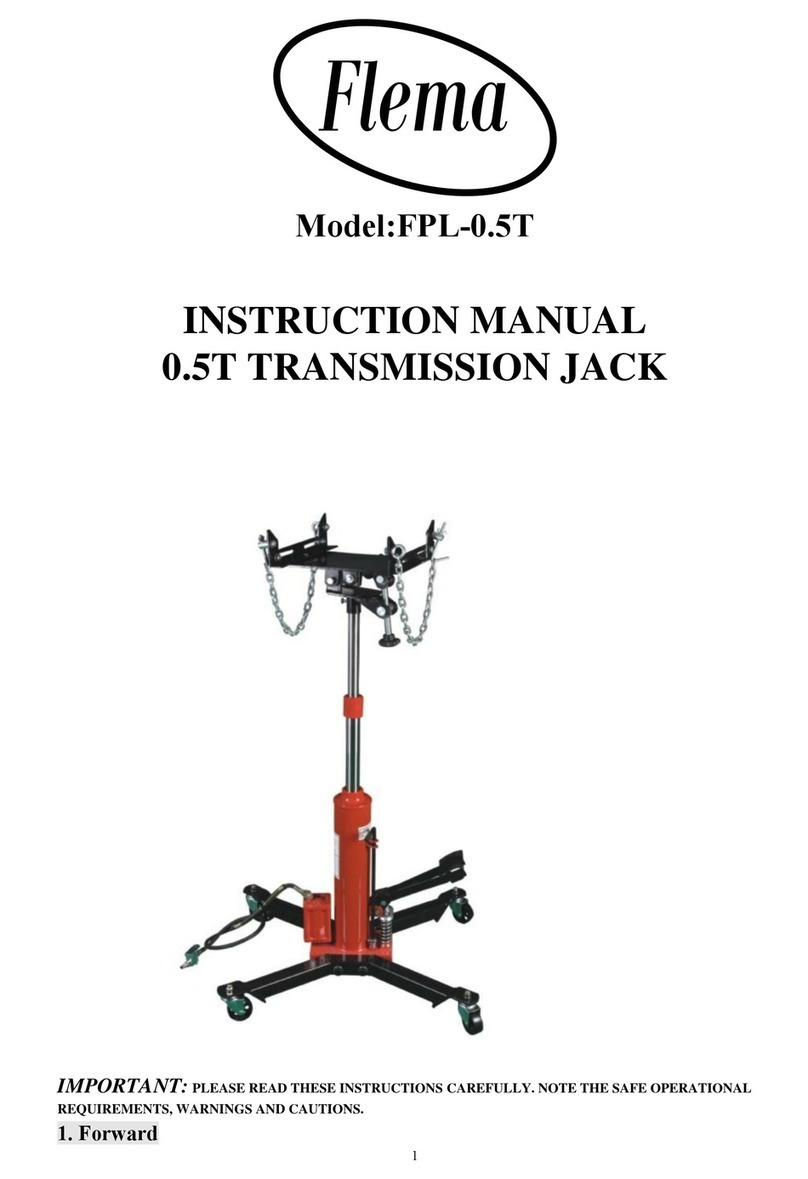

FLEMA FPL-1.5TF User manual

1-1/2 Ton Truck Transmission Jack

NOTE: BEFORE USING THIS JACK, PLEASE READ THIS MANUAL, UNDERSTAND

ITS OPERATING PROCEDURES, SAFETY WARNINGS AND MAINTENANCE OF THIS

JACK.

Carefully inspect all components for shipping damage. If shipping damage is found,

notify carrier at once. The carrier is responsible for any damage resulting from

shipment.

Model:FPL-1.5TF

1. SAFETY

To avoid personal injury or property damage, please follow all safety

precautions. We cannot be responsible for injury or damage resulting from

unsafe and incorrect products use or system operation, or lack of

maintenance.

WARNING indicates a potential danger that requires correct action to avoid personal

injury.

IMPORTANT indicates correct action to prevent damage or equipment failure.

