Benzlers BD Series Maintenance and service guide

IMC-1.00GB01/11

Series BD - Screw Jacks

Installation & Maintenance

Product Safety Information

General - The following information is important in ensuring safety. It must be brought to the attention of personnel involved in the selection

of power transmission equipment, those responsible for the design of the machinery in which it is to be incorporated and those involved in its

installation, use and maintenance.

Our equipment will operate safely provided it is selected, installed, used and maintained properly. As with any power transmission equipment

proper precautions must be taken as indicated in the following paragraphs, to ensure safety.

Potential Hazards - these are not necessarily listed in any order of severity as the degree of danger varies in individual circumstances. It is

important therefore that the list is studied in its entirety:-

1) Fire/Explosion

(a) Oil mists and vapour are generated within gear units. It is therefore dangerous to use naked lights in the proximity of gearbox openings,

GXHWRWKHULVNRI¿UHRUH[SORVLRQ

E,QWKHHYHQWRI¿UHRUVHULRXVRYHUKHDWLQJRYHUR&FHUWDLQPDWHULDOVUXEEHUSODVWLFVHWFPD\GHFRPSRVHDQGSURGXFHIXPHV

&DUHVKRXOGEHWDNHQWRDYRLGH[SRVXUHWRWKHIXPHVDQGWKHUHPDLQVRIEXUQHGRURYHUKHDWHGSODVWLFUXEEHUPDWHULDOVVKRXOGEH

handled with rubber gloves.

2) Guards - Rotating shafts and couplings must be guarded to eliminate the possibility of physical contact or entanglement of clothing. It should

EHRIULJLGFRQVWUXFWLRQDQG¿UPO\VHFXUHG

1RLVH+LJKVSHHGJHDUER[HVDQGJHDUER[GULYHQPDFKLQHU\PD\SURGXFHQRLVHOHYHOVZKLFKDUHGDPDJLQJWRWKHKHDULQJZLWKSURORQJHG

exposure. Ear defenders should be provided for personnel in these circumstances. Reference should be made to the Department of

(PSOR\PHQW&RGHRI3UDFWLFHIRUUHGXFLQJH[SRVXUHRIHPSOR\HGSHUVRQVWRQRLVH

4) Lifting - Where provided (on larger units) only the lifting points or eyebolts must be used for lifting operations (see maintenance manual or

general arrangement drawing for lifting point positions). Failure to use the lifting points provided may result in personal injury and/or damage

to the product or surrounding equipment. Keep clear of raised equipment.

5) Lubricants and Lubrication

D3URORQJHGFRQWDFWZLWKOXEULFDQWVFDQEHGHWULPHQWDOWRWKHVNLQ7KHPDQXIDFWXUHU¶VLQVWUXFWLRQPXVWEHIROORZHGZKHQKDQGOLQJ

lubricants.

(b) The lubrication status of the equipment must be checked before commissioning. Read and carry out all instructions on the lubricant

SODWHDQGLQWKHLQVWDOODWLRQDQGPDLQWHQDQFHOLWHUDWXUH+HHGDOOZDUQLQJWDJV)DLOXUHWRGRVRFRXOGUHVXOWLQPHFKDQLFDOGDPDJHDQGLQ

extreme cases risk of injury to personnel.

6) Electrical Equipment - Observe hazard warnings on electrical equipment and isolate power before working on the gearbox or associated

equipment, in order to prevent the machinery being started.

7) Installation, Maintenance and Storage

(a) In the event that equipment is to be held in storage, for a period exceeding 6 months, prior to installation or commissioning, we must be

consulted regarding special preservation requirements. Unless otherwise agreed, equipment must be stored in a building protected from

extremes of temperature and humidity to prevent deterioration.

The rotating components (gears and shafts) must be turned a few revolutions once a month (to prevent bearings brinelling).

E([WHUQDOJHDUER[FRPSRQHQWVPD\EHVXSSOLHGZLWKSUHVHUYDWLYHPDWHULDOVDSSOLHGLQWKHIRUPRID³ZD[HG´WDSHRYHUZUDSRUZD[¿OP

preservative. Gloves should be worn when removing these materials. The former can be removed manually, the latter using white spirit as

a solvent.

3UHVHUYDWLYHVDSSOLHGWRWKHLQWHUQDOSDUWVRIWKHJHDUXQLWVGRQRWUHTXLUHUHPRYDOSULRUWRRSHUDWLRQ

F,QVWDOODWLRQPXVWEHSHUIRUPHGLQDFFRUGDQFHZLWKWKHPDQXIDFWXUHU¶VLQVWUXFWLRQVDQGEHXQGHUWDNHQE\VXLWDEO\TXDOL¿HGSHUVRQQHO

(d) Before working on a gearbox or associated equipment, ensure that the load has been removed from the system to eliminate the possibility

of any movement of the machinery and isolate power supply. Where necessary, provide mechanical means to ensure the machinery

cannot move or rotate. Ensure removal of such devices after work is complete.

(e) Ensure the proper maintenance of gearboxes in operation. Use only the correct tools and our approved spare parts for repair and

PDLQWHQDQFH&RQVXOWWKH0DLQWHQDQFH0DQXDOEHIRUHGLVPDQWOLQJRUSHUIRUPLQJPDLQWHQDQFHZRUN

+RW6XUIDFHVDQG/XEULFDQWV

D'XULQJRSHUDWLRQJHDUXQLWVPD\EHFRPHVXI¿FLHQWO\KRWWRFDXVHVNLQEXUQV&DUHPXVWEHWDNHQWRDYRLGDFFLGHQWDOFRQWDFW

E$IWHUH[WHQGHGUXQQLQJWKHOXEULFDQWLQJHDUXQLWVDQGOXEULFDWLRQV\VWHPVPD\UHDFKWHPSHUDWXUHVVXI¿FLHQWWRFDXVHEXUQV$OORZ

equipment to cool before servicing or performing adjustments.

9) Selection and Design

(a) Where gear units provide a backstop facility, ensure that back-up systems are provided if failure of the backstop device would endanger

personnel or result in damage.

(b) The driving and driven equipment must be correctly selected to ensure that the complete machinery installation will perform satisfactorily,

avoiding system critical speeds, system torsional vibration, etc.

(c) The equipment must not be operated in an environment or at speeds, powers, torques or with external loads beyond those for which it

was designed.

(d) As improvements in design are being made continually the contents of this catalogue are not to be regarded as binding in detail, and

drawings and capacities are subject to alterations without notice.

