Fleck 9000 User manual

FLECK 9000 TWIN

TANK WATER SOFTENER

›InstallatIon GuIde

V1.0

PAGE 2 QualityWaterForLess.com Help: 888-426-5001

›Preface

Thank you for your purchase of a new water softener with Fleck 9000 Meter Control Valve from

QualityWaterForLess.com! We have put together these instructions as reference and to be used as gen-

eral installation guidelines.

It is always recommended that a licensed plumber perform all installa-

tion work according to all local codes.

We at QualityWaterForLess.com cannot assume responsibili-

ty for improper installation, application, or injury or damage as a result of improper installation.

PAGE 3Help: 888-426-5001 QualityWaterForLess.com

›table of contents

Page 6 Calculating your Hardness Level and Salt Grid Table

Page 7 Tank Size, Salt Setting, and Salt Grid Table

Page 8 Pre-Installation and Home Plumbing Diagram

Page 9 Placing and Filling the Tank

Page 10 Installing the Fleck 9000 Valve onto the Tank

Page 12 Plumbing the Fleck 9000 Valve into your Home and the Brine Tank Connection

Page 14 Making the Drain Connection and Meter Connection

Page 15 Programming: Entering Master Programming Mode and Initial Programming

Page 16 Programming: Tank Number, Capacity, Hardness, and Reserve Settings

Page 17 Programming: Day Override, Regeneration Time, Backwash, Brine Draw, Rapid

Rinse, and Brine Fill Duration

Page 18 Programming: Meter Type and Resetting the Time

Page 2 Preface (Click to Jump to Page)

Page 3 Table of Contents

Page 4 General Reference and Quick Electronic SXT Valve Programming

Page 5 Mechanical Valve Programming

Page 19 Initial System Start-Up and Testing for Leaks

PAGE 4 QualityWaterForLess.com Help: 888-426-5001

›QuIcK start sXt

electronIc ProGraM

If you have a Fleck 9000 SXT

electronic meter

valve, here are your program settings.

If not all of the

values are filled in, you can calculate the missing

values from the exercise on pages 6 and 7 of this

guide.

There we will cover identifying the 3 essential

values of

H - HARDNESS

,

C - UNIT CAPACITY

,

and

BF - BRINE FILL

. The remaining values that are

already filled in are general standards for all softener

sizes and hardness levels.

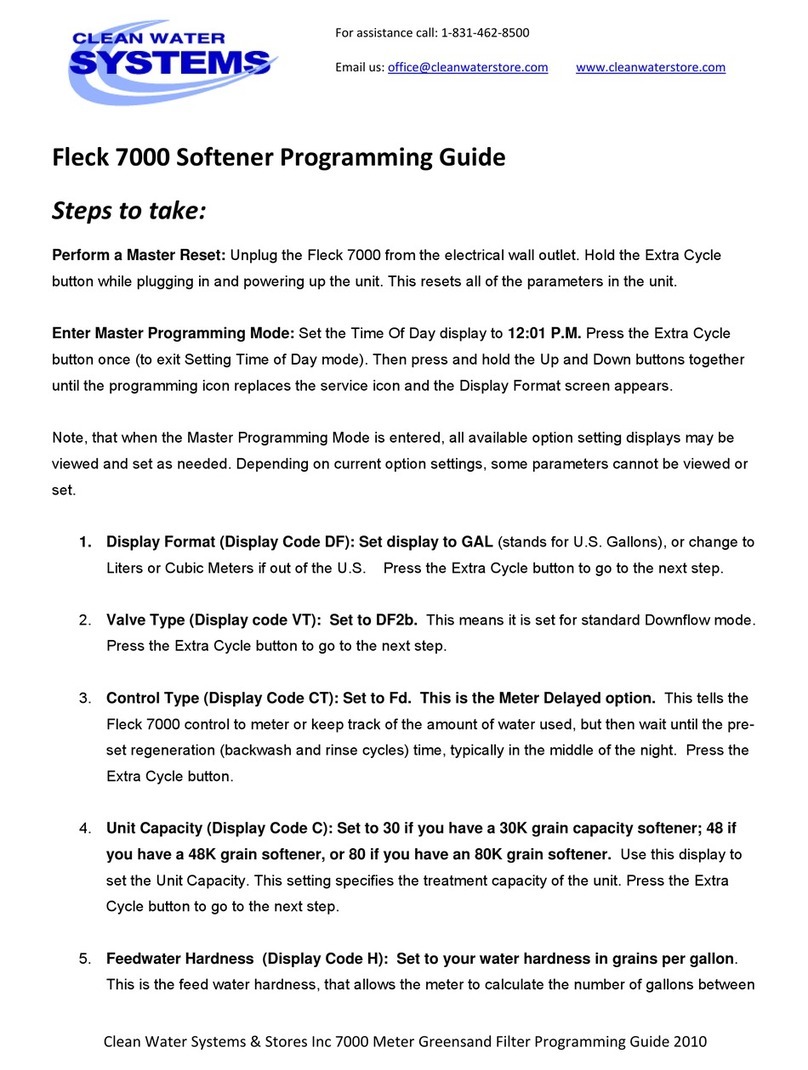

MASTER PROGRAMMING MODE:

To enter in/

check the adjacent values of your system, follow

these steps: With either the up or down arrow

button, change the clock to 12:01 PM, set the time

by clicking the left-most, CYCLE / REGEN button,

and then hold both the up and down arrow buttons

for 5 seconds to enter master programming mode.

Change values with the arrow buttons and set each

value and advance to the next setting by clicking the

CYCLE / REGEN button.

A more in-depth guide to programming the Fleck

9000 SXT is provided beginning on

page 15

.

settInG InPut Value

DF - Display Format GAL - Gallons

VT - Valve Type dF1b

CT - Control Type FI - Flow Immediate

NT - Number of Tanks 2 Tanks

TS - Tank in Service U X (Leave the Same)

C - UNIT CAPACITY ,000 Grains

H - HARDNESS Grains per Gallon

RS - Reserve Selection SF

SF - Safety Factor 10%

DO - Day Override 14 Days

RT - Regen Time 2:00 AM

BW - Backwash 10 Minutes

BD - Brine Draw 60 Minutes

RR - Rapid Rinse 12 Minutes

BF - BRINE FILL Minutes

FM - Flow Meter Type t0.7 or P0.7

›General reference

Please take a moment to review this page in order

to familiarize yourself with these four ports on the

valve. It is crucial not to mistake the inlet port with

the outlet port. Mistaking and reversing the inlet

and outlet ports will lead to failure of your softener

system (Figure 4-A).

