Flexball WR CONTROLS 3500 Series User manual

O

Op

pe

er

ra

at

ti

in

ng

g

m

ma

an

nu

ua

al

l

&

&

m

mo

ou

un

nt

ti

in

ng

g

i

in

ns

st

tr

ru

uc

ct

ti

io

on

ns

s

Flexball Italiana S.r.l.

2

WARRANTY

The Electronic Command Systems Flexball series 3500, 4000, 4200 and 4500 are guaranteed to have a good

performance in case they are operated according to the instructions mentioned in the referring product

manuals.

Flexball Italiana srl warrants as follows.

1. SCOPE OF WARRANTY

Warranty is limited to repair or supply with new one against Flexball Electronic Command Systems or their

parts which are occurred by defective materials or workmanship within warranty period.

2. WARRANTY PERIOD

Flexball Italiana srl warrants against defective materials or workmanship for a period of twenty-four (24)

months from the date of original shipment by Flexball Italiana srl to original customer or twelve (12) months

from the first sea trial, whichever occurs first.

3. WARRANTY NON EFFECTIVE (Flexball Italiana srl does not warrant)

a. The parts that are not produced by Flexball Italiana srl or genuine parts which are lost.

b. The cost or the breakdown that occurs for repairing before contacting Flexball Italiana srl

c. The breakdown which is occurred due to any modification of Electronic Command Systems or their parts

without previous consent of Flexball Italiana srl.

d. The breakdown that is occurred due to the customer's negligence, faulty maintenance, misuse or non

observance of recommended or operation instructions.

4. OBLIGATION OF USERS

a. Electronic Command Systems should be inspected and repaired according to the instructions mentioned in

the manuals.

b. Use of unsuitable parts, inspection or repair can cause a fatal damage. In case the Electronic Command

Systems should be repaired in a workshop, use a workshop that is appointed by Flexball Italiana srl.

5. WARRANTY REPAIR

This warranty letter is accompanied by the product and Users should summit this warranty letter to warranty

repairman when warranty repair or periodic inspection.

6. PRODUCT UPGRADE

Flexball Italiana srl does have no obligation to apply new specifications to the Electronic Command Systems

that was supplied before changing specifications.

7. WARRANTY SUCCESSION

In case that owner is changed because the Electronic Command System is resold or contributed to the other

customer within warranty period, Flexball Italiana srl warrants the rest of warranty period. In order to do that,

this warranty letter should be accompanied with the Electronic Command System.

Flexball Italiana S.r.l.

3

Index Version July 2019

1. Introduction ............................................................................................................................................ 6

1.1. How to start....................................................................................................................................6

1.2. System configuration and installer remarks.....................................................................................6

2. General installation features ................................................................................................................... 7

2.1. Description of the system and its parts ...........................................................................................7

2.2. Maximum extension of the system.................................................................................................. 7

2.3. System performance ...................................................................................................................... 7

3. Pilot instructions ..................................................................................................................................... 8

3.1. Control keypad...............................................................................................................................9

3.2. Acquisition of the command.......................................................................................................... 10

3.3. Engine Warm-up .......................................................................................................................... 10

3.4. Synchro mode.............................................................................................................................. 11

3.5. Fast Start-up Mode ...................................................................................................................... 11

3.6. Emergency lever .......................................................................................................................... 11

4. Command station ................................................................................................................................. 12

4.1. Dimensions .................................................................................................................................. 12

4.1.1. Command station series 3500.............................................................................................. 12

4.1.2. Command station series 4000.............................................................................................. 13

4.1.3. Command station series 4200.............................................................................................. 13

4.1.4. Command station series 4500.............................................................................................. 14

4.1.5. Removal of the protective cover (when present) ................................................................... 14

4.2. Friction adjustment....................................................................................................................... 15

4.2.1. Command station series 3500.............................................................................................. 15

4.3. Programming of the command station .......................................................................................... 15

4.3.1. For command stations before serial number 18500 .............................................................. 15

4.3.2. For command stations after serial number 18500................................................................. 16

4.3.3. 4500 twin-engine stations: how to assign the Synchro function to the operating lever (after

serial number 18500)............................................................................................................................ 16

4.4. Command station label................................................................................................................. 17

4.5. Trim/Flap option ........................................................................................................................... 18

Press with finger 2 to lift up the TRIM............................................................................................................ 18

Press with finger 3 is to move down the TRIM............................................................................................... 18

4.6. Classification of indoor and outdoor installation ............................................................................ 19

4.7. Advices about the mounting and preservation of the command station.......................................... 21

4.8. Command station codes............................................................................................................... 21

5. Actuator................................................................................................................................................ 22

5.1. Drawing of actuators with mechanical interface ............................................................................ 22

5.2. Drawing of full electronic actuator................................................................................................. 23

