationaboutyou,eitherdirectly

fromyouorthroughyourlocalT orocompanyordealer.T orousesthisinformationtofullcontractualobligations-suchastoregisteryourwarranty,

processyourwarrantyclaimortocontactyouintheeventofaproductrecall-andforlegitimatebusinesspurposes-suchastogaugecustomer

satisfaction,improveourproductsorprovideyouwithproductinformationwhichmaybeofinterest.Toromayshareyourinformationwithoursubsidiaries,

afliates,dealersorotherbusinesspartnersinconnectiontheseactivities.Wemayalsodisclosepersonalinformationwhenrequiredbylaworin

connectionwiththesale,purchaseormergerofabusiness.Wewillneversellyourpersonalinformationtoanyothercompanyformarketingpurposes.

RetentionofyourPersonalInformation

Torowillkeepyourpersonalinformationaslongasitisrelevantfortheabovepurposesandinaccordancewithlegalrequirements.Formoreinformation

aboutapplicableretentionperiodspleasecontact[email protected].

Toro’sCommitmenttoSecurity

YourpersonalinformationmaybeprocessedintheUSoranothercountrywhichmayhavelessstrictdataprotectionlawsthanyourcountryofresidence.

Wheneverwetransferyourinformationoutsideofyourcountryofresidence,wewilltakelegallyrequiredstepstoensurethatappropriatesafeguardsare

inplacetoprotectyourinformationandtomakesureitistreatedsecurely.

AccessandCorrection

Youmayhavetherighttocorrectorreviewyourpersonaldata,orobjecttoorrestricttheprocessingofyourdata.T odoso,pleasecontactusbyemail

at[email protected].IfyouhaveconcernsaboutthewayinwhichT orohashandledyourinformation,weencourageyoutoraisethisdirectlywithus.

PleasenotethatEuropeanresidentshavetherighttocomplaintoyourDataProtectionAuthority.

374-0282RevC

TheToroWarranty

Two-Yearor1,500HoursLimitedWarranty

ConditionsandProductsCovered

TheToroCompanywarrantsyourToroCommercialproduct(“Product”)

tobefreefromdefectsinmaterialsorworkmanshipfor2yearsor

1,500operationalhours*,whicheveroccursrst.Thiswarrantyis

applicabletoallproductswiththeexceptionofAerators(referto

separatewarrantystatementsfortheseproducts).Whereawarrantable

conditionexists,wewillrepairtheProductatnocosttoyouincluding

diagnostics,labor,parts,andtransportation.Thiswarrantybegins

onthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

Astheproductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Repairsforproductissues

causedbyfailuretoperformrequiredmaintenanceandadjustmentsarenot

coveredunderthiswarranty.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partsconsumedthroughusethatarenotdefective.Examplesofparts

whichareconsumed,orusedup,duringnormalProductoperation

include,butarenotlimitedto,brakepadsandlinings,clutchlinings,

blades,reels,rollersandbearings(sealedorgreasable),bedknives,

sparkplugs,castorwheelsandbearings,tires,lters,belts,andcertain

sprayercomponentssuchasdiaphragms,nozzles,owmeters,and

checkvalves.

•Failurescausedbyoutsideinuence,including,butnotlimitedto,

weather,storagepractices,contamination,useofunapprovedfuels,

coolants,lubricants,additives,fertilizers,water,orchemicals.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.Normal

“wearandtear”includes,butisnotlimitedto,damagetoseatsdueto

wearorabrasion,wornpaintedsurfaces,scratcheddecalsorwindows.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumber

ofkilowatt-hourstheycandeliverduringtheirlifetime.Operating,

recharging,andmaintenancetechniquescanextendorreducetotal

batterylife.Asthebatteriesinthisproductareconsumed,theamount

ofusefulworkbetweenchargingintervalswillslowlydecreaseuntilthe

batteryiscompletelywornout.Replacementofwornoutbatteries,

duetonormalconsumption,istheresponsibilityoftheproductowner.

Note:(Lithium-Ionbatteryonly):Refertothebatterywarrantyforadditional

information.

