TABLE OF CONTENTS

INTRODUCTION .............................................................................................................. 1

Safety Precautions........................................................................................................... 1

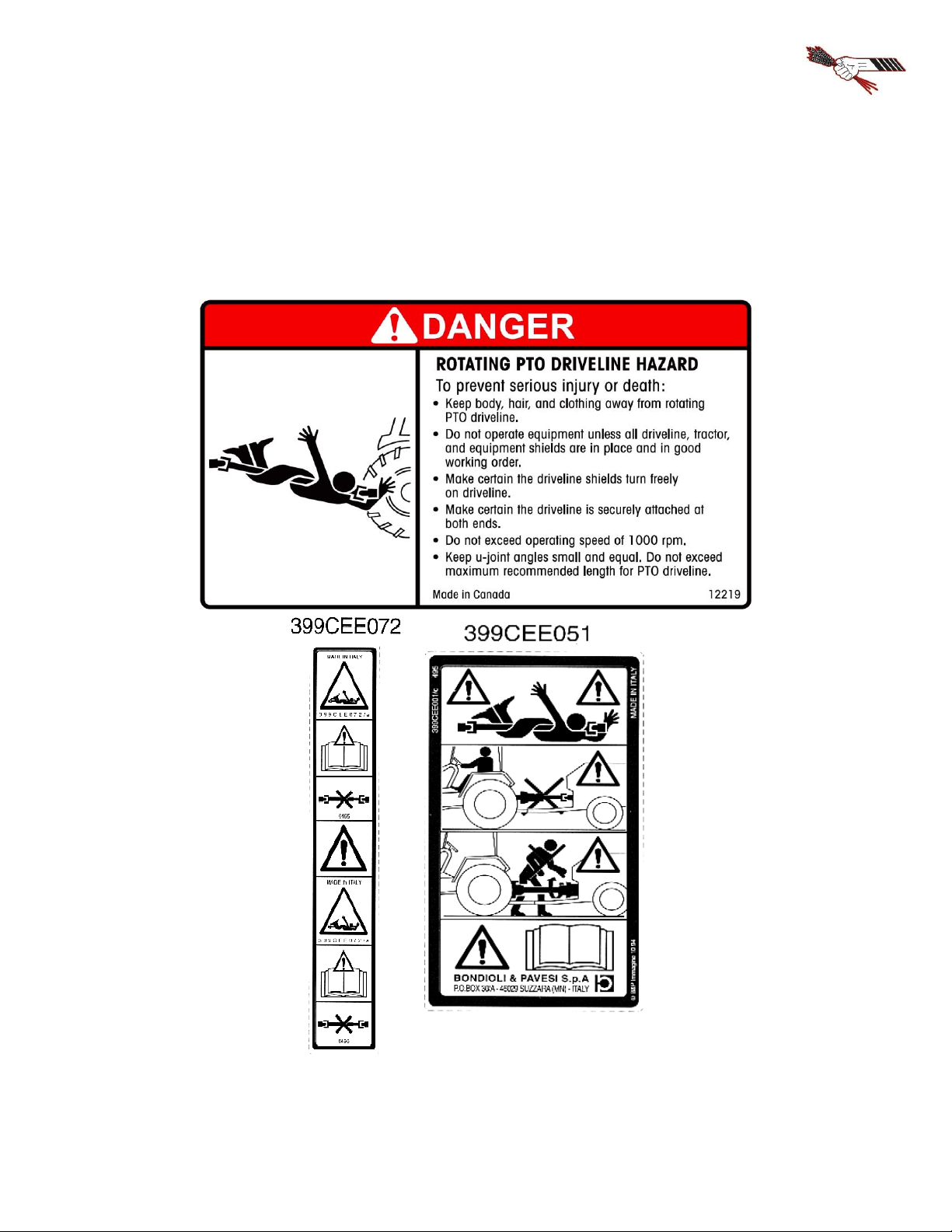

Safety Decals .................................................................................................................. 2