WARNING:

lThe hydraulic equipment operator must be a qualified operator familiar with correct

training and work experience of hydraulic equipment. Lack of knowledge in any of these

areas can lead to equipment damage or personal injury.

lRead, understand, and follow all instructions before operating this jack.

lInspect the jack before each use. Do not use jack if damaged, altered, modified, leaking

hydraulic fluid or with missing or loose components.

lTo avoid personal injury, never modify or weld hydraulic equipment.

lNever lift more that the rated capacity of the jack, overloading causes equipment failure

and possible personal injury.

lThe jack is a load lifting device, not a load holding device. Once the load has been

positioned, it must always be supported mechanically. Never work under, or around a

load only supported by hydraulic means.

lNever put unbalanced or off-center loads on the jack saddle. Do not use saddle

adapters or saddle extenders between the stock lifting saddle and the load. The

incorrect loading can result in equipment failure

lThis jack was designed for lifting transmissions only. Consult the vehicle manufacturer for

the transmission's center of balance.

lSecure the transmission to the jack's saddle with the anchorage restraint system provided

before raising or lowering the transmission.

lUse of this product is limited to the removal, installation and transportation in the lowered

position, of transmissions, transfer cases and trans axles.

lAlways wear safety glasses and/or other protective equipment that meet or exceed ANSI

Z87.1 and OSHA standards.

lUse the jack ONLY on hard, level surfaces capable of sustaining the load. Use on other

surface

IMPORTANT

lKeep the jack clean at all time.

lWhen the jack is not in use, release the valve and make all piston rod return to the jack.

lUse hydraulic equipment in normal operating temperatures. Do not use equipment in

temperatures of 65 ℃(150 ℉) or higher. Overheating will soften seals and weakens

hose material, resulting in oil leaking or other equipment failure.

2. DESCRIPTION

The Transmission Jack is used for the removal, installation and moving of heavy duty truck

transmissions.

SPECIFICATIONS

3. SETUP

PLEASE REFER TO THE EXPLODED VIEW DRAWING IN THIS MANUAL IN ORDER TO

IDENTIFY PARTS.

lInstall the Part #3-7 and Part 3-13 brackets in the Part #3-8 saddle plate with the Part

#3-6 bolts, Part #3-9 washers and Part #3-10 wing nuts.

lAttach the Part #3-4 chains to the Part #3-7 brackets. Secured to brackets with the Part

#3-1 bolts, Part #3-2 washers, Part #3-3 lock washers and Part #3-5 nuts.

lAssemble the Part #3-16 chain hooks to the Part #3-15 adaptor bolts with the Part #3-14

wing nuts..

lSecure the Part #3-15 adaptor bolts to the two remaining Part #3-13 brackets using the

Part #3-12 washers and Part #3-11 nuts.

4. PURGING AIR FROM THE HYDRAULIC SYSTEM:

lRotate the knob at the top of the hydraulic block in a clockwise direction until tight. Now

turn it in a counterclockwise direction two full turns.

lActivate the hand to pump about 15- 20 times.

lRotate the knob at the top of the hydraulic block in a clockwise direction until tight.

lActivate the hand pump until the lift arm is raised to maximum height.

5. OPERATING INSTRUCTIONS

lPosition the jack under the transmission.

lClose the control valve. Operate the pump handle to raise the boom and align the

mounting plate with the transmission.

lRemove the transmission according to the instructions in the vehicle service manual.

lPosition the transmission on the saddle plate, resting against the angle plates.

lSecure the transmission to the saddle plate.

lLower the load by slowly opening the control valve. The control valve regulates how fast

the boom is lowered.

6. MAINTENANCE

IMPORTANT: Dirt is the greatest single cause of failure in hydraulic units. Keep the jack clean

Model# Lifting

Capacity

Min.

Height

Max.

Height

Net

Weight

Gross

Weight

Package

Size

1.5 Ton 918mm 1854mm 66Kg 74Kg 1150*718*405mm

FPL-1.5TF

and well lubricated to prevent foreign matter from entering the system. If the jack has been

exposed to rain, snow, sand, or grit, it must be cleaned before it is used.

lStore the jack in a well-protected area where it will not be exposed to corrosive vapors,

abrasive dust, or any other harmful elements.

lRegularly lubricate the moving parts.

lTo check the oil level, place the jack on level ground and lower the lift arm completely.

Remove the filler plug. The oil level should be within 3/8' of the filler plug hole. Do not

overfill. If necessary, add approved anti-wear hydraulic jack oil, and install the filler plug

again.

IMPORTANT: The use of alcohol, hydraulic brake fluid or detergent motor oil could

damage the seals and result in jack failure.

lInspect the jack before each use. Do not use jack if damaged, altered, modified, leaking

hydraulic fluid or with missing or loose components.

