Flavor Burst TS 44SS/BEV User manual

©2014 Flavor Burst Company Printed in January Printed in

All Rights Reserved The United States of America

Flavor Burst®

Frozen Beverage System

Model TS 44SS/BEV

Manufactured by

Flavor Burst Company

499 Commerce Drive

Danville, IN 46122

For general information and to locate a

distributor near you, call or visit our website:

Phone: (317) 745-2952

Toll Free Number: (800) 264-3528

Fax: (317) 745-2377

www.flavorburst.com

For pricing, ordering and support, contact one

of our qualified distributors.

Warranty

An installation and warranty form is provided with every TS 44SS/BEV system, located inside the

TS 44SS/BEV unit with this manual. It is important that the operator carefully review the warranty and

installation documents accompanying the unit before using this system. Any questions or concerns

regarding the warranty should be clarified upon delivery or installation. For more information, contact

your local authorized Flavor Burst ®distributor.

1

TABLE OF CONTENTS

Safety Precautions and Procedure Notes….…………….………..……..….…………....3

Introduction……………………………...………………………………………….………….4

Parts Identification/Function……...……………………….……..…..……….……..….…..5

Daily Opening Procedures……..………………………….…….…..…….………..……...30

Sanitizing the Injector / Blending System…………………….……………...…...…30

Assembling the Injector / Blending Assembly……...………………...……….....…31

Installing the Injector / Blending System……………………………………….……31

Other items to check during opening procedures……………………………….…32

Daily Closing Procedures………………………………………….……………….………34

Removing the Injector / Blending System………………………...…………....…...34

Disassembling the Injector / Blending Assembly…………………………......……35

Sanitizing the Injector / Blending System……………………....…………........…..35

Replacing the Syrup Flavors…………...…………………………..…….………...……...38

Scheduled Maintenance…………...……………………………….…….………...…...….42

Clean-In-Place (CIP) Procedure…………………………………....…………..…...42

CIP –Phase 1: 9-Tube Assembly Cleaning……………………………...…42

CIP –Phase 2A: Soft Serve Syrup System Cleaning…………….......…...43

CIP –Phase 2B: Frozen Beverage Syrup System Cleaning………......…46

CIP –Phase 3: Reassembly………………………………….……….......…48

Priming the Syrup System………………………………….....…………...….......…50

Refilling the Sanitizer Tank…………………………………..........……………....…51

Cleaning the Spout Adapter………………………………….....…………...........…52

Replacing Injector / Blending Head O-Rings………………….....………...........…53

Miscellaneous Cleaning Procedures…………………………………………......…54

Area Under the Cabinet………………………………….....……………...…54

Inside the Cabinet………………………..…….....………….……….........…55

Tube / Cable Casing Assemblies………………………….………….…..…55

Injector / Blending Assembly Suspension Bracket………..………….……55

9-Tube Assembly Syrup Lines……………………....……………….…....…55

Winterizing the Unit ………………………………..…………...……………..…...…56

2

Equipment Setup……………………………………………………...…..……….……..….60

Installing the Spout Adapter.………………………………..…………………......…60

Installing the Touchscreen and Mounting Bracket……...………………...….....…61

Installing and Connecting the Spigot Switch to the Soft Serve Freezer…………62

Installing and Connecting the Spigot Switch to the Frozen Beverage Freezer…63

Installing the ELE 510 Spigot Switch Externally……………………………………63

Installing the ELE 510 Internally on a Taylor 428 / 430 Freezer………………….65

Sanitizing the Injector / Blending System………………………...………...........…66

Assembling the Injector / Blending Assembly……………………....…...…………67

Recommended Mounting Positions for the Injector / Blending System …………67

Installing the Injector / Blending System and Suspension Bracket……….…...…68

Mounting the Tube / Cable Casing Assemblies……………………...……….....…70

Connecting the Unit Syrup Lines…………………………………………….........…71

Installing and Filling the Sanitizer Tank………………………….…………….....…74

Power Connections and Power Up……………………………………….…........…75

Installing Flavors and Priming Syrup Lines………………………...……….…...…76

Touchscreen Operations…………...…….……………………………………....……...…78

Calibrating the Touchscreen……………..….…………………………………….…78

Enabling the TS 44SS/BEV System….…………………………………………...…79

Testing the TS 44SS/BEV System…………..…………………....……………...…82

Draw Modes Options….………………………………………………………...…….83

Enabling the Standard Manual Draw Mode…………............................…83

Dispensing Product –Standard Manual Draw Mode……………….…..…84

Enabling the Timed Serving Size Draw Mode………..………………….....85

Dispensing Product –Timed Serving Size Draw Mode……………….…..86

Setting Serving Size Timing……………....………………..…................................88

Adjusting the End of Serving Delay Timing………………………………...……….89

Assigning Flavors to the Menu……………………………………………………….91

Adjusting Flavor Dispense Rate………………………...…………………….......…92

Adjusting Alternating Flavor Timing………………………………….………..….…93

Enabling the Injector Flush Feature…..……………………………………………..94

......82 Accessing the Water / Syrup Flush Mode…………………………………….……95

Accessing the Prime Syrup Pump Mode…………………………………….…...…96

Enabling Pass Code Feature.…………………………………………..…..……..…97

Accessing and Resetting the Serving Count……………………………….……….98

Accessing the Diagnostics Information...…………………....................................99

Enabling the Second Language Option……………………………………………100

Enabling the Dispense Instruction Screen………………………………………...101

Enabling the Self Serve Mode………………………………………………………102

Updating and Creating Touchscreen Labels………………..………………….…104

Uploading the Touchscreen Labels…………………………….……………….....105

Reformatting the SD Card……..………………………………………………..…..107

Directory of Cleaning Procedures……………………………...……………………..…108

Parts Replacement Schedule………...………………….………………..…...…………109

Recommended Maintenance Items Replacement Schedule………………....…..…110

Alternate Parts and Kits by Freezer Model……………………………...…….…….…110

Ordering/Service Information………….…….…...……………………….…….......……111

3

Always follow these safety precautions when

operating the Flavor Burst®system:

DO NOT operate the system without

reading this operator’s manual. Failure to follow

this instruction may result in equipment

damage, poor system performance, health

hazards, or personal injury.

DO NOT operate the system unless it is

properly grounded. Failure to follow this

instruction may result in electrocution.

DO NOT operate the system with larger

fuses than specified on the system data label.

Failure to follow this instruction may result in

electrocution or damage to the machine.

Consult your electrician.

DO NOT put objects or fingers in the

door spout. Failure to follow this instruction may

result in contaminated product or personal

injury from blade contact.

The TS 44SS/BEV cabinet system must

be placed on a level surface capable of

supporting at least 220 lbs of weight. Failure to

comply may result in personal injury or

equipment damage.

DO NOT install the unit in an area where

a water jet could be used, and do not use a

water jet to clean or rinse the system. Failure to

follow these instructions may result in serious

electrical shock.

NOISE LEVEL: Airborne noise emission

does not exceed 70 dB(A) when measured at a

distance of 1.0 meter from the surface of the

machine and at a height of 1.6 meters from the

floor.

NOTE: Operations Manual subject to change.

Parts and part numbers may vary from what is

shown and listed. Contact your local distributor

for most recent updates concerning the unit.

