FLEMING TOP3 Installation and operation manual

INLINE or SEMI-OFF SET

3’, 4’, 5’ & 6’ PASTURE TOPPERS

Operators Manual & Parts List

Fleming Agri-Products Ltd

Newbuildings Industrial Estate

Newbuildings

Northern Ireland

BT47 2SX

Tel: (028) 7134 2637

Fax: (028) 7134 4735

Email:info@fleming-agri.co.uk

‘Quality, Strength & Personal Service’

This manual is provided to assist you in getting the best results from your machine and ensure that you do so safe-

ly. If you have any queries about the use of the machine contact your dealer before use. Please keep this manual

for future reference.

This topper has been designed to be easy to operate while also providing class-leading performance. The heavy-duty rotors with

swinging blade system allow the topper to withstand the excessive pressures of wet condions and to absorb small impacts with-

out eecng performance.

The cutting height is adjustable in convenient steps from the minimum depth of 30mm to a maximum depth of

120mm. The depth is easily adjusted by altering the position of the skids which are positioned at each side of the

topper. These skids ensure that the topper provides a uniform cut without grounding while on undulating pastures.

This topper will successfully operate in wet conditions and on heavy pasture such as rushes, however it is unsuita-

ble for topping set-aside. While this topper is primarily designed for agricultural use it performs excellently when

used for topping playing fields or other local authority areas.

1.1 FUNDAMENTAL PRECAUTIONS

On delivery, your dealer gave you an explanation of the operation and maintenance of this Fleming topper. Please

read and understand these operating instructions before operating the machine for the first time. It is essential that

you observe all safety instructions.

Incorrect use or mishandling of the machine can endanger:

Life and Limb of the operator, other persons or animals standing within the vicinity of the machine.

The machine and other material assets of the owner or third persons.

The performance of the machine.

Anyone who is involved in the commissioning, operation or maintenance of the topper must read and understand

the following instructions very carefully and observe them at all times.

NEVER DISTRACT ANYONE WHO IS USING A MACHINE.

1.2 AUTHORISED OPERATORS

Youths under the age of 16 must not operate this implement. The owner of the machine must provide the operator

with the operating instructions and make sure they have read and understood them. Only then may the topper be

put into operation.

The owner must ensure that only authorised persons operate/work on this machine. He is responsible for any third

persons or animals within the working area of the topper.

A SAFE DISTANCE OF AT LEAST 30M MUST BE OBSERVED BY ANY PERSON OR ANIMAL WITHIN THE

VICINITY OF THE TOPPER.

1.3 GENERAL SAFETY AND ACCIDENT PREVENTION REGULATIONS

Ensure the implement is correctly and securely attached to the operating vehicle 3-point linkage using the lift arm

pins and locking lynch pins provided.

NEVER attach to a tractor which would be rendered unstable when the implement is operated at its full ca-

pacity. Take note of the maximum load permissible on the linkage. The weights of the various models are given in

the table below.

Extra care must be taken as the implement can cause instability due to the projection out the rear of the tractor.

WARNING extra care must be taken to avoid a traffic accident went transporting this implement on the

road as it projects past the side of the tractor.

Take extra care when operating machinery on sloping ground. NEVER operate on ground on which there is a risk

of the tractor becoming unstable.

When detaching the implement from the tractor always ensure that it is stable and is safely positioned on a level

surface.

CAUTION extra care must be taken when detaching the implement from the tractor to ensure that the A

frame does not fall and injure the operator.

WARNING: The attaching and detaching of the implement to a tractor must be carried out by only one oper-

ator. There should not be any other people in the vicinity of the implement or in the tractor.

Before operation make yourself familiar with all elements and controls of the machine as well as their functions.

Under NO Circumstances should anyone attempt to use the topper or the three point linkage as a means of

personal transport. It is designed as a specialist purpose farm implement and is unsuitable for the safe transporta-

tion of passengers. To avoid personal injury do not allow hands or limbs to enter the area between the hitch and

main body.

NEVER allow children to play on or around tractors and machinery.

Operators should not wear loose fitting clothing when working close to PTO driven equipment. Keep long hair tied

back. NEVER be in the vicinity of a rotating PTO shaft.

ALWAYS disengage the PTO before dismounting from the tractor.

NEVER operate the topper unless all safety guards are fitted and are firmly in position. ALWAYS ensure

that all guards and covers are replaced after carrying out maintenance or adjustments.

NEVER attempt to adjust the topper skids without the topper being in a stable and safe position.

NEVER attempt to move this implement manually.

