Digitroll DMS 06 User manual

DMS 06

PLANTER MONITOR

INSTRUCTION MANUAL

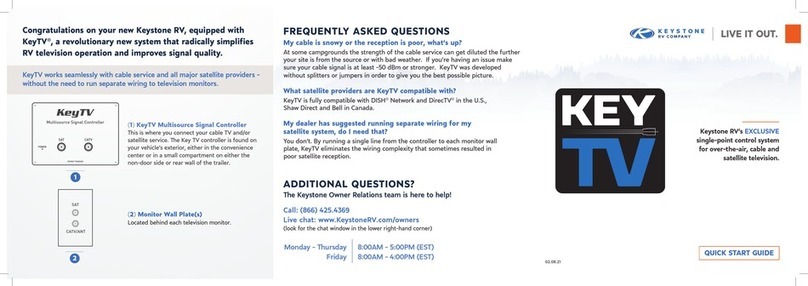

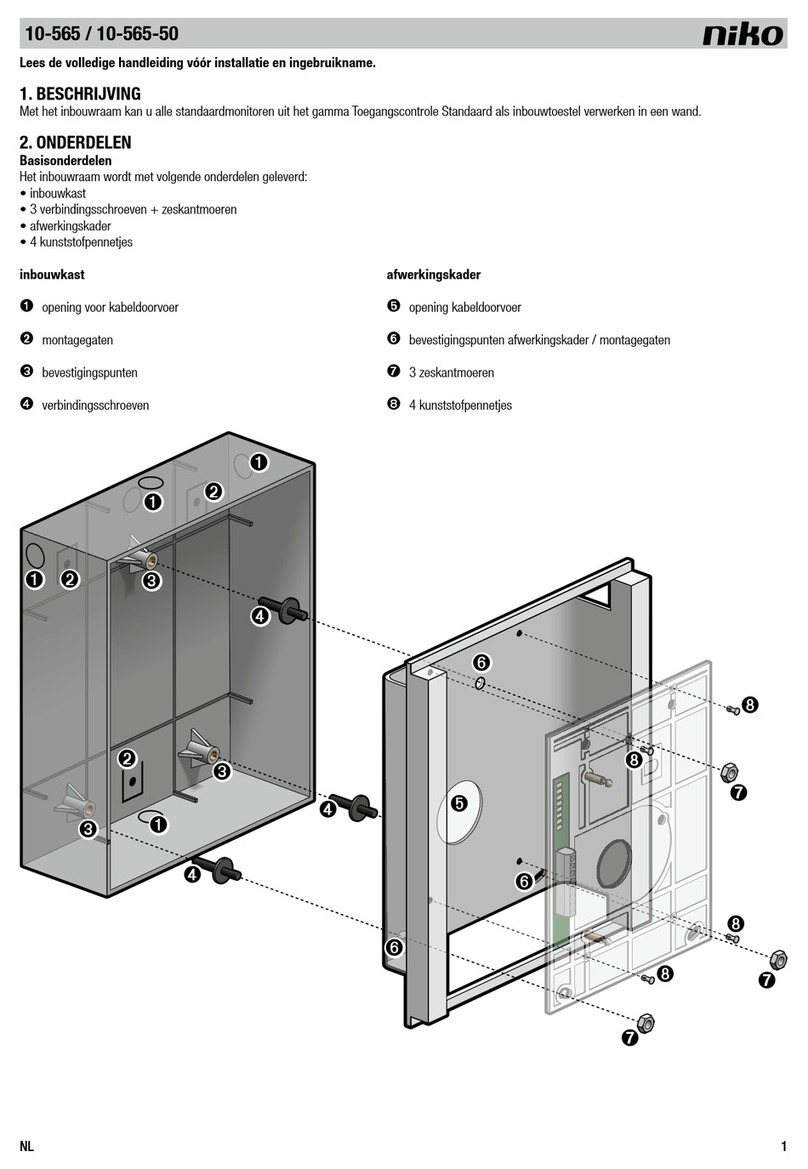

SYSTEM DRAFT

2

SYSTEM DRAFT

3

SYSTEM DRAFT

Planter monitoring system for single seed drills up to 6 rows

AK KU

PIR OS KÉK

OPT

O MODUL

OPT

O MODUL

OPT

O MODUL

OPT

O MODUL

OPT

O MODUL

3.1. 2. 4.