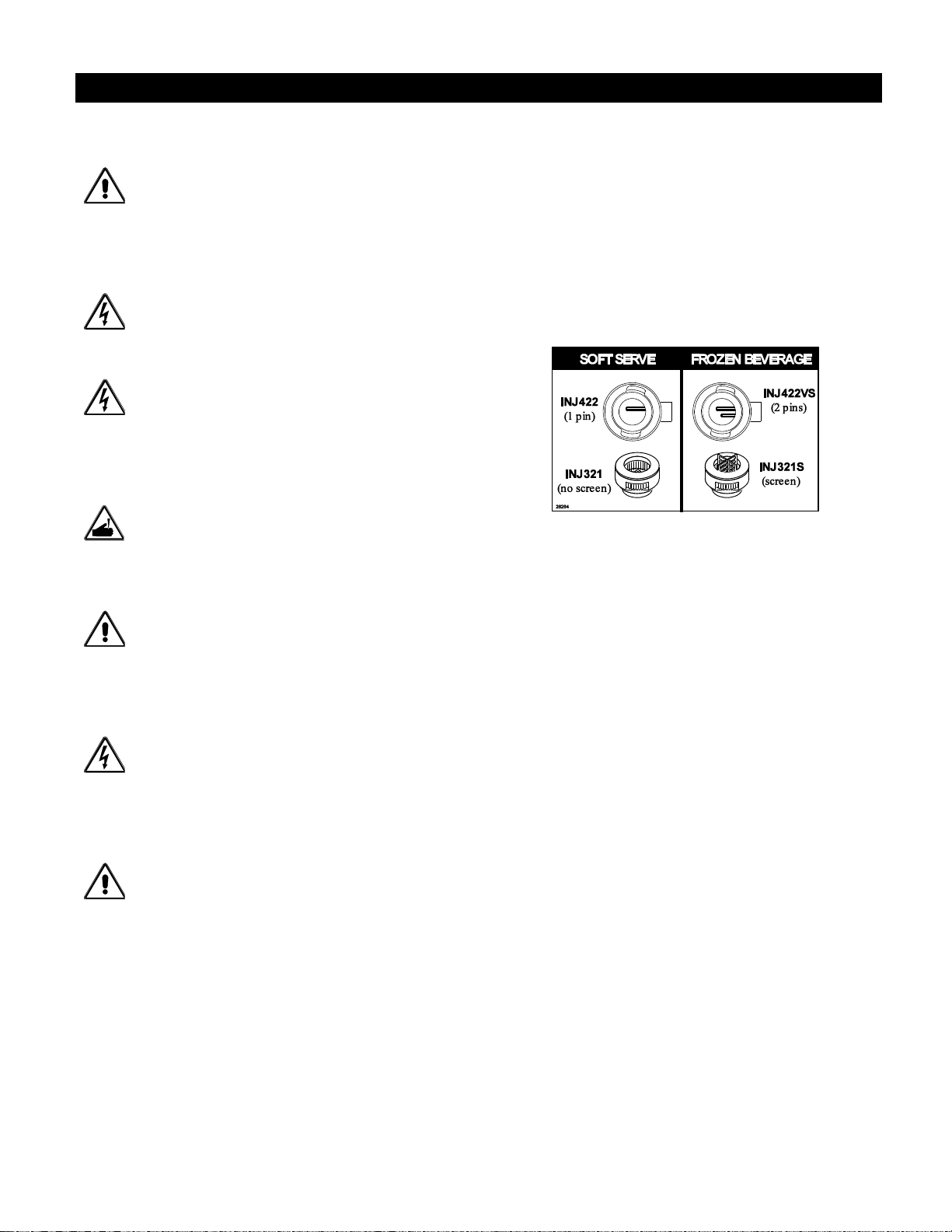

NOTE: The components of both the Injector

and Blending Assemblies appear very similar,

but are specifically designed to work for either

soft serve or shake product. Ensure the

Injector Head INJ 422 (has one internal pin) is

installed with Gear Cartridge INJ 321 (no

screen) on the soft serve freezer only. Ensure

the Blending Head INJ 422VS is installed with

the Gear Cartridge INJ 321S (with screen) on

the frozen beverage freezer only. Mismatching

parts may result in poor product quality.

NOTE: Illustrations may only show soft serve

parts, freezers and fitments when instructions

also apply to frozen beverage parts, freezers

and fitments where noted.

NOTE: Your hands should be cleaned and

sanitized before you perform these procedures.

NOTE: The procedures in this manual require

approved, serviceable and sanitized tools and

brushes. Contact your local distributor for

recommended supplies.

NOTE: Use an approved cleaner and sanitizer

for the procedures in this manual. Refer to

manufacturer’s instructions for proper

preparations of these cleaning agents.

NOTE: Inspect all wear items during

procedures and replace if necessary.

NOTE: Consult your local distributor if you

have any questions concerning differences.

NOTE: If installing this unit on a frozen

carbonated beverage freezer, please refer to

the TS 80FCB operations manual for

instructions on installing, maintaining and

operating the FCB side components.

SAFETY PRECAUTIONS & PROCEDURE NOTES -- PLEASE READ!

4

Congratulations on your purchase of a TS 44SS/BEV flavoring system! As a

food and beverage provider, your customers are your greatest asset. Your

primary concern must be the health and welfare of your customers. This manual

provides everyday operating guidelines and procedures. Special functions have

been incorporated into the equipment to provide simple and effective cleaning

and sanitizing of your unit. We urge you to follow these instructions carefully and

maintain strict sanitary practices in your daily operating routine.

The TS 44SS/BEV series unit is an add-on system that flavors both a soft-serve

freezer barrel and a frozen beverage freezer barrel, blending concentrated

flavorings throughout the base product as it is dispensed. Dispensing Flavor

Burst product is very simple. Select a flavor from the Touchscreen and draw the

product. The Flavor Burst system will automatically flavor the product at the

spout. You can also have multiple flavors per serving. Simply select the flavors

from the Touchscreen and draw the product. The system will switch from one

flavor to the next in a smooth, continuous motion, layering the serving with

delicious flavors.

Flavor Burst®syrup is stored within the equipment cabinet in 1 gallon disposable

bags. Proper syrup injection rate is maintained by adjusting the flavor level on

the Touchscreen.

Components of the TS 44SS/BEV system should be cleaned daily to ensure the

highest standard of sanitation. When your equipment arrives or if it has been

unused for more than 24 hours, follow the DAILY OPENING PROCEDURES.