As you work through this guide, please make

sure to follow all instructions exactly and to make

special note of the bolded instructions and warn-

ing symbols.

PDF viewers may click underlined

text to jump to that page or the page number

in the bottom corner of every page to jump to

the table of contents.

All our installation guides

may be found on our site under “Information.” Inlet

brIne

draIn

fIGure 4-a

outlet

FM - Flow Meter Type

t0.7 P0.7

Job Number:

Model Number:

Mineral Tank Size:

PAGE 5Help: 888-426-5001 QualityWaterForLess.com

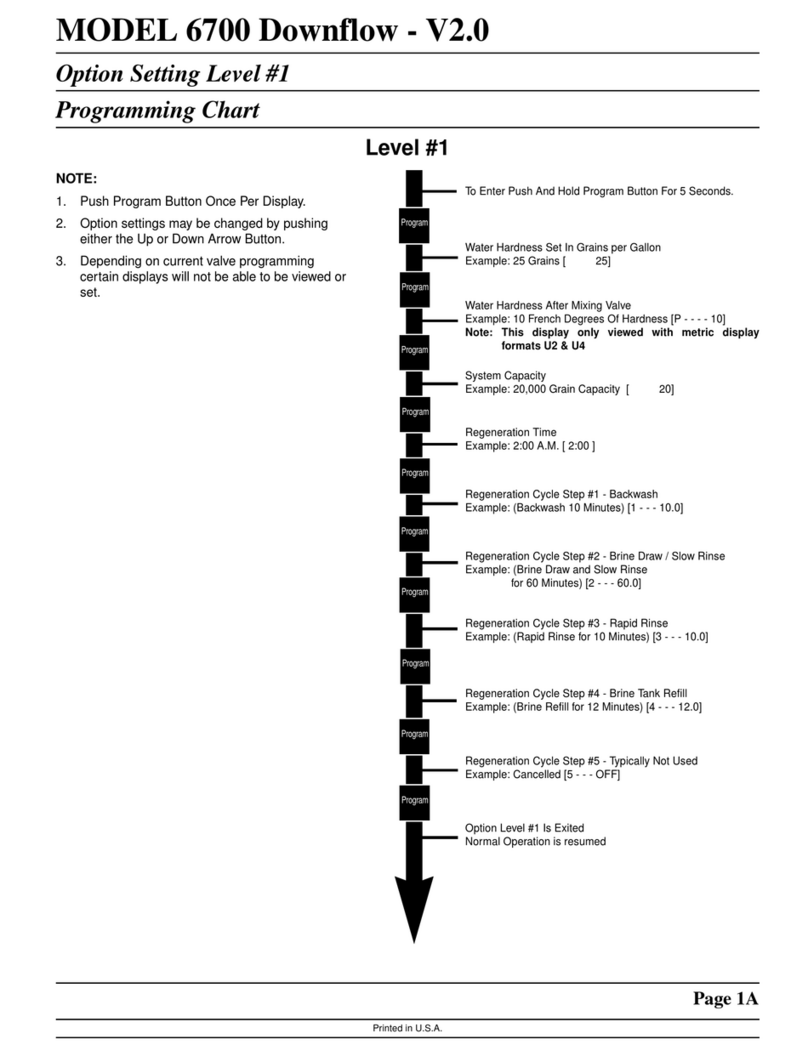

›MecHanIcal ProGraM

If you have a mechanical meter valve, here are your

softener program settings.

If you have an SXT valve,

refer to page 4 for your programming values.

If not

all of the values to the right are filled in, you can

calcu-

late the missing values below AND with the exer-

cise on pages 6 and 7 of this guide.

The remaining

values that are already filled in are general standards for

all softener sizes and hardness levels.

settInG InPut Value

GC - GAL CAPACITY

00 Gallons

BW - Backwash 10 Minutes, 5 Pins

BD - Brine Draw 60 Minutes, 30 Slots

RR - Rapid Rinse 12 Minutes, 6 Pins

BF - BRINE FILL

Minutes, Slots

fIGure 5-a

fIGure 5-b

The

GC - GALLON CAPACITY

equates

to the

C - UNIT CAPACITY

divided

by the

H - HARDNESS

minus

10% of the result (Ex: 64K tank / 28 gpg hardness =

2,286 gal; 2,286 gal - 229 = 2,057 gal capacity.

Unit Ca-

pacity and Hardness can be determined from pages

6 and 7

). If the result exceeds the highest number on

the dial, use the next smallest

Unit Capacity

listed on

the table on page 7

. With the front cover off of your

control valve and while looking at the panel on the left

side, pull out and rotate the dial and line up your gallon

capacity with the white dot (Figure 5-A).

Swing open the left panel with the capacity wheel to

the left to reveal the Program Wheel on the opposite

side of the panel (Figure 5-B). To set the regeneration

cycle times with the above input values, place the pins

in the slots surrounding the wheel.

Each slot/pin on

the Program Wheel represents 2 minutes during the

regeneration process.

fIGure 5-c

bacKwasH

brIne draw

raPId rInse

brIne fIll

fIGure 5-b

1.

The first

group

of pins represents the BW - Backwash

duration; 5 pins for 10 minutes (Figure 5-C).

2.

The next

span of empty slots

represents the

BD - Brine Draw duration; 30 empty slots for 60 minutes.

3.

The next

group

of pins represents the RR - Rapid

Rinse duration; 6 pins for 12 minutes.

4.

The next

span

of empty slots represents the

BF - BRINE FILL

duration

found on page 7.

If it calls

for an odd number of minutes, round up for the appro-

priate number of pins (Ex: 15 min 16 min 8 pins).

5.

The last

group

of 2 pins marks the end of regeneration.

PAGE 6 QualityWaterForLess.com Help: 888-426-5001

PPM Hardness ÷17.1 = gpg Hardness before Iron

gpg Hardness + ( PPM Iron x 5 ) = gpg H - COMPENSATED HARDNESS

PlaIn

GrId

11X11” G r I d 15X17” GrId 18” dIaMeter GrId

GrId +

3” leGs

GrId +

6” leGs

1 ›calculatInG Hardness, caPacIty, and brIne fIll

1)

Water Test: Before start-up, it is crucial that you know your water’s HARDNESS and IRON levels in

order to set up your unit properly.

