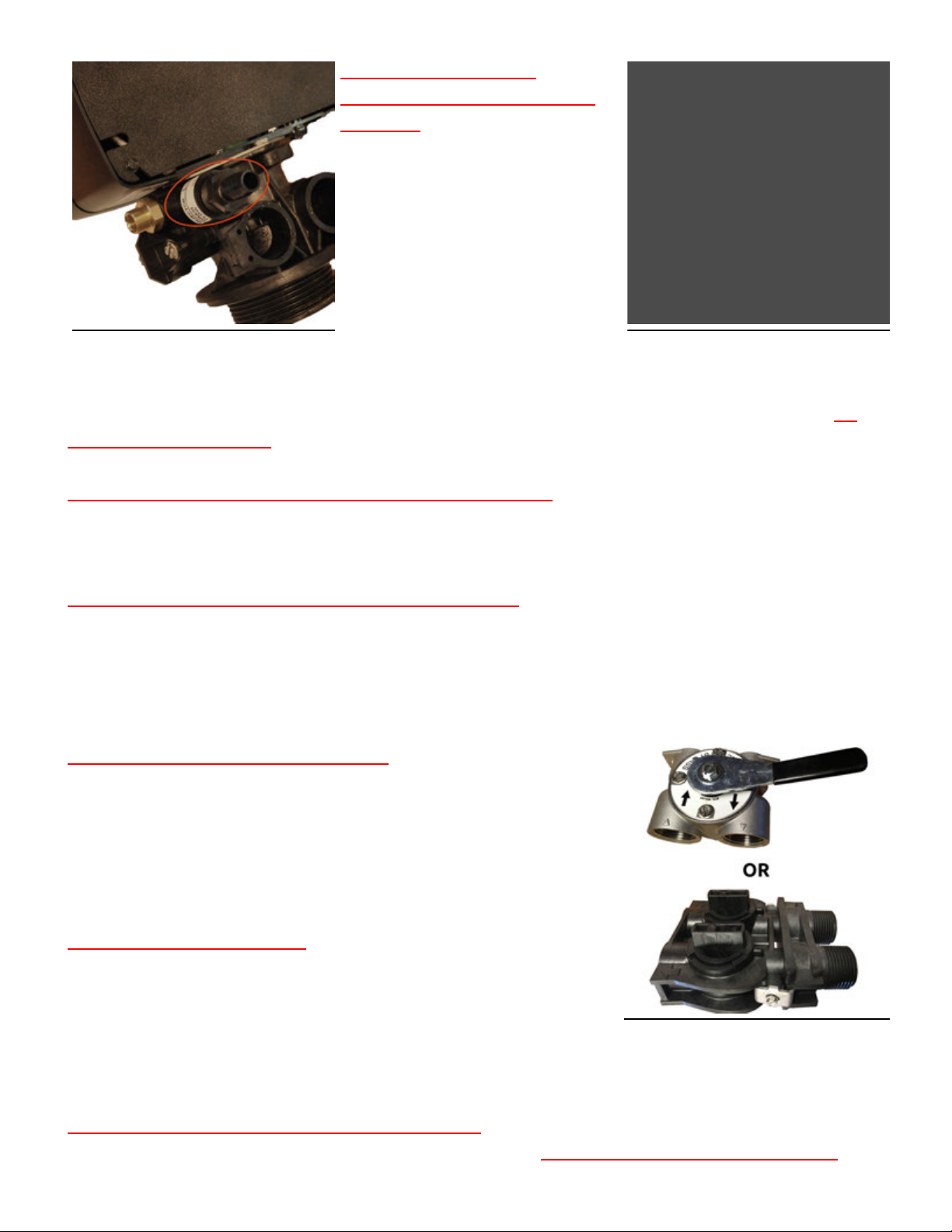

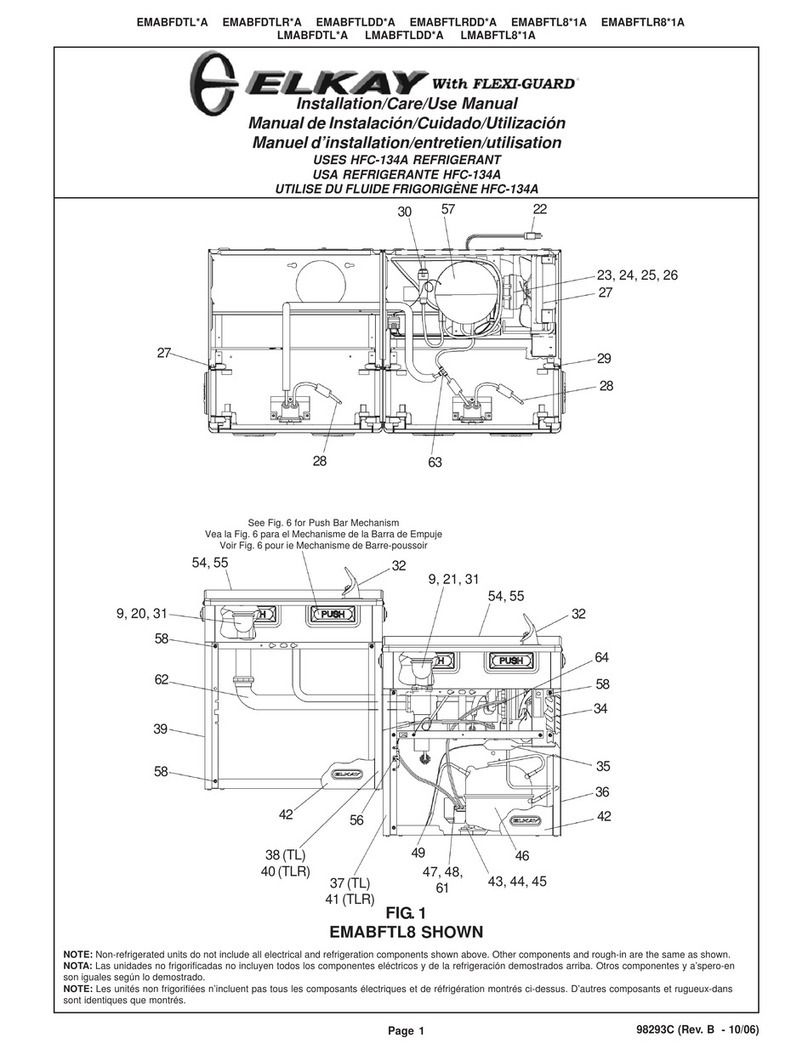

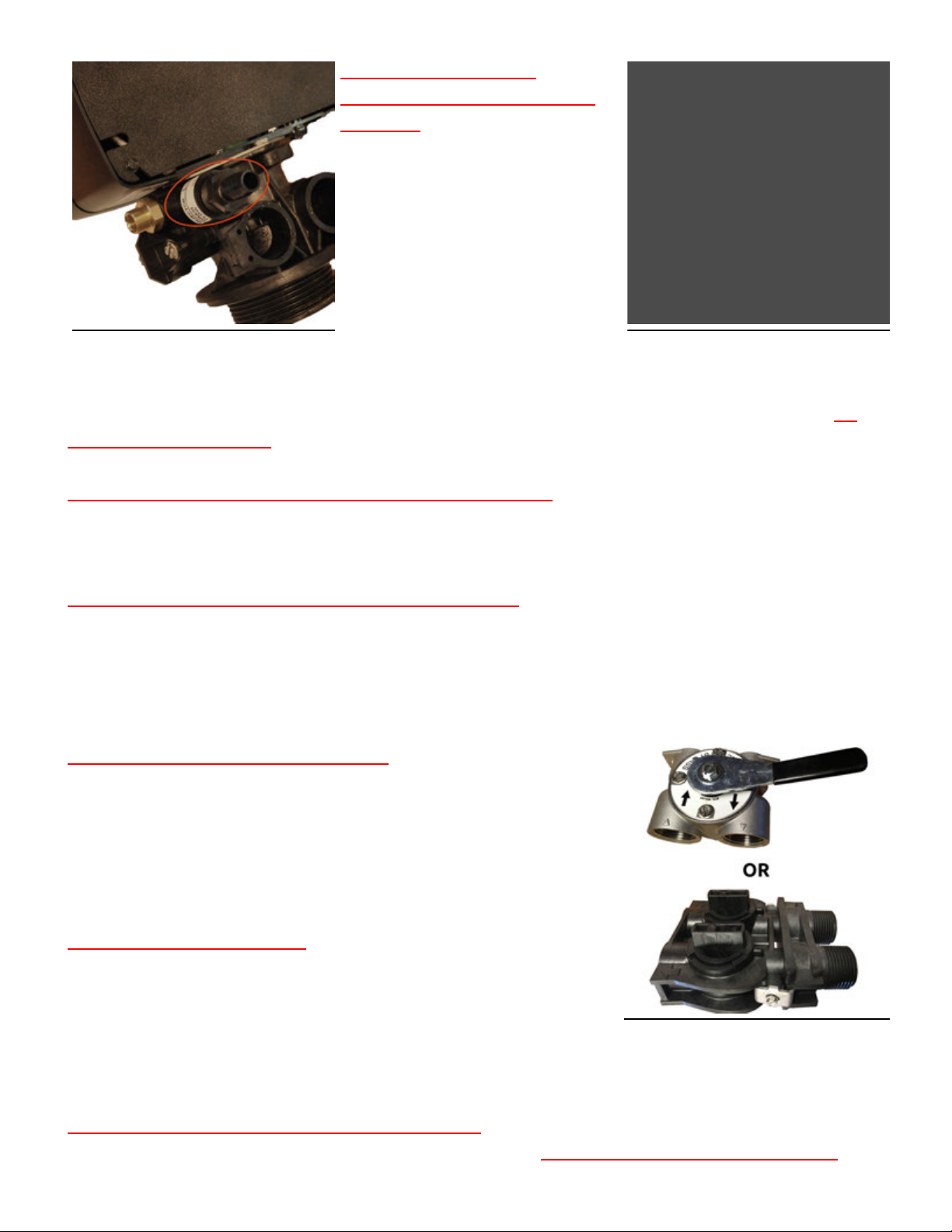

DD r r a a i i n n F F i i t t t t i i n n g g

EE xx aa mm pp l l ee DD r r aa i i nn ww / / AA i i r r GG aa pp

CC oo nn nn ee c c t t i i oo nn FF i i t t t t i i nn gg

NN e e v v e e r r mm a a k k e e a a d d i i r r e e c c t t

cc oo nn nn ee cc tt i i oo nn i i nn tt oo aa ww aa ss tt ee ww aa tt ee rr

least 3 inches (76 mm) between

the end of the drain line and the

wastewater level in the drain pipe

contamination of the line. An

additional gap of 3/4 inch (19 mm)

between the drain pipe and drain

line is recommended to prevent

any problems in the case of a pipe

over$ow. Using a simple P-trap as shown—

—is ideal as well, but a stand pipe with a diameter of

at least 1.5 inches (38 mm) is adequate. As the water coming out is under pressure, make sure to

ss ee cc uu rr ee tt hh ee dd rr aa i i nn l l i i nn ee

so that it does not move and create a mess.

DD o o n n o o t t t t i i e e mm u u l l t t i i p p l l e e s s y y s s t t e e mm s s i i n n t t o o a a s s i i n n g g l l e e d d r r a a i i n n l l i i n n e e . .

If hooking up multiple systems, each system needs a separate, independent drain line to ensure proper

operation and prevent damage. Systems can all be run to the same standpipe/sump/outside drain, but

the drain line from each system needs to be separate.

DD o o n n o o t t u u s s e e a a d d d d i i t t i i o o n n a a l l ## t t t t i i n n g g s s o o n n t t h h e e d d r r a a i i n n l l i i n n e e . .

Avoid installing any additional #ttings (check valves, ball/gate valves, etc.) as this can prevent proper

backwash and cause premature system failure.