INTRODUCTION

5

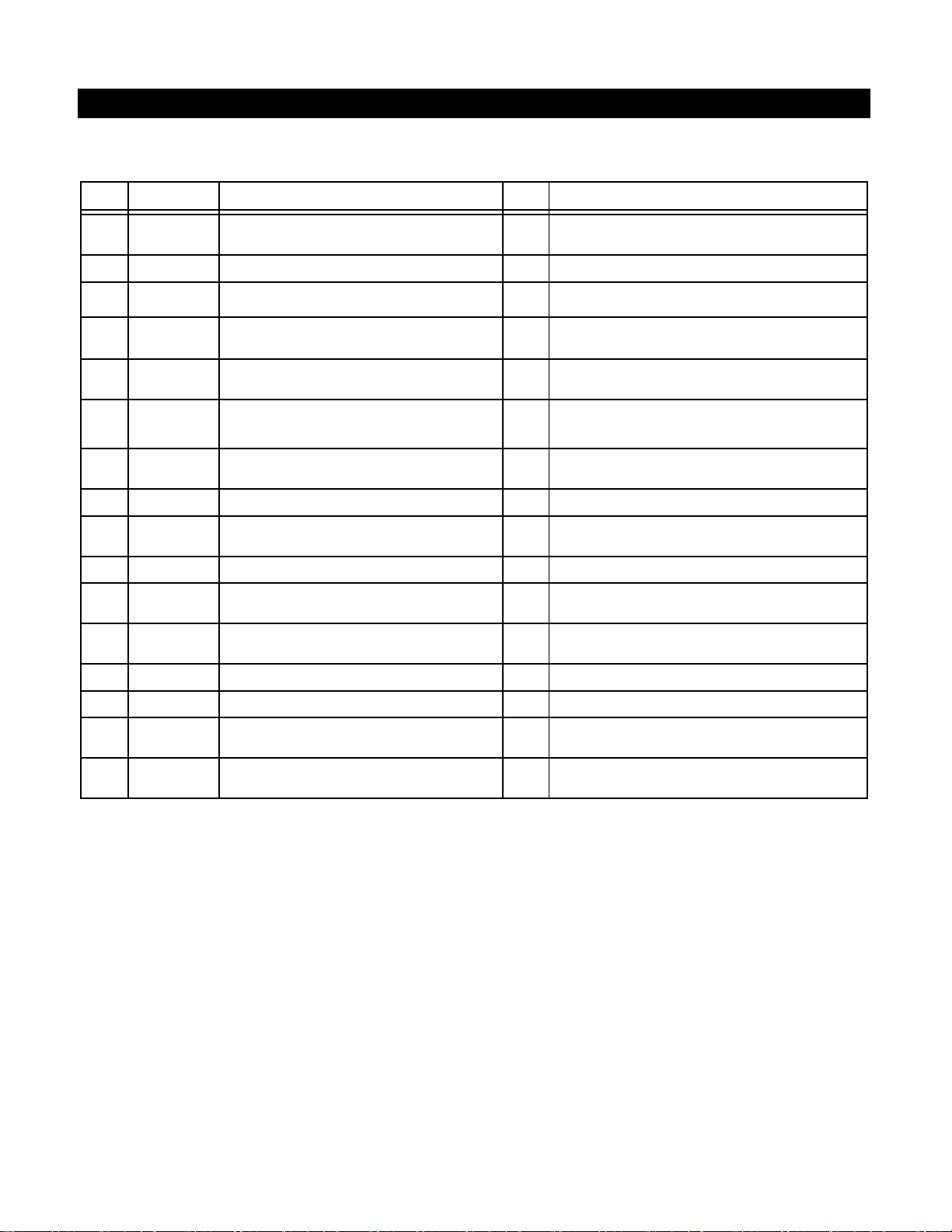

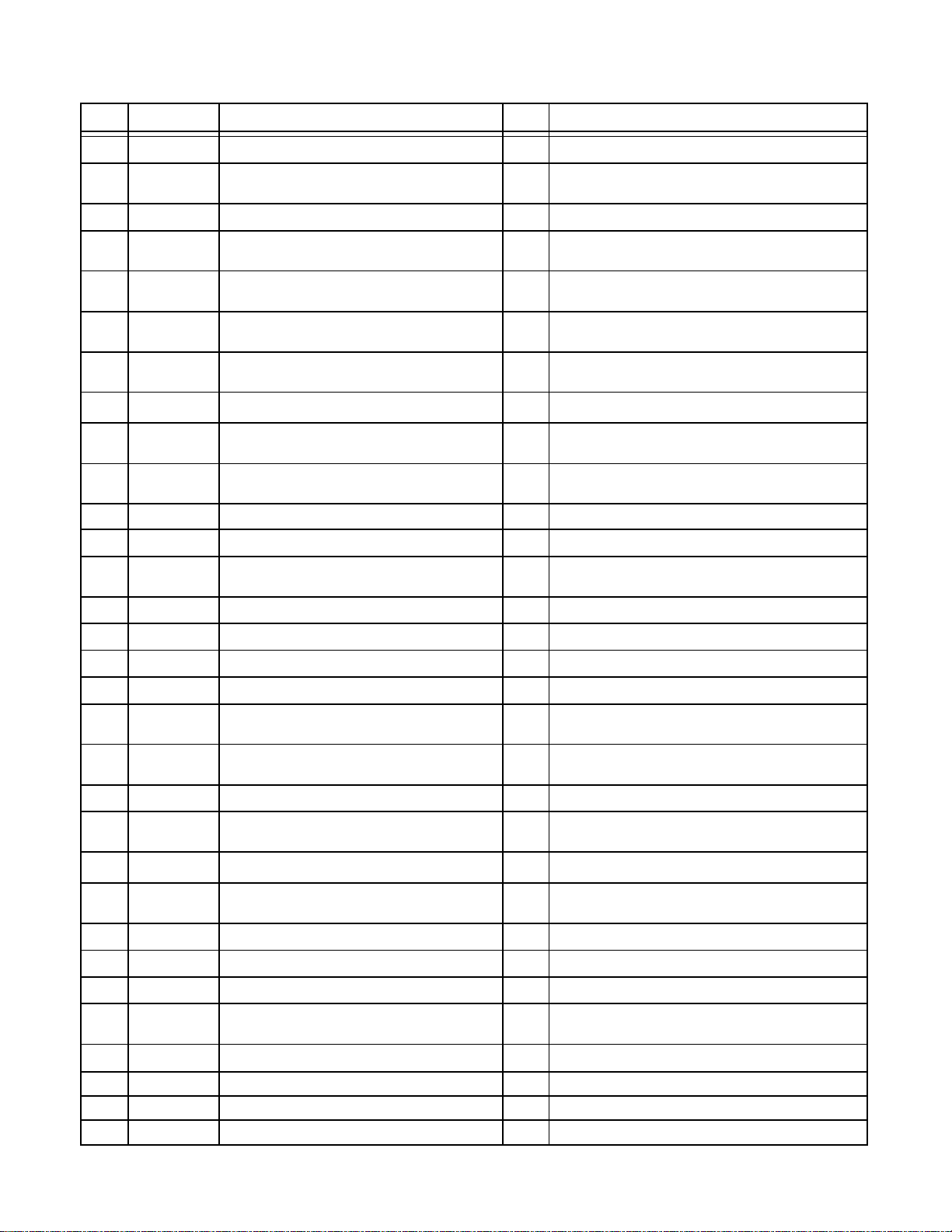

General System Overview (See Figure 1)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

1

ELE

805SS/BEV

TOUCHSCREEN ASSEMBLY

1

Flavor Burst unit command center.

2

ELE 434

POWER CABLE

1

Supplies the electronics board with power.

3

INJ 424VTS

VERTICAL BLENDING ASSEMBLY

1

Injects syrups into the product.

4

MIS 3196

STAINLESS TUBE / CABLE CASING

ASSEMBLY

3

Attaches the flavor lines and/or cables to the

side of the freezer.

5

SYR 944SH

SYRUP BAG CONNECTOR

ASSEMBLY - SHAKE

4

Transports syrup from the bag to the pumps.

6

CAB 113

FLAVOR TRAY

8

Houses syrup bags.

7

N/A

FLAVOR BURST MX CABINET

ASSEMBLY

1

Houses syrup trays and bags.

8

SAN 740

SANITIZER TANK ASSEMBLY

1

Houses sanitizer cleaning solution.

9

SYR 944

SYRUP BAG CONNECTOR

ASSEMBLY

4

Transports syrup from the bag to the pumps.

10

SYR 935

4’ 9-TUBE ASSEMBLY EXTENSION

1

Adds length to the flavor line assembly.

11

ELE 525

36” SPIGOT SWITCH EXTENSION

WIRE

1

Adds length to the spigot switch.

12

ELE 810

SD CARD READER

1

Transfers updated programming and files

from the computer to the SD card.

13

INJ 424TS

INJECTOR ASSEMBLY

1

Injects syrups into the product.

14

SPR 5800A

SPARE PARTS KIT SOFT SERVE

1

Houses extra spare parts and wear items.

15

SPR

5800BEV

SPARE PARTS KIT TOUCHSCREEN

FROZEN BEVERAGE

1

Houses extra spare parts and wear items.

16

SYR 941A

FLAVOR BAG ADAPTER

4

Connects soft serve flavor bag to syrup out

tube.