5.3. How to mount the Actuator ........................................................................................................... 23

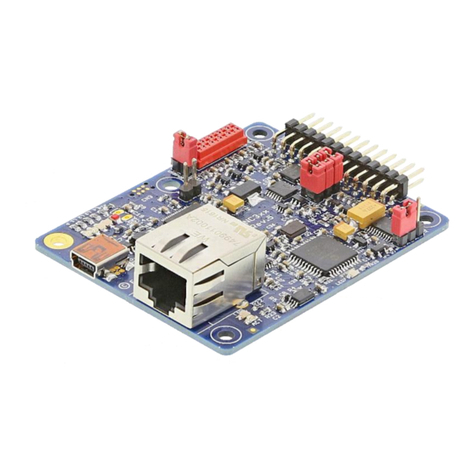

5.4. Electronic Actuator Boards ........................................................................................................... 24

5.4.1. Actuator board ver. 3.1......................................................................................................... 24

5.4.2. Relays PCB version RB 1.0 for TRIM-FLAP and neutral relays............................................. 25

5.4.3. Relays PCB version 2.0 for electronic gearboxes ................................................................. 26

5.4.4. ECAN-PCB for engine with CANBus interface...................................................................... 27

5.4.5. Galvanic insulation PCB for analogue voltage signals .......................................................... 27

5.4.6. VANCONV PCB................................................................................................................... 28

5.5. Actuator labels and codes ............................................................................................................ 29

6. Accessories and Options ...................................................................................................................... 31

6.1. CANBus cable.............................................................................................................................. 32

6.1.1. CANBus data transmission cable ......................................................................................... 32

6.1.2. CANBus extension cable ..................................................................................................... 32

6.2. Cable actuator - electronic engine ................................................................................................ 32

6.2.1. Cable actuator for electronic engine 1 channel: voltage, PWM, 4-20 mA .............................. 32

6.2.2. Cable actuator – electronic engine (V) with 2 channels......................................................... 33

6.2.3. Nanni Diesel – Throttle cable for Toyota ECU ...................................................................... 33

6.2.4. Nanni Diesel – Cable only for the inverter (hybrid engines)................................................... 34

6.2.5. Nanni Diesel – Command cable for throttle and inverter ....................................................... 34

6.2.6. Nanni Diesel – Y cable for Toyota engine base (V) + inverter (V)......................................... 35

6.2.7. Nanni Diesel – Y cable for VM engine base + inverter ......................................................... 35

6.2.8. FPT – Throttle CANBus command cable.............................................................................. 36

Flexball Italiana S.r.l.

4

6.2.9. Cable actuator – CANBus engine with free wire ................................................................... 36

6.2.10. FNM – Throttle cable ........................................................................................................... 36

6.2.11. Hyundai - Throttle cable...................................................................................................... 37

6.2.12. Steyr - Throttle cable, type A (Ch2 = IVS signal).................................................................. 37

6.2.13. Steyr -Throttle cable, type B, for engines series "SE" .......................................................... 38

6.3. Cable actuator – gearbox solenoid driven..................................................................................... 38

6.3.1. Nanni Diesel – Cable for gearbox solenoid driven ................................................................ 39

6.3.2. FPT – Cable for gearbox solenoid driven.............................................................................. 39

6.3.3. Cable actuator - gearbox solenoid driven + neutral relay signal ............................................ 39

6.3.4. Nanni Diesel – Cable for gearbox solenoid drive + neutral signal.......................................... 40

6.4. Cable actuator – trim/flap ............................................................................................................. 40

6.4.1. Nanni Diesel – Cable for the trim/flap command................................................................... 40

6.5. Cable actuator – Mercruiser® trim pump ...................................................................................... 41

6.6. T-Splitter ...................................................................................................................................... 42

6.7. Power supply connector ............................................................................................................... 42

7. Configuration of the CANBus network................................................................................................... 43

7.1. Installation with 2 mechanical actuators – solution A..................................................................... 43

7.2. Installation with 2 mechanical actuators – solution B..................................................................... 44

7.3. Installation with 2 mechanical actuators – solution C..................................................................... 45

7.4. Installation with 1 actuator – solution D......................................................................................... 46

7.5. Installation with 1 actuator – solution E......................................................................................... 47

7.6. Configuration: end of line termination resistor and address setting of command stations and

actuators .................................................................................................................................................. 48

7.6.1. Configuration of the command station .................................................................................. 48

7.6.2. Configuration of the actuator................................................................................................ 50

7.7. Configuration with more than 3 command stations........................................................................ 51

10. Electrical installation ............................................................................................................................. 52

10.1. Wiring from the battery to the actuator (input cables) .................................................................... 52

10.1.1. The supply connector........................................................................................................... 52

10.1.2. The ignition key switch......................................................................................................... 53