The above guidance is based on the current state of knowledge and our best assessment of the potential hazards in the operation of the gear units

.

$Q\IXUWKHULQIRUPDWLRQRUFODUL¿FDWLRQUHTXLUHGPD\EHREWDLQHGE\FRQWDFWLQJRXU$SSOLFDWLRQ(QJLQHHUV

IMPORTANT

PRODUCT SAFETY

1 IDENTIFICATION ...................................................................................1

1.1 Machine description .........................................................................................1

1.1.1 Description of purpose...........................................................................1

1.1.2 Reasonably foreseeable misuse and prohibited usages ......................1

1.1.3 System overview ....................................................................................2

1.1.4 Drawings/layouts ...................................................................................2

1.2 Manufacturer and technical data .....................................................................3

1.2.1 Identification...........................................................................................3

1.2.2 External Electrical Power — Supply data..............................................3

1.2.3 IP code, clear text...................................................................................4

1.2.4 Environmental conditions and limits.....................................................4

1.3 Product marking ...............................................................................................5

1.3.1 Product sign ...........................................................................................5

1.3.2 Option – extra sign according to ATEX directive....................................6

1.3.3 Understanding ATEX Directive - Markings............................................7

2 USE OF THIS MANUAL .......................................................................... 9

2.1 General information about this manual...........................................................9

2.2 Important information about this manual .......................................................9

2.3 Target group for this information .....................................................................9

2.3.1 Demands on personnel..........................................................................9

2.3.2 Procedure for revision and amendment................................................9

3 DESCRIPTION OF FUNCTION.............................................................. 10

3.1 Overall .............................................................................................................10

3.1.1 Control devices.....................................................................................11

3.2 Options ............................................................................................................12

3.2.1 Stop nut (SM)........................................................................................12

3.2.2 Stop nut (SM) + Limit Switch (LS)........................................................13

3.2.3 Locked against rotation – two options ................................................13

3.2.4 LR - Locked Against Rotation (Tube)...................................................14

3.2.5 LRK - Locked Against Rotation (Key) ..................................................15

3.2.6 Safety Nut (SHM)..................................................................................15

3.2.7 Antibacklash (ABL)...............................................................................16

4 SAFETY INFORMATION ....................................................................... 17

4.1 General machine safety................................................................................. 17

4.1.1 Emergency stop function .....................................................................17

4.1.2 Safety layout – emergency & safety stops zones................................17

4.1.3 Hazard text ...........................................................................................17

4.2 Operators locations.........................................................................................18

4.2.1 Noise.....................................................................................................18

4.2.2 Stability .................................................................................................18

4.2.3 Remaining risks ...................................................................................19

4.3 Personal protection, unintentional use..........................................................20

4.4 Safety instruction ............................................................................................20

4.4.1 Specific safety rules .............................................................................20

5 PREPARATIONS BEFORE USE ............................................................ 21

5.1 Safety precautions before use ........................................................................21

5.2 Transport and storage ....................................................................................21

5.2.1 Repackaging to prevent damage in transport.....................................21

5.2.2 Unpacking.............................................................................................21

5.2.3 Safely disposing of packaging material...............................................21

5.3 Preparatory work before installation and assembling..................................22

5.3.1 Prior to Installation ..............................................................................22

5.3.2 Fitting of components to the unit input shaft......................................22

5.3.3 Lifting....................................................................................................23

5.4 Installation ......................................................................................................24

5.4.1 Fitting the screw jack to the machine .................................................24

5.4.2 Units for use in a potentially explosive atmosphere...........................25

5.4.3 Motor Connections...............................................................................26

6 OPERATORS SETTINGS ETC ............................................................... 27

6.1 Instructions from sub suppliers – Quick reference.......................................27

7 OPERATING INSTRUCTIONS ............................................................... 27

7.1 Preparations before start ...............................................................................27

7.1.1 Start-up of safety systems...................................................................27

7.2 Operation.........................................................................................................28

7.2.1 Noise.....................................................................................................28

7.2.2 General safety ......................................................................................28

7.2.3 Initial start up in a potentially explosive atmosphere.........................28

7.2.4 Spillage of grease.................................................................................28

8 EMERGENCY, MISHAP AND SUSPENSION ......................................... 28

8.1 Change of direction of motion, relief of stored energy..................................28

8.2 Measures for the escape and rescue of trapped persons.............................28

8.3 Method to be followed in cases of accident or breakdown ...........................29

8.4 Storing and protecting ....................................................................................29

8.5 Taking product out of operation .....................................................................29

8.5.1 Advice on disposal / disposal of waste................................................29

9 MAINTENANCE AND CLEANING......................................................... 29

9.1 Protection Instructions ...................................................................................30

9.1.1 Prior to any maintenance operations..................................................30

9.2 Control of safety functions..............................................................................30

9.2.1 Control of markings .............................................................................30

9.3 Adjustment......................................................................................................30

9.3.1 Prevent self loosening object...............................................................30

9.4 Maintenance and cleaning by users...............................................................31

9.4.1 Lubrication – general...........................................................................31

9.4.2 Lubrication – temperature limitations ................................................31

9.4.3 Screw jack body grease quantity .........................................................32

9.4.4 Lubrication – periods ...........................................................................33

9.4.5 Worm wheel and Lifting nut.................................................................33

9.4.6 Measuring of thread wear in worm wheel ..........................................34

9.4.7 Measuring of thread wear in running nut ...........................................35

9.4.8 Antibacklash.........................................................................................35

9.4.9 Bearings ...............................................................................................35

9.4.10 Cleaning...............................................................................................35

9.5 Maintenance and cleaning by qualified personnel........................................35

9.5.1 Renew grease.......................................................................................36

10 TROUBLE-SHOOTING ........................................................................ 37

10.1 Trouble-shooting, fault diagnosis, and repair.................................................37

10.1.1 Common errors with actions..............................................................37

10.1.2 Other errors.........................................................................................38

11 SERVICE AND REPAIRS ..................................................................... 40

11.1 Service cycles for sub suppliers......................................................................40

11.2 Addresses of service agents............................................................................40

11.3 Repackaging.....................................................................................................40

11.4 List of spare parts and consumables..............................................................40

11.4.1 Drawings and spare part lists.............................................................40

11.4.2 Consumables.......................................................................................40

1

1. IDENTIFICATION

This manual contains technical data and safety instructions on installation, settings, startup, operation and

maintenance of serie BD.

1.1 MACHINE DESCRIPTION

BD is a screw jack with single or double start trapezoidal lifting screw available with a translating lifting

screw.