7. TROUBLESHOOTING

Repair procedures must be performed in a dirt-free environment by qualified personnel who

are familiar with this equipment

Trouble Cause Solution

Jack does not lift 1. Release valve is open. 1. Close release valve.

2. Low/no oil in reservoir. 2. Fill with Oil and bleed system.

3. Air-locked system. 3. Bleed system.

4. Load is above capacity of jack. 4. Use correct equipment

6. Packing worn out or defective. 6. Install seal kit

Jack lifts only

partially

1. Too much or not enough oil. 1. Check Oil/eve!

Jack advances

slowly

1. Pump not working correctly. 1. Install seal kit, or replace power Unit.

Jack lifts load, but

doesn't hold

1. Cylinder packing is leaking. 1. Install seal kit

2. Valve not working correctly

(suction, delivery, release, or

bypass).

2. Inspect valves. Clean and repair seat

surfaces.

3. Air-locked system. 3. Bleed system.

Jack leaks oil 1. Worn or damaged seals. 1. Install seal kit.

Jack will not

retract

1. Release valve is closed. 1. Open or clean release valve.

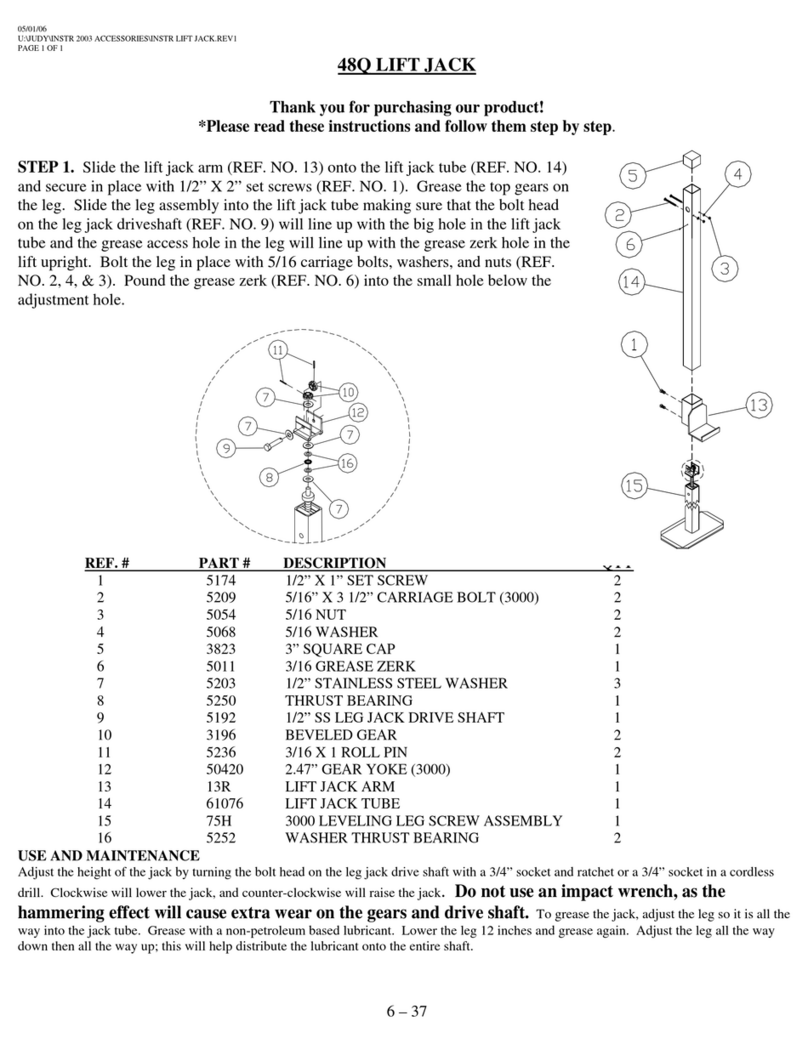

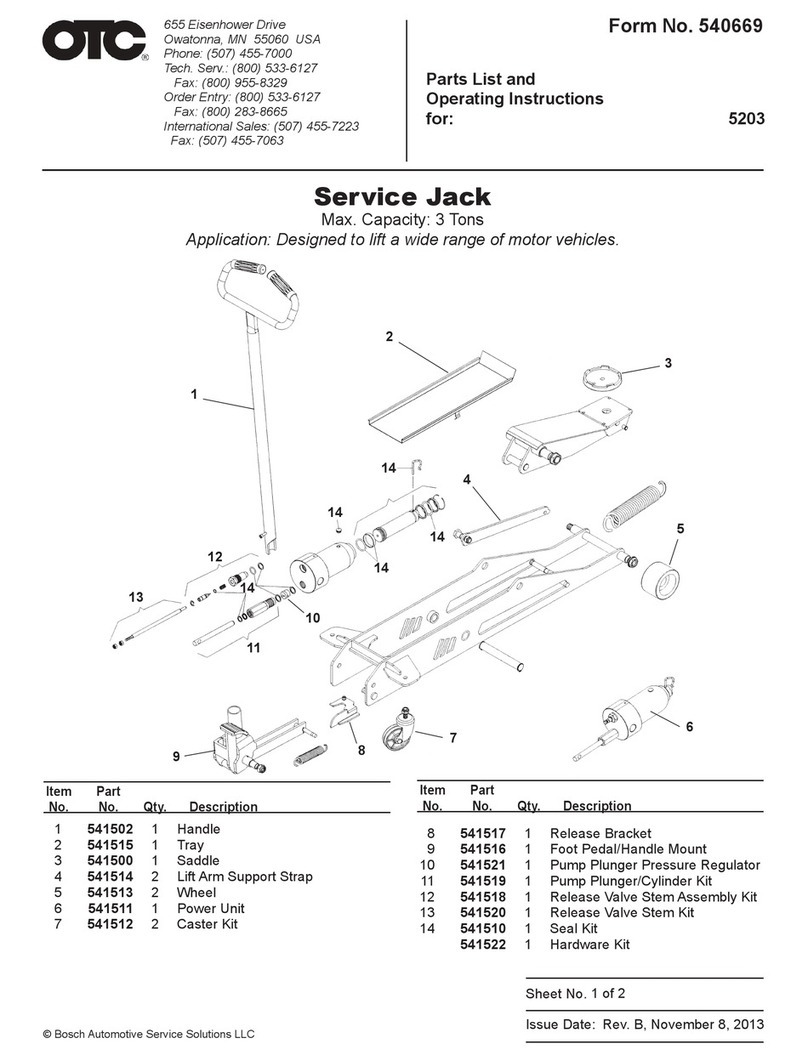

1- 1/2 TON TRANSMISSION JACK PART LIST

PART LIST

Part No Description Qty. Part No Description Qty.