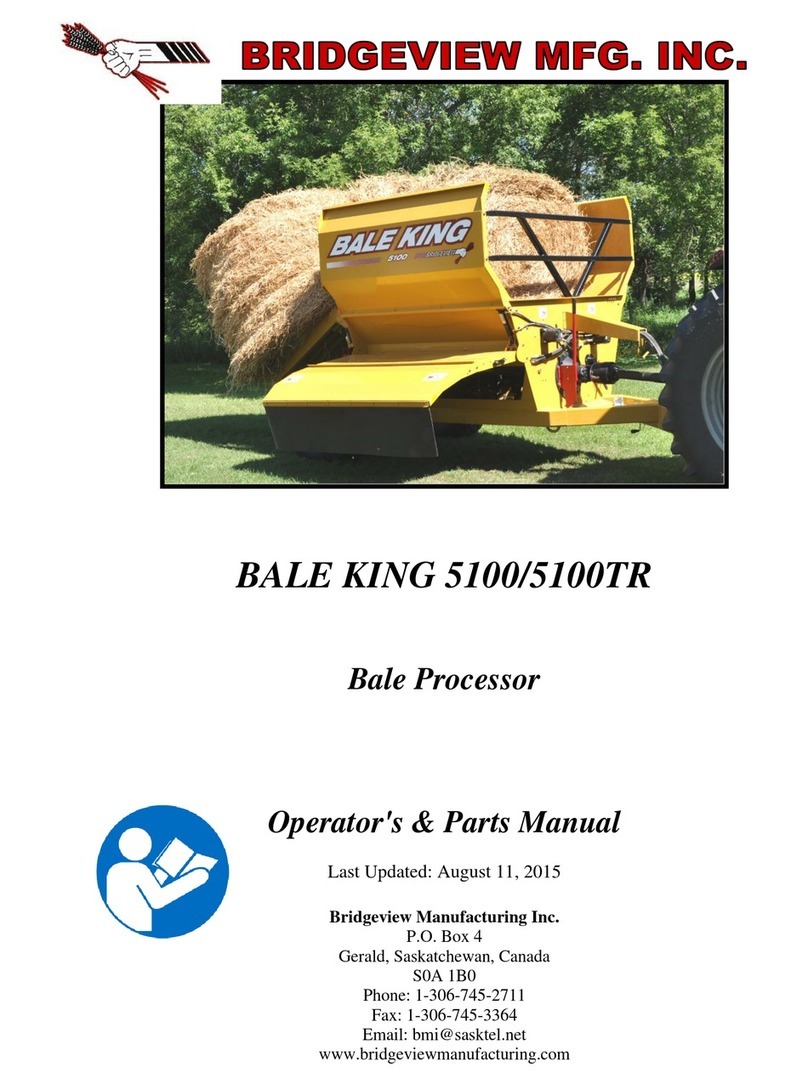

FEATURES & OPERATION............................................................................................. 5

Power Take-off ............................................................................................................... 5

Hydraulics....................................................................................................................... 9

Cylinder Maintenance................................................................................................... 10