If your unit is not programmed with your particular hardness level, it will

either regenerate too early or too late. If you do not know your water hardness or iron levels, you can take a

sample of your untreated water to a local pool shop, hardware store, or well driller

(city water has no iron)

2)

Initial Hardness:

Your Hardness test results may be recorded in Grains per Gallon (gpg), Parts per Million

(PPM), or Milligrams per Liter (mg/L). Note that

PPM and mg/L are the same measure

and both figures can

be used interchangeably.

If you get a hardness level in PPM or mg/L, please divide this number by 17.1

to get Grains (gpg).

Ex: If your hardness is measured at 300 PPM, take 300 / 17.1 = 18 gpg before iron

3)

H - COMPENSATED HARDNESS:

Your Iron results should also be measured in either PPM or mg/L.

Take

your level of iron multiplied by 5 and add it to the hardness level from the previous step.

This final figure

will be your

Compensated Hardness Level

that we will program into your softener system. Ex: If your iron level

is measured at 2 PPM, add 2 x 5 = 10 Grains of hardness to existing hardness total. 18 + 10 = 28 Grains Total

4)

The compensated hardness level you just calculated will be the “H” value you use to program your

softener. You may record this in the table on page 4 or 5.

Depending on your compensated hardness

level, you will be able to use a different salt setting for programming and running your softener unit. The

lower the hardness level, the more efficient you will be able to be with salt consumption for regeneration

PAGE 7Help: 888-426-5001 QualityWaterForLess.com

5)

C - UNIT CAPACITY:

In the first column, identify the

section

containing your softener tank size and then within this

section, find the

row

pertaining to your

H - Compensated Hardness

level. Then look under the

C - Capacity

column

to find the most efficient program value to enter for your

C - Unit Capacity

and record it

in the table on page 4 or 5.

Note that your unit capacity program value may actually be lower than the tank’s rated capacity.

This is to

accommodate a lower salt dose for regeneration.

6)

BF - BRINE FILL:

In the first column, identify the

section

containing your softener tank size and then within this

section, find the

row

pertaining to your

H - Compensated Hardness

level. Then look under the

BF - Brine Fill

column

to find the most efficient program value to enter for your

BF - Brine Fill

and record it

in the table on page 4 or 5.

7)

Example:

If you ordered a 64K grain capacity system and have 28 gpg compensated hardness, you would look under the

64K, 2.0 cu ft section and then look under the 25+ gpg row for your particular programming values. Note that the 11x11”

and the 15x17” brine tanks are too small for the amount of brine needed to regenerate a 64K grain capacity system with

25+ gpg hardness. According to the table you would opt for an 18” diameter brine tank with a grid plus 6” legs

Tank Size

H

HARDNESS

C

CAPACITY

BF

BRINE FILL

lbs of Salt 11x11” Gr id 15x17” Grid 18x33” Grid 18x40” Grid 24x41” Grid 24x50” Grid

24K

0.75 cu ft

8x44”

0 - 12 gpg 15K 3 Min 4.5 lbs Grid NO GRID NO GRID NO GRID

TOO

LARGE

TOO

LARGE

12 - 25 gpg 20K 5 Min 7.5 lbs Grid Grid NO GRID NO GRID

25+ gpg 24K 7 Min 11. 25 lbs Grid + 3” Legs Grid Grid Grid

32K

1.0 cu ft

9x48”

0 - 12 gpg 20K 4 Min 6 lbs Grid NO GRID NO GRID NO GRID

TOO

LARGE

TOO

LARGE

12 - 25 gpg 27K 7 Min 10 lbs Grid + 3” Legs Grid Grid Grid

25+ gpg 32K 10 Min 15 lbs Grid + 6” Legs Grid + 3” Legs Grid Grid

40K

1.25 cu ft

10x44”

0 - 12 gpg 25K 5 Min 7.5 lbs Grid Grid NO GRID NO GRID

TOO

LARGE

TOO

LARGE

12 - 25 gpg 34K 9 Min 12.5 lbs Grid + 3” Legs Grid Grid Grid

25+ gpg 40K 13 Min 18.75 lbs TOO SMALL Grid + 3” Legs Grid + 3” Legs Grid + 3” Legs

48K

1.5 cu ft

10x48”

0 - 12 gpg 30K 7 Min 9 lbs Grid + 3” Legs Grid Grid Grid

TOO

LARGE

TOO

LARGE

12 - 25 gpg 41K 10 Min 15 lbs Grid + 6” Legs Grid + 3” Legs Grid Grid

25+ gpg 48K 15 Min 22.5 lbs TOO SMALL Grid + 6” Legs Grid + 3” Legs Grid + 3” Legs

64K

2.0 cu ft

12x52”

0 - 12 gpg 40K 8 Min 12 lbs Grid + 3” Legs Grid Grid Grid

Grid +

5” Legs

Grid +

5” Legs

12 - 25 gpg 54K 14 Min 20 lbs TOO SMALL Grid + 6” Legs Grid + 3” Legs Grid + 3” Legs

25+ gpg 64K 20 Min 30 lbs TOO SMALL TOO SMALL Grid + 6” Legs Grid + 6” Legs

80K

2.5 cu ft

13x54”

0 - 12 gpg 50K 10 Min 15 lbs Grid + 6” Legs Grid + 3” Legs Grid Grid

Grid +

5” Legs

Grid +

5” Legs

12 - 25 gpg 68K 17 Min 25 lbs TOO SMALL Grid + 6” Legs Grid + 3” Legs Grid + 3” Legs

25+ gpg 80K 25 Min 37.5 lbs TOO SMALL TOO SMALL TOO SMALL Grid + 6” Legs

96K

3.0 cu ft

14x65”

0 - 12 gpg 60K 12 Min 18 lbs TOO SMALL Grid + 3” Legs Grid + 3” Legs Grid + 3” Legs

Grid +

6” Legs

Grid +

6” Legs

12 - 25 gpg 81K 20 Min 30 lbs TOO SMALL TOO SMALL Grid + 6” Legs Grid + 6” Legs

25+ gpg 96K 30 Min 45 lbs TOO SMALL TOO SMALL TOO SMALL TOO SMALL

120K

4.0 cu ft

16x65”

0 - 12 gpg 80K 16 Min 24 lbs TOO SMALL Grid + 6” Legs Grid + 3” Legs Grid + 3” Legs