1.1.1 Description of purpose

These jacks are intended for (examples):

• indooruseandintheinteriorofanindustrialenvironment(suchassteelmills,foodindustry,paper

industry) and

• outdooruseinthemarineenvironmentwherethereissomeeffectofsplashingfreshorsaltwater

(stainless execution only).

1.1.2 Reasonably foreseeable misuse and prohibited usages

• Yourchoiceofjack/jacksis/arecarefullyevaluatedbasedonyourrequirementswhichareveriedthrough

our selection guide in our lifting jack catalogue. We can not guarantee the safety if our products are used

for purposes other than what they are originally designed for.

At the slightest doubt, you are requested to contact our Sales

Department. They will help you with computer calculations and suggestions, for both standard and special

applications.

WARNING: SELECTION AND DESIGN!

As improvements in design are being made continual- ly the contents of this catalogue

are not to be regar- ded as binding in detail, and drawings and capacities are subject to

alterations without notice.

BD

Range of working temperature

(ºC) from -30 to +100

The degree of utilization (ED) at full load must not exceed, and... 40% per 10 minutes

... still not more than 20% per hour totally...

...in valid at ambient temperature +25° C

NOTE: ABOUT GREASE!

Benzlers screw jacks are filled with grease in EP-Ad- ditive quality at delivery. The lifting

screw should be lubricated with the same type of grease.

NOTE: ABOUT MANUALLY OPERATING THE JACK!

AB Benzlers jacks are not primarily intended to be used manually using a crank, wheel

or similar. If the jack is to be used manually this must comply with the machine directive

2006/42/EG, contact our Sales Department for assistance.

DANGER: RISK OF PERSONAL INJURY!

It is prohibited to use the jack to lift persons.