PARTS IDENTIFICATION/FUNCTIONS

6

General System Overview

Figure 1

7

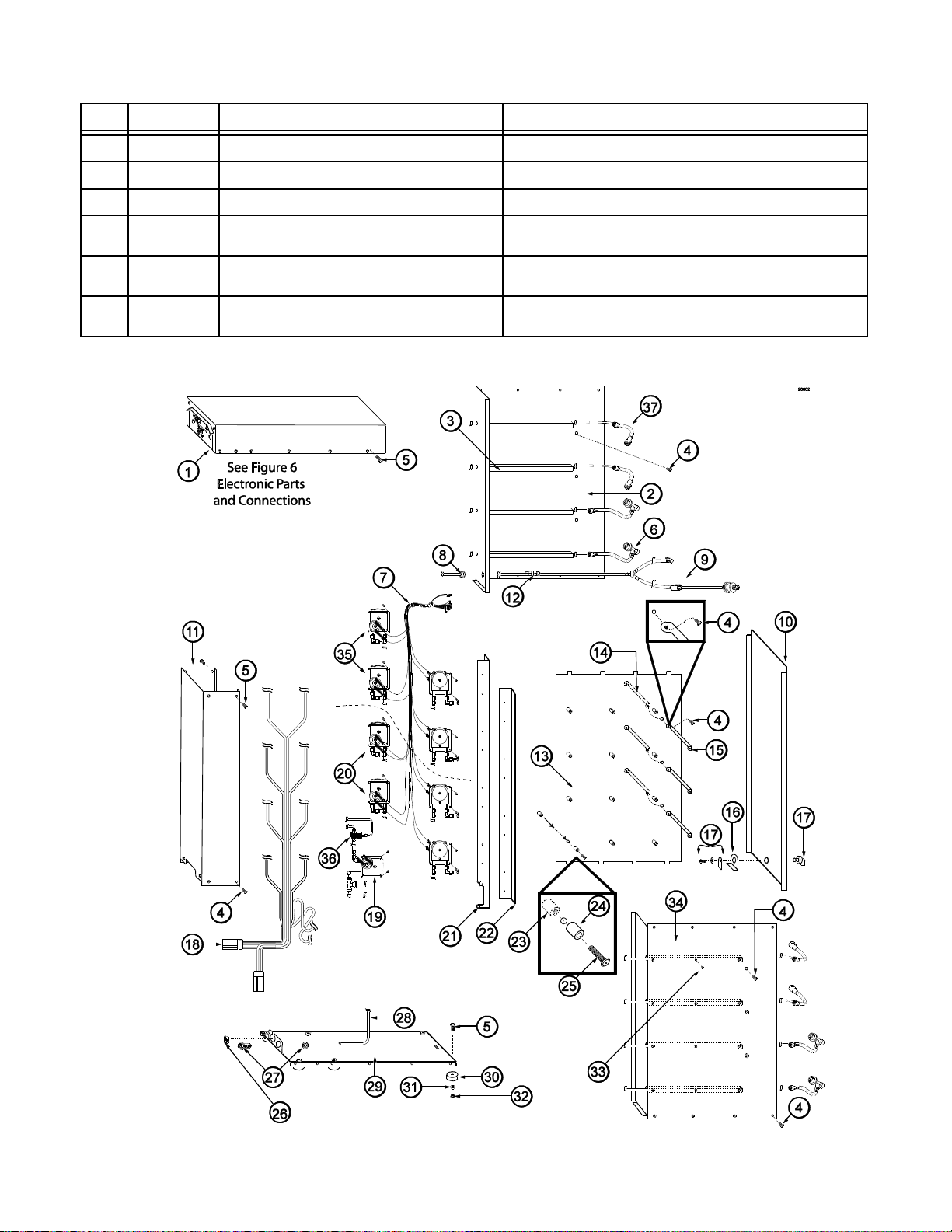

Cabinet –(See Figure 2)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

1

N/A

ELECTRONICS SYSTEM

1

Houses microprocessor and electronics.

2

CAB 135R-A

RIGHT SIDE PANEL

1

Holds tray support brackets and panel

brackets.

3

CAB 145

TRAY SUPPORT BRACKET

8

Supports flavoring trays.

4

FAS 2024

8-32 X 1/4 PAN HEAD

28

Fastens panel brackets to divider panel,

secures sides.

5

FAS 2014

8-32 X 1/2" PAN HEAD

25

Attaches top panel, back cover, and

feet to cabinet.

6

SYR 944SH

SYRUP TUBE ASSEMBLY –

SHAKE

4

Transports the flavoring from the syrup bag

to the syrup pump.

7

ELE 496TS

PUMP & SANITIZER CABLE

HARNESS

1

Provides power to syrup / sanitizer pumps.

8

MIS 3066

MINI BUSHING

1

Protects flush tube.

9

MIS 3028-

CMX

FLUSH TUBE ASSEMBLY - CMX

1

Connects with flavor line to flush with

sanitizer solution.

10

CAB 139

FRONT DOOR PANEL

1

Provides easy access to syrup bags and

connectors.

11

CAB 136-A

REAR PUMP COVER

1

Back panel to cover pumps.

12

FIX 1023

3/16" X 3/16" BARB TUBE CONNECT

1

Splices together flush tubes.

13

CAB 134

DIVIDER PANEL

1

Holds tray support brackets and divides

flavor trays.

14

CAB 144R

RIGHT PANEL BRACKET

3

Holds tray support rails.

15

CAB 144L

LEFT PANEL BRACKET

3

Holds tray support rails.

16

CAB 143

LATCH BRACKET

1

Provides latching tab for front panel.

17

FAS 2001

FRONT DOOR PANEL LATCH

1

Latches front door to cabinet front.

18

SYR 938

MX SERIES INTERNAL 9-TUBE

ASSEMBLY

1

Transports syrup from bags to flavor

9-Tube Assembly.

19

SAN 748

PERISTALTIC SANITIZER PUMP

1

Pumps sanitizer solution to flush tube

and sanitizer line.

20

SYR 926

PERISTALTIC SYRUP PUMP - SHAKE

4

Pumps syrup from flavor bags to flavor lines.

21

CAB 155L

PUMP MOUNTING STRIP

1

Support for syrup trays and spacing

between panels.

22

CAB 155R

PUMP MOUNTING STRIP

1

Supports syrup trays and spaces panels.

23

FAS 2037

TAPPED NYLON SPACER

12

Secures screw to center panel, and

support for trays.

24

FAS 2032

STANDARD NYLON SPACERS

12

Provides extra support for flavor trays.

25

FAS 2034

8-32 X 3/4" MACHINE SCREW

12

Attaches bushings to divider panel.

26

MIS 3067

OPEN/CLOSED BUSHING

1

Strain relief for internal 9-Tube Assembly.

27

FIX 1033

1/4" X 1/4" BLKHD (PUSH-TO-

CONNECT)

1

Connects Sanitizer Tank tube to the unit.

28

TUB 803

TUBING-PER FOOT

1

Transports sanitizer from tank to pump.

29

CAB 133

BASE PANEL

1

Attaches inner and side panel bottoms.

30

RUB 618

RUBBER BUMPER WITH WASHER

6

Provides spacing between base and table.

31

FAS 2035

8-32 NUTS - EXT. LOCK WASHER

6

Holds rubber bumper in place.

8

Cabinet (Continued)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

32

MIS 3074

SHORTY PLUG #1672

6

Covers screw hole in rubber bumper.

33

FAS 2040

6-32 X 1/4" TAPPING SCREW

24

Secures tray support bracket to side panels.

34

CAB 135L-A

LEFT SIDE PANEL

1

Holds support brackets and panel brackets.

35

SYR 307

PERISTALTIC SYRUP PUMP –SOFT

SERVE

4

Pumps syrup from flavor bags into flavor

lines.

36

VAL 210

MX SERIES VALVE ASSEMBLY

1

Splits & diverts syrup from pump to activate

syrup line.

37

SYR 944

SYRUP BAG CONNECTOR

ASSEMBLY

4

Transports syrup from the bag to the pumps.