Grid +

8” Legs

Grid +

8” Legs

12 - 25 gpg 108K 27 Min 40 lbs TOO SMALL TOO SMALL TOO SMALL TOO SMALL

25+ gpg 120K 40 Min 60 lbs TOO SMALL TOO SMALL TOO SMALL TOO SMALL

PAGE 8 QualityWaterForLess.com Help: 888-426-5001

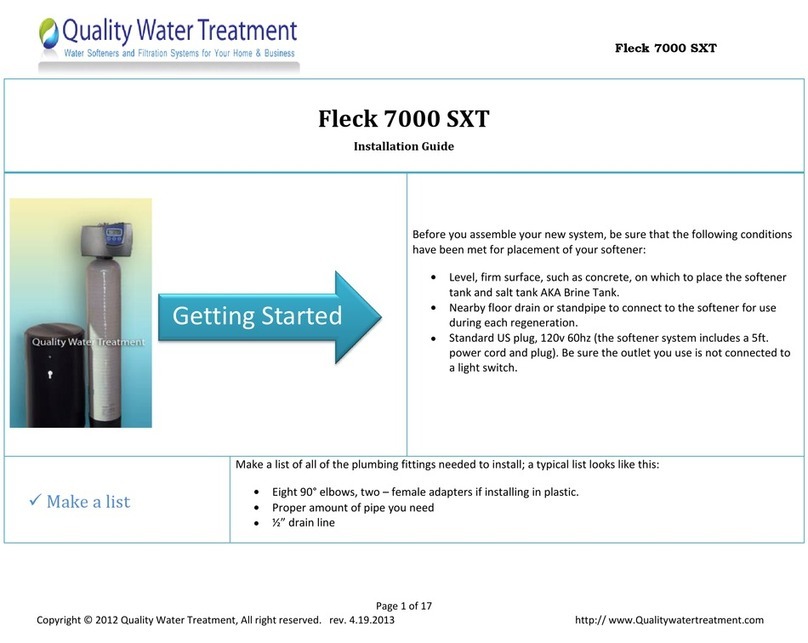

›Pre-InstallatIon

Before assembly of your new system, be sure that the following conditions have been met for the place-

ment of your system:

• Level, firm surface, such as concrete, on which

to place the softener tanks and salt tank (also

known as a

brine

tank)

• Un-switched power source, standard US plug,

120v 60hz (the softener system includes a

5 ft power cord and plug)

• Access to the water main coming into your

home. You will need to install the softener at

this point to assure that water for the home is

going through the system

• Nearby floor drain or standpipe to connect to the

softener for use during each regeneration

Well

Pump or

City

Meter

Water

Heater

Bypass

Bath Sink Toilet Kitchen

SpigotSpigot

Softener

Drain Line

Hard Water

Soft Water

Overflow

(Optional)

Floor

Drain

PAGE 9Help: 888-426-5001 QualityWaterForLess.com

fIGure 9-c fIGure 9-d

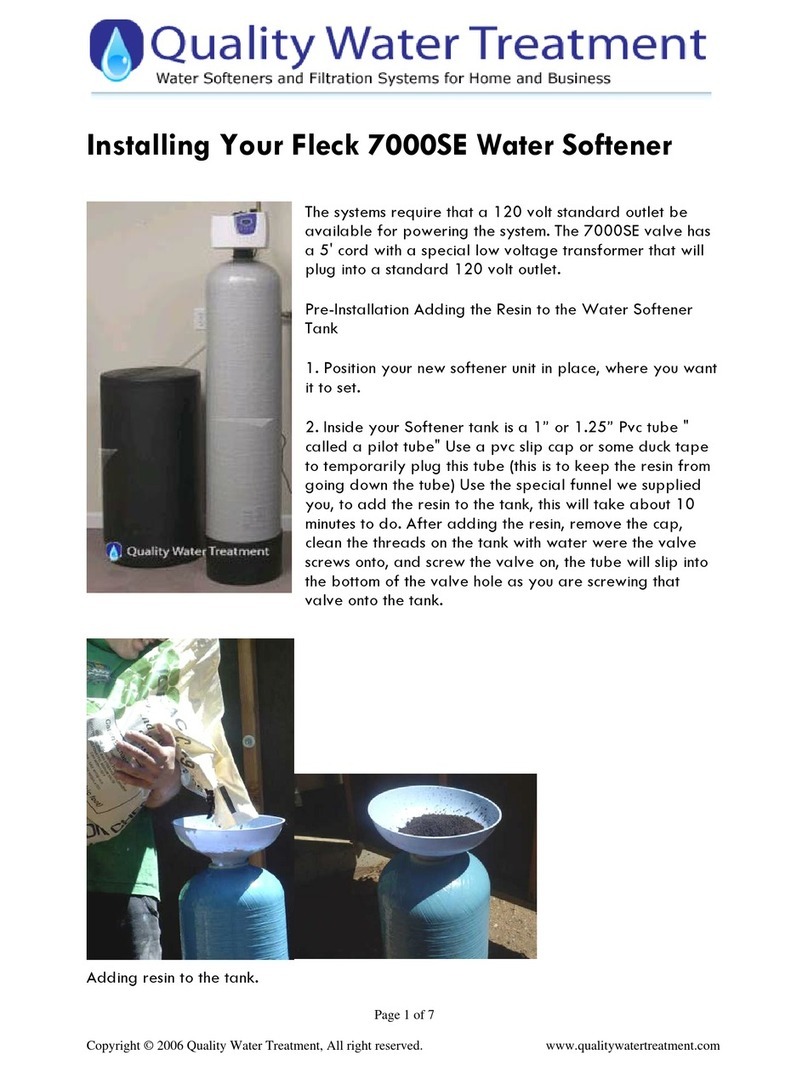

2 ›PlacInG and fIllInG tHe tanK

1) Choose the final location for your water softener

and place the tanks upright and level on the surface.

Filling the tanks may be necessary on some larger

system sizes. Your tanks may have also come pre-

filled, and in this case you only need to unscrew the

protective cap as shown in

Figure 9-A

2)

If your tanks are not filled

, place the riser

tubes into the tanks as shown in

Figure 9-B

.

