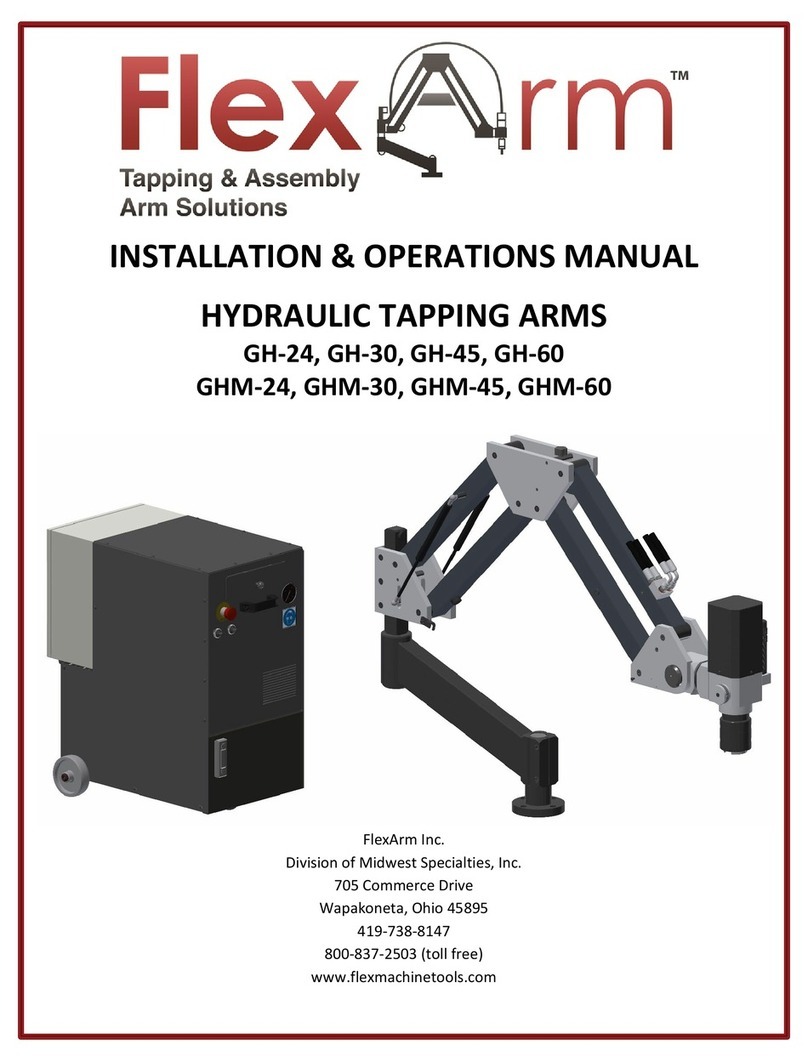

FlexArm GH-18 User manual

Correct handling and maintenance is absolutely necessary.

Read the following instructions for installation and operation carefully.

GH-18 Operations Manual

Machine Power: 2Hp

Voltage: 110V

1-800-837-2503

705 Commerce Drive

Wapakoneta, Ohio 45895

www.flexmachinetools.com

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

1

Index

Page

2.) Index

3.) Installation

3.) Startup and Shutdown Procedures

4.) Improper Shutdown

4.) Guarantee

5.) Tap Lubricator System

6.) Multi-Position Head

7.) Machine Drawings

8.) Technical Details

9.) Electric Diagram

10.) Electrical Parts List

11.) Hydraulic Diagram

12.) Hydraulic Parts List

13.) Spare Parts Diagrams

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

2

Installation

1) Mount the arm in the pivot of the angle mount.

2) Adjust the counterbalance of the arm to eliminate the possibility of the arm striking the

operator when positioned at its lowest point.

3) Connect the machine to a grounded 110 volt, 1 phase electric supply.

CAUTION: When making repairs to this unit, always disconnect the main power supply.

4) Flip the forward switch on the hydraulic motor of the tapping head. The rotation of the

hydraulic motor is correct if the tapping head rotates clockwise. If it turns

counterclockwise or does not rotate, reserve the two phases at the supply connection,

not in the internal electric panel.

5) Always wear safety glasses and use proper safety precautions when operating this unit.

Gloves are not recommended when operating this machine.

ALWAYS SECURE THE WORK PIECE TO THE TABLE BEFORE OPERATING.

This machine is designed for tapping, chamfering and light reaming of holes up to M18 diameter.

FlexArm Inc is not responsible for accident or injury resulting from the misuse of this machine.