2

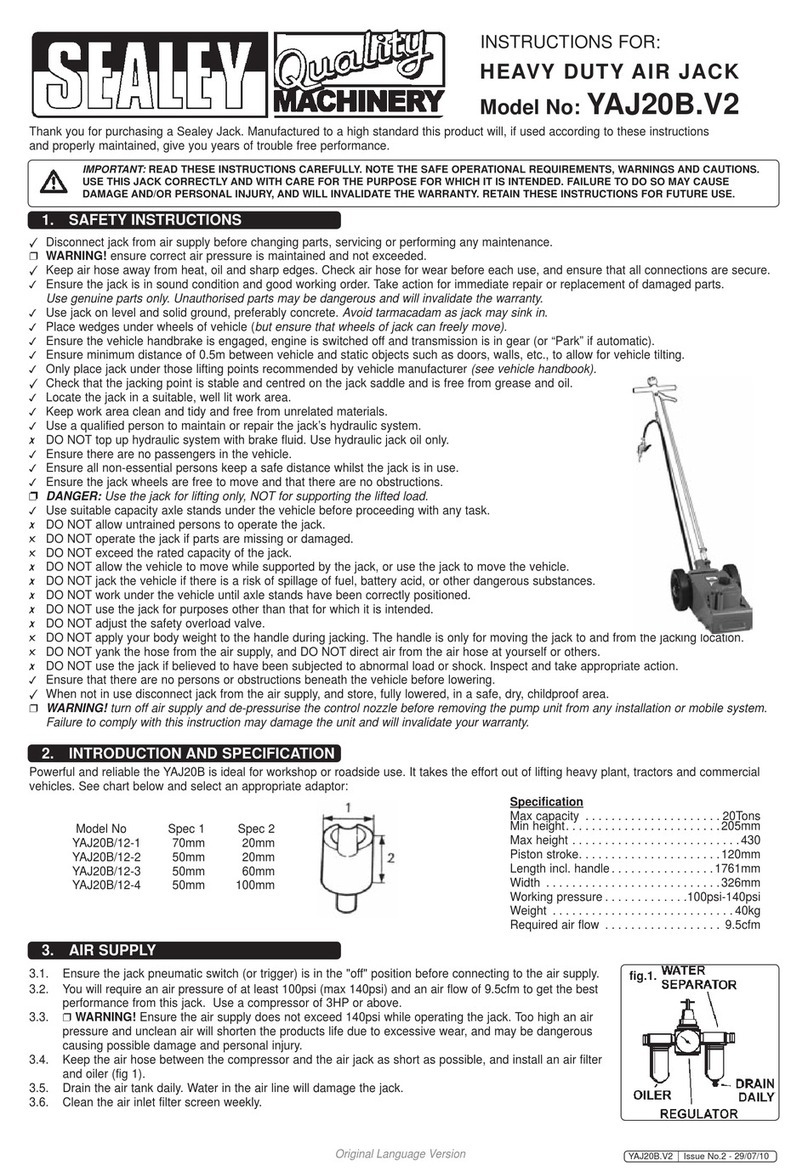

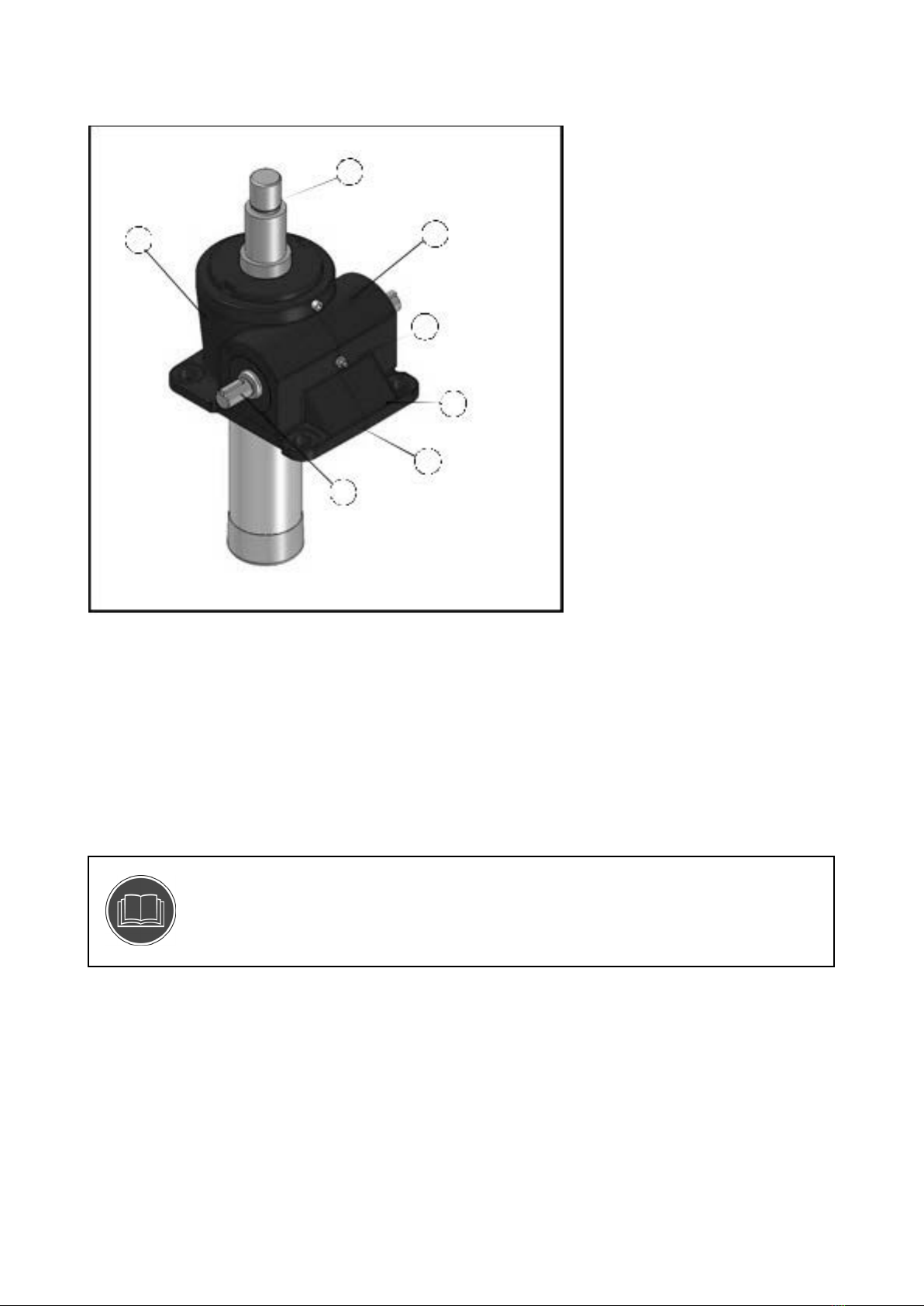

1. Trapezoidal lifting screw

2. Thrust and radial bearings

3. Grease with EP-additive

4. Housing of nodular cast iron

5. Alkyd paint 85 micron thickness in RAL 5009

6. Worm screw hardened and ground

7. Worm wheel of centrifugally cast tin bronze

8. Bellows in PVC or steel (Not shown. Other materials are available upon request)

1.1.3 System overview

1.1.4 Drawings/layouts

NOTE: ABOUT DRAWINGS/LAYOUT!

Drawings/layouts for your specific application, may where appropriate, also be

supplied from our website (if appropriate also including technical documentation from

subcontractors).

1

2

3

4

5

6

7

3

1.2 TECHNICAL DATA

1.2.1 Identification

Product type BD

Serial number See Product Sign

Yearofmanufacture See Product Sign

Compression load / Tension load (kN) See Product Sign

Load Case (Euler I, II or III See Product Sign

Single start spindle:

Product size 27 40 58 66 86 100 125 200

Max capacity (kN) 10 25 50 150 200 300 500 1000

Ratio (L) 9:1 7:1 6.75:1 7:1 7:1 7:1 7.5:1 12:1

Starting torque (Nm) 6 23 55 210 320 640 1280 2235

Ratio (H) 27:1 30:1 27:1 28:1 28:1 28:1 30:1 36:1

Starting torque (Nm) 5 10 32 115 160 320 640 1335

Double start spindle:

Product size 27 40 58 66 86 100 125 200

Max capacity (kN) 8 20 40 120 160 240 400 800

Ratio (L) 9:1 7:1 6.75:1 7:1 7:1 7:1 7.5:1 12:1

Starting torque (Nm) 6 23 55 210 320 640 1280 2120

Ratio (H) 27:1 30:1 27:1 28:1 28:1 28:1 30:1 36:1

Starting torque (Nm) 4.8 10. 1 32.5 117 164 323 624 1265

1.2.2 External Electrical Power — Supply data

Connecting information regarding electric system.

Connecting voltage and number of phases See Product Sign

Frequency See Product Sign

Power See Product Sign

Motor Effect See Product Sign

Protection class See Product Sign

Classification of degree IK 08

The jack complies with IEC standards. The effect required depends on the load. For further information

contact AB Benzlers.

NOTE: ABOUT IK CODE!

IK code means the classification of degrees of protec- tion provided by enclosure for

motors against external mechanical impacts. IK 08 = Resistance against im- pacts with an

energy up to 5,00 J.

4

1.2.3 IP code, clear text

The IP Code (International Protection Rating) classifies the degrees of protection provided against the

intrusion of solid objects such as dust, accidental contact and water in electrical enclosures as defined in the

international standard IEC 60529. An IP Code consists of the letters IP followed by two digits and an optional

letter. The first digit indicates the level of protection that the enclosure provides against access to hazardous

parts and the ingress of solid foreign objects. The second digit indicates the protection of the equipment

inside the enclosure against harmful ingress of water.

See the motor manual for the IP Code of the connected motor. The table below shows the IP Code of the most

common used motors.

Motor types IP Code Protected against Details

M2V A M3A A IP 55 Dust

Water jets

Ingress of dust is not entirely pre- vented,

but it must not enter in suf- ficient

quantity to interfere with the satisfactory

operation of the equip- ment; complete

protection against contact. Water

projected by a nozzle against enclosure

from any direction shall have no harmful

effects.

NOTE: ABOUT IP CODE FOR THE JACK!

The IP code for the jack is different from the motor’s IP code and only jacks in stainless

execution (not standard) are allowed to operate in a moist environment.

1.2.4 Environmental conditions and limits

All Series BD units are provided with protection against normal weather conditions.

The lifetime of the jack are 200 operating hours (minimum).

Where units are to operate in extreme conditions, or where they are to stand for long periods without running,

e.g. during plant construction, consult AB Benzlers so that arrangements for adequate protection can be

made.

• Intheeventthatequipmentistobeheldinstoragesee”Storingandprotecting”onpage29.

NOTE: ABOUT OTHER CONDITIONS!

For other conditions consult Benzlers. Being an inter- national company, we are able,

through our own sub- sidiaries and active agents, to give the optimum- solution, on a local

basis.