1 Wheel Assy. 4 1-15 Copper Washer 1

2 Washer 6 1-16 Valve 1

3 Nut 6 1-17 Steel Ball 2

4 Frame 1 1-18 O-ring 2

5 Bolt 2 1-19 Release Valve 1

6 Shaft 1 1-20 Pin 1

7 Washer 1 1-21 Release Knob 1

8 Rod Link 2 1-22 Bolt 1

9 Washer 2 1-23 Steel Ball 1

10 Saddle Seat 1 1-24 Ball Seat 1

11 Shaft 1 1-25 Spring 1

12 Washer 4 1-26 Screw 1

13 Bracket 1 1-27 Sealing Washer 1

14 Nut 2 1-28 Screw 1

15 Shaft 1 1-29 Spring 1

16 Pin 2 1-30 Steel Ball 1

17 Bolt 7 1-31 Spring 1

18 Hand Wheel 2 1-32 Copper Washer 1

19 Adjustment Rod 2 1-33 Screw 1

20 Nut 3 1-34 Copper Washer 1

21 Shaft 1 1-35 Washer 3

22 Retaining Ring 6 1-36 Bracket 1

23 Nut 2 1-37 Pin 1

24 Bearing 4 1-38 Y-ring 1

25 Nut 2 1-39 O-ring 1

26 Shaft 1 1-40 Cylinder Pump 1

27 Shaft 1 1-41 Pump Cylinder 1

28 Grease Fitting 1 1-42 Wiper Ring 1

29 Lift Arm 1 1-43 Link Plate 2

30 Pin 2 1-44 Pin 2

31 Shaft 2 1-45 Handle 1

32 Rod Link 2 1-46 Handle Sleeve 1

33 Washer 2 3-1 Bolt 2

34 Rod Link 1 3-2 Washer 2

35 Pin 1 3-3 Washer 2

36 Pin 2 3-4 Chain 2

1-1 Snap Ring 1 3-5 Nut 2

1-2 Washer 2 3-6 Bolt 4

1-3 O-ring 1 3-7 Bracket 2

1-4 Piston Rod 1 3-8 Bracket 1

1-5 Piston Ring 1 3-9 Washer 4

1-6 Sealing Washer 1 3-10 Nut 4

1-7 O-ring 1 3-11 Nut 2

1-8 Washer 1 3-12 Washer 2

1-9 Washer 1 3-13 Bracket 2

1-10 Body 1 3-14 Nut 2

1-11 Oil Filler Plug 1 3-15 Bolt 2

1-12 Washer 2 3-16 Hut 2

1-13 Bolt 2 3-17 Bolt 2

1-14 Bolt 1 3-18 Board 1

Table of contents

Other FLEMA Jack manuals

Popular Jack manuals by other brands

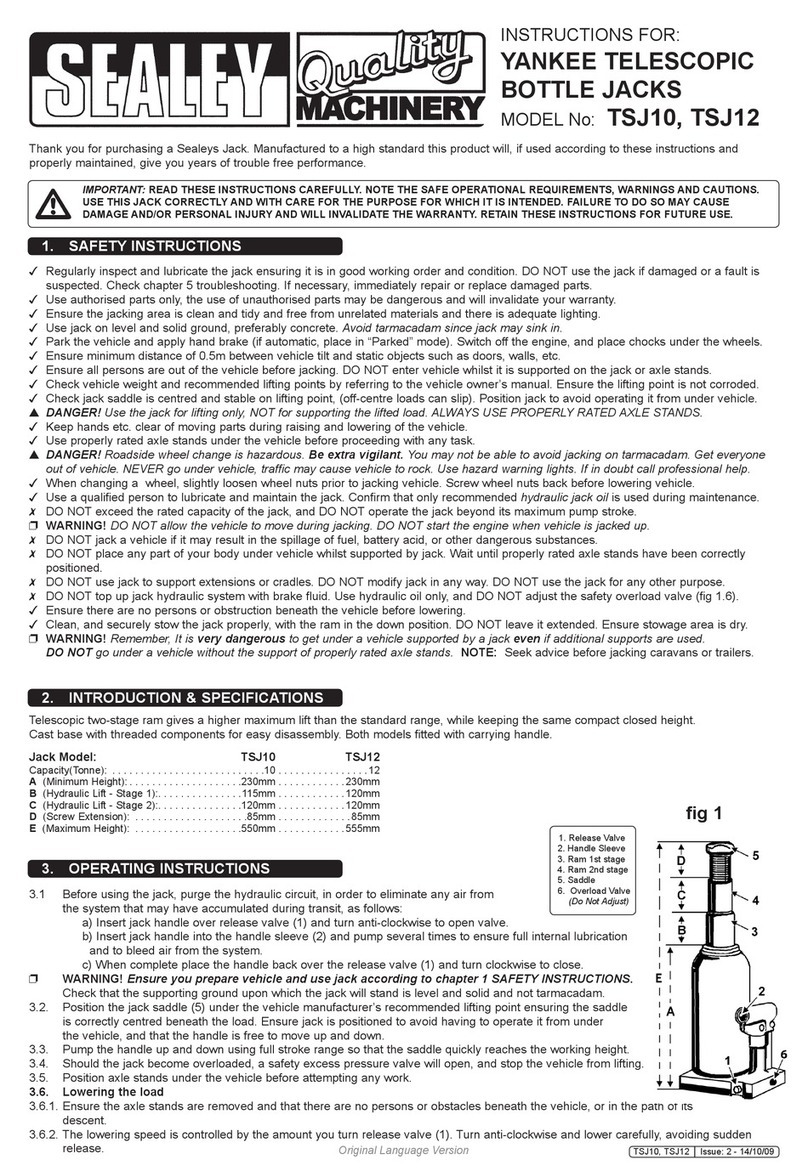

Sealey

Sealey TSJ10 instructions

Tractel

Tractel hydrofor H 5 Operation and maintenance manual

K Tool International

K Tool International KTI63709 owner's manual

Sealey

Sealey SJ3.V3 instructions

Cattini

Cattini YAK 215/N Operating and maintenance manual

Pittsburgh

Pittsburgh 57047 Owner's manual & safety instructions