MAX.

6.

DS 1000 VAGY DS 2000 OPTOMODULOK

DA 01 MODUL

5m 12VDC

DS 1000 - tipusfüggő fejkialakítással

magvezető csőhöz

DS 2000 - tipusfüggő fejkialakítással

csoroszlyához

DMS 06 PL ANT ER MO NIT OR

1 2 3 4 5 6 ROWS

AUTO OFF

sec

TES T

PO

E

R

W

OU T

DI GI TROLL

String Circ uitry

0,25 0,5 0,75 11,5 2

INTEL LIGEN T SENSOR TECHNOLO GY

DMS 0 6 MONITOR

DS 1000 OR DS 2000 OPTOMODULES

DS 1000 - With type-dependent head configuration for air hose

DS 2000 - With type-dependent head configuration for coulter

blue

red

GENERAL INFORMATION

4

TABLE OF CONTENTS

SYSTEM DRAFT .......................................................................................................... 2

GENERAL INFORMATION ......................................................................................... 4

INSTALLATION ........................................................................................................... 5

CONTROL DEVICE ...................................................................................................... 5

TURNING THE SYSTEM ON ...................................................................................... 6

SYSTEM TEST .............................................................................................................. 6

SEEDING CONTROL ................................................................................................... 6

SEED SHORTFALL THRESHOLD FOR ERROR INDICATION .............................. 6

MAINTENANCE, STORAGE ....................................................................................... 7

WARRANTY ................................................................................................................. 7