5

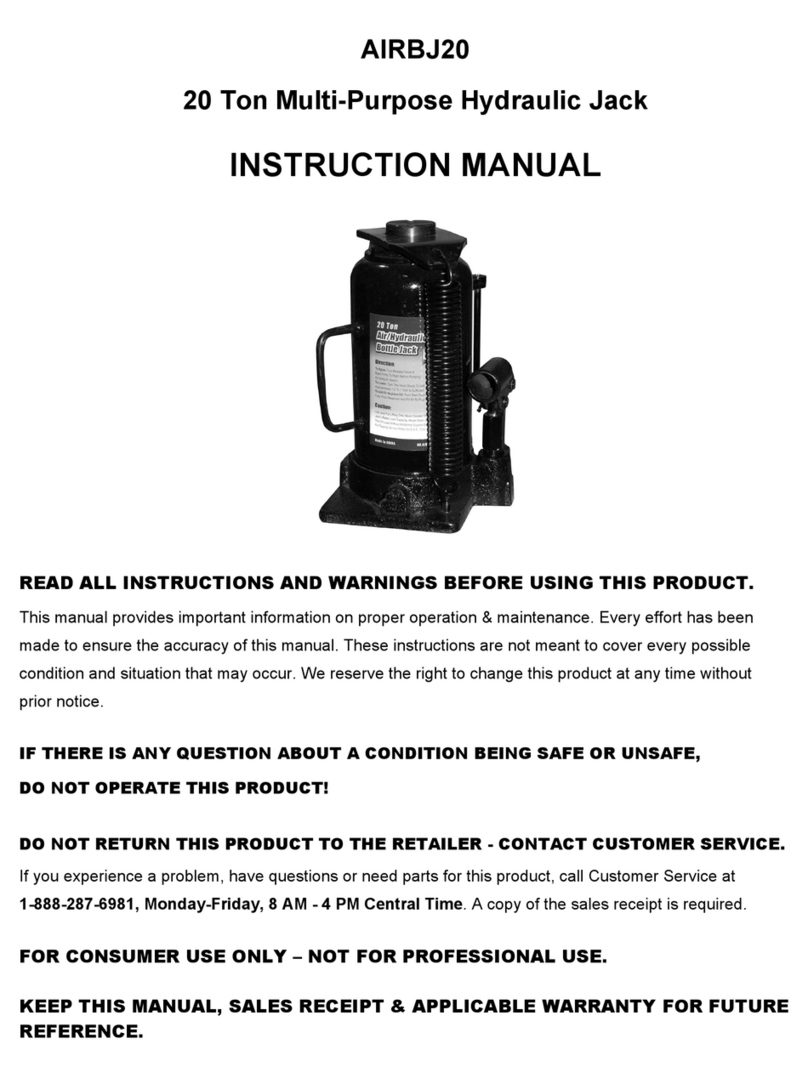

1.3 PRODUCT MARKING

Figur2.Productsign–Generaldescription(type”BD”asanexample):

1. Line 1: Productcode

2. Line 2: –

3. Line 3: Exampel with

– motor: Power (kW), Voltage (V) Frequency (Hz), Pos. of terminal box, Gap at delivery SHM

– IEC motor flange: Max running power at 20% degree of utaliza- tion, IEC size, Gap at delivery SHM

– Free input shaft (Reducer only): Max running power at 20% de- gree of utalization, Gap at delivery SHM

4. Line 4: Lubrication = Lub, Total weight of the unit (Kg)

5. Line 5: Order-number and sub-number of the order position, Manufacturing- year

Product examples:

Motor

IEC motor flange

Free input shaft

1.3.1 Product sign

6

NOTE: ABOUT MOTOR CONNECTIONS!

Formoreinformationaboutmotorconnectionsee”MotorConnections”onpage26.

NOTE: ABOUT STARTING TORQUE AND LOAD CASES!

Formoreinformationaboutstartingtorqueandloadcasessee”Options”onpage6.

