Flexicon BULK-OUT BFC User manual

FLEXICONBULK-OUT®

Bulk Bag Discharger

Models: BFC, BFF & BFH

Installation and Operation Manual

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 1 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

FOREWORD

Thank you for purchasing a BULK-OUT®Bulk Bag Discharger from FLEXICON®. Please refer to the

following instructions for installing and operating your FLEXICON®Bulk Bag Discharger system. If

you encounter any problems which prevent safe reliable installation and / or operation of the system,

please call the FLEXICON® service department immediately to address any concerns you may have.

The BULK-OUT®Bulk Bag Discharger appearance may be slightly different than the details depicted

in this manual. Any differences do not affect the function, designed capacity, or operation of the

equipment.

FLEXICONCorporation has made every effort to ensure the accuracy and validity of this document

however errors and omissions may have occurred. If an error or omission is found, please contact

FLEXICONCorporation.

No part of this publication may be distributed, reproduced or transmitted in any form without the

written permission of the FLEXICONCorporation.

Familiarity with Manual and Regulations

In order for this machine to be installed, operated, cleaned & maintained safely, all of the provisions

of this manual and all other applicable codes and regulations, some of which have been referred to

herein, must be strictly adhered to. Codes and regulations enacted to protect personnel from hazard

of injury may change from time to time. It is the customer’s responsibility to remain familiar with, and

to comply with all codes, and regulations related to this equipment or its use. It is also the customer’s

responsibility to teach its employees how to operate the equipment properly, including how to

recognize and avoid risks. All personnel who will be involved in installing, operating, cleaning or

maintaining the system should be given a copy of this manual to read, and follow.

Documentation Package

Each bulk material handling system from Flexicon®is supplied with a USB Flash Drive containing a

Documentation Package that was specifically prepared for the equipment provided. This Flash Drive

contains manuals, drawings, schematics, video clips and spare parts lists that will be a useful

reference for proper installation, operation, and maintenance of your system. If you cannot locate

this Flash Drive then please see the Contacting FLEXICON®page of this manual for the telephone

number and the information required to identify your material handling system and its components.

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 2 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

TABLE OF CONTENTS

TABLE OF FIGURES 3

CONTACTING FLEXICON®

Telephone and Fax Numbers 4

Hours of Operation 4

System Identification 4

INTRODUCTION

Safety Terms & Summary 5

Equipment Safety Warnings 6

Applicable FLEXICON®Equipment 7

INSTALLATION

Standing up the Base Frame 9

Locating the Base Frame 10

Anchoring the Base Frame 10

Assembling the BFF Frame 11

Assembling the BFC Frame 12

Electric Hoist Wiring 15

Pneumatic Hoist Air Connection 15

OPERATION

Connection of bulk bag Loops to Z-CLIP™16

Connection of bulk bag Liner 16

Loading a bulk bag into a BFF Frame 17

Loading a bulk bag into a BFC Frame 17

OPTIONAL EQUIPMENT

FLOW-FLEXER®Bulk Bag Agitation Device 19

Operation 19

Adjustment 20

Load Cells 20

POP-TOP®Bulk Bag Elongation Option (BFF only) 21

Power-Cincher®Flow Control Valve 22

TELE-TUBE®Telescoping Tube 22

CVD Interface with Iris Valve 22

CVD Operation 22

MAINTENANCE

Maintenance Instructions 23

LONG TERM STORAGE 24

SPARE PARTS 25

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 3 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