TROUBLESHOOTING ................................................................................................. 8

TABLE OF SEED SHORTFALL .................................................................................. 9

GENERAL INFORMATION

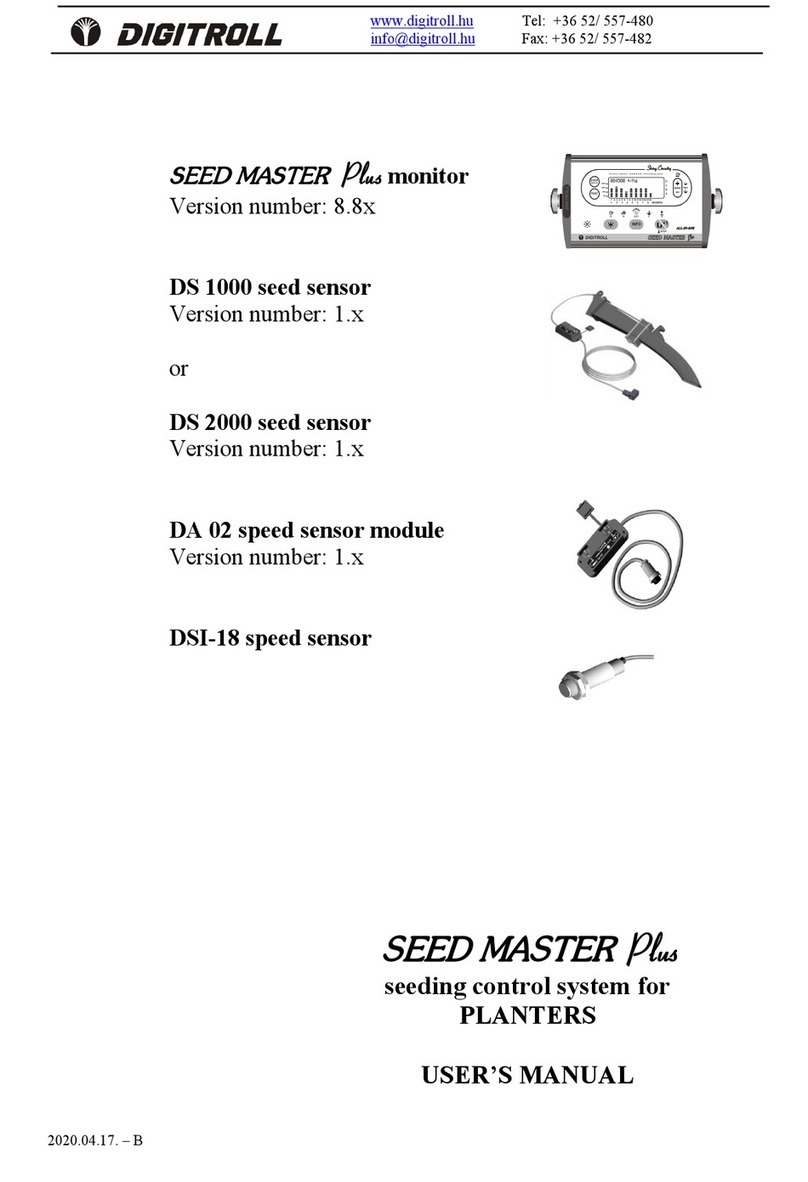

DMS 06 MONITOR

· Durable aluminium case

· Audible and visual alarms

· Automatic shut-down

SYSTEM CONFIGURATION

· Photosensor modules, infrared sensors

· Modules in chain-linked array up to 6 rows

· Modules are interchangeable, their sequence is determined when

connected

· Harness-free network – easy cabling and mounting

SYSTEM TEST

Sensor diagnostics to:

· identify the operability and number of photosensors

· detect and display dust accumulation or blockage of seed sensors

SEEDING CONTROL

· Simultaneous display for the operation of all seeding rows

· Adjustable duration of seed shortfall for error indication. The

sensitivity of error indication for a given seeding speed can be

determined experimentally or on the basis of the Table of Seed

Shortfall

INSTALLATION

5

INSTALLATION

MONITOR LOCATION

The monitor has to be mounted in the compartment at a well visible place with

the attaching clip being in lower or upper position using 2 plate screws. Avoid

direct sunlight to reach the display. The most favourable location for the

monitor is right under the compartment roof.

• The monitor is to be connected to the 12V system of the power machine

behind a minimum 1A fuse with regard to polarity (red = positive, blue =

negative). The wire between the connection point and the 12V

accumulator of the power machine should be as short as possible.

• Connect the sensors’ extension cable to the monitor.

• Do not share power supply with devices that may cause interference (fans,

magnetic valves, etc.).

• Welding works are only allowed when both power cables of the monitor

are disconnected from the tractor’s electronic system.