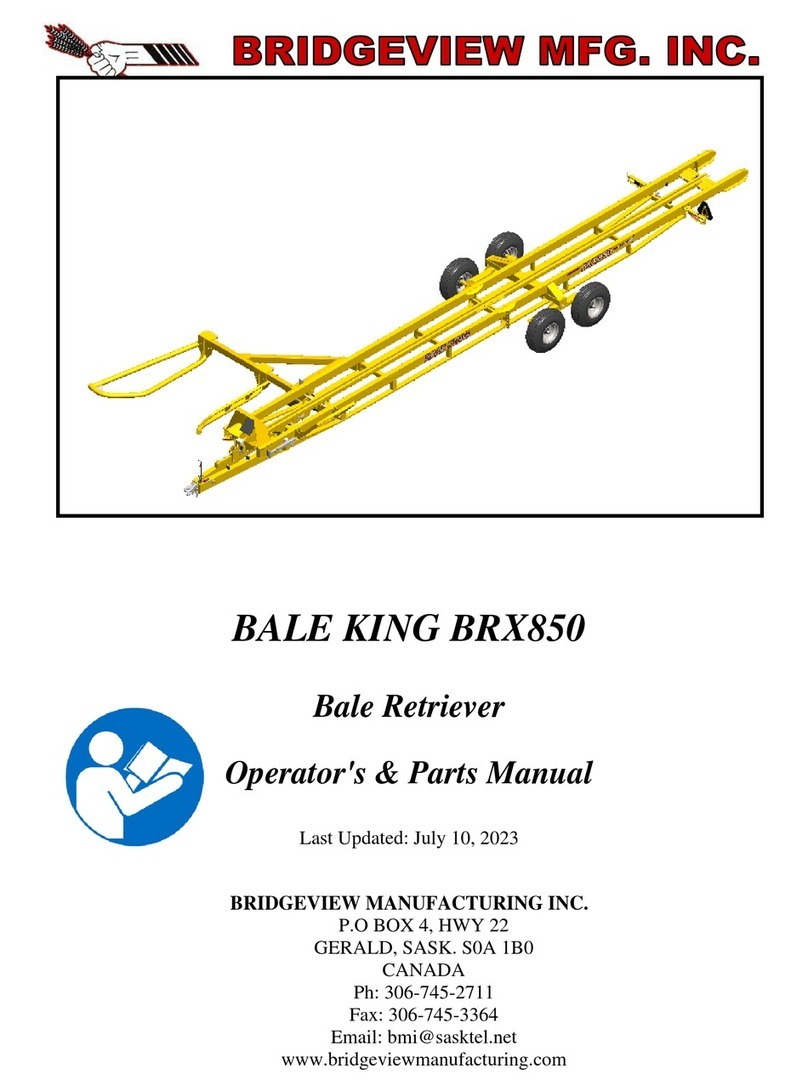

Implement Tongue........................................................................................................ 10