GH-18 Startup and Shutdown Procedures

Startup:

1. Plug in

2. Lockout breaker on

3. Green button press on (Hold for 2-3 seconds on initial startup)

Shutdown:

1. Red button off

2. Lockout breaker off

a. allow the motor in the power pack to spool down completely before turning lockout breaker

off (approximately 3 seconds)

b. this is only necessary if locking out the unit

3. Unplug (this is only necessary if moving locations)

a. allow the motor in the power pack to spool down completely before unplugging the unit

(approximately 3 seconds)

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

3

CMA recommend change of hydraulic oil every 5000 work hours.

Any ISO Viscosity Grade 46 Hydraulic Oil will work for this model.

Guarantee

The machines have a one year warranty against manufacturer defect from the date of

delivery. Cases of incorrect use or incorrect connection are not covered by the warranty.

(Due to constant product improvement, the manufacturer reserves the right to modify

machines without prior notice.).

Improper Shutdown:

• Turning the machine off with the lockout breaker before turning off the machine with the red

button.

• Turning the lockout breaker to off before the motor in the power pack has spooled down

completely. (approximately 3 seconds)

• Suddenly removing power from the machine i.e. pulling the plug out of the wall before turning

off the machine with the red button.

• Unplugging the unit before the motor in the power pack has spooled down completely.

(approximately 3 seconds)

• Pressing the green button while lockout breaker is off and residual power is still in the inverter

(approximately 45 seconds after shutdown)

If improper shutdown occurs:

Reset the power pack:

1. Lockout breaker off

2. Unplug the machine (wait 45 seconds to allow the inverter to reboot)

3. Plug the machine back in

4. Lockout breaker on

5. Green button press on (Hold for 2-3 seconds on initial startup)

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

4

Use of tap lubricator system

FlexArm mounts a standard tap lubricator system in its tapping units. [Refer to diagram]

•Connect air inlet and arm pneumatic tube to the regulator-manometer which is adjusted in our factory.

•Fill oil tank located in front lower arm: uncover the filler plug and fill with tapping oil to the maximum level.

•Press and hold the starting lever until you see atomized oil begin to leave for the lance tip. The first time, the

atomized oil will take time to reach the lance tip, but later uses will be much quicker.

•Adjust the quantity of oil mixture released by adjusting the oil regulator mounted behind lance.

•The tap lubricator system can be used before, during and after tapping pieces.

Oil regulator

Oil tank

Filler plug

Lance

Regulator, manometer

Starting lever

Caution! Don´t use corrosive oil, It can damage the system's plastic valves.

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

5

Use of the multi-position head

FlexArm models GH-18 that are equipped with a multi-position head.

The multi-positional head allows taping in additional positions. This kind of

tapping doesn't guarantee the perfect thread but will provide a good tapping

quality.

PRESS RED

LEVER

•Loosen the large lever to adjust the position of the tapping head

between vertical and horizontal tapping. Loosen the small lever to adjust

the head position from right to left.

•Before Tapping, check the small lever isn't fixed, since it must be loose for

tapping.

•When returning the head to the vertical tapping position, remember that

both levers must be secure to tap.

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

6

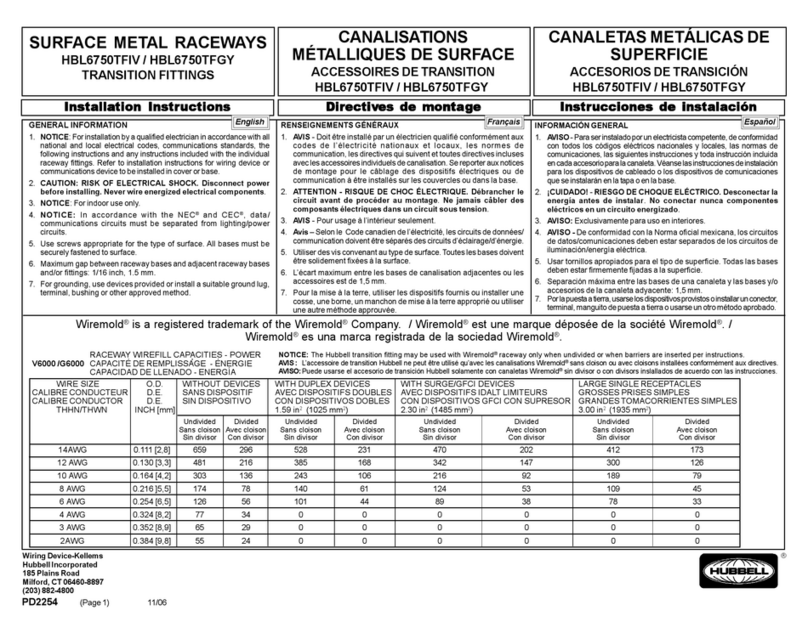

Machine drawing

Stop switch

Emergency stop

Manometer

Speed governor

Oil level

Master switch

Forward and reverse switches

Start switch

Cylinder governors

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

7

Technical details

GH-18, GHM-18

Electric motor 2Hp

The best maximum pressure 120

Security maximum pressure 140

Minimum threaded capacity #6

Maximum threaded capacity 5/8"