II nn ll ee tt // OO uu tt ll ee tt CC oo nn nn ee cc tt ii oo nn ss

DD o o n n o o t t o o v v e e r r t t i i g g h h t t e e n n t t h h e e s s c c r r e e ww s s . .

The clips simply hold the

connection #ttings together and the screws only need tightened

enough to keep the clips in place. Further tightening will not stop

leaks and tightening too much can damage the system, which will

not be covered under warranty. The meter assembly is expensive to

replace, so extra care is recommended on these systems.

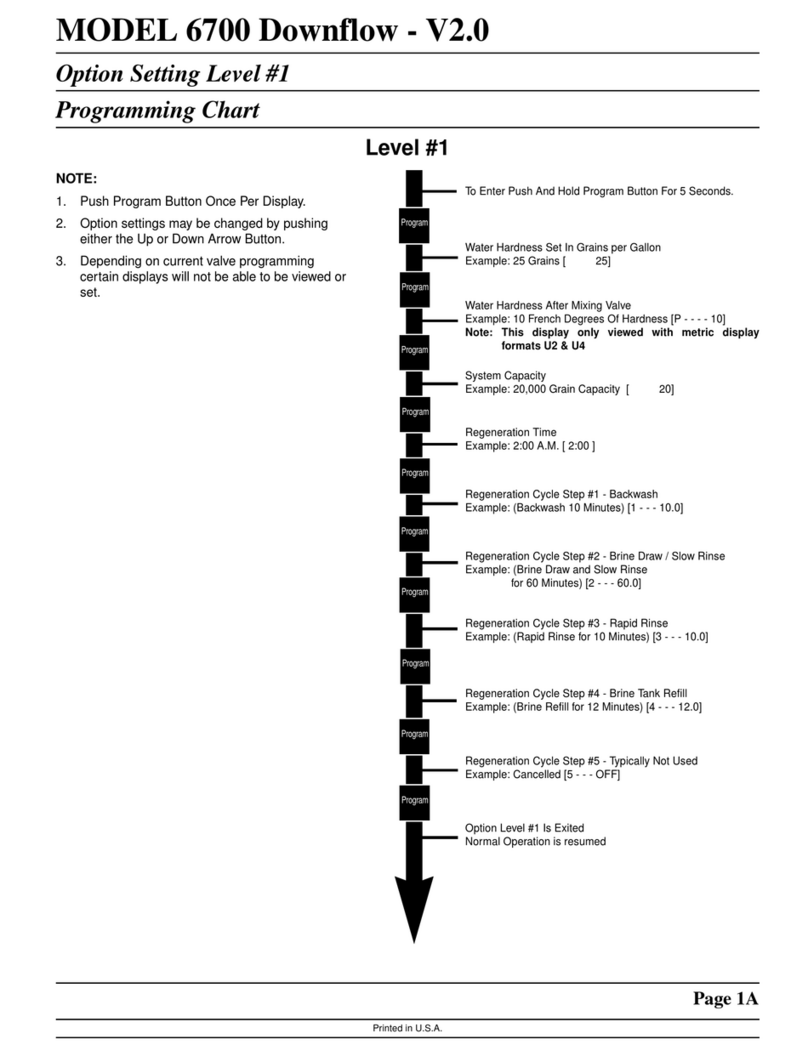

VV ee r r i i f f y y $$ oo ww dd i i r r ee c c t t i i oo nn . .

Untreated water will enter the

system on the side marked with an arrow pointing toward the front

of the control head (on both the bypass valve and the control head

itself). Treated water will exit the system on the side marked with

an arrow pointing away from the front of the control head (on both

the bypass valve and the control head itself).

CC oo r r r r ee c c t t i i nn l l ee t t / / oo uu t t l l ee t t c c oo nn nn ee c c t t i i oo nn s s aa r r ee vv i i t t aa l l . .

Improper $ow direction will prevent proper

operation and can damage your system and your plumbing.

TT hh ee dd i i r r ee cc t t i i oo nn oo f f $$ oo ww cc aa nn nn oo t t bb ee

15 of 19