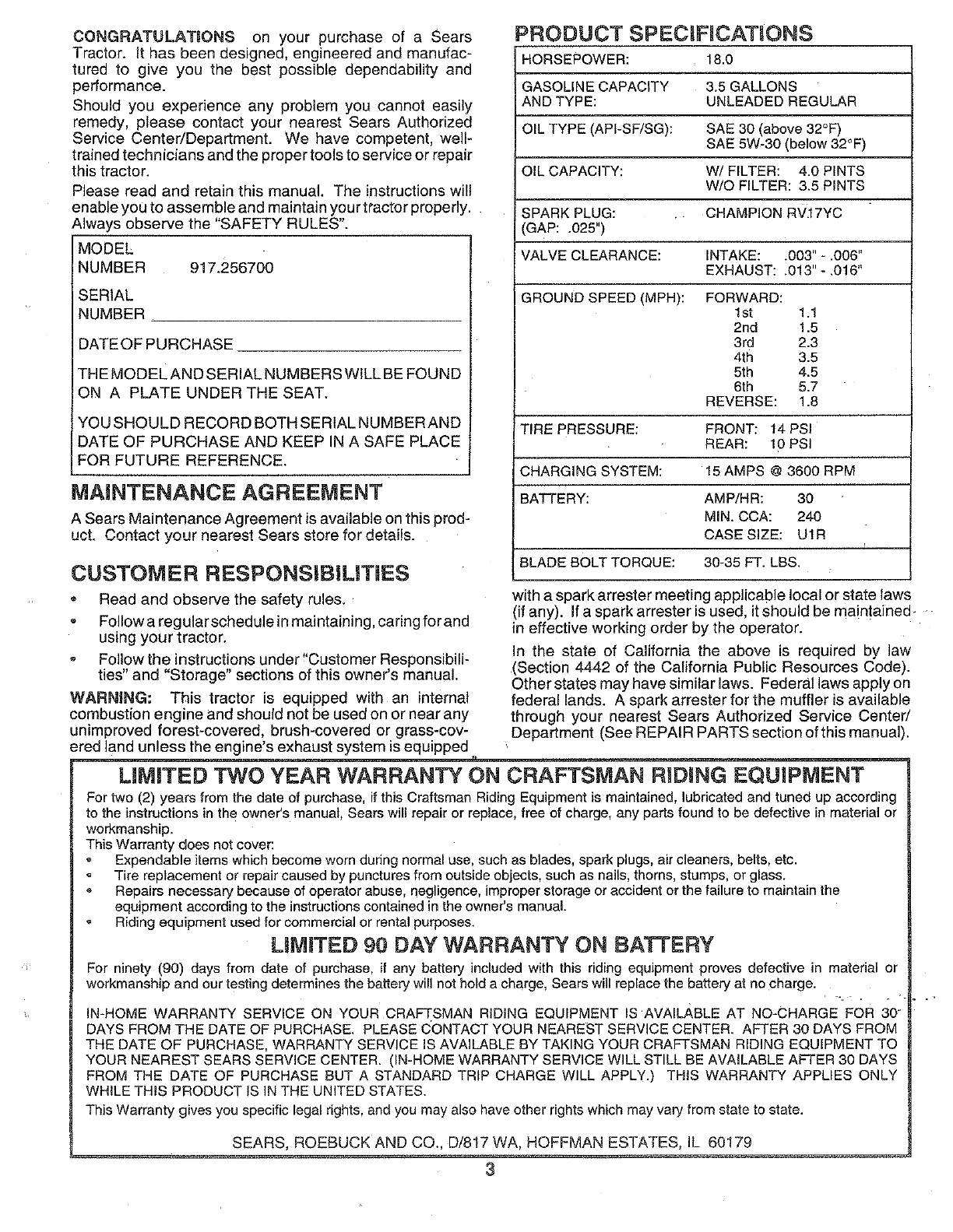

SAFETY

RULES

,

Safe Olseration Practicesfor Ride-On Mowers

GENERAL OPERATION

Read, understand, andfollow all instructions inthe manual

and on the machinebefore starling.

Only allow responsible adults, who are familiar with the

instructions,to operate the machine.

Clear the area of objects such as rocks, toys, wire; etc.,'

which could be pickedupand thrown bythe blade.

Besuretheareaisclearof otherpeoplebeforemowing.Stop

machine if anyone enters the area.