10.1.3. Electrical installation of systems with 1 engine, 1 actuator and 1 ignition key........................ 53

10.1.4. Electrical installation of systems with 2 engines, 1 actuator and 2 ignition keys..................... 54

10.1.5. Electrical installation systems with 1 engine, 1 actuator and 2 ignition keys. ......................... 54

10.1.6. Electrical installation of systems with 2 engines, 2 actuators and 2 ignition keys................... 55

10.1.7. Electrical installation of systems with 2 engines, 2 actuators and 2+2 ignition keys............... 56

10.1.8. Dimensional criteria of the power supply cables ................................................................... 56

10.2. Wiring from the actuator to command stations, engines, gearboxes, trim/flaps, etc (output cables)57

10.2.1. Actuator with mechanical interface without neutral relay....................................................... 57

10.2.2. Actuator with mechanical interface and neutral relay ............................................................ 58

10.2.3. Actuator with full electronic interface .................................................................................... 59

10.2.4. Actuator with full electronic interface and neutral relay ......................................................... 59

10.2.5. Wiring scheme to gearbox in case of actuator without neutral relay ...................................... 60

10.2.6. Wiring scheme to gearbox in case of actuator with neutral relay........................................... 60

10.2.7. Wiring scheme from actuator to trim/flap with external supply............................................... 61

10.2.8. Wiring scheme from actuator to trim/flap with internal supply................................................ 61

11. Programming of the actuator, general guidelines .................................................................................. 62

11.1. Programming keypad ................................................................................................................... 62

11.2. Display and Parameters ............................................................................................................... 62

11.3. Actuator parameters..................................................................................................................... 63

12. Installation of the push-pull cable and stroke’s programming on the actuator......................................... 64

12.1. Push-pull cables choice................................................................................................................ 64

12.1.1. Connection kit...................................................................................................................... 64

12.1.2. Standard push-pull cable (E2, E3, Volvo®, C0, C3, C33…) .................................................. 64

12.1.3. Mercruiser® stern drive push-pull cable ............................................................................... 65

12.1.4. Johnson® push-pull cable.................................................................................................... 65

12.2. Mounting of the push-pull cables between engine and actuator..................................................... 66

12.2.1. Connection of the push-pull cable to the engine ................................................................... 66

12.2.2. Connection of the push-pull cable to the actuator ................................................................. 66

12.3. Mounting of the push-pull cable between gearbox and actuator .................................................... 69

12.3.1. Connection of the push-pull cable to the gearbox side.......................................................... 69

13. Programming of the strokes on actuator with mechanical interface to engine and gearbox .................... 72

13.1. Programming of the push-pull cable strokes ................................................................................. 73

13.2. Sea trials...................................................................................................................................... 75

Flexball Italiana S.r.l.

5

13.3. Specific parameters...................................................................................................................... 76

14. Programming of actuators for installations with electronic engine and mechanical gearbox ................... 77

14.1. Programming of the gearbox strokes ............................................................................................ 78

14.2. Sea trials...................................................................................................................................... 80

14.3. Specific parameters...................................................................................................................... 82

14.3.1. Parameters to configure the voltage output signal for electronic engines .............................. 82

14.3.2. Parameters to configure the voltage output signals .............................................................. 83

15. Programming of actuators for mechanical engines and electronic gearbox............................................ 84

15.1. Installation of engine the push-pull cable and programming of throttle mechanical strokes............ 84

15.2. Programming of the push-pull cable strokes ................................................................................. 84

15.3. Electrical cabling of the gearbox................................................................................................... 84

15.4. Specific parameters...................................................................................................................... 84

16. Programming of actuators with electronic engine and electronic gearbox .............................................. 85

16.1. Electrical wiring ............................................................................................................................ 85

16.2. Specific parameters...................................................................................................................... 85

17. Programming of actuators with electronic CANBUS engine and mechanical gearbox ............................ 86

17.1. Installation of the push-pull cable and programming of the cable stroke ........................................ 86

17.2. Specific parameters...................................................................................................................... 86

17.2.1. CANBus protocol ................................................................................................................. 86

17.2.2. Setting of the CANBus parameter values ............................................................................. 87

17.2.3. Technical data of the CANBus interface card ....................................................................... 88

17.3. Wiring of the outgoing actuator cables.......................................................................................... 88

17.4. Connection to FPT engines through CANBus interface................................................................. 88

Micro switch B4, here shown with tag “4”, must be switched in OFF position in order to allow CANBus

communication between Flexball Electronic Command System and FPT engine. .......................................... 88

18. Programming of actuators with electronic CANBUS engine and electronic gearbox............................... 90

18.1. CANBus engine parameters......................................................................................................... 90

18.2. Electronic gearbox parameters..................................................................................................... 90

18.3. Wiring of the actuator outgoing cables.......................................................................................... 90

