Fleck 7000 User manual

Other manuals for 7000

3

Table of contents

Other Fleck Water Dispenser manuals

Fleck

Fleck 5600 Econominder User manual

Fleck

Fleck 9100TS Upflow User manual

Fleck

Fleck 5600SXT User manual

Fleck

Fleck 5800 SXT User manual

Fleck

Fleck 5600 Econominder User manual

Fleck

Fleck 5600 Econominder User manual

Fleck

Fleck 7000SE User guide

Fleck

Fleck 7000 Operating instructions

Fleck

Fleck 5600 Econominder User manual

Fleck

Fleck 5600SXT Owner's manual

Popular Water Dispenser manuals by other brands

l'eau miracle water

l'eau miracle water MW-30 Installation and operation manual

Kenmore

Kenmore 625.383000 Use & care guide

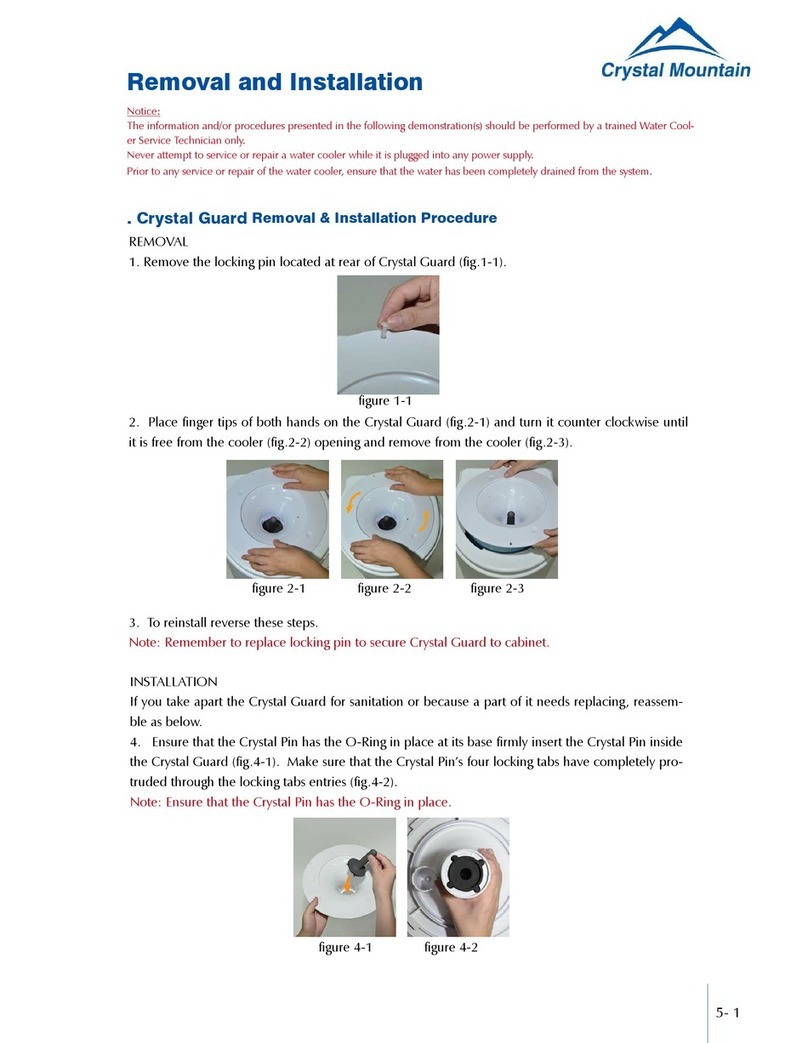

Crystal Mountain

Crystal Mountain Mogul Removal and installation

Morton

Morton System Saver MSD20F Installation and operation manual

Philips

Philips ADD4963 user manual

NuvoH2O

NuvoH2O Manor Duo installation guide

Kool Tek

Kool Tek FG8 user manual

Kenmore

Kenmore UltraSoft 180 owner's manual

ScaleBlaster

ScaleBlaster SB-75 Installation & operation manual

3M

3M CFS1254 Installation and operation instructions

Bunn

Bunn dispenser Installation and operating guide

Water Quality Control Systems

Water Quality Control Systems 2401 Series Unit Installation Guide

Runxin

Runxin RL-R150 Programming manual

Elkay

Elkay LFAEH8F 2LJO CCC Series Installation, care & use manual

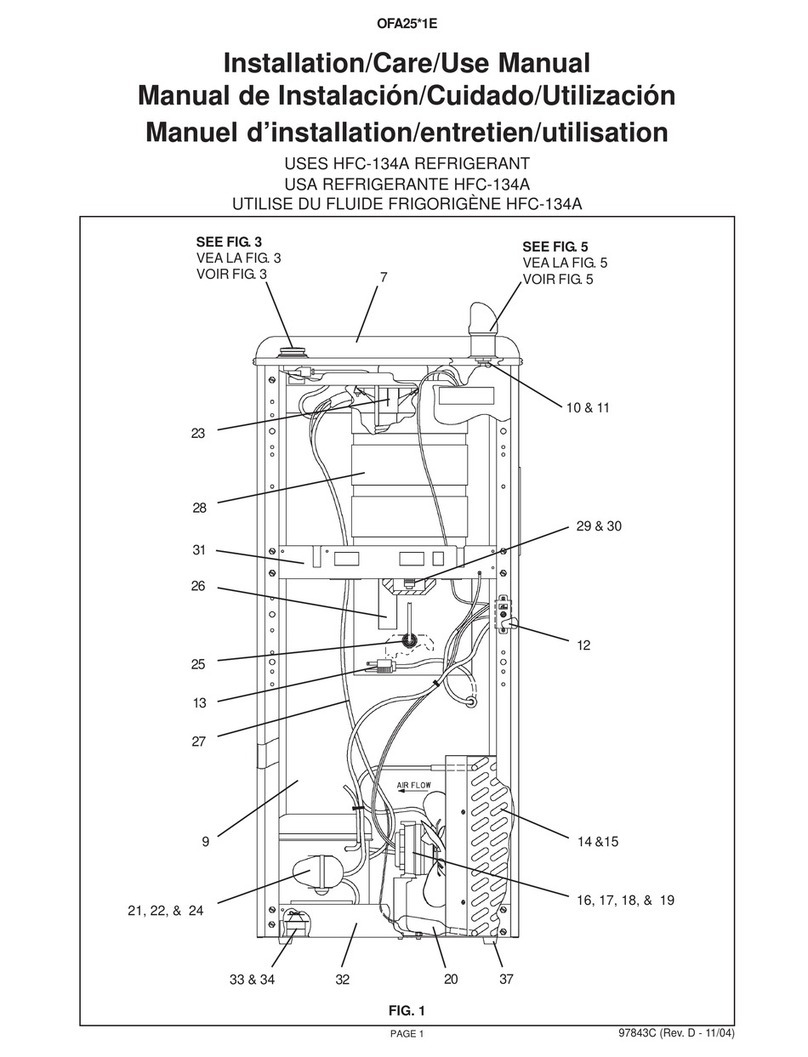

Elkay

Elkay OFA25 1E Series Installation, care & use manual

WaterLogic

WaterLogic WL3 Firewall Technical manual

CalMag

CalMag Duplex operating manual

iCoolsport

iCoolsport iCool Compact Series owner's manual