Please make sure that the riser tubes seat into

the bottoms of the tanks and that the tops of the

tubes are flush with the tops of the tank openings

fIGure 9-a fIGure 9-b

3) Before filling the tanks, place a piece of paint-

er’s tape over the top of the riser tubes to pre-

vent resin from dropping down inside the riser

tubes as shown in

Figure 9-C. iAvoid using

duct tape which leaves behind unwanted

residue

4) Place the included filling funnel over the top of

the tank as shown in

Figure 9-D

and prepare to

fill the tank. If your softener system came with

gravel

, please pour this into the tank

first

, then

pour in the included resin media afterwards. Do

this for both tanks

PAGE 10 QualityWaterForLess.com Help: 888-426-5001

sta n dar d

fIne MesH

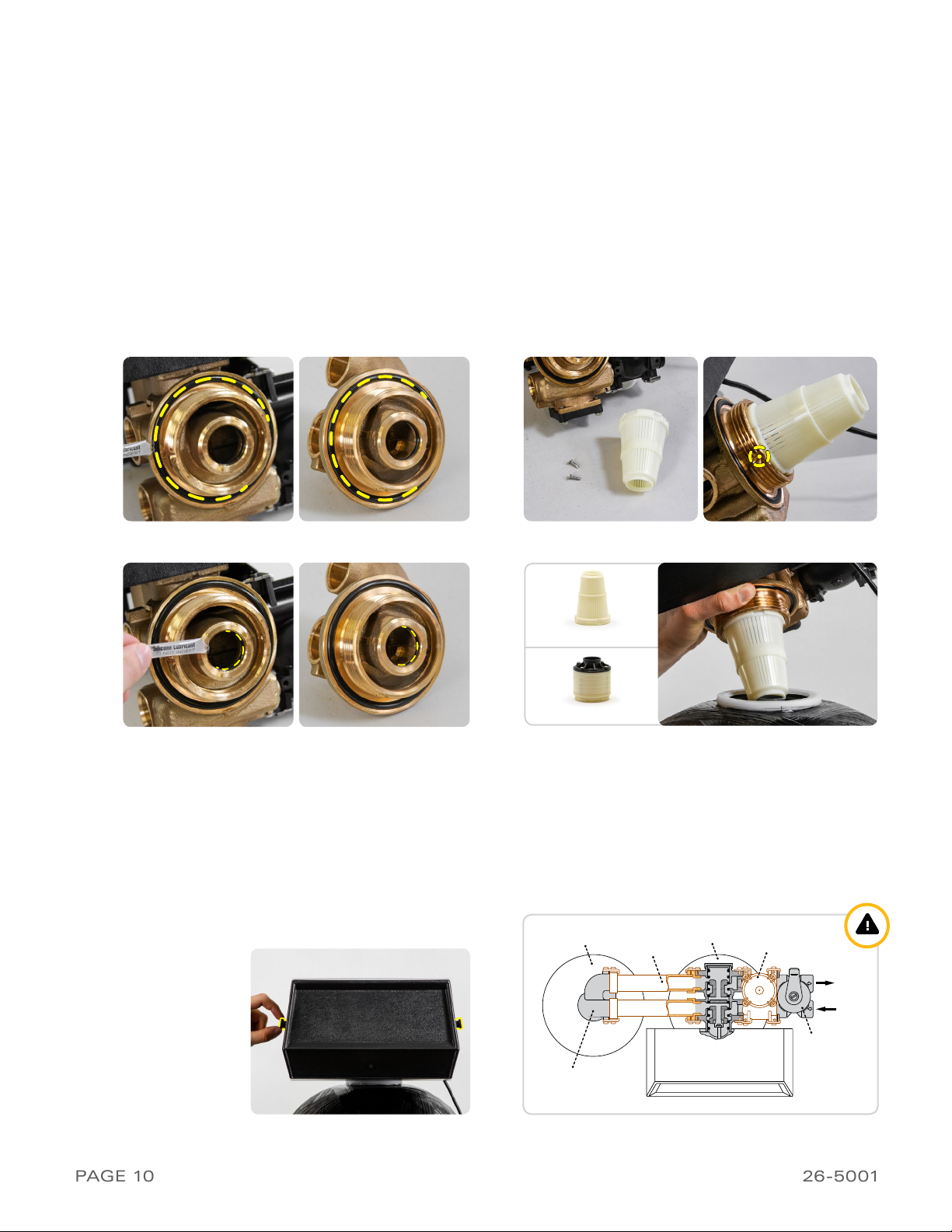

3 ›InstallInG tHe flecK 9000 ValVe

1) Remove the filling funnel and tape and while

using the included silicone lubricant packet, lu-

bricate the inner and outer o-rings on the bottom

of the Fleck 9000 Meter Valve and the second

tank adapter as shown in Figures 10-A and 10-B

2) Loosely fit a

top screen/upper distributor (stan-

dard OR fine mesh)

to the bottom of the Fleck

9000 Meter Valve and the second tank adapter,

make a mark through both of the screen screw

holes on both screens, drill two 3/32” holes on both

top screens at those marks, and screw into place

(Figure 10-C). Then place the valve onto the top of

the tank with the riser tube fitting into the central

o-ring on the valve (Figure 10-D).

Hand-tighten

the

valve to the tank.

Do not use Teflon tape or pipe

dope on the valve or tank threading

adaPter . fIGure 10-aValVe fIGure 10-c

adaPter . fIGure 10-bVa lV e fIGure 10-d

fIGure 10-e systeM toP VIew . fIGure 10-f

3) Loosen the two valve case screws to uncover the

front of the valve to prepare for the next step of

removing the plumbing adapter clips (Figure 10-E)

4) Please review the diagram below to make sure

you install the meter, bypass, and tube assembly

on the correct side of the valve (Figure 10-F).

i

Please note that you absolutely must not

attach these components on the wrong side

of the valve

Tank 1

Tank 2

Tube Assembly Water Meter

Outlet

Inlet

Bypass Valve

Main Control Valve

Tank 2 Adapter

PAG E 11Help: 888-426-5001 QualityWaterForLess.com

bacK . fIGure 11-afront

fIGure 11-c

5) Loosen the screws holding the plumbing adaptor

clips in place as shown in Figure 11-A and locate

the plumbing adapter that came with your system

6) Using the included silicone lubricant packet,

lubricate the o-rings on the meter of the Fleck

9000 Meter Valve as shown in Figure 11-B

fIGure 11-d

bacK . fIGure 11-ffront

fIGure 11-e

7) Attach the plumbing adaptor to the valve as

shown in Figure 11-C (your bypass/plumbing

adapter model may vary). When assembling

the clips back onto the valve, leave the first clip

loose, tighten the second clip, and complete

the assembly by going back and tightening the

first clip.

i

Please lightly tighten the screws

into the meter as overtightening will easily

cause cracking

8) Lubricate all four tube assembly adapters as

shown in Figure 11-D and insert two into each end

of the tube assembly

9) First, locate the tube assembly clips and attach

the tube assembly to the second tank adapter as

shown in Figure 11-E

10) Then attach the plastic tube assembly onto the

Fleck 9000 Meter Valve as shown in Figure 11-E

(you will need to swing open the program panel to

access and tighten the hidden tube assembly clip)

fIGure 11-b

PAGE 12 QualityWaterForLess.com Help: 888-426-5001

4 ›PluMbInG your flecK 9000 ValVe

1) Before beginning your installation, please first

familiarize yourself with the IN and OUT ports on

the Fleck 9000 Meter Valve.