LifetimeCrankshaftWarranty(ProStripe02657Model

Only)

TheProstripewhichisttedwithagenuineToroFrictionDiscand

Crank-SafeBladeBrakeClutch(integratedBladeBrakeClutch(BBC)+

FrictionDiscassembly)asoriginalequipmentandusedbytheoriginal

purchaserinaccordancewithrecommendedoperatingandmaintenance

procedures,arecoveredbyaLifetimeWarrantyagainstenginecrankshaft

bending.Machinesttedwithfrictionwashers,BladeBrakeClutch(BBC)

unitsandothersuchdevicesarenotcoveredbytheLifetimeCrankshaft

Warranty.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesToroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

TheToroCompanyisnotliableforindirect,incidentalorconsequential

damagesinconnectionwiththeuseoftheToroProductscoveredby

thiswarranty,includinganycostorexpenseofprovidingsubstitute

equipmentorserviceduringreasonableperiodsofmalfunctionor

non-usependingcompletionofrepairsunderthiswarranty.Except

fortheEmissionswarrantyreferencedbelow,ifapplicable,thereisno

otherexpresswarranty.Allimpliedwarrantiesofmerchantabilityand

tnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

NoteRegardingEmissionsWarranty

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentation.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contactyourAuthorizedT oroServiceCenter.

374-0253RevH

Other manuals for 03200 Reelmaster 3100-D

12

This manual suits for next models

1

Table of contents

Other Toro Cutter manuals

Popular Cutter manuals by other brands

Logan

Logan FoamWerks W3002 instruction manual

Holmatro

Holmatro BCU 05 A Series manual

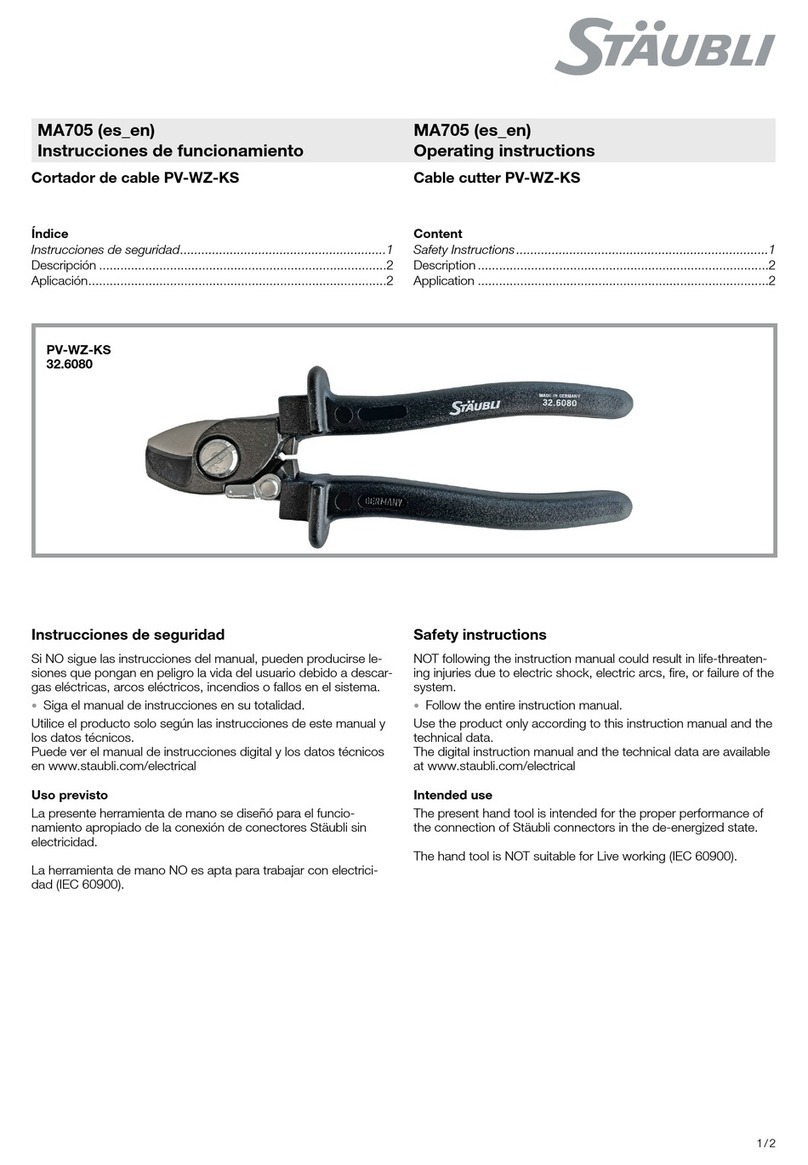

Staubli

Staubli PV-WZ-KS operating instructions

Mafell

Mafell KF 1000 Translation of the original operating manual

Mafell

Mafell KSS40 18 M bl Translation of the original operating instructions

Inder

Inder P-305 Series User instruction manual