R.P.M. 420

Table dimensions

---

Oil tank capacity 9G

Voltage in knobs 24 V

Effective range

Full 360º degrees

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

8

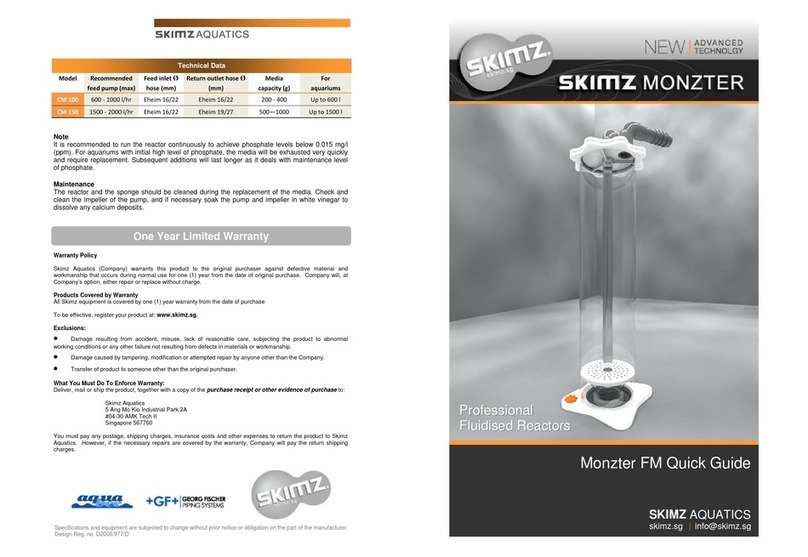

Electric diagram

PE

L1

L2

M

1.5 ~

L1 L2 BR

+UD

u v w PE

PE w v v

1

2

3

4

5

6

7

8

9

10

11

12

PT

= 5 K

IG

U

VV

U

WW

TTTT

220

N

24

N

T

S1 S2 P2

P1

PM