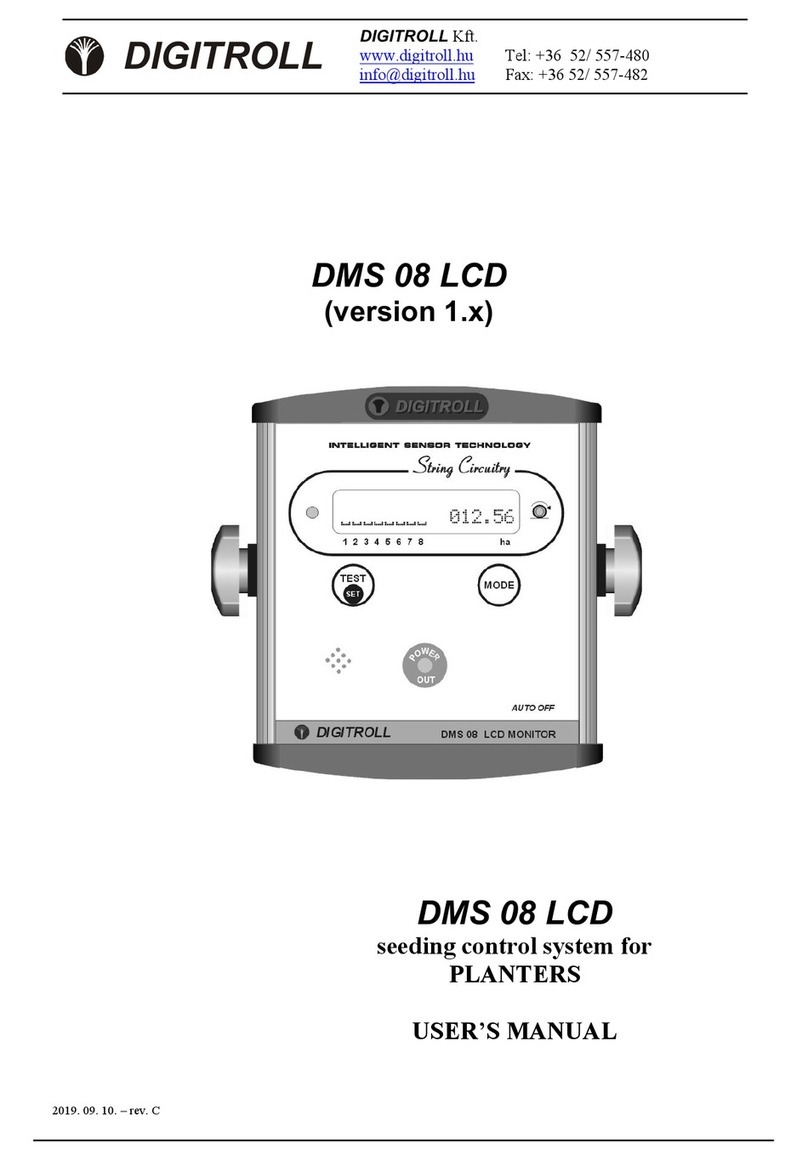

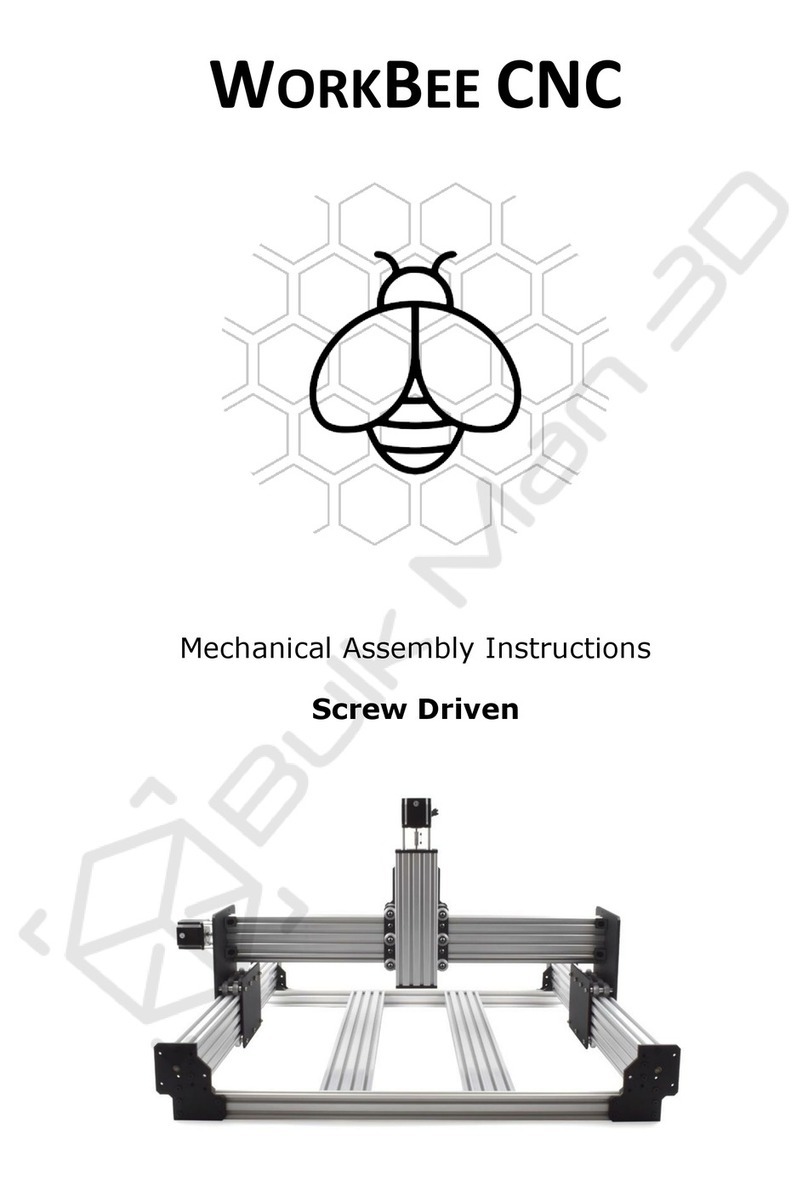

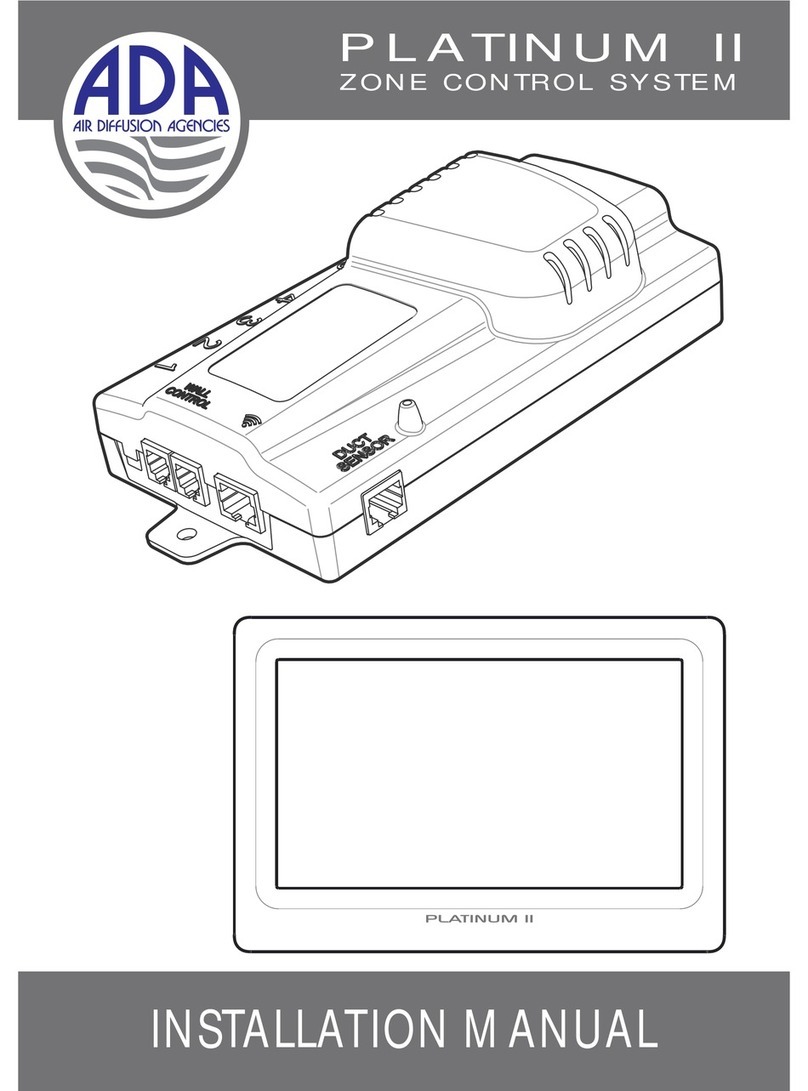

CONTROL DEVICE

DMS 06 PLANTER MONITOR

1 2 3 4 5 6 ROWS

AUTO OFF

sec

TEST

P

O

W

E

R

OUT

DIGITROLL

StringCircuitry

0,25 0,5 0,75 11,5 2

INTELLI GENT SEN SOR TECHNOLOGY

Horn

ON and TEST button

(searching seed

sensors, checking

dust level)

Stand-by signal

(red light)

Switched on, 12V OUT= continuous light

Sensor search = darkens for a short time

Cable short = dark during operation

Switched off = dark

error = red light

Selectable time

intervals (0.25 – 2 sec)

Number of seeder

elements (1-6)

Adjusting sensitivity of

error indication

(max. time period of

seed shortfall)

TURNING THE SYSTEM ON

6

TURNING THE SYSTEM ON

Press the button. Upon turning the device on, a system test is performed.

Then the device is ready to monitor the interruptions in the seeding process.

SYSTEM TEST

This test is performed:

• every time the monitor is turned on,

• upon pressing the button.

TEST function is to be used only if seeding is not in progress!

During the test process, the monitor detects the number and status of seed

sensors (operability, dust level check).