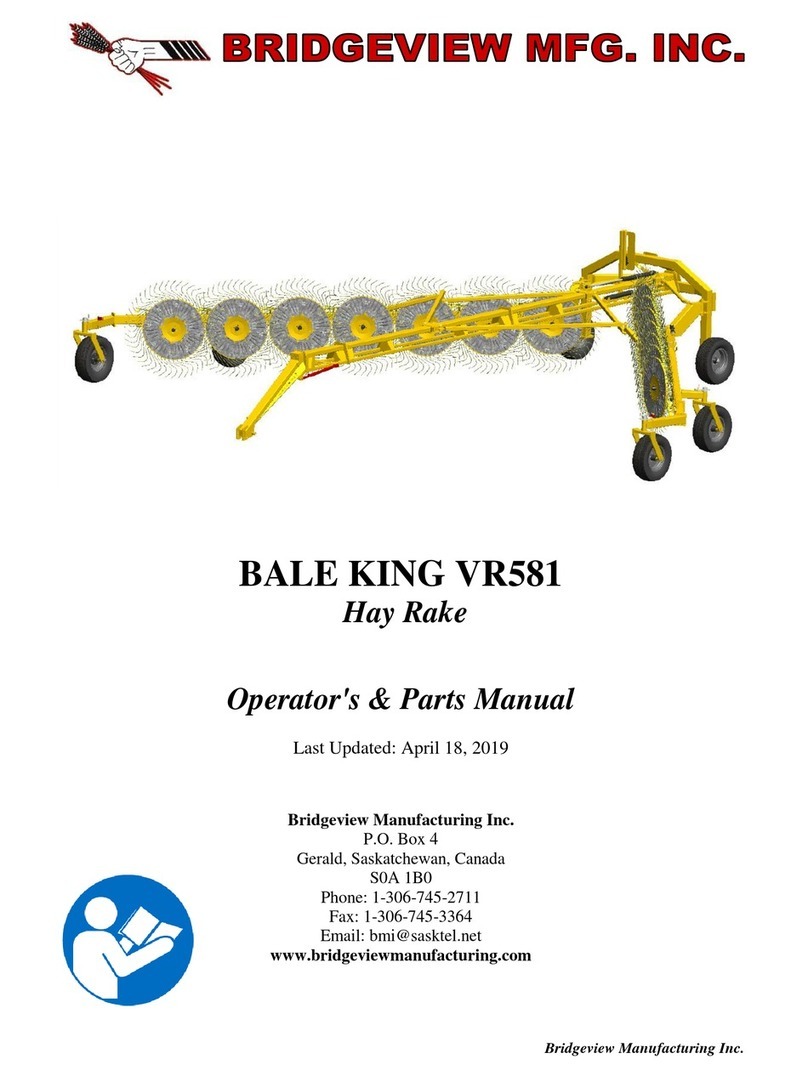

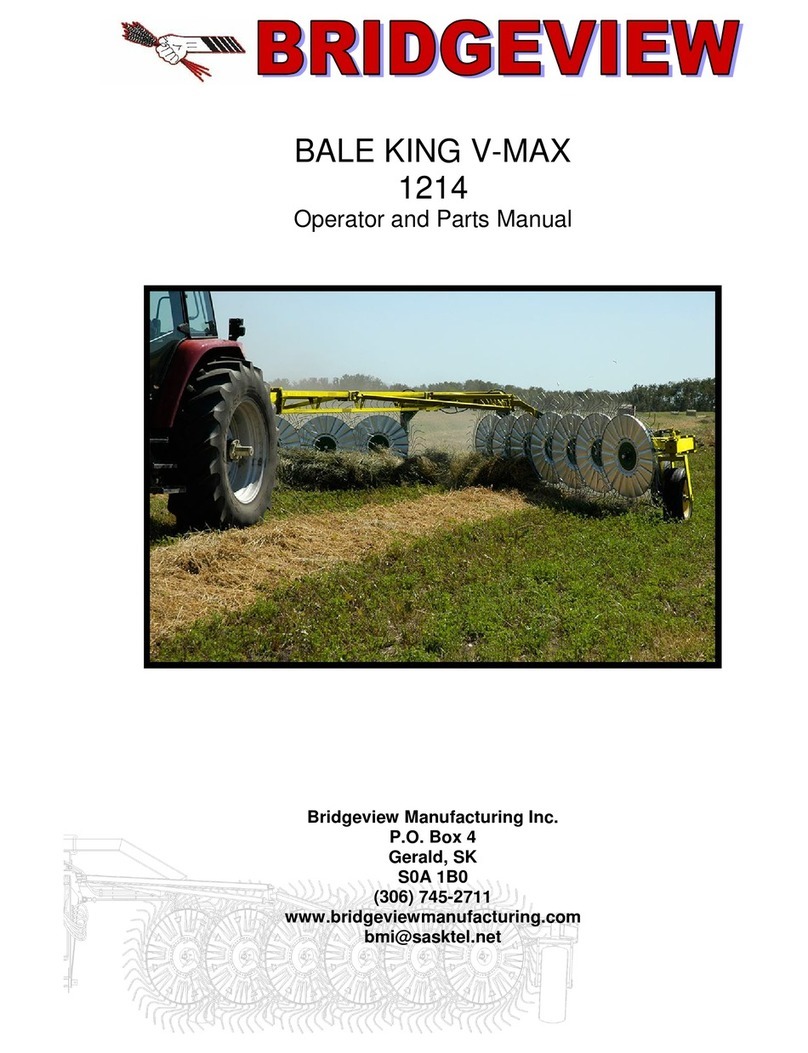

Rear Fork Tines............................................................................................................. 11

Wing.............................................................................................................................. 11

Hoop Grate Adjustment................................................................................................ 12

Deflector ....................................................................................................................... 13

Agitators........................................................................................................................ 16

Loading Bales ............................................................................................................... 17

Optional Fine Chop Kit................................................................................................. 18

Lubrication and Maintenance ....................................................................................... 19

Tire Inflation and Rating............................................................................................... 21

Twine Removal............................................................................................................. 22

Rotor and Flail Replacement ........................................................................................ 23

Transportation............................................................................................................... 24

Features and Specifications........................................................................................... 26

Optional Fine Chop Kit (Installation)........................................................................... 28

PARTS MANUAL............................................................................................................ 29

Machine Overview........................................................................................................ 29

Jack & Hitch ................................................................................................................. 30

Wheels & Hub............................................................................................................... 31

Spindle .......................................................................................................................... 32

Rotor & Drive Components.......................................................................................... 33

Gearbox......................................................................................................................... 34

PTO Shaft...................................................................................................................... 36

Agitators........................................................................................................................ 37

Grates............................................................................................................................ 38

Upper Tub Components................................................................................................ 39

Slow Moving Vehicle Sign Kit..................................................................................... 41

Rear Forks..................................................................................................................... 42

Deflector & Hose Cover ............................................................................................... 43

Main Frame................................................................................................................... 45

Manual Holder.............................................................................................................. 46

PTO Holder................................................................................................................... 47

Twine Cutter ................................................................................................................. 48

Fine Chop Kit (Optional).............................................................................................. 49

Diverter Valve............................................................................................................... 50

Decals............................................................................................................................ 51

ELECTRICAL & HYDRAULIC SCHEMATICS........................................................... 52

NOTES.............................................................................................................................. 60