19. System configuration in case of options ................................................................................................ 90

19.1. Commissioning of actuators for installations with Trim or Flap command option............................ 90

19.2. Commissioning of actuators for installations with Trolling option ................................................... 90

19.3. Commissioning of the actuators with Neutral Relay option............................................................ 91

19.4. Programming of the actuators with Hybrid Engine option .............................................................. 92

21. Trouble shooting................................................................................................................................... 93

21.1. What to do in case of system failure .............................................................................................93

21.1.1. Behavior of the system in case of unforeseen shutdown....................................................... 93

21.1.2. Emergency lever and how to overcome faults during navigation in case of system with

mechanical interface............................................................................................................................. 93

21.1.3. Self-protection in case of overload or breakage of the push-pull cables ................................ 94

21.2. Analysis of the electronic system behavior....................................................................................95

21.3. Diagnosis through the command station....................................................................................... 97

23. Drilling mask for command station ........................................................................................................ 98

23.1. Command station series 3500 ...................................................................................................... 98

23.2. Command station series 4000 ...................................................................................................... 98

23.3. Command station series 4200 ...................................................................................................... 99

23.4. Command station series 4500 ...................................................................................................... 99

24. Drilling mask for actuator .................................................................................................................... 100

Flexball Italiana S.r.l.

6

1. Introduction

This manual describes the electronic remote control system in general and its operating, performance and

safety aspects. If it is the first time that you install a Flexball electronic control system, go to the next section

where you will be guided to the necessary steps.

1.1. How to start

Once you have received the system package, follow these steps:

1) identify all the components necessary to build up your system with the help of instructions at

sections 4,5,6 and report all the relevant data in the frame here below

2) identify your installation type with the help of section 7.

3) configure the CANBus network, set dip-switches and end of line termination of actuators and

command stations, as described at section 7.6

4) mount command stations and actuators with the help of drilling mask (section 23)

5) make electrical wiring (section 10)

6) install push-pull cables, if your application requires it (section 12)

7) make setting of mechanical strokes, if your application requires it (section 13, 14 and 15)

8) program the actuator specific installation parameters (from section 13 to section 18 included)

9) make the programming of the options, if your application requires it (section 19)

10) once you have set-up the electronic system, read the pilot’s instruction (section 3). Good

navigation!

1.2. System configuration and installer remarks

Component Position aboard Serial number

Command station 1

Command station 2

Command station 3

Actuator left engine

Actuator right engine

Boat registration number

Date of installation

Name and signature of

authorized installer

Flexball Italiana S.r.l.

7

2. General installation features

2.1. Description of the system and its parts

The electronic engine remote control implements mechanical and electronic solutions with digital

communication technology. Only few devices are required to compose a complete electronic engine remote

control:

•Command stations

•Actuators

•Data communication cables which connect the command stations to the Actuators

2.2. Maximum extension of the system

The maximum configuration of the system is as shown in the following table:

Actuators The maximum number of engines that the system can control is 2

Command stations The maximum number of command stations in the installation is 3

80 meters Maximum distance between cockpit and engine room

2.3. System performance

Temperature

Operating temperature From - 10 to 85°C

Storage temperature From - 40 to 90°C

Humidity max operating limit: 90% (relative humidity)

Protection degree of main system components

Command Station series 3500 IP 66

Command Station series 4000 IP 54

Command Station series 4200 IP 67

Command Station series 4500 IP 67

Actuator IP 54

Mechanical features

Nominal load when actuator is providing a

pushing force 150 N (15 kg) with power consumption 1.5 A

Max load when actuator is providing

a pushing force 450 N (45 kg) with power consumption 5 A (with time <1 s)

Stroke of gearbox – forward Stroke can be set between 5 and 40 mm

Stroke of gearbox – reverse

Throttle stroke Stroke can be set between 5 and 80 mm

Electrical features

Power supply from 9,0 to 28 Vdc (for standard installations)

from 20,0 to 28,0 Vdc (for special installations)

Max. current absorbed 5 A

Current absorbed when the system isn’t loaded 0,5 A

Flexball Italiana S.r.l.