PE

IN

INVERTER

E

TTTT

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

9

Electrical parts list

Pos #

Type of component

1 --

Binding clamp 39061

2 T

Transformer Type M

3 IG

Main Switch

4 PE

Emergency Stop

5 PM

Start/stop switch

6 P1 – P2

Forward and reverse switches

7 --

Connector Han-Kit-3 AGM

8 IN

Inverter

9 PT

Speed governor

10 E

Electrovanne

11 M

Electric motor 2 Hp

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

10

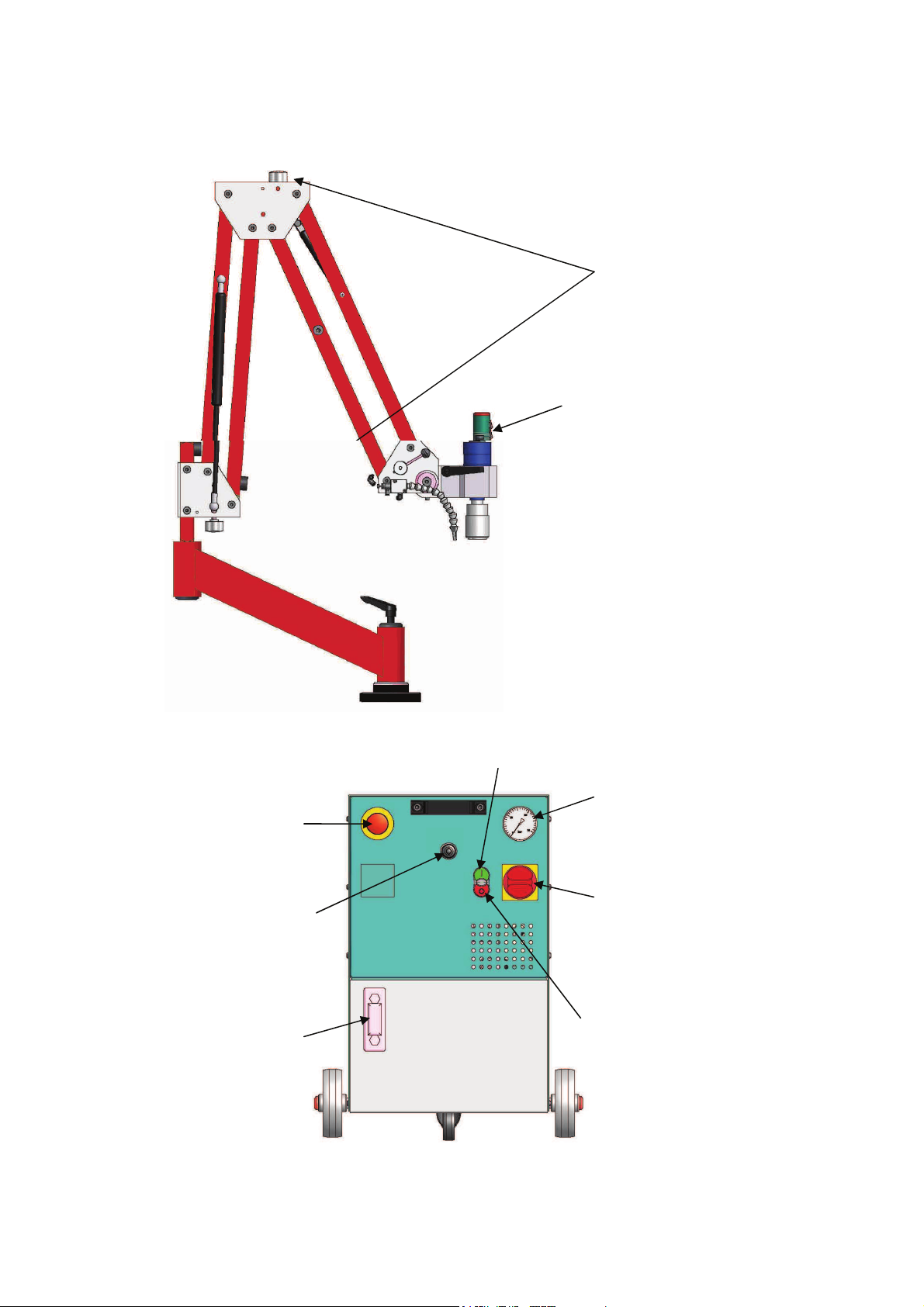

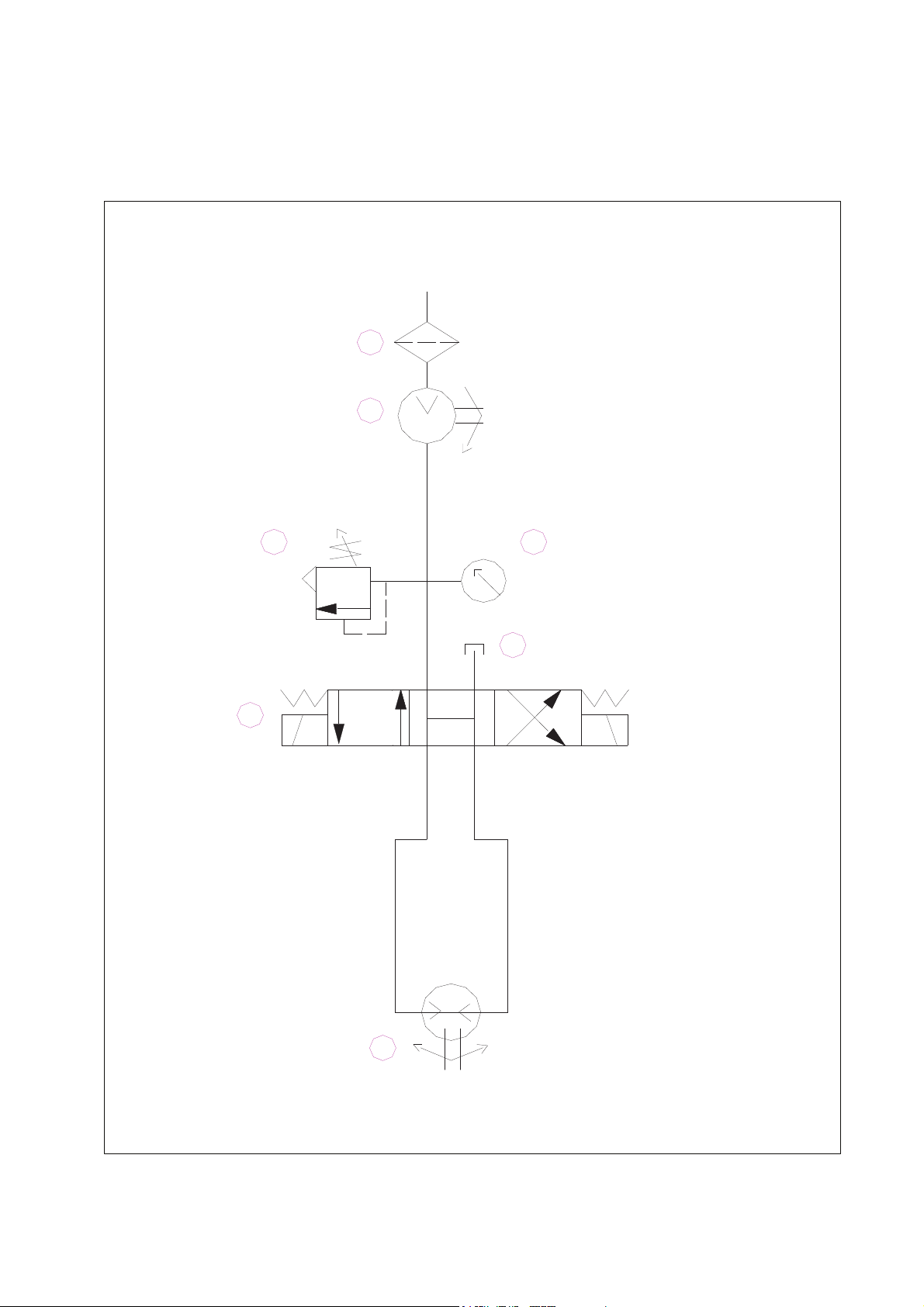

Hydraulic diagram

5

3

4

21

7

8

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

11

Hydraulic parts list

Type of component

1

Filter suction

2

Gear pump

3

Base plate with security limitator

4

Manometer

5

Electrovalve

6

7