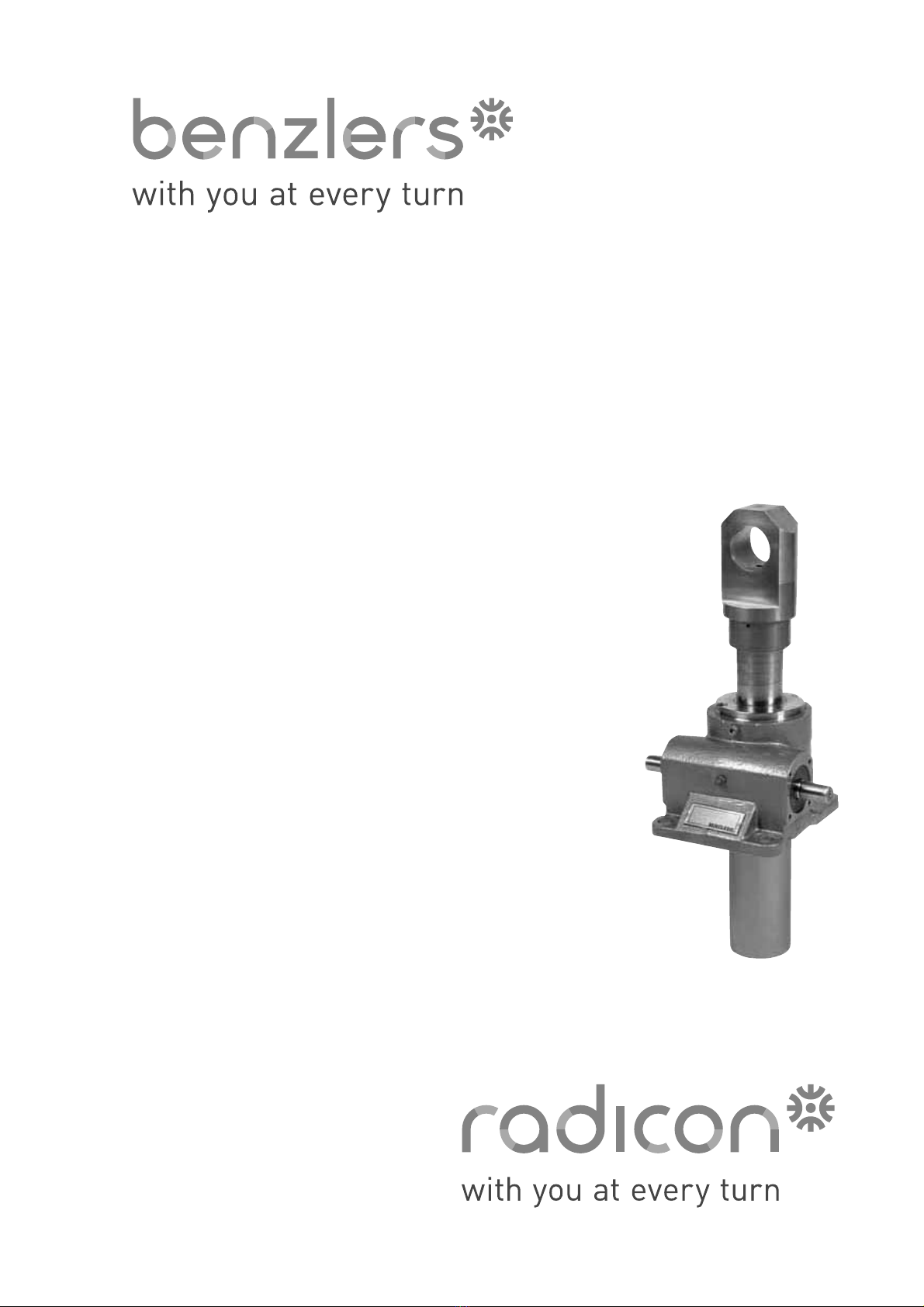

1.3.2 Option – extra sign according to ATEX directive

Jacks ordered to comply with EU directive 94/9/EC ATEX 100a have an extra sign.

Figur 3. Extra sign according to ATEX directive

NOTE: ABOUT ATEX!

AB Benzlers must be consulted in advance to adapt the jack to comply with 94/9/EC (ATEX

100a). The jack will be marked with an extra sign according to ATEX directive. For more

information see our Product Catalog.

7

1.3.3 Understanding ATEX Directive - Markings

NOTE: ABOUT ANY OTHER EQUIPMENT FITTED TO THE SCREW JACK!

Motors, gears, couplings, or any other equipment fitted to the screw jack unit must also

comply with this directive.

If the screw jack unit is supplied with a motor (or any other equipment fitted) it is important

to check that the nameplate corresponds with the classification of the potentially explosive

atmosphere in which the unit is to be installed.

CAUTION: RISK OF MACHINE DAMAGE!

Only jacks ordered to comply with 94/9/EC (ATEX 100a) and marked with an ATEX sign are

allowed to be used in an explosive environment.

The jack will be typically marked as shown

Figur 4. ATEX marking

The maximum surface temperatures for the jack are 200 °C (T3) and 135°C (T4).

CAUTION: RISK OF MACHINE DAMAGE!

Standard configuration is not suitable for these temperatures.

The protection type in areas with combustible dust and in hazardous areas is ‘ck’ where ‘c’ stands for

protection by constructional safety (couplings and gear drives) and ‘k’ stands for protection by liquid

immersion (gears).

GD means that the jack is suitable for gas and dust explosive atmospheres.

Group II means areas with potentially explosive atmospheres (except mines and firedamp areas).

8

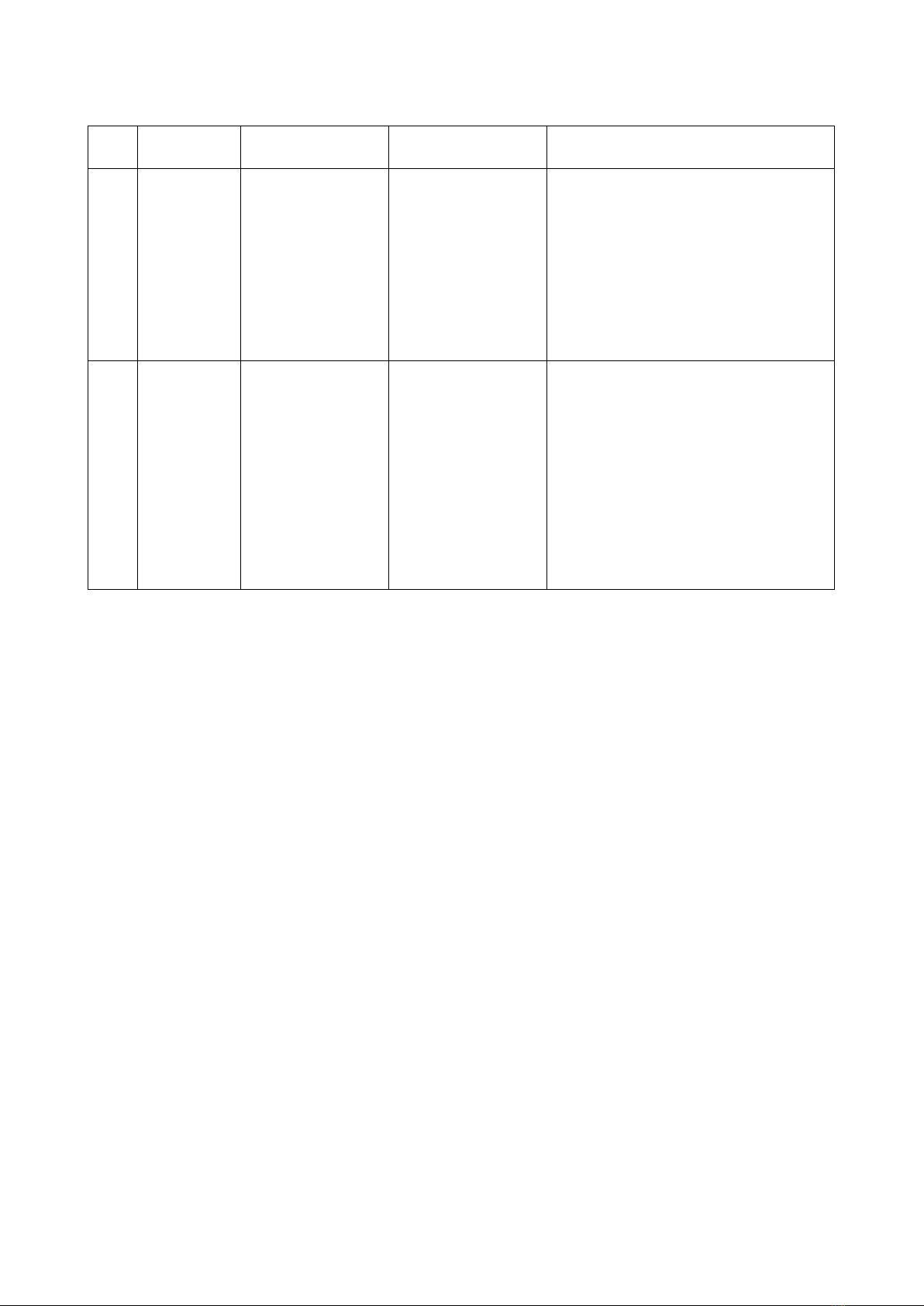

For Category 2 and Category 3 see table below.