8

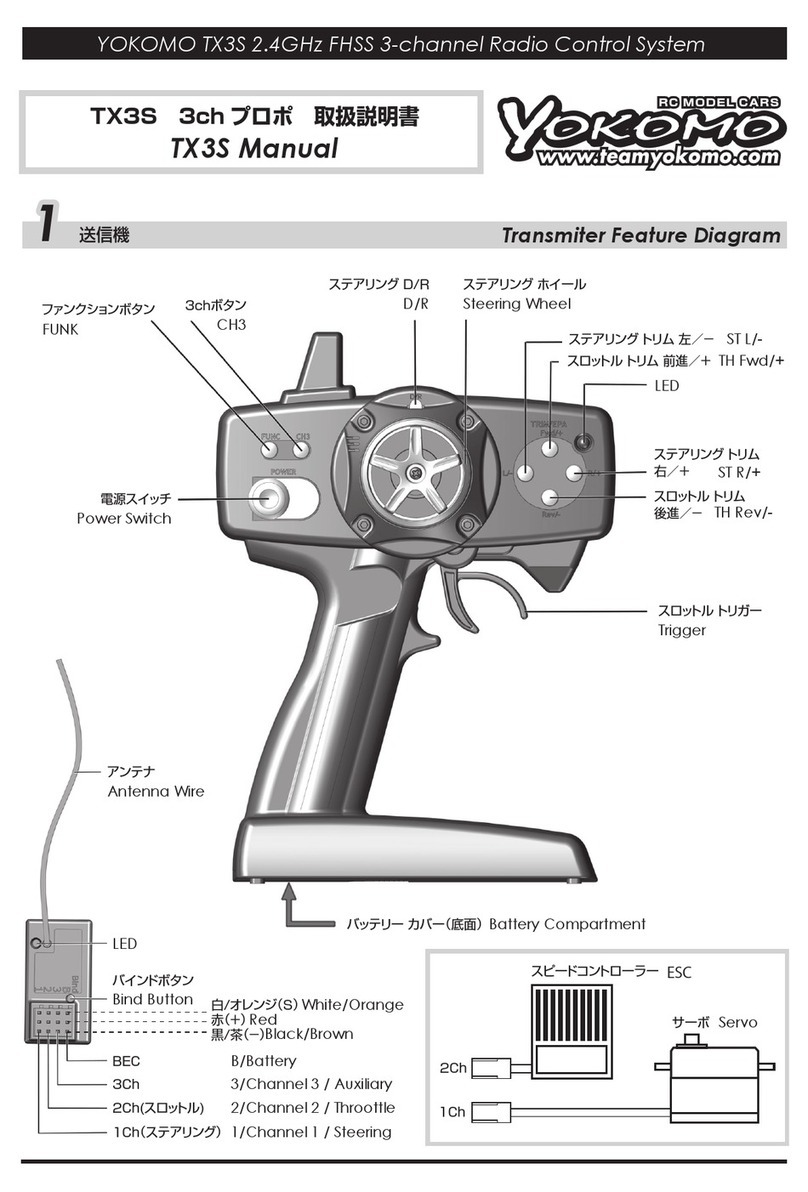

3. Pilot instructions

In the Flexball electronic control system can be mounted any of the following command stations: 3500 - 4000 -

4200 - 4500. Depending on the system configuration and on the type of command station, the latter can be

used for the command of one or two engines. Here below are reported the instructions for some types of

levers: although the functions are the same, due to the command station’s construction, push buttons, LEDs

and keypads might look slightly different. For more detailed information look at the specific command station

product instruction.

Each command station repeats the functionality of a traditional mechanical lever. Moving the lever from the

neutral position, after an angle between 16° and 20° forward or reverse (it depends on the lever’s type),

automatically the electronic system clutches-in respectively the forward or reverse gear. It follows then the

lever’s stroke in forward and backward direction for the throttle control.

Command station series 3500

Command station series 4000

Command station series 4200

Command station series 4500

Acceleratore

Acceleratore

Throttle

Throttle

Reverse

Indietro

Forward

Avanti

20°

62°

20°

62°

16°

16°

35°

25°

Neutral

Reverse

Forward

Max

Min

Min

Max

Flexball Italiana S.r.l.