Once the test is completed, “found” modules are displayed:

• properly working photosensors: continuous red light,

• sensors require cleaning: flashing light and intermittent sound.

SEEDING CONTROL

The unit simultaneously monitors the seed flow in each row. If seed flow is

continuous, the LED is off. In case flow is interrupted e.g. because of

blockage, incorrectly set seed sweeper, low vacuum, etc. for longer than the

previously set shortfall tolerance time value, an audible alarm is given and the

LED related to the given row turns on.

The length of audible alarm correlates to the duration of shortfall. The audible

alarm is automatically skipped when the power machine is turning.

SEED SHORTFALL THRESHOLD FOR ERROR

INDICATION

On the monitor front the scale above the LEDs indicate the seed shortfall

tolerance time related to the LEDs.

By keeping the button pressed, the red light “circulates” on the display.

The time value above the LED lighting when the button is released will be the

selected threshold value.

Checking the selected value: press the button once. The red light flashes

above the selected value.

Selectable time intervals: 0.25, 0.5, 0.75, 1, 1.5 and 2 seconds.

MAINTENANCE, STORAGE

7

See the Table of Seed Shortfall on the last page for further information.

When started after shutdown, the default setting of 2 seconds is applied. When

started after automatic switch-off, the last threshold value is used.

MAINTENANCE, STORAGE

• The most important is to maintain and periodically check that cables and

connectors are intact.

• Sensor heads must always be cleaned at the end of each season (even if no

dust is indicated) and extension cable connectors must be sealed off

watertightly.

• Monitor cannot be exposed to direct moisture and temperatures below –20

ºC and above +40 °C. Protect from dust and excessive heat. Remove

monitor from compartment during winter and store at a dry and moisture-

free place.

• Protect front panel, display and keypad from mechanical damage. Monitor

may be cleaned with a slightly damp, soft cloth.

• There are no batteries or accumulators in the device or other part requiring

maintenance.

WARRANTY

See the WARRANTY CARD enclosed.

TROUBLESHOOTING

8

TROUBLESHOOTING

Malfunction

Possible cause

Resolution

Device cannot be switched

on.

Stand-by LED (red light on

the left) is off.

Reverse polarity.

Interruption in supply

current circuit.

Defective monitor

Check polarity.

Check the power machine’s

mains, fuse panel, etc.

Return it to the manufacturer or

one of its services.

The green "POWER ON"

LED is off or flashes but

then goes off.

Power outage in the wires

of seed sensors or the

circuitry causes overload,

thus, the monitor limits or

switches off power output.

Seek the cause of power outage

by visual inspection and moving

the cables. The defective part has

to be replaced.

Connect the sensors to the

monitor section by section to find

the unit where the green light

goes off. This one is the cause of

power outage.

The monitor does not

detect some or all of the

seed sensors during the

Test. Some of the seed

sensor LEDs is off.

Damaged connecting leads

or loose connector causes

disturbance in power

supply.

Check whether the red LEDs on

seed sensors are on in normal

position. Disconnect the module

indicated with the first dark LED

in the sequence or the module

before this one. Check

connectors.

The monitor does not

detect some of the seed

sensors during the TEST.

The sensors are indicated

with red light.

Communication error

caused by a broken cable

or loose connector.

Check the first module indicated

as faulty or the module before

this one. Tighten connectors.

Sensor does not indicate

drilling, seeds are not

sensed. TEST indicates

high dust level.

Sensor is blocked or

defective.

Carefully insert an object (e.g. a

screwdriver) into the sensor head.

The LED should be darkened for

a moment. If module does not

react, it has to be cleaned or

replaced.