Cat Design of

Safety

Design

Requirements

Application Zone of Use

2 High level of

safety

Safe with frequently

occu. Disturbances

or with an

operating fault

Where explosive

atmospheres are

likely to occur

Zone 1 - An atmosphere where

a mixture of air and flammable

substances in the form of gas, vapor

or mist is likely to occur in normal

operation occasionally.

Zone 21 - An atmosphere where a

cloud of combus- tible dust in the air

is likely to occur in normal operation

occasionally.

3 Normal level

of safety

Safe in normal

operation

Where explosive

atmospheres are

likely to occur

infrequently and be

of short duration

Zone 2 - An atmosphere where

a mixture of air and flammable

substances in the form of gas, vapor

or mist is not likely to occur in nor-

mal operation but, if it does occur, will

persist for only a short period.

Zone 22 - An atmosphere where a cloud

of combus- tible dust in the air is not

li- kely to occur in normal operation but,

if it does oc- cur, will persist for only a

short period.

9

2 USE OF THIS MANUAL

2.1 GENERAL INFORMATION ABOUT THIS MANUAL

The manual contains operating and safety instructions.

Carefully study the manual and check that the manual is constantly available to the staff concerned. The

instructions apply all types of work, the machine as well as immediate surroundings around the machine.

Serious personal injuries and machine damages may occur if the information is not attended to.

Consider all the danger-, warning-, caution- and note- signs mentioned in the manual.

• Considerthatalltypesofelectricequipmentmaybelive.

• Duringserviceandmaintenance:switchoffthemachineandmakesurethattheelectricalsupplyisoff

(safety and main switches locked). Supervision may be carried out by an operator. Remaining service may

be performed by qualified service staff only.

Consideration shall be taken to the local restrictions inside the factory.

2.2 IMPORTANT INFORMATION ABOUT THIS MANUAL

The following is compulsory:

• Themanualtogetherwithsimilarusefuldocumentsshallbekeptduringtheentirelifeoftheequipment.

• Thismanualtogetherwithsimilarusefuldocumentsshallbeconsideredpartoftheequipment.

• Theinformationinthemanualshallbeupdatedwhenthemachineownermakescompletionsorother

modifications of this equipment.

• Incaseofownerexchangethemanualshallbeenclosedtothenewowneroruseroftheequipment.

• Incaseofrebuildingorreconstructionanewriskanalysisshouldbeestablished.

All changes shall be approved by the machine owner.

2.3 TARGET GROUP FOR THIS INFORMATION

The manual shall be used for information about safety for all staff, who perform or will perform any kind of

work near the screw jacks, as an example:

• Installationandmaintenancepersonnel

• Operators

• Cleaners,etc.

2.3.1 Demands on personnel

Information about instructions in this manual. Site/location of instructions.

NOTE: ABOUT OPERATORS!

Operators and other staff are only allowed to handle that part of the screw jack for which

they are trained. The operators shall be provided with all necessary information about

training and about pumping and translating forces.

The place shall be clearly marked and this manual shall be available in direct connection to the other

instructions of the screw jack.

2.3.2 Procedure for revision and amendment

If necessary and especiallity according to issues about safety the content of this manual may need to be

updated at any time.

On these occasions, it is especially important that this manual is replaced with a new updated manual and

that the old manual is collected and archived /discarded.

10

3 DESCRIPTION OF FUNCTION

3.1 OVERALL

BD is a screw jack with single or double start trapezoidal lifting screw available with translating lifting screw.

Figur 5. BD

It is available in 8 sizes as standard.

This type is the most frequently used screw jack, competively priced.

NOTE: ABOUT STOP NUT!

BD is available with a stop nut. If you chose not to use the stop nut another security feature

must be included in the system.

The jack is used to push, pull, lift, lower and position loads of anything from a couple of kilograms up to one

hundred of tons with good precision and consistency.

11

3.1.1 Control devices

Control devices for the jack shall be designed according to the description below:

• Controldevicesforsettingpowerdrivenjacksinmotionshallbeofthehold-to-runtype.

• Controldevicesforpowerdrivenjacksshallbeprotectedagainstunintentionaloperation.

• Thedirectionofmovementcausedbythecontroldeviceshallbeidentiedinadurable,unambiguousand

easily recognisable manner.

• Thedirectionofmotioncanbeidentiedbysymbolsorwords.Theidenticationcanbeattachedtothe

control device itself or immediately alongside it.

NOTE: ABOUT CONTROL DEVICES!

Control devices are not included at standard delivery.

WARNING: CRUSHING RISK!

This protection prevents the possibility of pinched fingers or chruched hands, which can

lead to permanent injury.

WARNING: RISK OF ENTANGLEMENT!

This shaft protection prevents, for example, loose clo- thing or similar to entangle itself in

the shaft, which can lead to permanent injury.

DANGER: CRUSHING RISK!

This safety component prevents the lifting screw from being able to run out of the jacks

house, which, if a person/persons standing under the jack, can lead to instant danger to life.

Moreinformation,see”Stopnut(SM)”onpage12.

12

3.2 OPTIONS

NOTE: IMPORTANT INFORMATION ABOUT ALL OPTIONS!

For the up-to-date configuration of your Srew Jack, see the product code on the product

sign that is mounted on the jack.

3.2.1 Stop nut (SM)

Stop nuts can be fitted to all screw jacks, both above and below the main body.

These must be included when there is an inherent risk of over travel resulting in the spindle becoming

disengaged from the worm thread.

Figur 6.

6. Stop nut

7. Protection tube

8. Tube sleeve

13

3.2.2 Stop nut (SM) + Limit Switch (LS)

All jacks can be supplied with limit switches to suit most applications. Standard is two limit switches and one

stop nut. Upper/lower limits can be mounted on the protection tube. Adjustable limits are also available on

request.

Figur 7.

1. Stop nut

2. Carrier

3. Limit switch

3.2.3 Locked against rotation – two options are available:

– LR - Locked Against Rotation (Tube)

– LRK - Locked Against Rotation (Key)

NOTE: IMPORTANT INFORMATION ABOUT THESE OPTIONS!

For applications where a load is to be raised/lowered and permanent fixing i.e. top plate/

clevis, is not prac- tical, the spindle must be prevented from rotating.

Combinations with other options are restricted.