ALWAYS disengage the PTO shaft, apply the hand brake, stop the tractor and remove the key before carry-

ing out any maintenance or adjustments to the topper. The blades continue to rotate for some time after the tractor

is stopped. ALWAYS ensure that the blades have totally stopped moving before approaching the topper.

Take extra care when carrying out maintenance and adjustments, as this is when most farm accidents occur.

ENSURE the PTO shaft is the correct length to suit the tractor.

ALWAYS ensure that the PTO tubes and universal joints have sufficient grease.

Regularly check the PTO shaft and guard for damage and replace if any damage is found.

ALWAYS use M8 x 50mm shear bolts with a rating of 8.8 on the knuckle joint. Standard bolts or shear

bolts with a rating greater than 8.8 may cause undue stress to the topper and risk life and limb.

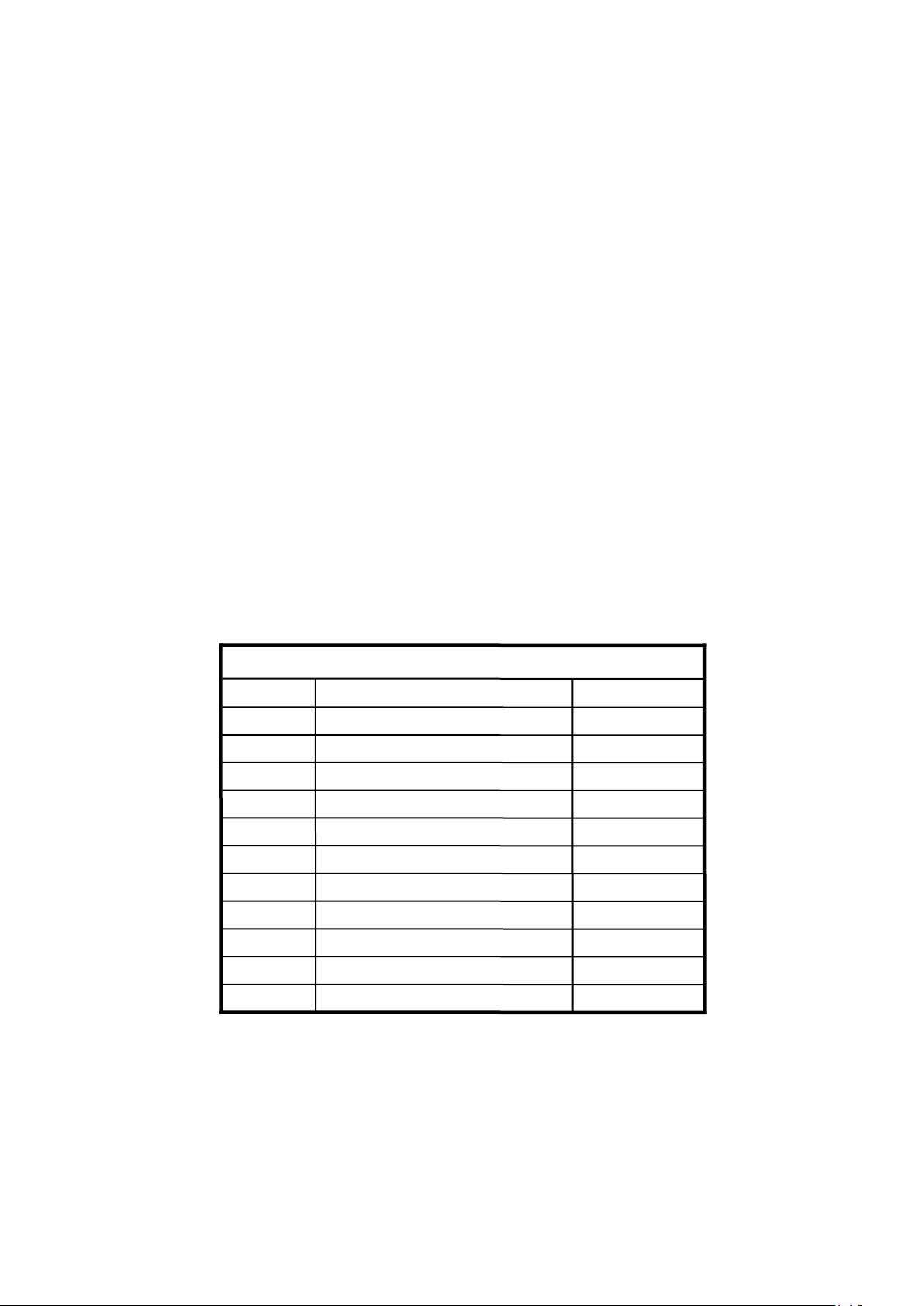

Model Weight

TOP3 130 kg

TOP4 202 kg

TOP5 246 kg

TOP6 323 kg

1.4 GENERAL OPERATING INSTRUCTIONS

This is a tractor-mounted implement. Attempts should not be made to attach the topper to any other type of vehi-

cle. If the topper is to be transported on a trailer then it should be securely attached using suitable restraints.