In order to prevent

damage to your home and to the softener

system, install the softener according to the

IN and OUT arrows on the softener valve

2) Locate the main shut-off valve for your house

and turn it to the OFF position. If you have a

private well, this valve should be near your well

pressure tank. If you have a city water supply,

your valve should be near your water meter

3) Depressurize and drain your home of water by

turning on all faucets and fixtures in your home,

including those outside

4) Pick your installation point and cut a section of

pipe out to run to and from your softener.

In

most cases it is preferred to keep outside

lines UNSOFTENED. If you wish to keep

your outside lines unsoftened, you must

plumb BYPASS lines to run hard water to

these fixtures

5) Using soldered copper, PVC plastic pipe, or flex-

ible connections, plumb the system according to

all local plumbing codes.

If using copper pipe,

please pre-fabricate at least a 12” section

of pipe for the IN and OUT bound lines and

use a wet rag on the lines being soldered to

prevent heat damage during soldering

6) Once all connections have been made, place the

system into bypass by either using your existing

3-valve bypass (if ordered with a YOKE adap-

tor), or by switching your included bypass ON (if

ordered with a bypass)

7) Next, gradually open your main valve and allow

all air in your plumbing lines to escape slowly.

Also, you may turn off all outside and inside

faucets and fixtures

8) Check for leaks at your plumbing site for signs

of slow drips and rectify if necessary.

Please do

NOT take the softener out of BYPASS as the

installation is not completed yet. Please take

this opportunity to check and re-check the IN

and OUT ports to make sure they are correct

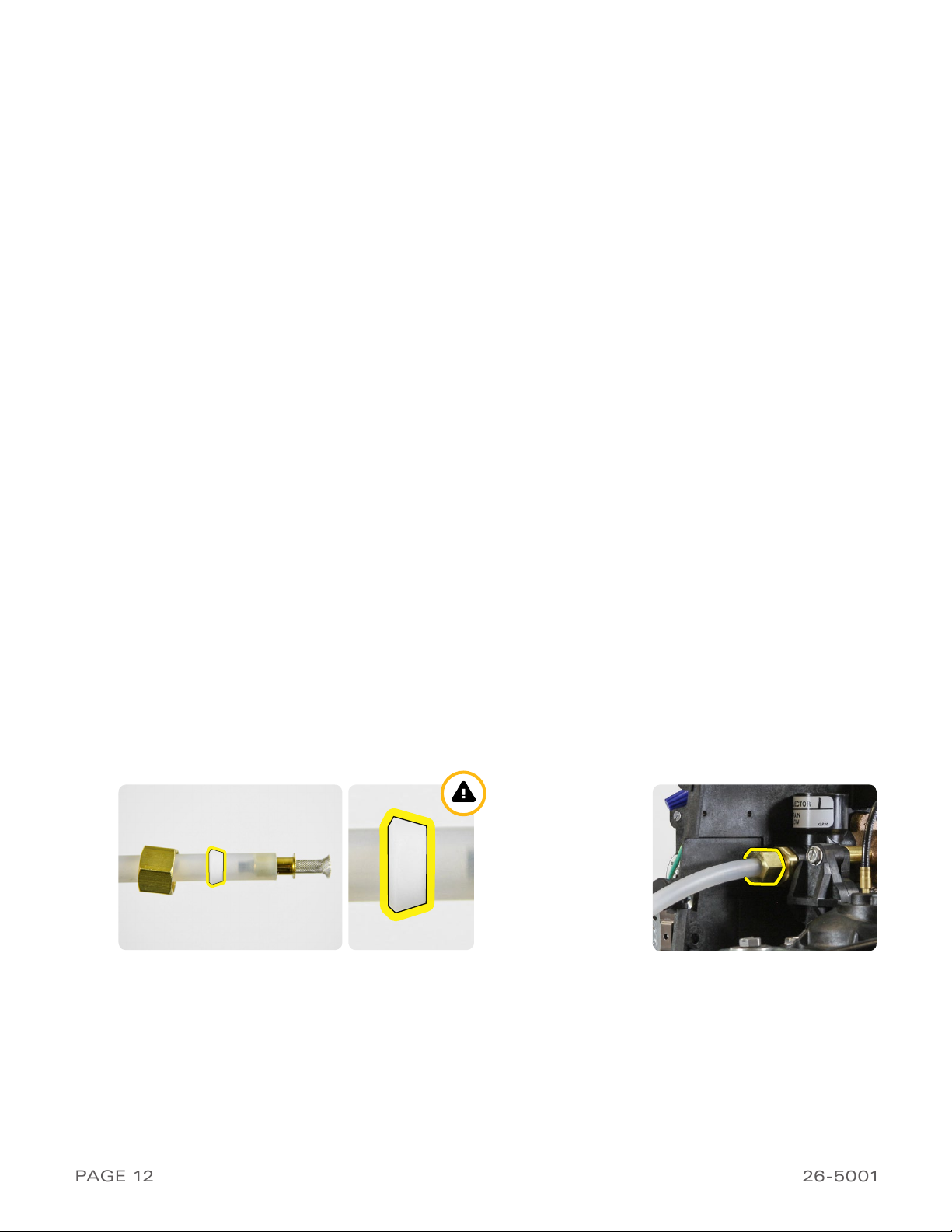

5 ›MaKInG tHe brIne tanK connectIon

1) Attach the brine nut, tapered ferrule, metal tube

insert, and brine line screen to one end of the

included brine tubing as shown in Figure 12-A.

i

Be sure to face the tapered side of the

ferrule towards the end of the brine line

2) Next, connect this prepared end of the tubing

to the Fleck 9000 Meter Valve as shown in

Figure 12-B. Tighten the nut to the valve using

a wrench until snugly in place. Be careful not to

over tighten as you may sever the brine line

fIGure 12-a fIGure 12-b

PAGE 13Help: 888-426-5001 QualityWaterForLess.com

3) Locate the brine well and remove the cap.