Cabinet

Figure 2

9

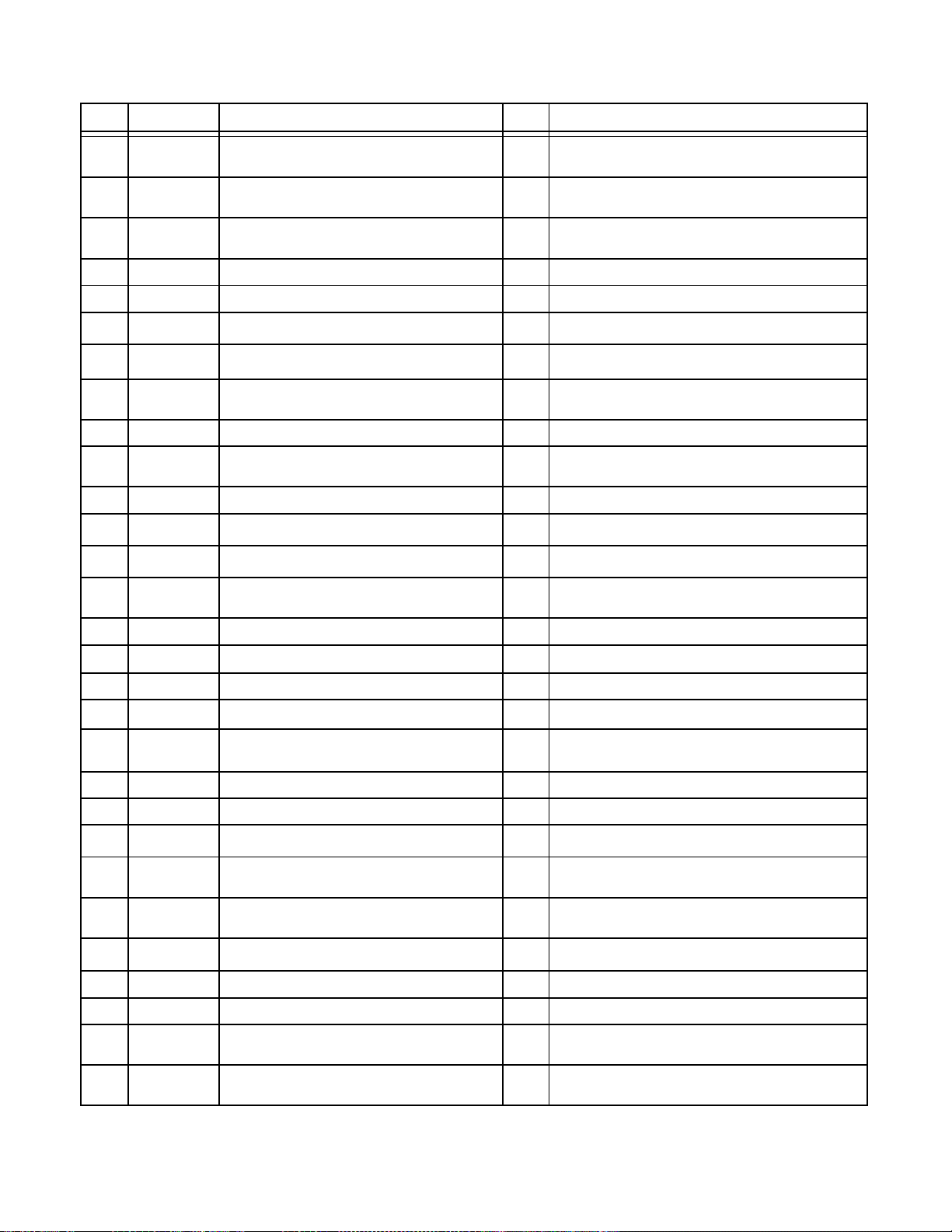

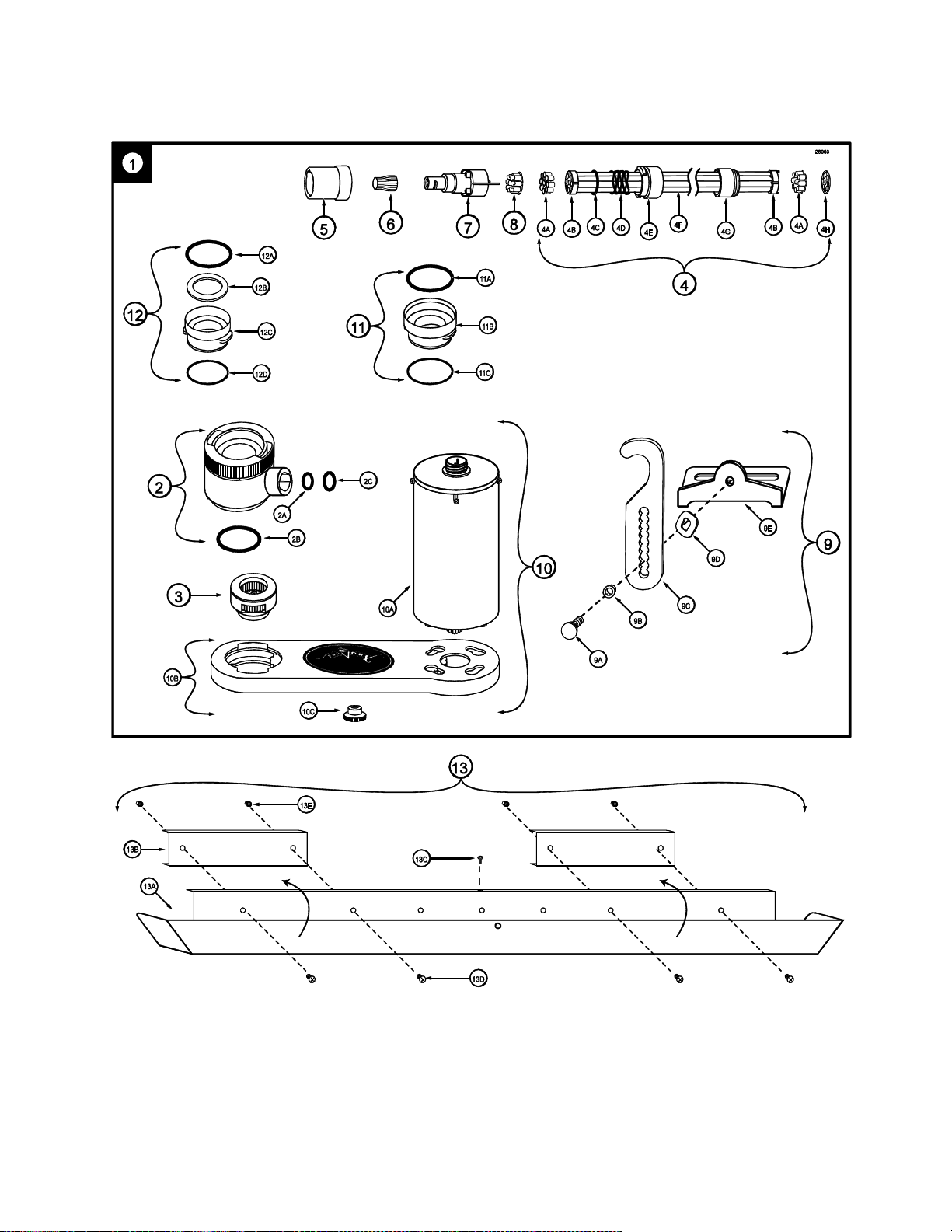

Injector Assembly and Related Parts (See Figure 3)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

1

INJ 424TS

INJECTOR ASSEMBLY WITH SYRUP

LINES, ADAPTER, & BRACKET

1

Transports and blends syrup into product.

2

INJ 422

INJECTOR HEAD ASSEMBLY

1

Connects flavor line to inject syrups into

product.

2A

RUB 652-

RSS

SMALLER SYRUP PORT O-RING

1 ea.

Provides sealed cavity inside syrup port.

2B

RUB 651

INJECTOR HEAD O-RING 2-020

1 ea.

Provides a sealed cavity.

2C

RUB 660

LARGER SYRUP PORT O-RING

1 ea.

Provides sealed cavity inside syrup port.

3

INJ 321

GEAR CARTRIDGE ASSEMBLY

1

Rotates product for even syrup distribution.

4

SYR 932

6' 9-TUBE ASSEMBLY

1

Supplies syrup to Injector Head from pumps.

4A

FAS 2051

ROLLED FLANGE EYELET

18

ea.

Provides tension in syrup line to affix to line

coupler.

4B

ROT 510

LINE COUPLER

2 ea.

Holds flavor lines in place.

4C

RUB 610

BAG CONNECTOR O-RINGS

1 ea.

Provides extra tension between tube

connectors.

4D

ROT 515-A

9-TUBE ASSEMBLY WAVE SPRING

1 ea.

Provides tension between tube connectors.

4E

INJ 116

LINE COUPLER NUT - BLACK

1 ea.

Attaches flavor tubes to flavor manifold.

4F

SYR 901

6' 9-TUBE ASSEMBLY TUBES

9 ea.

Brings syrup from pump to Injector Head.

4G

ROT 511

LINE COUPLER NUT

1 ea.

Connects flavor lines to the internal 9-Tube

Assembly.

4H

RUB 602

9-POS TUBE CONN. GASKET

1 ea.

Provides sealed cavity.

5

INJ 117

TUBE CONNECTOR BODY –BLACK

1

Secures flavor line manifold to flavor lines.

6

MIS 3142

FLAVOR LINE DUST CAP –FB 80

1

Covers syrup manifold when not connected.

7

INJ 201A

SYRUP MANIFOLD - BLACK

1

Connects flavor line to Injector Head.

8

RUB 601

9-POS DUCKBILL CHECK VALVE

1

Provides sealed cavity and prevents syrup

leakage.

9

MIS 3143

SUSPENSION BRACKET ASSEMBLY

1

Secures Inj. Assembly to the freezer door.

9A

FAS 2107

INJECTOR BRACKET KNOB

1 ea.

Secures the two bracket pieces.

9B

MIS 3144

NYLON SHOULDER WASHER

1 ea.

Allows free horizontal movement for bracket.

9C

MIS 3143A

SUSPENSION BRACKET PART A

1 ea.

Attaches to freezer door bolts to hang

Injector Assembly.

9D

ROT 535

INJ. BRACKET SPRING WASHER

1ea.

Allows space between hanging and base

brackets.

9E

MIS 3143B

SUSPENSION BRACKET PART B

1 ea.

Secures Bracket Assembly to Inj. Assembly.