TABLE OF FIGURES

Figure 1: Sample Serial Number Nameplate 4

Figure 2: Base Frame Arrangement 10

Figure 3: BFF Frame Arrangement 11

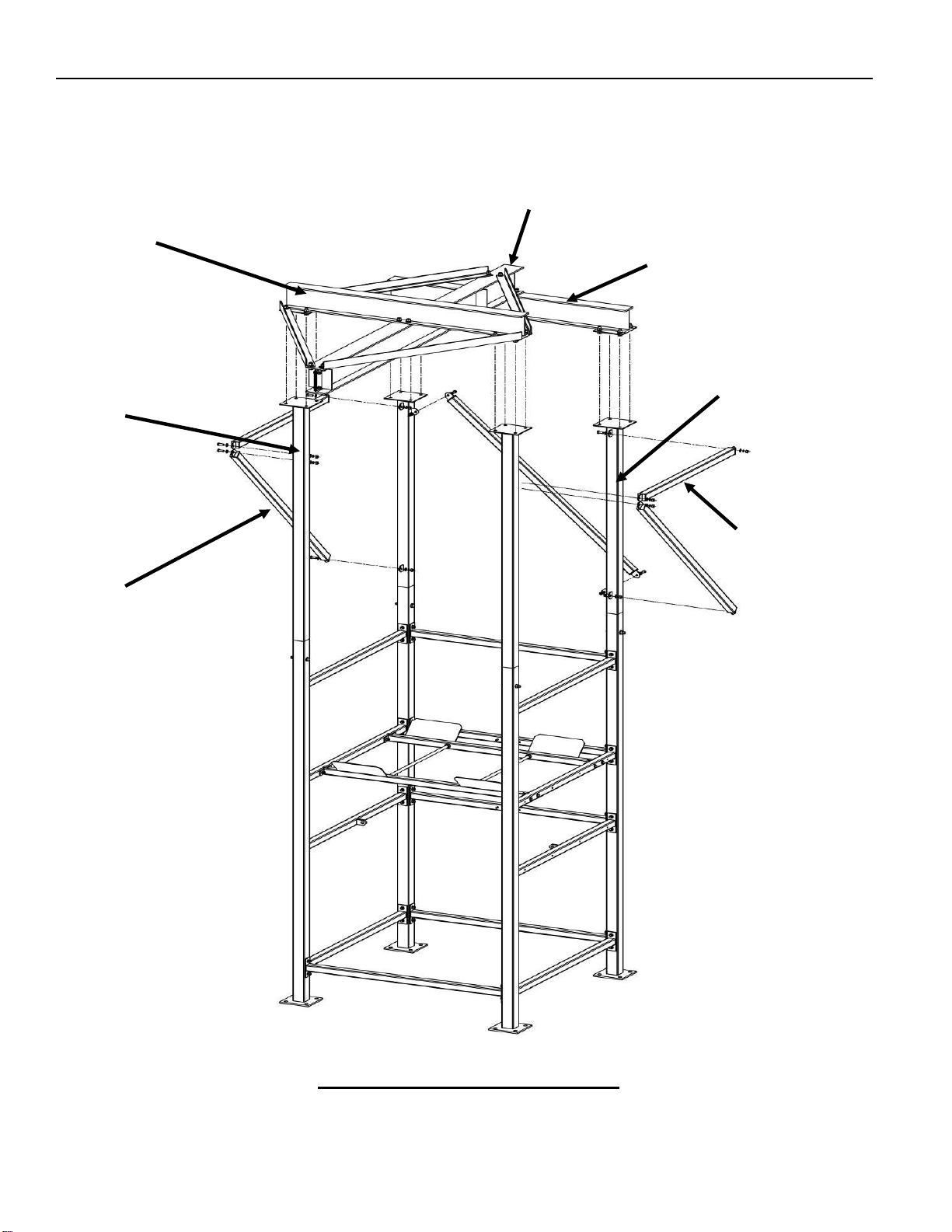

Figure 4: BFC Frame Arrangement 12

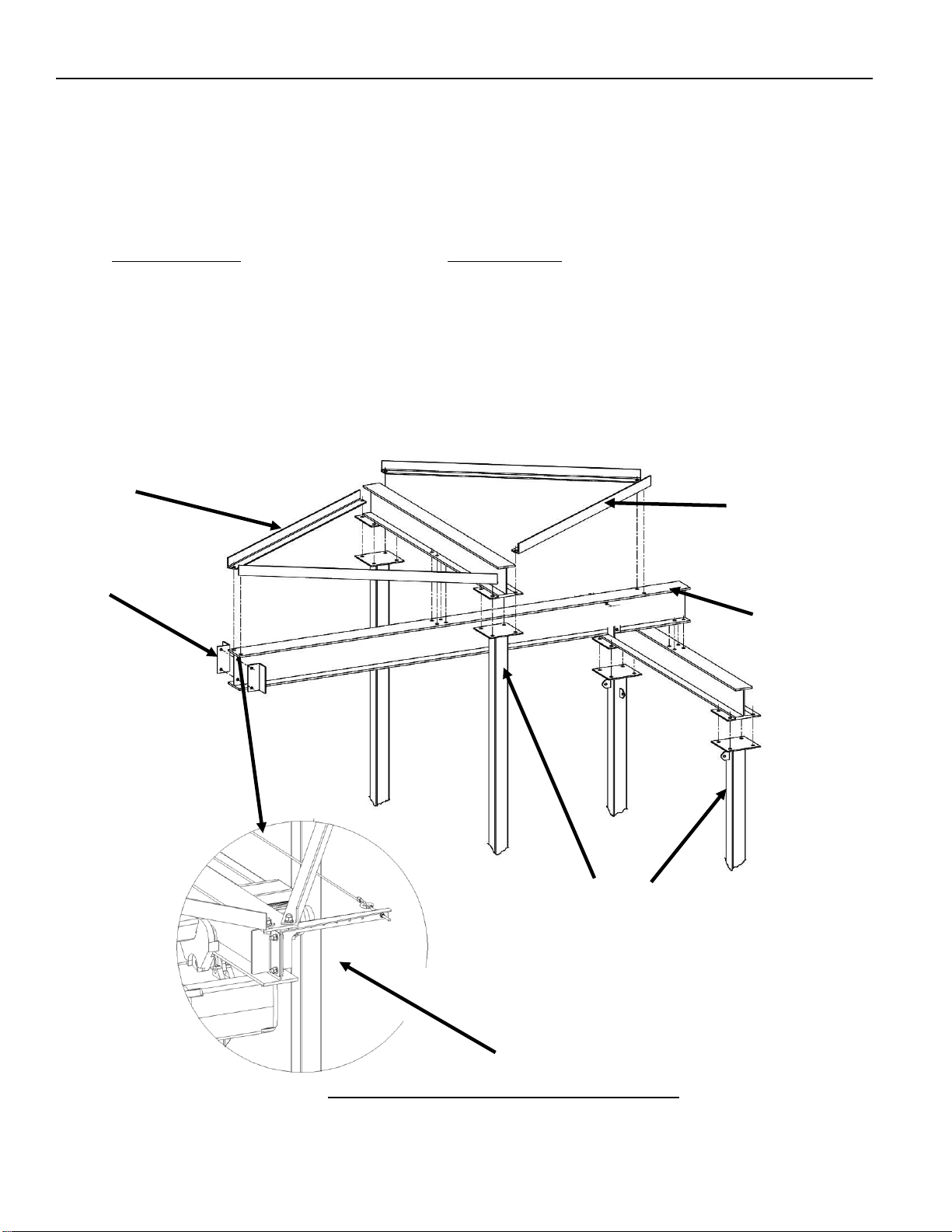

Figure 5: BFC Hoist I-Beam Assembly 14

Figure 6: BFC Hoist Festooning Assembly 15

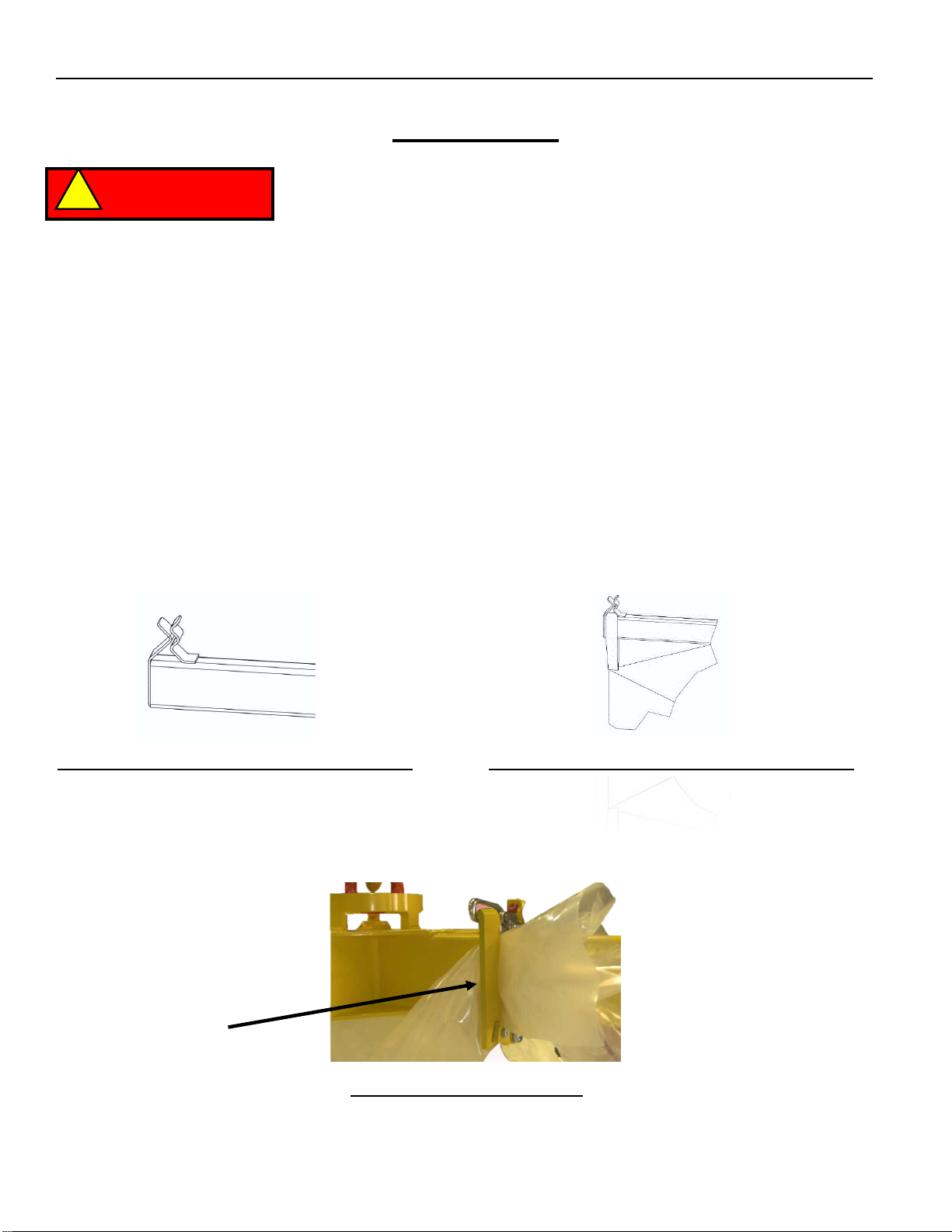

Figure 7: Z-CLIP™Bag Loop Retainer 16

Figure 8: Bag Loop Location in Z-CLIP™16

Figure 9: Bag Liner Clamp Connection 16

Figure 10: Bag Lift Position 18

Figure 11: Bag Lift Frame Orientation 18

Figure 12: Swaying Bulk Bag 18

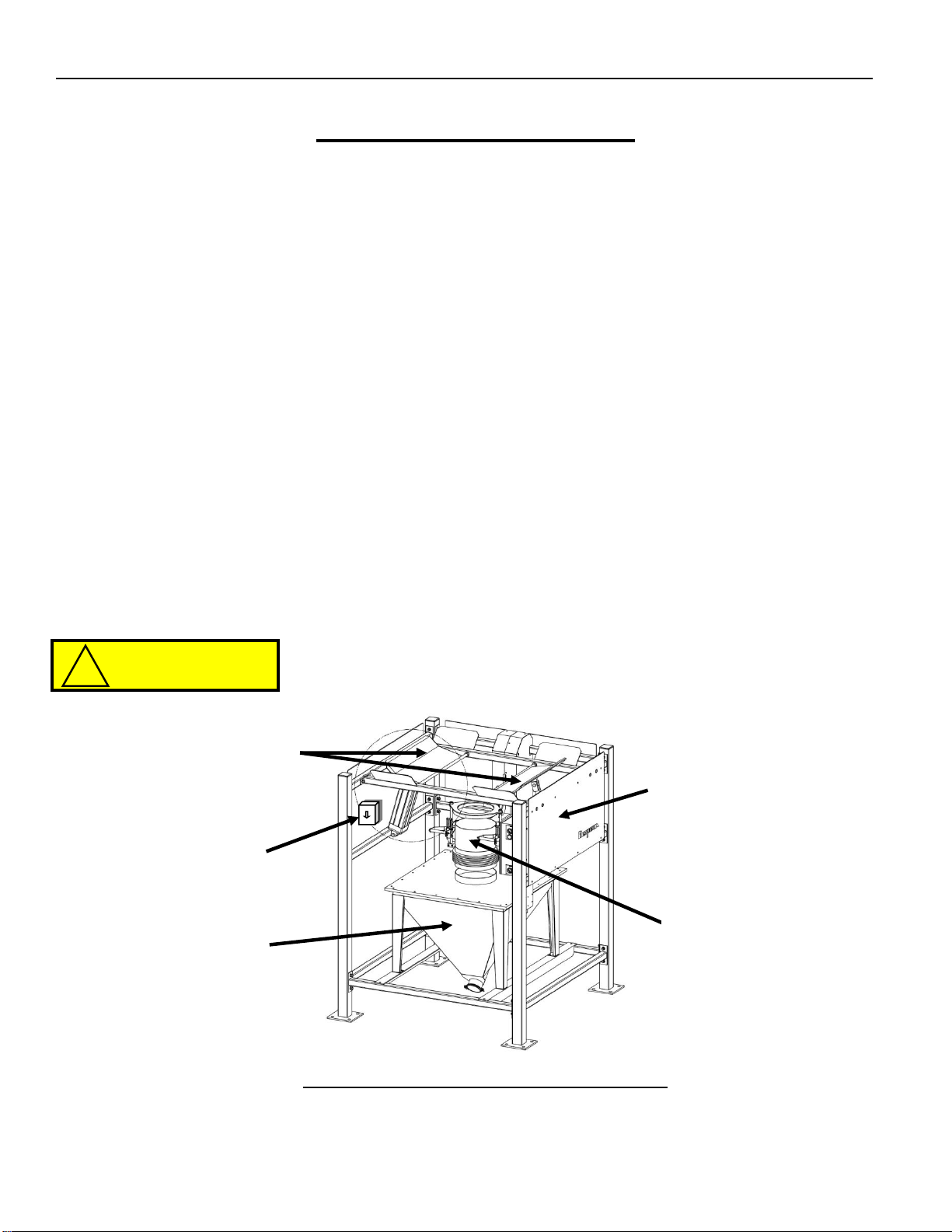

Figure 13: FLOW-FLEXER®Arrangement 19

Figure 14: FLOW-FLEXER®Assembly 20

Figure 15: Assembly of POP-TOP®Extension Arms 21

Figure 16: CVD Interface with Iris valve 22

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 4 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

CONTACTING FLEXICON

Telephone and Fax Numbers

Phone: 1-888-FLEXICON[1-888-353-9426]

610-814-2400

Fax: 610-814-0600