9

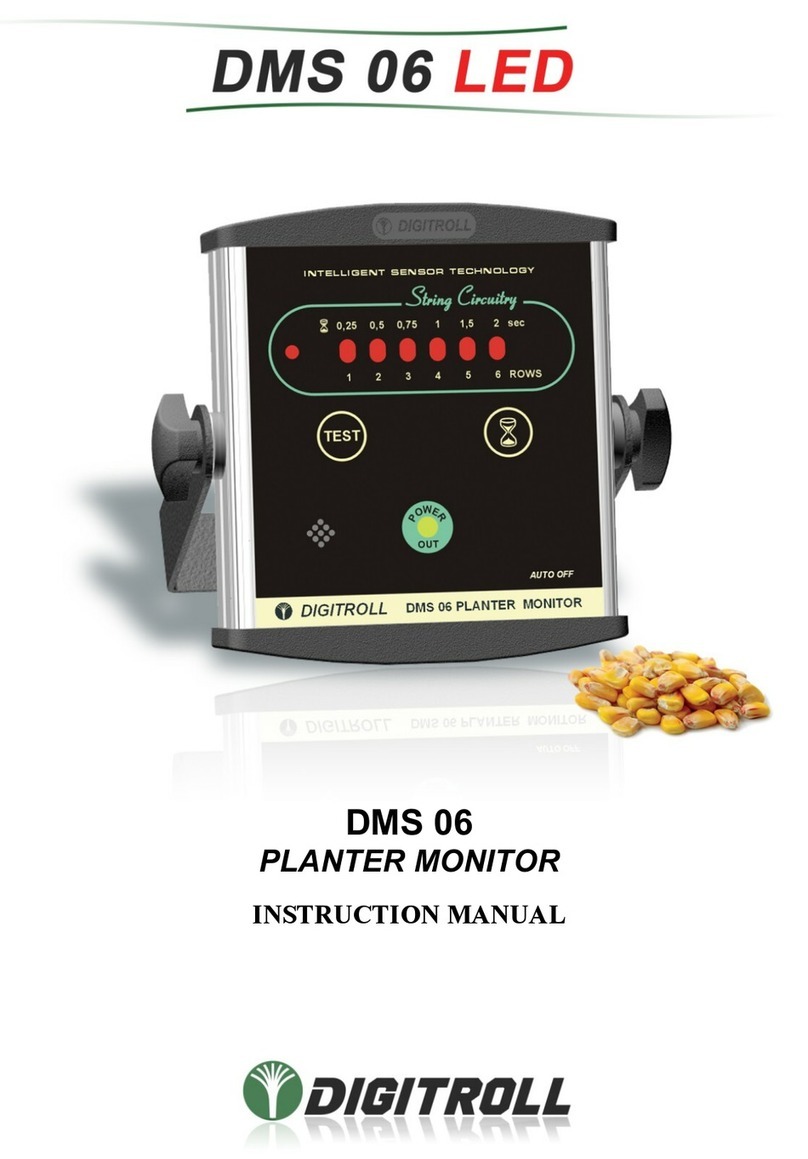

3.1. Control keypad

On each command station are mounted an electronic

keypad, push-buttons and LEDs.

In installations with single engine (*), both the green LEDs

are referring to the same engine. In systems with 2

engines the push button and the green LED on the right

are referring to the starboard engine while the push button

and the green LED on the left side are referring to the port

engine.

To engage the gear you must keep pressed

the push button on the lever in the movement

from neutral to forward or reverse position.

Description LEDs colour

Engine (*) Green

Warm/Sync Yellow

Command Red

Engine (*) Green

Command station series 4000Command station series 3500

Command station series 4200 Command station series 4500

Flexball Italiana S.r.l.

10

It follows the table with the definition of LED and push buttons.

Push-button LED Description

(Command) (Meaning)

Engine

The left LED is for the port (left) engine, while the right LED is for the

starboard (right) engine. If the LED has a fixed light on (green), the

corresponding gearbox is in neutral position.

If the LED is blinking (green), the lever on the LED’s side is synchronised

with the lever of the station that at the moment has the Command.

Command If it is switched off, the Station has not the command.

If is switched on, the Station has the command.

Warm/Sync

If it is blinking, the navigation system is in Warm-up mode; this means that

the engines can be warmed up without clutching-in the gear.

If the LED is fix lighted, the system is in Synchro mode.

Warm/Sync

When both the levers of the Station that has the command are in neutral

position, if you press for 1,5 seconds the button Warm, it is activated the

function Warm-up.

Command

If you press Command for 1,5 seconds the station takes the command, only

if one of these two conditions are respected:

- both the lever of the station are in neutral

- both the lever are synchronized with respect to the levers of the station

that at the moment has the command.

All LEDs are blinking The control system isn’t working correctly.

3.2. Acquisition of the command

It is possible to acquire the command of the boat from any Station in the following cases:

The boat isn’t moving

1. Position all the levers in neutral and press Command for 1,5 seconds.

2. LED “Command” is now lighted on while the warm/synch LED is blinking. You are in Warm-up mode:

throttle command is enabled but clutch command is disabled.

3. To take the command you must press for 1,5 seconds the Warm/Sync bush-button, afterwards the

station acquires the command.

In navigation

1. Synchronize the 2 levers of the Station which wants to acquire the command with respect to the

Station which has the command.

2. When LEDs “Engine” of two levers of the station which wants to acquire the command are blinking,

these levers are synchronised with respect to the levers of the Station which still has the command.

3. By pressing the pushbutton Command for 1,5 seconds, the new Station takes the command.

►Important: before taking the command, proof that all the passengers are safely on board.

3.3. Engine Warm-up

If both levers are in neutral, by pressing for 1,5 seconds the button Warm/Sync of the Station which has the

command, you enter in Warm-up mode. If you move the lever, it is only affected the accelerator but not the

gear. In Warm-up mode the LED Warm/Sync is blinking.

After positioning again both levers in neutral and pressing for 1,5 seconds the Warm/Sync, the system comes

back to the normal operation mode.