10

INJ 323TS

INJECTOR ASSEMBLY - NO HEAD

1

Powers Injector system.

10A

INJ 330TS

INJECTOR MOTOR ASSEMBLY

1 ea.

Supplies power to Motor which turns gears.

10B

INJ 331

INJECTOR GEARBOX ASSEMBLY

1 ea.

Gears turn Gear Cartridge for even syrup

distribution.

10C

FAS 2023

ACCESSORY MOUNTING BRACKET

KNOB

1 ea.

Secures base Mounting Bracket to Gear Box.

10

Injector Assembly and Related Parts (Continued)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

11

ADPT 8750-A

CROWN ADAPTER WITH

O-RINGS

1

Attaches Injector Assembly to freezer door.

11A

RUB 659

TAYLOR ADAPTER O-RING 8750

1 ea.

Creates tension to secure adapter to freezer

door.

11B

ADPT 8750

CROWN ADAPTER WITOUT

O-RINGS

1 ea.

Attaches Injector Assembly to freezer door.

11C

RUB 632

INJECTOR ADAPTER O-RING

1 ea.

Creates tension to secure adapter to Injector

Head.

12

ADPT 101A

INJECTOR ADAPTER W/ O-RINGS

1

Attaches Injector Assembly to freezer door.

12A

RUB 642

ADAPTER O-RING

1 ea.

Creates tension to secure Adapter to freezer

door.

12B

RUB 640

FLAT ADAPTER GASKET

1 ea.

Provides sealed cavity inside Adapter.

12C

ADPT 101

INJECTOR ADAPTER

1 ea.

Attaches Injector Assembly to freezer.

12D

RUB 632

INJECTOR ADAPTER O-RING

1 ea.

Creates tension to secure Adapter to Injector

Head.

13

MIS 3196

STAINLESS 9-TUBE CASING

ASSEMBLY

3

Protects and holds the cables and 9-Tube

Assembly in place on the freezer side panel.

13A

MIS 3190

STAINLESS 9-TUBE CASING HINGED

CHANNEL

1 ea.

Covers and protects the cables and tubes of

the Casing Assembly.

13B

MIS 3051

CH-6 CHANNEL MAGNET ASSEMBLY

2 ea.

Holds the Casing Channel to the freezer

panel.

13C

FAS 2040

6-32 x 1/4 PAN HEAD SCREW

1 ea.

Secures the Casing cover to the mounting

brackets.

13D

FAS 2024

8-32 x 1/4 PAN HEAD SCREW

4 ea.

Secures the magnet assembly to the

mounting brackets.

13E

FAS 2035

8-32 NUTS –EXT. LOCK WASHER

4 ea.

Secures the magnet assembly to the

mounting brackets.