14

3.2.4 LR - Locked Against Rotation (Tube)

Protection tube manufactured in box section mild steel. Spindle end complete with nut

(sized to suit box section).

Figur 8.

1. Gear housing

2. Locking nut

3. Locking assembly (size dependent variant 1)

4. Tube

5. Pin (size dependent variant 2)

3.2.5 LRK - Locked Against Rotation (Key)

Jack internals are modified to incorporate a rectangular key which engages in a precision keyway cut into the

spindle length. Primarily used in precision applications requiring minimal radial movement.

Figur 9.

1. Jack cover

2. Lifting screw

3. Key

15

3.2.6 Safety Nut (SHM)

In certain applications the addition of a safety nut may be required. The object of the above is to prevent the

load collapsing in the event of the

lifting nut thread failing.

NOTE: IMPORTANT INFORMATION ABOUT THIS OPTION!

Load direction important!

Combinations with other options are restricted.

Monitoring of the safety gap (s) between the spacer (2) and the safety nut (1) gives an indication of the

intermediate wear.

NOTE: THE SAFETY GAP MUST BE CHECKED REGULARY!

When the safety gap reaches zero the thread in worm wheel has reached its wear limit

and requires chang- ing. In applications where the safety nut is inacces- sible, electro/

mechanicalswitchesareavailabletoindicatemaximumwear,moreinformation,see”Mea-

suringofthreadwearinrunningnut”onpage35.

Figur 10.

1. Safety nut

2. Spacer

3. Worm wheel

16

3.2.7 Antibacklash (ABL)

Where the loading on a screw jack can be in both tension and compression and the spindle backlash is

critical, units can be supplied with a Back-lash Eliminator comprising of a modified worm wheel fitted with a

secondary nut, allowing contact on both face and flank of driving thread.

Backlash 0.0l-0.05 mm - During operation excessive backlash can be removed by adjustment of the top cover.

The nuts are separated by a pre-determined gap to eliminate the adjustment of the backlash

eliminator when drive thread width has been reduced by 25%.

NOTE: IMPORTANT INFORMATION ABOUT THIS OPTION!

Combinations with other options are restricted.

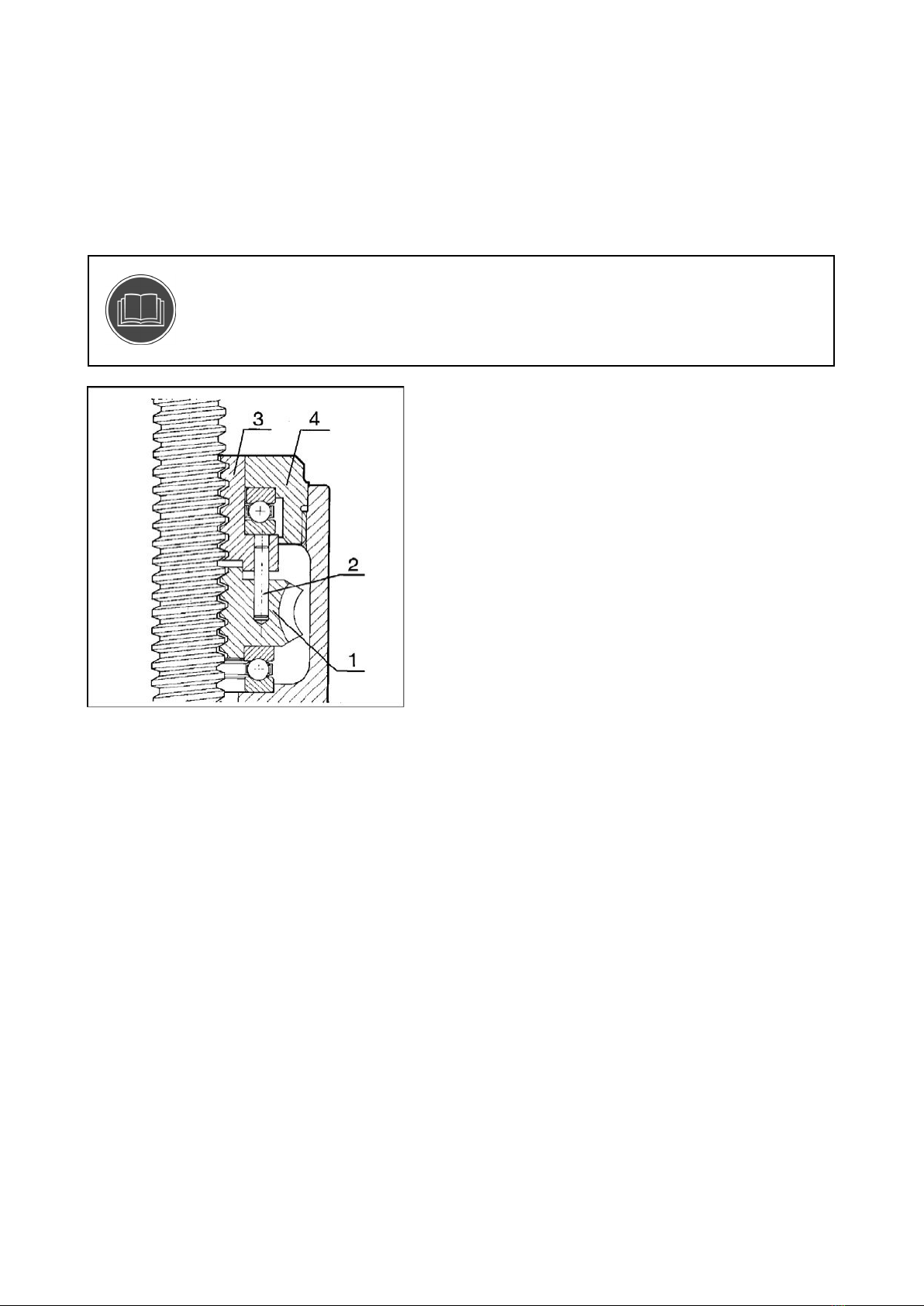

Figur 11.

1. Worm wheel

2. Dowel pin

3. Adjusting nut

4. Jack cover

This manual suits for next models

8

Popular Jack manuals by other brands

TradeQuip

TradeQuip 2051T owner's manual

Mega

Mega FMG-300 Operation and maintenance instructions

ATD Tools

ATD Tools ATD-7384W owner's manual

ELECTRODRIVE

ELECTRODRIVE Tug Tough 10T operating manual

Tractel

Tractel tirfor TU-8 Operating and maintenance instruction

Bulldog Security

Bulldog Security Velocity Series instructions