You

may also take this moment to prepare and

insert the brine support grid determined

from pages 6 and 7

. Then pull the

474 Brine

Float Assembly

out of the brine well as shown

in Figure 13-A

4) Next, fix the 474 Brine Float Assembly to the

brine well through the pre-drilled hole and

hand-tighten as shown in Figure 13-B

fIGure 13-bfIGure 13-a

fIGure 13-c

5) Take the other end of your brine line tube, make

sure this end is clean cut, recut if it is not clean,

mark 3/4” from the end of the tube, and insert the

tube through the small hole drilled through the brine

tank and brine well (Figure 13-C)

6) Firmly insert the tubing end 3/4” into the tube

opening on the 474 Brine Float Assembly as

shown in Figure 13-D. i

Make sure the tube is

fully inserted into the assembly

7) If you ever need to remove the tube, evenly press on

both sides of the grey ring surrounding the tube and

pull out as shown in Figure 13-E. i

Be sure to recut

the end of the tube each time you remove it to

ensure a proper seal when the tube is inserted

8) Finally, use ½” inner diameter (I.D.) tubing to connect

the drain barb fitting on the brine tank to a floor drain

as shown in Figure 13-F. Note that this is not neces-

sary as the 474 assembly is designed to prevent an

overflow from occuring, but it is a good precaution

fIGure 13-d

fIGure 13-e fIGure 13-f

PAGE 14 QualityWaterForLess.com Help: 888-426-5001

fIGure 14-a fIGure 14-b

fIGure 14-d

fIGure 14-c

6 ›draIn connectIon

1) Locate the drain barb fitting and use Teflon tape

to wrap the threading as shown in Figure 14-A.

Be sure to wrap the tape clockwise with the

threading towards you

2) Install the drain barb fitting to the Fleck 9000

Meter Valve by screwing the fitting using a

wrench snugly into the threads as shown in

Figure 14-B.

i

Please use caution not to over

tighten this fitting

7 ›Meter connectIon

1) Locate the meter cable on the rear of the control valve just in front of

the drain port and plug it into the meter as seen in Figure 14-D (Your

meter cable and meter model may vary. The model in Figure 14-D is

the mechanical version).

i

If you fail to connect the meter cable

to the meter on your meter demand softener, your system will

not regenerate on time

3) Next, connect your ½” I.D. drain line to the drain

barb. Be sure to use rigid wall ½” I.D. tubing that

will not flatten. Wrap electrical tape over the drain

tubing to prevent a tubing split, and clamp the

tubing securely into place with the included clamp

as shown in Figure 14-C

4) Connect the other end of this drain line tubing

securely to a standpipe or drain in accordance with

all local plumbing codes.

Be sure that the drain

line is securely in place before the use of the

water softener system. When the system

regenerates, there will be increased flow via

this tubing which may cause the tubing to

become loose

PAGE 15Help: 888-426-5001 QualityWaterForLess.com

fIGure 15-a fIGure 15-b

fIGure 15-c fIGure 15-d

8 ›ProGraMMInG tHe flecK 9000 sXt ValVe

1) To begin programming, first plug in your 9000

Valve to a nearby wall outlet. The system will

illuminate 4 digits. The system will show the

time of day and the amount of gallons remaining

before the next regneration. This display will

switch between these values about every 10

seconds

2) Set the time on the system to 12:01 PM by

pressing either the UP or DOWN button as

shown in Figure 15-A.

i

Be careful to confirm

the presence of the PM symbol in the top

right corner.

You may hold the button to allow

the time to scroll faster. Once the time display is

set to 12:01 PM, press the REGEN button once

as shown in Figure 15-B

3) To enter MASTER PROGRAMMING MODE,

press the UP and DOWN buttons TOGETHER

and HOLD both for 5 seconds as shown in

Figure 15-C

4) The display should now show

DF / GAL

as shown

in Figure 15-D. This indicates U.S. Operational

Mode measuring consumption in gallons. Do not

change this value and press the REGEN button

once to advance to the next setting

fIGure 15-e fIGure 15-f

5) The display should now show

VT / dF1b

as

shown in Figure 15-E. This indicates Regeneration

Flow Downflow Single Backwash. Do not change

this value and press the REGEN button to advance

to the next setting

6) The display should now show

CT / FI

as shown in

Figure 15-F. This indicates Control Type Meter Im-

mediate Mode. Do not change this value and press

the REGEN button to advance to the next setting

PAGE 16 QualityWaterForLess.com Help: 888-426-5001

fIGure 16-a

fIGure 16-c

fIGure 16-b

fIGure 16-d

7) The display should now show

NT / 2

. As shown

in Figure 16-A. This indicates Number of Tanks

is Dual. Do not change this value and press the

REGEN button once to advance

8) The display should now show

TS / U1 or U2

as

shown in Figure 16-B. This indicates which tank

is currently in service. Leave this value the same

and advance with the REGEN button

9) The display should now show

C / 32.0

. This

indicates the Capacity is 32,000 grains.

i

Use

the UP or DOWN button to change this

value to the one listed on page 4/calculated

on pages 6 and 7

and press the REGEN button

as shown in Figure 16-C

10) The display should now show

H / 20

. This

indicates the Hardness is 20 gpg.

i

Use the

UP or DOWN button to change this value to

the total hardness level of your water listed

on page 4/calculated on pages 6 and 7

and

press the REGEN button as shown in Figure 16-D

11) The display should now show

RS / SF

as shown

in Figure 16-E. This indicates that the Reserve

Selection is Safety Factor percentage. Do not

change this value and press the REGEN button

to advance to the next setting

12) The display should now show

SF / 10

. This indi-

cates the Safety Factor is 10%. This means the

system will leave 10% of the softening capacity

for the day before regeneration. Leave this value

the same and press the REGEN button as shown

in Figure 16-F

fIGure 16-e fIGure 16-f

PAGE 17Help: 888-426-5001 QualityWaterForLess.com

17) The display may now show

RR / 12

as shown in

Figure 17-E. This indicates Rapid Rinse time is 12

minutes long. Do not change this value and press

the REGEN button to advance to the next setting

18) The display may now show

BF / 10

. This indi-

cates the length of the Brine Fill cycle during

regeneration is 10 minutes.