11

PAGE INTENTIONALLY LEFT BLANK

12

Injector Assembly and Related Parts

Figure 3

13

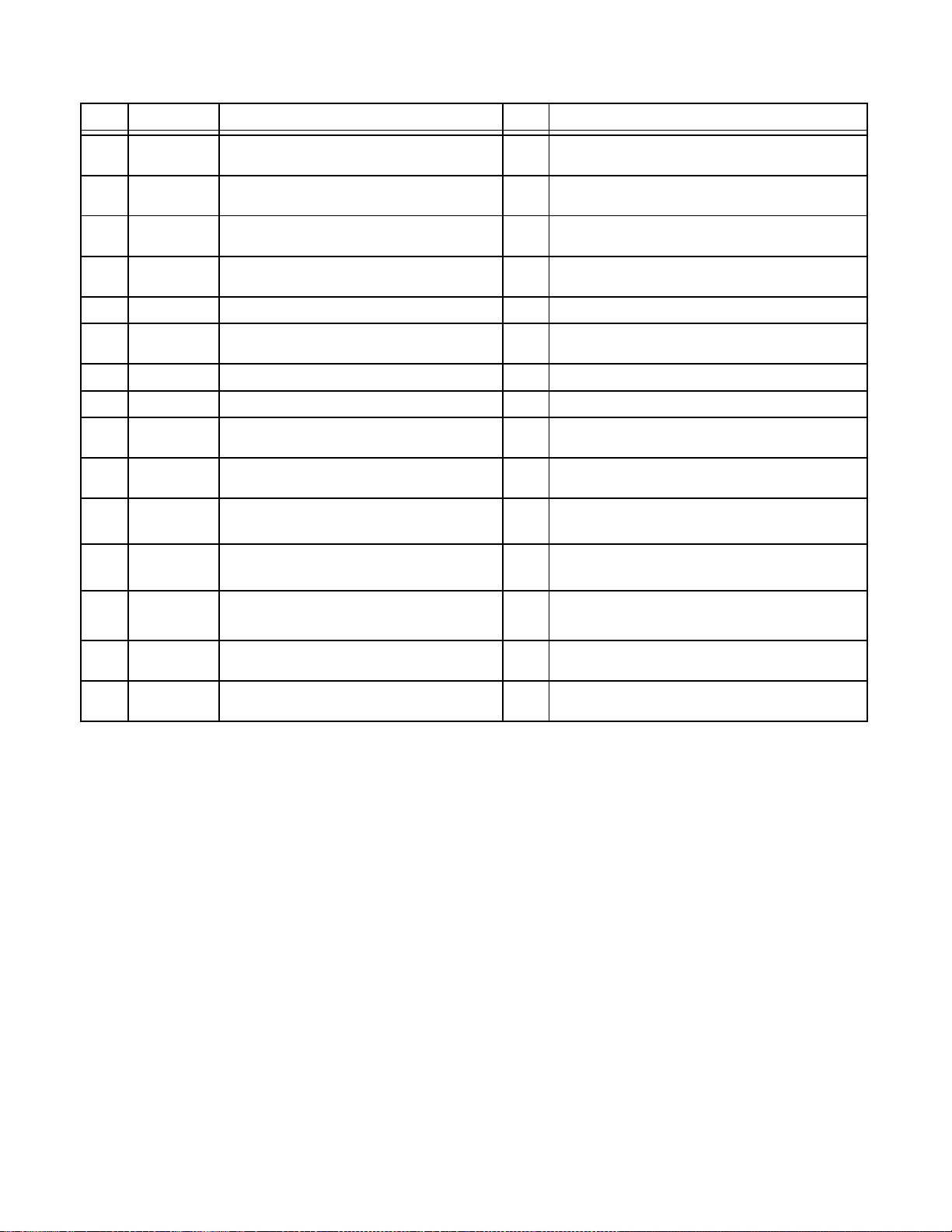

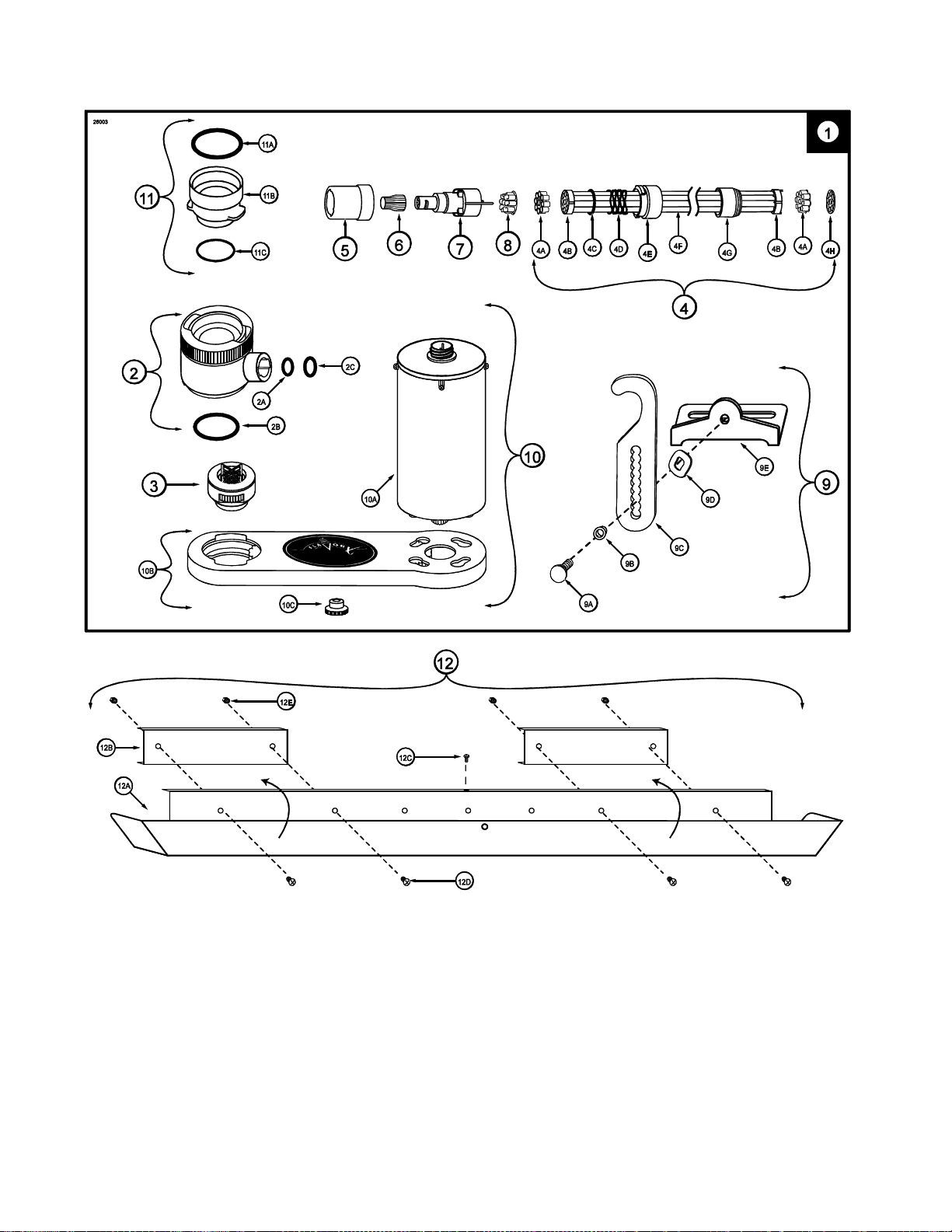

Blending Assembly and Related Parts (See Figure 4)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

1

INJ 424VTS

VERTICAL BLENDING ASSEMBLY

WITH SYRUP LINES, ADAPTER, &

BRACKET

1

Transports and blends syrup into product.

2

INJ 422VS

BLENDING HEAD ASSEMBLY –

VERTICAL SHAKE

1

Connects flavor line to inject syrups into

product.

2A

RUB 652-

RSS

SMALLER SYRUP PORT O-RING

1 ea.

Provides sealed cavity inside syrup port.

2B

RUB 651

BLENDING HEAD O-RING 2-020

1 ea.

Provides a sealed cavity.

2C

RUB 660

LARGER SYRUP PORT O-RING

1 ea.

Provides sealed cavity inside syrup port.

3

INJ 321S

GEAR CARTRIDGE ASSEMBLY –

VERTICAL BLENDER

1

Rotates product for even syrup distribution.

4

SYR 932

6' 9-TUBE ASSEMBLY

1

Supplies syrup to Blending Head from

pumps.

4A

FAS 2051

ROLLED FLANGE EYELET

18 ea

Provides tension in syrup line to affix to line

coupler.

4B

ROT 510

LINE COUPLER

2 ea.

Holds flavor lines in place.

4C

RUB 610

BAG CONNECTOR O-RINGS

1 ea.

Provides extra tension between tube

connectors.

4D

ROT 515-A

9-TUBE ASSEMBLY WAVE SPRING

1 ea.

Provides tension between tube connectors.

4E

INJ 116

LINE COUPLER NUT - BLACK

1 ea.

Attaches flavor tubes to flavor manifold.

4F

SYR 901

6' 9-TUBE ASSEMBLY TUBES

9 ea.

Brings syrup from pump to Blending Head.

4G

ROT 511

LINE COUPLER NUT

1 ea.

Connects flavor lines to the internal 9-Tube

Assembly.

4H

RUB 602

9-POS TUBE CONN. GASKET

1 ea.

Provides sealed cavity.

5

INJ 117

TUBE CONNECTOR BODY –BLACK

1

Secures flavor line manifold to flavor lines.

6

MIS 3142

FLAVOR LINE DUST CAP –FB 80

1

Covers syrup manifold when not connected.

7

INJ 201A

SYRUP MANIFOLD - BLACK

1

Connects flavor line to Blending Head.

8

RUB 601

9-POS DUCKBILL CHECK VALVE

1

Provides sealed cavity and prevents syrup

leakage.

9

MIS 3143

INJECTOR SUSPENSION BRACKET

1

Secures Injector Asmb. to freezer door.

9A

FAS 2107

INJECTOR BRACKET KNOB

1 ea.

Tightens positioning of hanging bracket.

9B

MIS 3144

NYLON SHOULDER WASHER

1 ea.

Allows free horizontal movement for

bracket.

9C

MIS 3143-A

INJECTOR BRACKET PART A

1 ea.

Attaches to freezer door bolts to hang

Injector Assembly.

9D

ROT 535

INJ. BRACKET SPRING WASHER

1 ea.

Allows space between hanging and

base brackets.

9E

MIS 3143-B

INJECTOR BRACKET PART B

1 ea.

Secures bracket assembly to Injector

Assembly.

14

Blending Assembly and Related Parts (Continued)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

10

INJ 323TS

BLENDING ASSEMBLY - NO HEAD

1

Powers Blending system.

10A

INJ 330TS

BLENDING MOTOR ASSEMBLY

1 ea.

Supplies power to Motor which turns gears.

10B

INJ 331

BLENDING GEARBOX ASSEMBLY

1 ea.

Gears turn Gear Cartridge for even syrup

distribution.

10C

FAS 2023

ACCESSORY MOUNTING BRACKET

KNOB

1 ea.

Secures base Mounting Bracket to Gear Box.

11

ADPT 104R-A

CROWN ADAPTER WITH

O-RINGS

1

Attaches Blending Assembly to freezer door.

11A

RUB 627

TAYLOR ADAPTER O-RING 8750

1 ea.

Creates tension to secure adapter to freezer

door.

11B

ADPT 104R

CROWN ADAPTER WITOUT

O-RINGS

1 ea.

Attaches Blending Assembly to freezer door.

11C

RUB 632

BLENDING ADAPTER O-RING

1 ea.

Creates tension to secure adapter to

Blending Head.

12

MIS 3196

STAINLESS 9-TUBE CASING

ASSEMBLY

3

Protects and holds the cables and 9-Tube

Assembly in place on the freezer side panel.

12A

MIS 3190

STAINLESS 9-TUBE CASING HINGED

CHANNEL

1 ea.

Covers and protects the cables and tubes of

the Casing Assembly.

12B

MIS 3051

CH-6 CHANNEL MAGNET ASSEMBLY

2 ea.

Holds the Casing Channel to the freezer

panel.

12C

FAS 2040

6-32 x 1/4 PAN HEAD SCREW

1 ea.

Secures the Casing cover to the mounting

brackets.

12D

FAS 2024

8-32 x 1/4 PAN HEAD SCREW

4 ea.

Secures the magnet assembly to the

mounting brackets.

12E

FAS 2035

8-32 NUTS-EXT. LOCK WASHER

4 ea.

Secures the magnet assembly to the

mounting brackets.

15

PAGE INTENTIONALLY LEFT BLANK

16

Blending Assembly and Related Parts

Figure 4

17

Syrup Pump and Related Parts –Soft Serve (See Figure 5)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

1

N/A

SOFT SERVE SYRUP PUMP

4

Pumps syrup from flavor bags to flavor

lines.

1A

SYR 307

PERISTALTIC SYRUP PUMP –

SOFT SERVE

1 ea.

Pumps syrup from flavor bags to flavor

lines.

1B

TUB 806

1/8” SYRUP PUMP REPL TUBE

1 ea.

Transports syrup through pump.

1C

FAS 2066

SYRUP PUMP TUBE WASHER-1/4

1 ea.

Secures pump tube.

1D

FAS 2067

SYRUP PUMP CLAMP-HOSE-1/4"

1 ea.

Prevents pump tube from slipping.

1E

FAS 2051

ROLLED FLANGE EYELET

1 ea.

Creates tension for tighter fit.

1F

FIX 1036

1/4" TO 1/4" OD UNION ELBOW

1 ea.

Connects syrup in tube to pump.

1G

FIX 1035

1/4 TO 3/16 OD REDUCING UNION

1 ea.

Connects syrup pump to flavor line out.