Never use incorrectly sized lift arm or top link pins when attaching the topper. Ensure top link has sufficient ad-

justment to facilitate correct setting of the topper.

Fit the topper to the three-point linkage in the normal way. Ensure that the PTO is correctly connected before use.

ENSURE the restraining chains on the PTO cover are attached to the hole provided on the fixed guard and on the

tractor PTO guard.

Adjust the topping height by removing the 4 bolts on each skid and set to the required height. Only adjust the

height when the topper is on stable ground and suitably supported. ENSURE TRACTOR IS STOPPED, THE

BLADES HAVE STOPPED MOVING AND THE TOPPER IS SUFFICIENTLY SUPPORTED.

Ensure the working area is clear of stones or anything which may cause damage to the topper or increase the

danger to life and limb.

With the PTO shaft and all safety guards in place it is safe to start topping.

Begin to operate at a low RPM and gradually increase to 540 RPM before moving forward

To change the 3, 4’ and 5’ toppers from the semi-offset position to the inline position or vice-versa ensure that the

topper is safely positioned and is detached from the tractor. Remove the 3 restraining bolts, reposition the A

frame over the relevant 3 holes and reattach the 3 bolts. ENSURE the bolts are securely tightened before use.

1.5 MAINTENANCE

As a rule, disengage the driving system and stop the engine prior to carrying out maintenance, servicing, cleaning

or repair work. ALWAYS remove the ignition key.

Prop the topper with appropriate supports and ensure the blades have stopped moving before carrying out any

maintenance.

The manufacturer will not be responsible for any damages or injuries caused by unauthorised repair, alterations or

mishandling of the product.

Maintain product with care checking regularly for damage that would affect the safe operation of the implement.

ALWAYS use genuine Fleming parts.

Check oil level in gearboxes before operating and at regular intervals. Oil should be at the level of the bung on

the side of the gearbox on the 3’ 4’ and 5’ models and 10mm below the bung on the 6’ model.

Change oil after first 50 hours and every 500 hours after. Correct oil quantity is 0.8 litre. Use SAE 90 Gear Oil.

Fill oil by removing plugs at top and side of gearbox.

CAUTION The gearboxes may become hot during use. Allow time for the housing and the oil to cool suffi-

ciently before carrying out any maintenance.

To ensure that all the sludge's and contaminants are removed during an oil change, the oil should still be warm

when it is drained.

Grease PTO shaft tubes, universal joints and all other greasing points (marked with a sticker) daily.

Check holding bolts and rotor blade lock nut on gearbox after every 5 hours of use and tighten if necessary for the

first 20 hours and periodically afterwards.

Regularly check that blades are kept sharp and free from damage. Replace if any damage is apparent.

When replacing the blades ensure only the correct FLEMING blades are used. Blades should be replaced in pairs

to ensure that the rotor remains balanced. ALWAYS replace the blade bolts with new genuine Fleming bolts when

the blades are changed.

The bolts which attach the blades should be tightened fully and then slacked off until the blade is free to rotate.

ALWAYS ensure all warning stickers are kept clean and in good condition replacing where necessary.

CAUTION paintwork may be damaged if high-powered washers are used when cleaning the topper.

1.6 INITIAL ASSEMBLY

Remove all components from the bag which was attached to the machine on delivery.

Slacken the bolts which attach the A frame to the frame of the topper, reposition the A frame into a vertical position

and retighten the bolts.

Attach the large D-shackle to the eye on the back of the A frame.

Attach one end of the chain to the eye(s) on the rear of the topper.

For the 4’, 5’ and 6’ Topper, feed the chain through the large D-shackle and use the final small D-shackle to attach

the remaining end of the chain to the other eye on the rear of the machine.

Ensure the chain does not cross over itself and is free to travel through the large D-shackle.

On the 3’, 4’ and 5’ models, the lift arm pins must be attached to the frame of the topper. Pass the threaded part of

the pins through the holes in the frame of the topper, in the area below the A frame. Ensure the threaded parts of

the pins face towards each other.

Ensure the spring washers are located under the nuts and the nuts are fully tightened.