i

Use the value

listed on page 4/calculated on pages 6 and

7

and then use the UP or DOWN button to adjust

this. Then press REGEN as shown in Figure 17-F

fIGure 17-a

fIGure 17-c

fIGure 17-b

fIGure 17-d

13) The display should now show

DO / 14

as shown

in Figure 17-A. This indicates the Day Override is

14 days; the system will regenerate in 14 days if

the meter has not measured water consumption

to have reached the calculated capacity. Do not

change this value and press the REGEN button

14) The display should now show

RT / 2:00

as

shown in Figure 17-B. This indicates the system

will regenerate at 2:00 AM following the day

override period. If you prefer an alternate regen-

eration time, please enter it here and then press

the REGEN button to advance

15) The display should now show

BW / 10

as

shown in Figure 17-C. This indicates Backwash

time is 10 minutes long. Do not change this

value and press the REGEN button to advance to

the next setting

16) The display should show

BD / 60

as shown in

Figure 17-D. This indicates Brine Draw time is 60

minutes long. Do not change this value and press

the REGEN button to advance to the next setting

fIGure 17-e fIGure 17-f

PAGE 18 QualityWaterForLess.com Help: 888-426-5001

fIGure 18-a fIGure 18-b

19) The display may now show

FM / t0.7

as shown

in Figure 18-A. This indicates Flow Meter type

3/4” Turbine. Set the setting to t0.7 if you have

the 3/4” turbine meter or P0.7 for the 3/4”

paddle wheel meter. Press the REGEN button to

advance to the home screen

20) The system will now exit Master Programming

mode and the display should now show the time

of day followed by the number of gallons remain-

ing as shown in Figure 18-B. Change the time

of day to your current time with either the UP

or DOWN button and confirm the time with the

REGEN button

fIGure 18-c

21) Remember to replace the valve cover when you

are finished installing your system as shown in

Figure 18-C

turbIne

Paddle

PAGE 19Help: 888-426-5001 QualityWaterForLess.com

9 ›InItIal start-uP

1) With one nearby softened faucet running in the COLD position, slowly open your bypass valve or 3-valve bypass

to about ¼ open to allow the air trapped in the softener to escape via your running faucet.

NOTE: Opening the

bypass too quickly or too open may damage your softener or plumbing

2) Allow the softener tank to slowly fill with water. After a few minutes, you will see a trickle of water coming from

the cold water faucet. Allow the water to run slowly in this manner for an additional 5 minutes. Next, with the

cold water faucet still running, gradually move your bypass valve to the fully open position.

NOTE: You may see

some initial discoloration from the softened water – this is normal and should dissipate within the first

40-50 gallons of water used.

Turn off the running cold water faucet when the water runs clear

3) Repeat steps 1 and 2 for the other tank (it will switch to the other tank automatically after a regeneration)

›conG r atu l atI on s

Your new softener with Fleck 9000 Meter Valve is now properly installed and programmed! Please

maintain your system by keeping the softener plugged-in and always keep your brine tank filled

with salt to at least above the water level. We appreciate your business and hope that you enjoy

years of trouble-free softened water!

4)

i

To test the integrity of your new system and all connections

,

it is strongly encouraged that you

perform a short form regeneration to check for leaks before service.

Begin this process by adding approxi-

mately 5 gallons of water/the amount of water needed to cover the brine grid into the brine tank

5)

If you have the mechanical version of the Fleck 9000,

begin a regeneration by turning the timer wheel

clockwise, let the regeneration run its full course to completion, and check the entire system for leaks. If you

notice a leak originating from the drain line/connection,

return to page 14

to review preparing the drain con-

nection. If you notice a leak originating from the brine line/connections,

return to pages 12 and 13

to review

preparing the brine tank connection

6)

If you have the electronic Fleck 9000 SXT version,

begin the regeneration sequence by HOLDING the

REGEN button for 5 seconds. Once the screen stops flashing BW, let BW - Backwash run for about 1 minute

to observe the water leave out the drain line and check for leaks. If you notice any leaks,

return to page 14

to

review preparing the drain connection. Click the REGEN button ONCE to move on to BD - Brine Draw

7) Once the screen stops flashing BD, let BD - Brine Draw run for about 1 minute to observe the water level in

the brine tank being drawn lower. Also check the brine line and the float valve in the brine well for leaks. If the

water level doesn’t lower or there is a leak,

return to pages 12 and 13

to review preparing the brine tank

connection. Click the REGEN button ONCE to move on to RR - Rapid Rinse

8) Once the screen stops flashing RR, advance from RR - Rapid Rinse to BF - Brine Fill by clicking the REGEN

button ONCE more. Once the screen stops flashing BF, let BF - Brine Fill run for about 1 minute to observe the

water level in the brine tank rise. Also check the brine line and float valve in the brine well for leaks. If the water

level doesn’t rise or there is a leak,

return to pages 12 and 13

to review preparing the brine tank connection.

Click the REGEN button ONCE to finish

9) Now you may add 120-160 pounds of pellet, solar, or block salt to your brine tank.

Always keep your brine tank

filled with salt to at least above the water level.

You do not need to perform a full regeneration immediately

after installation as the new resin arrives at full softening capacity. Simply let your softener meter automatically

trigger regenerations by tracking the water consumption

Other manuals for 9000

1

Table of contents

Other Fleck Water Dispenser manuals

Fleck

Fleck 5600 Econominder User manual

Fleck

Fleck 5600 Econominder User manual

Fleck

Fleck 5600 Econominder User manual

Fleck

Fleck 5600SXT Owner's manual

Fleck

Fleck 7000 User manual

Fleck

Fleck 5800 SXT User manual

Fleck

Fleck 9100TS Upflow User manual

Fleck

Fleck 7000SE User guide

Fleck

Fleck 7000 User manual

Fleck

Fleck 7000 Operating instructions

Popular Water Dispenser manuals by other brands

Star

Star S07EC24 owner's guide

GE

GE GXSH39E Owner's Manual & Installation Instructions

Grunbeck

Grunbeck GENO-mat MN-Z 20/10 operating manual

Valrom Industrie

Valrom Industrie aquaPUR SOFT 18 Handbook of Installation and Operation

Oasis

Oasis PM instructions

Hellenbrand

Hellenbrand H-150 Series Specifications