TABLE OF SEED SHORTFALL

9

TABLE OF SEED SHORTFALL

Seeding speed: 4 km/h

Seeding speed: 9 km/h

Seed 6

0,25

0,50

0,75

1,00

1,50

2,00

Seed 6

0,25

0,50

0,75

1,00

1,50

2,00

shortfall (m)

0,28

0,56

0,83

1,11

1,67

2,22

shortfall (m)

0,63

1,25

1,88

2,50

3,75

5,00

Plant

spacing (cm)

Number of seeds

Plant spacing

(cm)

Number of seeds

6

4

9

13

18

27

37

6

10

20

31

41

62

83

8

3

6

10

13

20

27

8

7

15

23

31

46

62

10

2

5

8

11

16

22

10

6

12

18

25

37

50

12

2

4

6

9

13

18

12

5

10

15

20

31

41

14

1

3

5

7

11

15

14

4

8

13

17

26

35

16

1

3

5

6

10

13

16

3

7

11

15

23

31

18

1

3

4

6

9

12

18

3

6

10

13

20

27

20

1

2

4

5

8

11

20

3

6

9

12

18

25

22

1

2

3

5

7

10

22

2

5

8

11

17

22

24

1

2

3

4

6

9

24

2

5

7

10

15

20

26

1

2

3

4

6

8

26

2

4

7

9

14

19

Seeding speed: 6 km/h

Seeding speed: 10 km/h

Seed 6

0,25

0,50

0,75

1,00

1,50

2,00

Seed 6

0,25

0,50

0,75

1,00

1,50

2,00

shortfall (m)

0,42

0,83

1,25

1,67

2,50

3,33

shortfall (m)

0,69

1,39

2,08

2,78

4,17

5,56

Plant spacing

(cm)

Number of seeds

Plant spacing

(cm)

Number of seeds

6

6

13

20

27

41

55

6

11

23

34

46

69

92

8

5

10

15

20

31

41

8

8

17

26

34

52

69

10

4

8

12

16

25

33

10

6

13

20

27

41

55

12

3

6

10

13

20

27

12

5

11

17

23

34

46

14

2

5

8

11

17

23

14

4

9

14

19

29

39

16

2

5

7

10

15

20

16

4

8

13

17

26

34

18

2

4

6

9

13

18

18

3

7

11

15

23

30

20

2

4

6

8

12

16

20

3

6

10

13

20

27

22

1

3

5

7

11

15

22

3

6

9

12

18

25

24

1

3

5

6

10

13

24

2

5

8

11

17

23

26

1

3

4

6

9

12

26

2

5

8

10

16

21

Seeding speed: 8 km/h

Seeding speed: 12 km/h

Seed 6

0,25

0,50

0,75

1,00

1,50

2,00

Seed 6

0,25

0,50

0,75

1,00

1,50

2,00

shortfall (m)

0,56

1,11

1,67

2,22

3,33

4,44

shortfall (m)

0,83

1,67

2,50

3,33

5,00

6,67

Plant spacing

(cm)

Number of seeds

Plant spacing (cm)

Number of seeds

6

9

18

27

37

55

74

6

13

27

41

55

83

111

8

6

13

20

27

41

55

8

10

20

31

41

62

83

10

5

11

16

22

33

44

10

8

16

25

33

50

66

12

4

9

13

18

27

37

12

6

13

20

27

41

55

14

3

7

11

15

23

31

14

5

11

17

23

35

47

16

3

6

10

13

20

27

16

5

10

15

20

31

41

18

3

6

9

12

18

24

18

4

9

13

18

27

37

20

2

5

8

11

16

22

20

4

8

12

16

25

33

22

2

5

7

10

15

20

22

3

7

11

15

22

30

24

2

4

6

9

13

18

24

3

6

10

13

20

27

26

2

4

6

8

12

17

26

3

6

9

12

19

25

Example: Seeding speed = 8 km/h Plant spacing = 16 cm

We want the monitor to indicate error if 2-3 successive seeds are missed. Select 0.25 sec. The

machine covers a distance of 0.56 m. This is the maximum length of seed shortfall. If this value

is exceeded, an alarm is given immediately.

TABLE OF SEED SHORTFALL

10

TABLE OF SEED SHORTFALL

11

TABLE OF SEED SHORTFALL

12

Table of contents

Other Digitroll Control System manuals

Popular Control System manuals by other brands

Graco

Graco Horizon Fluid Management Systems instructions

Aritech

Aritech RF-4041-07-2 Installation sheet

LK Systems

LK Systems Wired Room Control NC Assembly instructions

Siemens

Siemens SINUMERIK 802S Technical manual

Helios

Helios WHSH HE 24 V 0-10 V Installation and operating instructions

Triple Plus

Triple Plus CLM Installation & operation manual