Nevercary passengers.

Donot mow inreverseunlessabsolutelynecessary. Always

look down and behindbefore and while backing.

Be awareofthe mower dischargedirectionand do not point

it at anyone. Do not operate the mower without either the

entire grass catcheror the guard in place.

Slow down beforeturning.

Neverleavea runningmachineunattended. Alwaysturn off

blades, set parking brake, stop engine, and remove keys

beforedismounting.

Turnoff blades when not mowing.

Stop engine before removing grass catcher or unclogging

chute.

Mow only in daylight or good artificiallight.

Do not operate the machine while under the influence of

alcoholor drugs.

Watchfor traffic whenoperating near or crossingroadways.

Use extracarewhen loadingor unloadingthe machineinto

atrailer or truck.

81.

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

tipoveraccidents, whichcanresult insevereinjuryordeath.

All slopes requireextracaution.

If

you cannot back upthe

slope or

if

you feel uneasy on it, do not mow it.

DO:

Mow up and downslopes, not across.

Removeobstacles such as rocks, tree limbs, etc.

Watch for holes, ruts, or bumps. Uneven terrain could

overturnthe machine. Tallgrass canhideobstacles.

Useslowspeed. Choosealowgearsothat youwill nothave

to stop or shift while on the slope.

-

Follow the manufacturer's recommendations for whee

weignts or countew~eightsto Improvestabll~ty

Use extra care with &ass catchers or other attachments.

These can change the stability of the machine.

.

Keepall rnovemenlon tnc slopes slorvand yradual Do no1

make sudden changes in speedor

direction

Avoid starting or stoppingon a slope. If tires lose traction,

disengage the bladesand proceedslowly straightdownthe

slope.

DO

NOT:

-

Donot

turnonslopesunlessnecessay,

andthen,turnslowly

and gradually downhill,

if

possible.

-

DO

nitmow "ear drop-olfs,ditches,or embankments. Ttie

mower co~ldsuddenly turn over

11

a wheel ,sover the edge

"4

-

-,;"

-.

.';...k

".

;'

--

..A,.-

""

;-

-,a

&a,,#

u,

"3,L,,,

",

4.

a,,

CLqC

-avca

,v..

-

Do not mow on wet grass.-~educedtraction could cause

siidinq.

Donittryto stabilizethe machinebyputtingyourfootonthe

ground.

00

notuse grass catcher on steep slopes,

III.

CHILDREN

Tragic accidentscanoccur

if

theoperator

is

notalert tothe

presence of children. Children are often attracted to the

machine and the mowing activity.

Never

assume that

childrenwill remain where you last saw them.

Keepchildrenout of themowingareaandunderthewatchful

care of another responsibleadult.

Be alert and turn machineoff

if

childrenenter the area.

Before and when backing, look behind and downfor small

children.

Never cary children. They may fall off and be seriously

injuredor interferewith safe machineoperation.

Never allow children to operate the machine.

Use extra care when approaching blind corners, shrubs,

trees, or other objects that may obscure vision.

IV.

SERVICE

.

Useextracarein

handlinggasol~neanaotherfucls.

Theyare

flammableand vapors are explosive

Useonly an approvedcontainer.

Never remove gas cap or add fuel with the engine

running. Allow engine to cool before refueling. Do not

smoke.

Never refuelthe machine indoors.

Never store the machlneor fuelcontalner lnsldewnere

there

is

an open flame, stlch

as

a water healer

Never run a machineinsidea closedarea.

Keepnutsandbolts,

especially

bladeattachmentbolts.tight

and keep equipmcnr in good conoition.

Never tamper with safety devices. Check their proper

operation regularly.

Keepmachinefreeof grass, leaves,orother debrisbuild-up.

Clean oil or fuel spillage. Allow machine to cool before

storing.

Stop and inspect the equipment

if

you strike an object.

Repair, if necessary,beforerestarting.

Nevermakeadjustmentsor repairswith the enginerunning.

Grasscatchercomponentsaresubjectto

wear,damage,and

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replacewithmanufacturer'srecommendedparts,whennec-

essay.

Mower bladesare sharp and cancut. Wrap the blade@)or

wear gloves, and useextra caution when servicingthem.

-

Check brake operation frequently. Adjust and service as

required.

wireand

w lace wire

where

itcannotcontact

spark in order to prevent accidental

slafling when setting up, transporting,

zdj-sting

0:

making repalm.