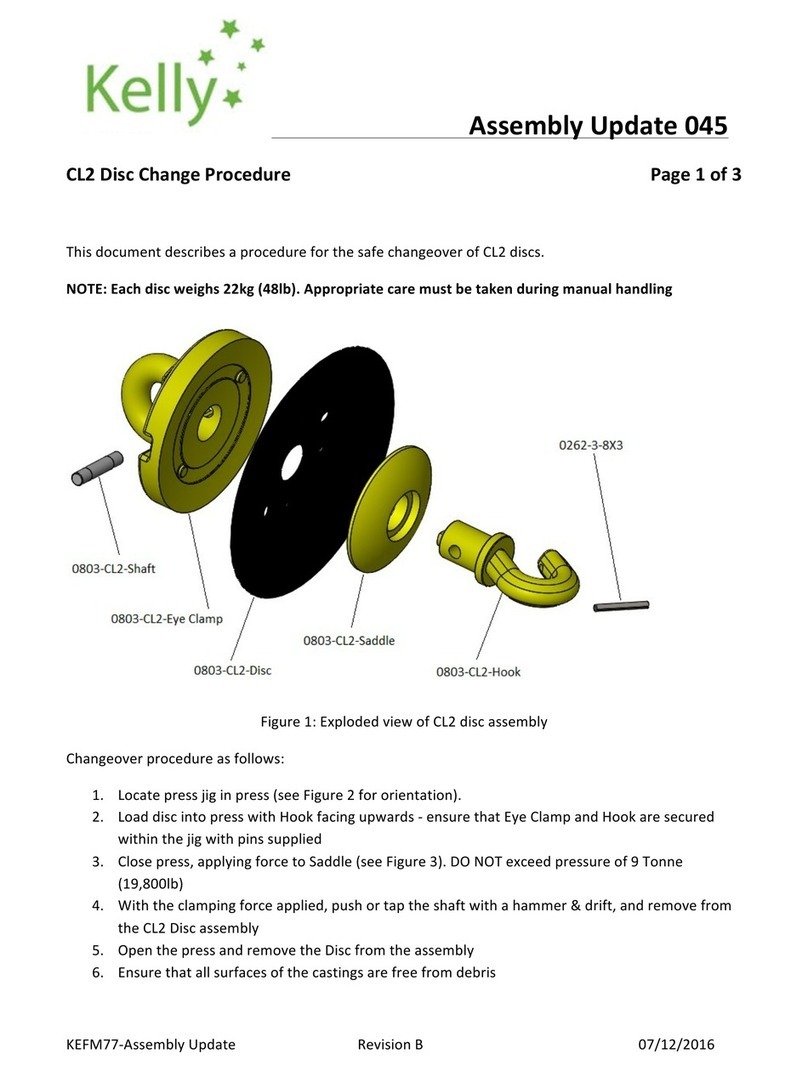

1FLAIL CARRIER11

4M14 X 50 BOLT 10

2M24 X 50 BOLT9

28

2M24 LOCKNUT7

1ROTOR BAR HOLDER6

4M14 LOCKNUTS5

4M16 X 50 BOLT4

1MAIN CHASSIS3

1GEARBOX2

4M16 LOCKNUT1

QTYDESCRIPTIONITEM

PARTS LIST FOR FIGURE ON NEXT PAGE

RIGHT HAND FLAIL

Rotor maintenance

The rotor should be checked after the first 10 hours, the first 50 hours, and the first 100 hours of use.

The rotor should then be checked periodically to ensure it has remained tight.

1) Ensure PTO is turned off completely.

Remove key from ignition.

2) To access the topper castle nut, remove the rotor bar.

Remove M14x50 bolts from rotor bar/rotor bar holder assembly. Rotor bar

You can now take the rotor bar off its holder. Place the rotor bar aside.

Do NOT remove blades from the rotor bar.

3) You now have access to the Topper castle nut, with the split pin.

Remove split pin from gear box shaft/ topper castle nut assembly.

Split pin

4) When split pin is removed, tighten the castle nut.

After the Topper castle nut is tightened, replace the split pin.

Secure the rotor bar back in place with the M14x50 bolts, and M14 Nylock.

M14x50 Bolt

M14 Nylock

Topper castle nut

EU CERTIFICATE OF CONFORMITY

CONFORMING TO EC Machinery Directive 98/37 EC.

We:

Fleming Agri-Products Ltd

Newbuildings Industrial Estate

Newbuildings

Northern Ireland

BT47 2SX

declare in sole responsibility, that the product

Type: 3’ Inline/Offset Topper

Type: 4’ Inline/Offset Topper

Type: 5’ Inline/Offset Topper

Type: 6’ Inline/Offset Topper

This manual suits for next models

3

Table of contents

Other FLEMING Farm Equipment manuals