2

SYR 944

SYRUP TUBE ASSEMBLY –

SOFT SERVE

4

Transports flavor from bag to pump.

2A

FIX 1054

1/4” ID HOSE BARB SHUTOFF

1 ea.

Connects flavor line to flavor bag.

2B

SYR 902

FLAVOR-IN TUBE

1 ea.

Carries syrup from syrup bag to pump.

2C

TUB 811

TUBE-SILICONE .188X.375 PE

FB80

1 ea.

Connects barb fitment to tube port.

2D

FIX 1048

FITTING-1/4X1/4 BARB FB80

1 ea.

Connects syrup tube to silicone tube.

3

SYR 901

6' 9-TUBE ASSEMBLY TUBE

11

Brings syrup from pump to Injector Head.

4

ROT 511

LINE COUPLER NUT

2

Connects flavor lines to the internal

9-Tube Assembly.

5

ROT 512

TUBE CONNECTOR BODY

2

Connects internal 9-Tube Assembly to

flavor lines.

6

ROT 510

LINE COUPLER

2

Holds flavor lines in place.

7

FAS 2051

ROLLED FLANGE EYELET

18

Secures flavor lines to line coupler.

8

MIS 3023

FLAVOR LINE DUST CAP

2

Cover to protect end of flavor lines.

9

CAB 113

FLAVORING TRAY

8

Houses syrup bags.

10

ELE 496TS

PUMP & SANITIZER CABLE

HARNESS

1

Provides power to the syrup and sanitizer

pumps.

11

SYR 941A

SYRUP BAG ADAPTER

4

Connects bag fitment to flavor lines.

11A

SYR 940

SYRUP BAG ADAPTER CAP

1 ea.

Attaches to flavor bag fitment.

11B

SYR 939B

SYRUP BAG ADAPTER VALVE

ASSEMBLY

1 ea.

Transports syrup to quick connect fitment.

11C

RUB 662

SYRUP BAG ADAPTER O-RING

1 ea.

Provides sealed cavity for Syrup Bag

Adapter.

18

Syrup Pump and Related Parts –Soft Serve

Figure 5

19

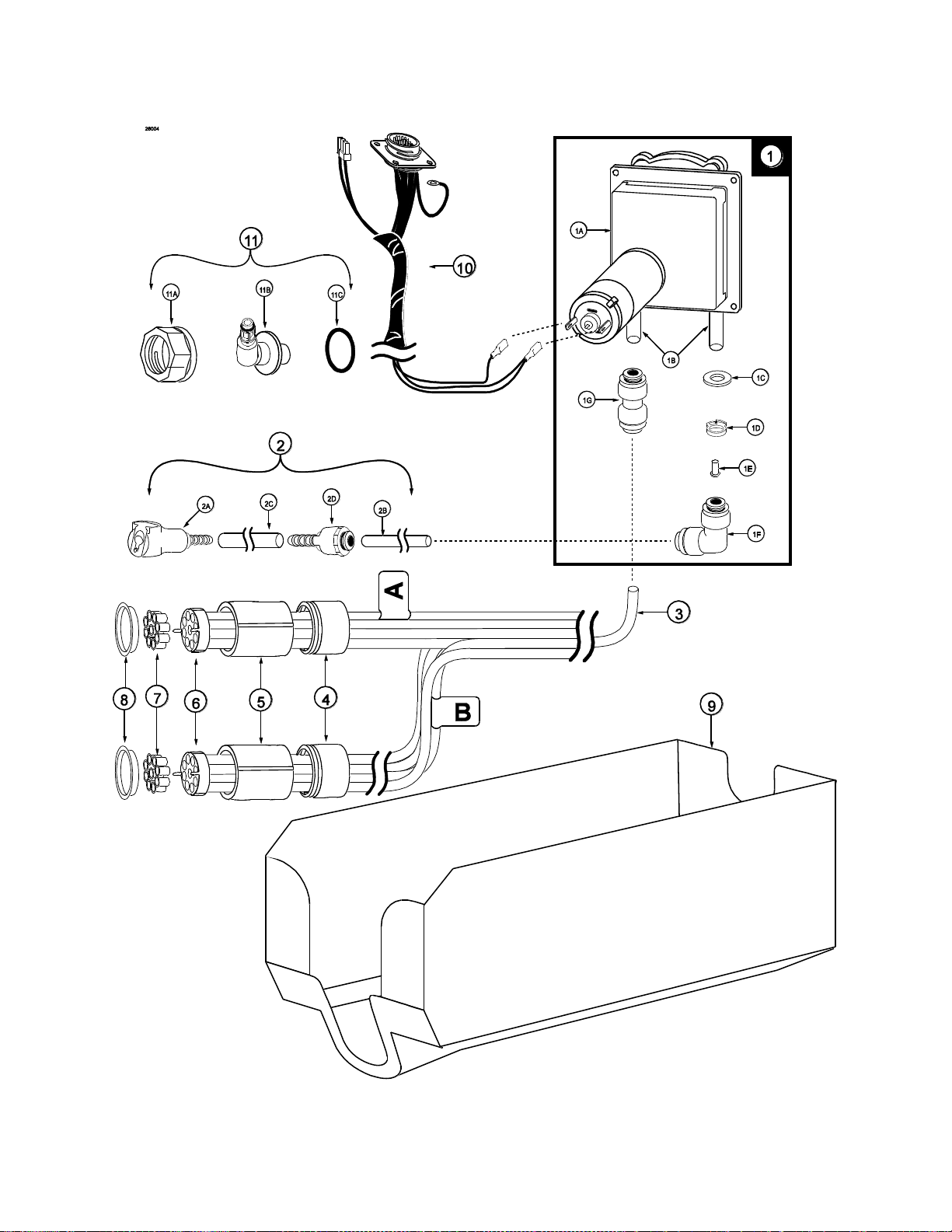

Syrup Pump and Related Parts –Frozen Beverage (See Figure 6)

ITEM

PART NO.

DESCRIPTION

QTY.

FUNCTION

1

N/A

SHAKE SYRUP PUMP

4

Pumps syrup from flavor bags to flavor

lines.

1A

SYR 926

PERISTALTIC SYRUP PUMP -

SHAKE

1

EACH

Pumps syrup from flavor bags into flavor

lines.

1B

TUB 809

1/4" SYRUP SHAKE PUMP

REPLACEMENT TUBE

1

EACH

Transports syrup through pump.

1C

FIX 1045

1/4" TUBE TO 1/4" HOSE STEM

2

EACH

Creates tension for tighter fit, connects

pump to fitment.

1D

FIX 1035

1/4 TO 3/16 OD REDUCING UNION

1

EACH

Connects syrup pump to flavor line out.

1E

FIX 1036

1/4" TO 1/4" OD UNION ELBOW

1

EACH

Connects bag connector assembly to flavor

line/pump.

2

SYR 944SH

SYRUP TUBE ASSEMBLY –

SHAKE BAG COUPLER

4

Transports the flavoring from the syrup bag

to the syrup pump.

2A

SYR 928

#27-1102-99 .265" BAG COUPLER

1

EACH

Fastens bag fitment to bag connector.

2B

TUB 811

TUBE-SILICONE .188X.375 PE

FB80

1

EACH

Provides sealed cavity inside bag fitment.

2C

FIX 1048

FITTING ¼ X ¼ BARB FB80

1

EACH

Connects bag coupler assembly to flavor

line/pump.

2D

SYR 902

FLAVOR-IN TUBE

1

EACH

Carries syrup from syrup bag to pump.

3

SYR 901

6' 9-TUBE ASSEMBLY TUBE

11

Brings syrup from pump to Injector Head.

4

ROT 511

LINE COUPLER NUT

2

Connects flavor lines to the internal

9-Tube Assembly.

5

ROT 512

TUBE CONNECTOR BODY

2

Connects internal 9-Tube Assembly to

flavor lines.

6

ROT 510

LINE COUPLER

2

Holds flavor lines in place.

7

FAS 2051

ROLLED FLANGE EYELET

18

Secures flavor lines to line coupler.

8

MIS 3023

FLAVOR LINE DUST CAP

2

Cover to protect end of flavor lines.

9

CAB 113

FLAVORING TRAY

8

Houses syrup bags.

10

ELE 496TS

PUMP & SANITIZER CABLE

HARNESS

1

Provides power to the syrup and sanitizer

pumps.

Table of contents