Hydraulic motor 32 cc

8

Oil tank

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

12

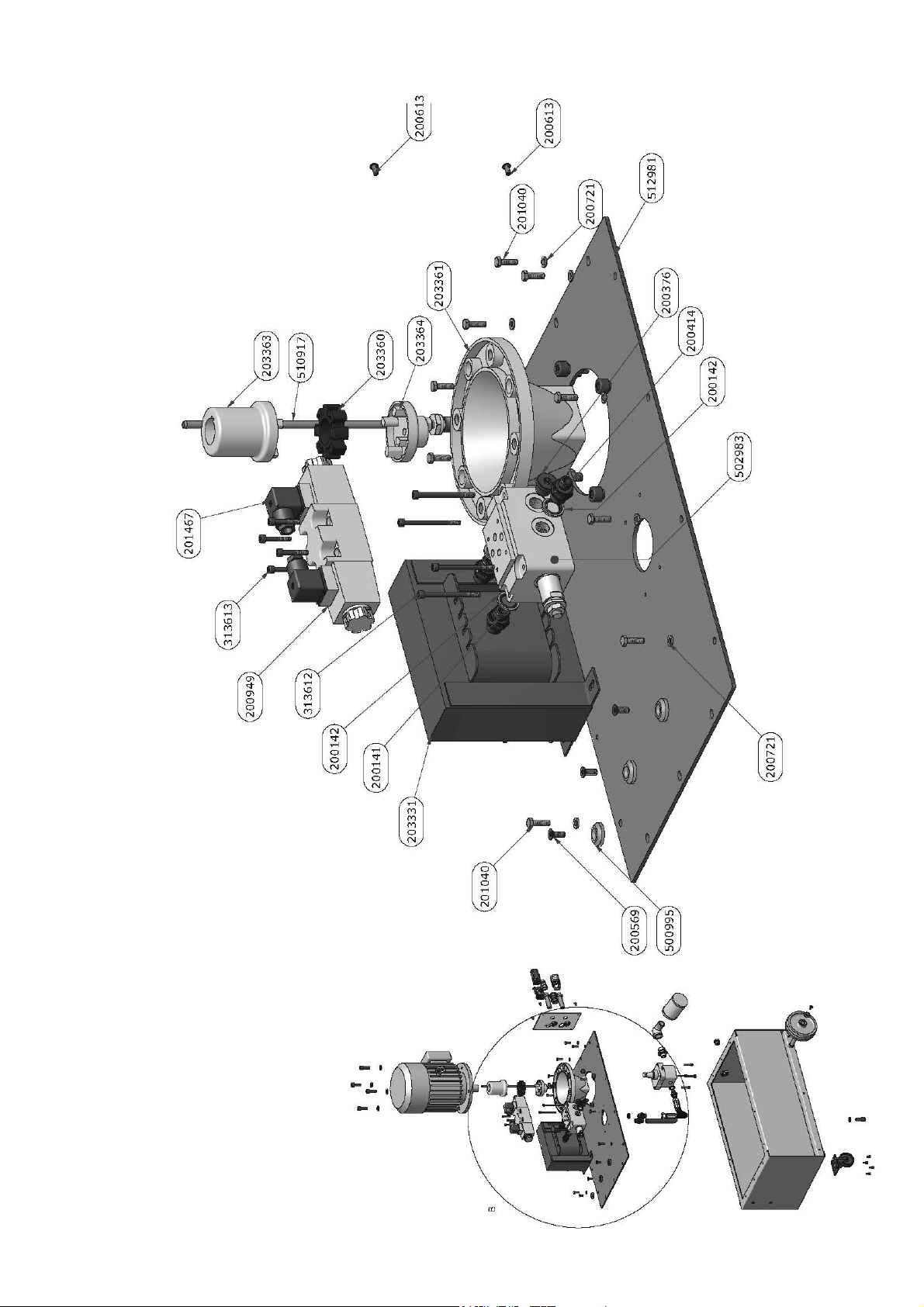

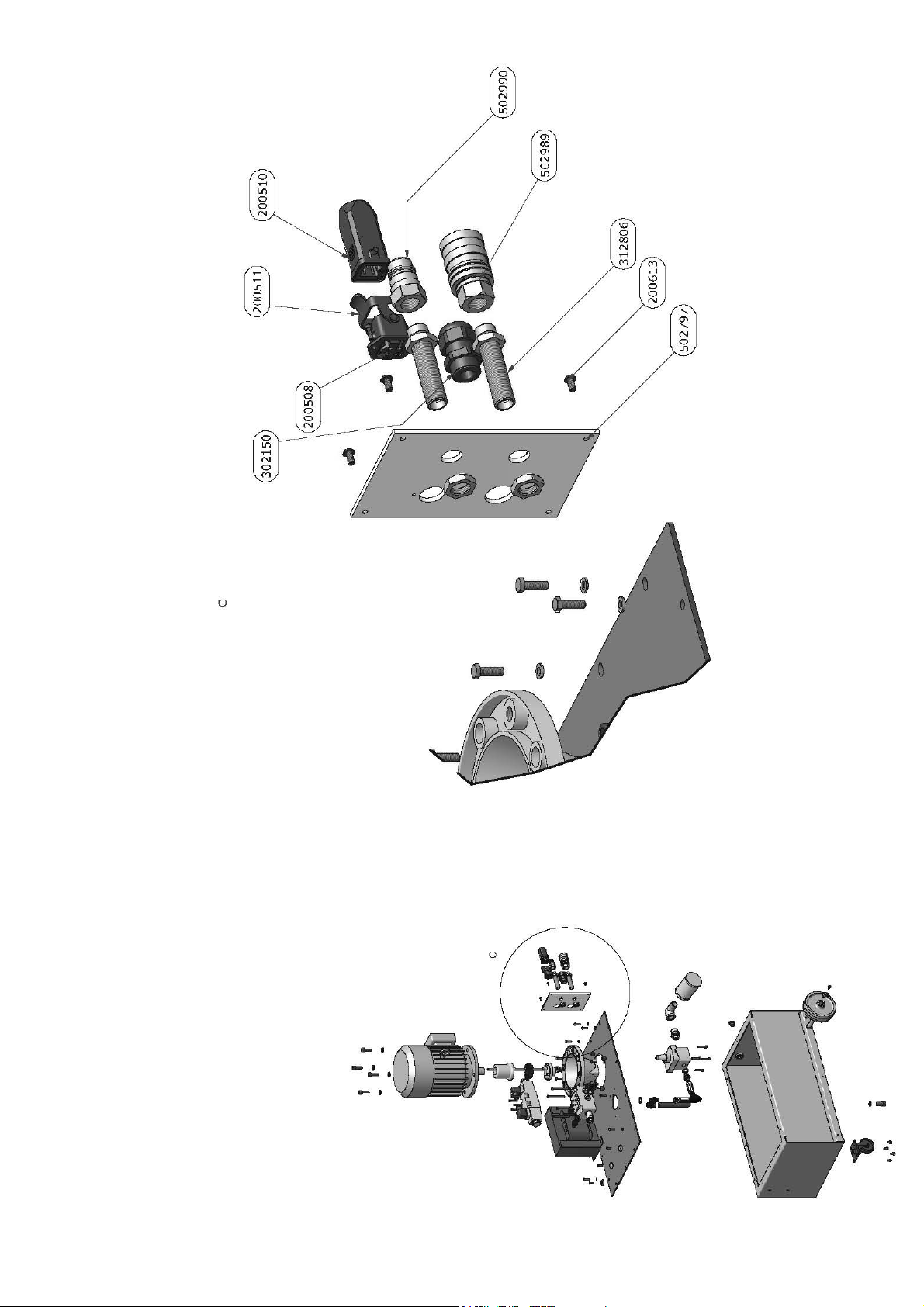

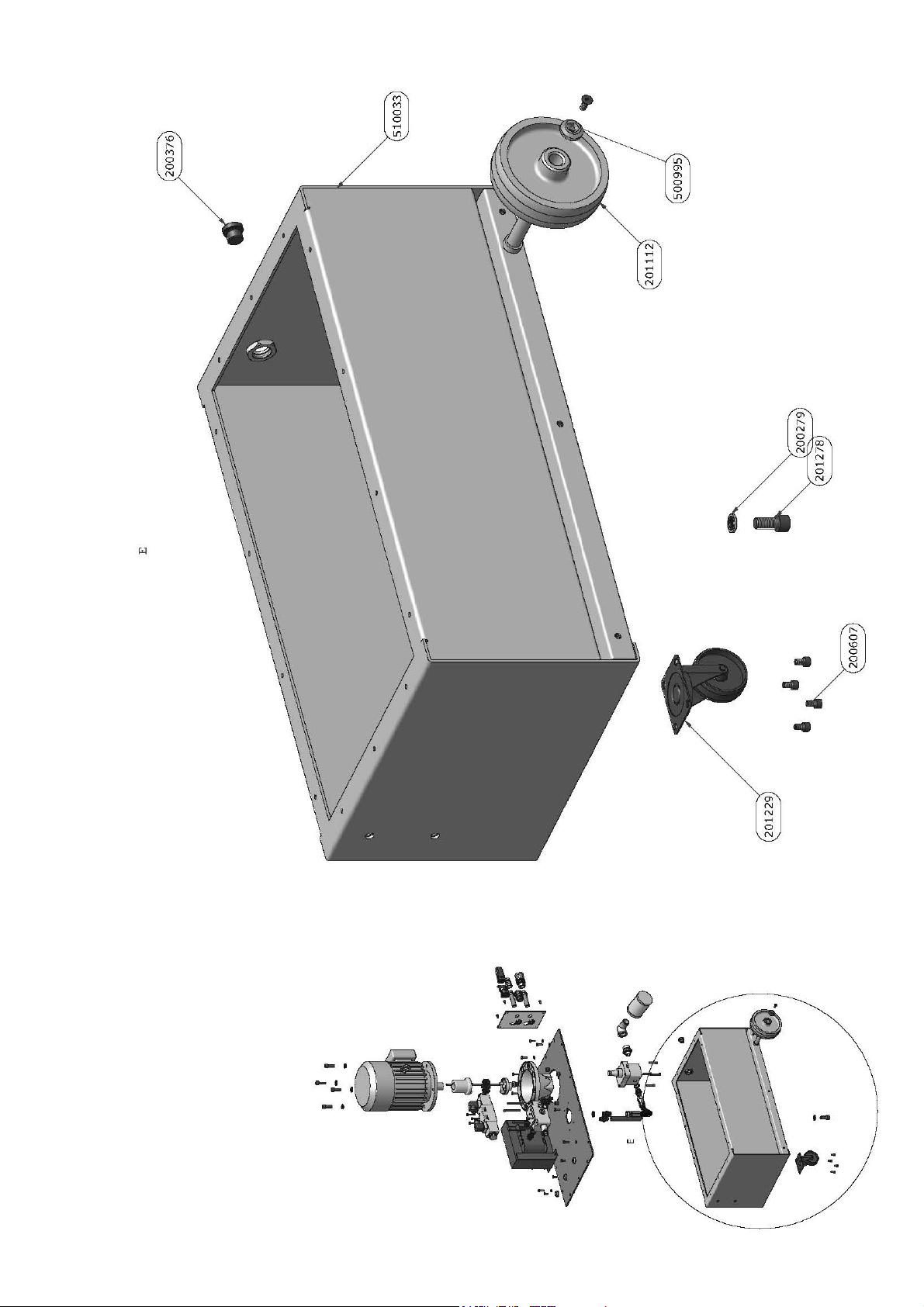

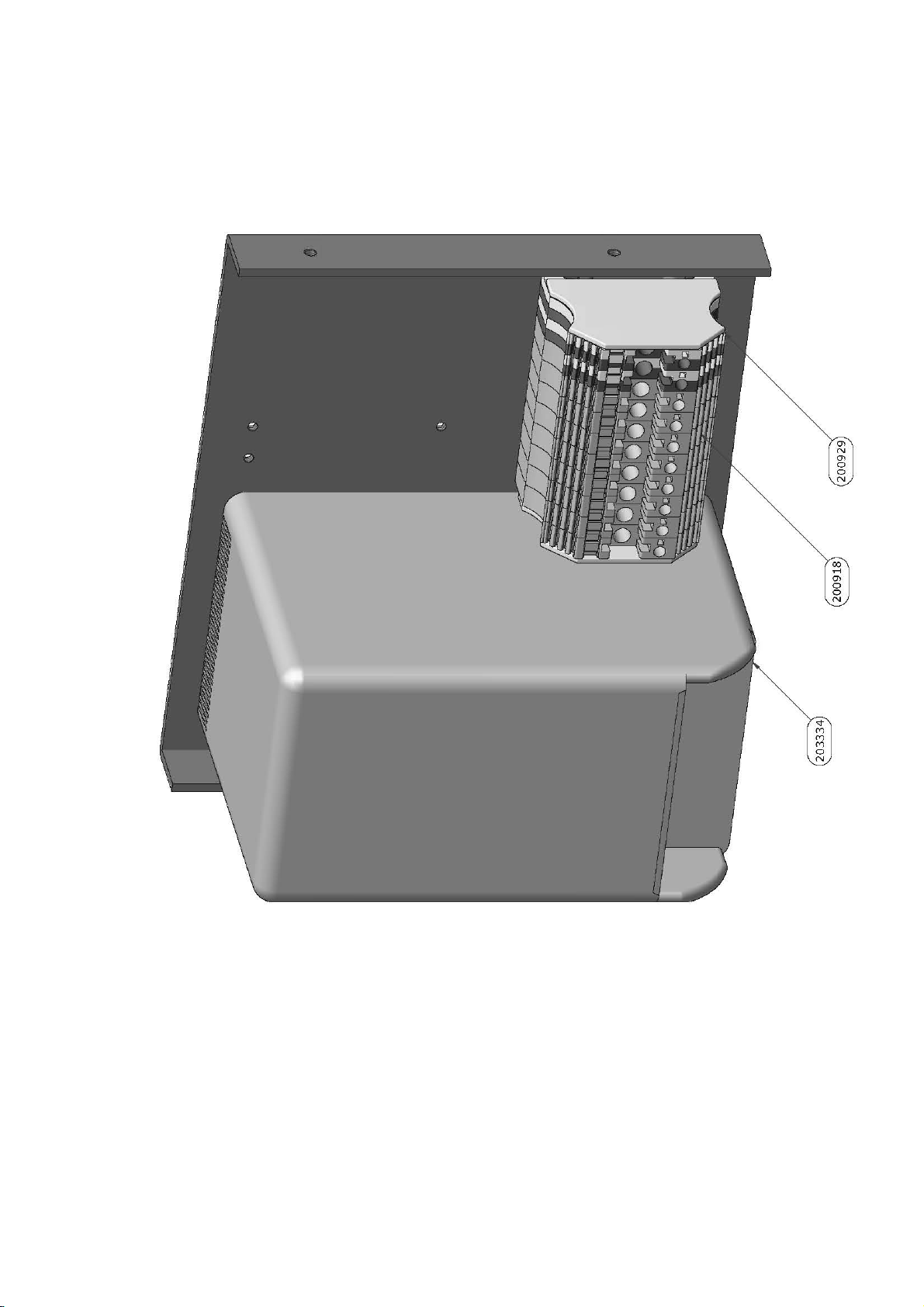

Spare Parts Diagram

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

13

$$

$

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

14

%

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

15

&&&&

&

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

16

''''

'

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

17

((((

(

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

18

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

19

FlexArm Inc

GH-18 Tapping Arm Manual

10/17/2019

REV. 001

20

Table of contents

Other FlexArm Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

CIAT

CIAT DynaCIAT LG instruction manual

4Protect

4Protect COLORADO User instruction manual

Emerson

Emerson Rosemount 2410 instructions

LOVATO ELECTRIC

LOVATO ELECTRIC EXM10 12 instruction manual

DEHN + SÖHNE

DEHN + SÖHNE HVI Series installation instructions

HEIDENHAIN

HEIDENHAIN MSE 1300 installation instructions