Flexball Italiana S.r.l.

11

3.4. Synchro mode

It is possible to command both engines at the same speed and direction with only one lever. This function can

be activated only by the command station which has the command.

With both levers in neutral position, press at the same time for 1,5 seconds the two “engine” push-buttons. The

command of both engines is now on the right lever. In Synchro operation mode, the LEDs “Warm/Sync” and

“Command” are lighted on.

From “Synchro” operation mode, if you position both levers in neutral, and press contemporaneously for 1,5

seconds the two “Engine” push buttons, the command of each engine is again assigned to the respective lever

and LED “Warm/Sync” is switched off.

The same operation of synchronisation or de-synchronisation can be performed on the station which has the

command, in case the RPM between the two engines doesn’t differ more than 10%.

3.5. Fast Start-up Mode

This function is available on the first command station as described in section 7.6 of this manual. When the

configuration FSM (Fast Start-up Mode) is enabled, the command station with the FSM enabled takes

automatically the command at the power on, only if this command station is in neutral position.

If the command station is not in neutral position, the command station will take the command as soon the

neutral position will be reached.

3.6. Emergency lever

In case of emergency, the electronic system can be switched off quickly and the engines can be operated

directly with the mechanical emergency levers.

Emergency levers are fitted

on the control box. It is

sufficient to turn completely

on (clockwise) knob (A). After

this operation, the gearbox

can be operated manually

using levers (B) and with the

throttle set to minimum.

In order to reset the system,

unscrew completely (counter-

clockwise) knob (A). The

emergency lever

automatically goes back to

the position where it was

before activating the

emergency mode, at the first

movement of the command

lever.

Flexball Italiana S.r.l.

12

4. Command station

Command stations are classified as devices for the control of one or two engines, with or without trim/flap

command. After serial number 18500 there can be mounted in the same installation an unlimited number of

command stations, before serial number 18500 the number of command stations in the same installation is

limited to 3; for detailed information look at section 7.7.

Depending on the application, it is very important to set the dip-switches present on the bottom part of the

command station, as described in sections 4.4 and 7.6 of this manual.

How to mount the Command Station

Command stations cannot be directly or indirectly mounted onto sources of vibrations. At chapter 23 of this

manual you find the drilling mask schemes.

4.1. Dimensions

4.1.1. Command station series 3500

►Important: in case the screws to fix command station to the dashboard panel are not long enough, don’t

open the command station to replace them but ask for an adaptation kit.

Flexball Italiana S.r.l.

13

4.1.2. Command station series 4000

4.1.3. Command station series 4200

160

120

200

96 25

170

Flexball Italiana S.r.l.

14

4.1.4. Command station series 4500

4.1.5. Removal of the protective cover (when present)

With the engines switched off and the command station deactivated:

1. move both levers to “ maximum throttle” position;

2. place the fingers of your hand under the slot as shown by the arrow;

3. pull up to the complete removal of the protective cover.

►Important 2: the max water protection of this cover is obtained when both levers are placed in full forward

throttle position.

Flexball Italiana S.r.l.

15

4.2. Friction adjustment

4.2.1. Command station series 3500

To adjust the inner friction of the command lever,

remove the PVC cap (A) and unscrew the fixing

screw. It is possible to adjust the friction screwing

and unscrewing the inner screw placed into the hole

(B). When the regulation will be done, mount the

screw and the plastic cap.

►Important: in case of command station for one

engine, the friction is placed under the right

command lever.

4.3. Programming of the command station

4.3.1. For command stations before serial number 18500

At power up, the command station makes a sequence of two flashes. The first flash identifies the number of

engines and the second identifies the number of actuators present in the system. According to the length of

each flash, the command station is differently configured.

You need to configure the command station in relation to the type of installation. It is also possible to modify

the configuration of the command station by keeping pressed before powering up and continuing to keep them

pressed for 6 seconds after power up, the following push buttons:

Warn/Sync + Command, in this case you want to change the number of actuators

Engine left + Engine right, in this case you change the number of engines on the boat

Possible configurations are according to the following table:

1° flash

(identifies the number of engines)

2° flash

(identifies the number of actuators)

Installation with 1 engine

and 1 actuator Long (3 seconds) Long (3 seconds)

Installation with 2 engines

and 1 actuator Short (less than 1 second) Long (3 seconds)

Installation with 2 engines

and 2 actuators Short (less than 1 second) Short (less than 1 second)

►Important: from the factory, the command station is configured with the first flash short and the second

flash long.

1. To configure the command lever for an installation with 2 actuator boxes, press the push buttons

Warm/Sync e Command before powering up the command station and continue to keep them pressed

for 6 seconds. The lever is now configured for installations with two engines and two actuators. At the

next normal power up, the command lever will make a sequence of 2 short flashes.

2. In case you need to configure again the command lever for installation with 2 engines and 1 actuator,

repeat the procedure of point 1.

Flexball Italiana S.r.l.

16

4.3.2. For command stations after serial number 18500

At power-up, the command station emits a sequence of flashes that depends on the type of station (single or

double) and on the status of the DIP-SWITCH2. The possible behaviours of the command station are the

following:

1. If the station is single lever all the LEDs remain ON for 2s before moving on to the next state; if the

station is double lever, all the LEDs remain ON for 0.25s before moving on to the next state

2. If the DIP-SWITCH 2 is ON, the two central LEDs (Command and Warm-Up) are turned on for

0.25s and then the two side LEDs (Engine) stay ON for another 0.25s. Otherwise the station goes to

the next state

After step 1 and step 2 the station will perform with the normal LEDs management, based on station and

system status.

1° flash

(identifies the number of engines)

2° flash

(only if DIP switch n° 2 is ON)

Installation with 1 engine Long (2 seconds) Short (0,25 seconds)

Installation with 2 engines

Short (less than 0,25 second) Short (0,25 seconds)

Note: the number of flashes corresponding to the number of actuators present in the system (as depicted in

section 4.3.1.) is no longer executed.

4.3.3. 4500 twin-engine stations: how to assign the Synchro function to the

operating lever (after serial number 18500)

By default the Synchro function is assigned to the left lever. It is possible to change or assign the Synchro

function either to the left or to the right lever, following the instructions here below:

1. activate the Synchro as usual

2. bring both levers in neutral

3. press the two push-buttons on the side of the lever that you want to use for the Synchro:

"Engine" left and "Syncro / WarmUp" for the left lever

"Command" and "Engine" right for the right lever

4. keep the push buttons pressed for at least 10s

5. if the operation is successful, the LEDs pair corresponding to the push buttons pressed will flash

The programming is then stored in the device memory. The operation must be repeated for all the control

stations of the system.

Flexball Italiana S.r.l.

17

4.4. Command station label

Under the base of the command station it is present the label here below.

This label reports code and serial number of the command station. The dip-switches configure the command

station according to its position in the CANBus network. The selector of the dip switch is represented in the

nearby label with the black square.

►Important 1: these configurations are valid according to scheme at section 7.1; for different system

configurations please refer to schemes from section 7.2 to 7.5 where are reported the correspondent dip-

switch positions.

►Important 2: in the same installation can’t coexist a “1st command station FSM” and a “1st command

station”. “1st command station FSM” replaces “1st command station” and vice versa.

Dip-switch configuration details

Command station 1

Command station FSM

(Fast Start-up Mode)

Command station 2

Command station 3

Flexball Italiana S.r.l.

18

4.5. Trim/Flap option

Flap/trim command can be activated directly from the command station with the buttons ‘+’ and ‘-’. The

commands are sent to the actuator from the command station. The relay card fitted on the actuator box

activates the flap/trim commands on the hydraulic pump.

For installations with two engines, in case of “Synchro” mode operation, the buttons on the right-hand side

operate the trims of both engines simultaneously.

Command station series 3500

Command station series 4200

Push buttons are placed in the back side of

the control lever.

Press with finger 2 to lift up the TRIM

Press with finger 3 is to move down the

TRIM

Command station series 4500

1 engine version

Trim or flap can be activated directly from the command station with “+” and “-“

pushbuttons. These pushbuttons are placed on the side of the left lever.

2 engines version

1 engine

version

2 engines version

Trim or flap are tuned with “+” and “-“

pushbuttons placed on the keypad (a

couple for each engine).

It is also possible to command in

Synchro trim or flap of both engines with

the “+” and “-“ push buttons placed on

the side of the left lever.

+

Flexball Italiana S.r.l.

19

4.6. Classification of indoor and outdoor installation

The following section is a guideline to help the installer to define if the place where will be mounted the

command station is indoor or outdoor. It follows a list of pictures and examples.

Indoor installation

The command station is installed into a place bordered by ceiling and, at least, three walls, windows or doors.

Considering these conditions, it is impossible that the command station is exposed to rain water and splashes.

Flexball Italiana S.r.l.

20

Outdoor installation

The command station is installed at open air, and it is exposed directly to rain water and splashes.

This manual suits for next models

15

Table of contents

Popular Control System manuals by other brands

Aqua Control

Aqua Control SL3 Deluxe 1,6 l/h manual

Intelligent Lighting Controls, Inc.

Intelligent Lighting Controls, Inc. LightLEEDer Operation manual

ENERCORP

ENERCORP AQT-2000 Installation and operation manual

Delta

Delta NC2B M Series quick start

BM PRO

BM PRO JAYCOMMAND owner's manual

Pro-tec

Pro-tec Algo-Tec 6500 user manual