FlexiconOfficial Site: www.flexicon.com

Flexicon Parts Department:

Phone: 610-814-2400 ext. 10660 or 10692

Email: [email protected]

Hours of Operation

Monday through Friday 8:00 am to 5:00 pm E.S.T.

System Identification

The system will have a Serial Number nameplate similar to the example below that will be attached to

the equipment near the base in the operator access point.

Figure 1: Sample Serial Number Nameplate

12345

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 5 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

INTRODUCTION

Safety Terms and Summary

This manual provides important information for personnel involved in the installation, operation, and

maintenance of this product. Even though you may be familiar with this, or similar equipment, it is

highly recommended that you read this manual before installing, operating, or maintaining this

particular equipment.

Throughout this manual there are steps and procedures that can present hazardous situations. The

following words are used to identify the degree or level of hazard seriousness.

Notice is used to notify people of installation, operation,

or maintenance information which is important but not

directly hazard-related.

Danger indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury, and property damage.

Warning indicates an imminently hazardous situation which, if

not avoided, could result in death or serious injury, and

property damage.

Caution indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury, or property damage.

!

CAUTION

!

DANGER

!

WARNING

!

!

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 6 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

Equipment Safety Warnings

Please read this section prior to installing your system.

Locating and installing the FLEXICON® BULK-OUT®Bulk Bag Discharger is a very important step in

the correct and efficient use of this equipment. We recommend that you follow these procedures to

achieve complete satisfaction.

FLEXICON® BULK-OUT®Bulk Bag Discharger Base Frames are supplied factory assembled. If in a

rare occasion it has been supplied unassembled contact Flexicon for more information.

Do not use the FLEXICON® BULK-OUT®Bulk

Bag Discharger for materials other than which it

was specified for. If you wish to add new

materials please consult with FLEXICON®before

doing so.

Make sure the vent tube on the hopper cover, if

supplied, is fitted with a filter sock before

discharging a Bulk bag.

Do not mount peripheral equipment on the Bulk

bag Frame.

Do not allow individuals to stand on any part of

the frame or under any bulk bags as they are

being loaded or unloaded.

DANGER

!

Do not allow tools, rags, bags (other than Bulk

bags called for in the specifications) to remain in

or enter the system during its operation.

Do not allow agglomerating or hygroscopic

material to remain in the FLEXICON®BULK-

OUT®Bulk Bag Discharger for extended periods

of time. These materials may tend to set up or

become hard making it difficult to discharge the

Bulk bag.

DANGER

For jobs installed in any classified hazardous areas

ensure the system is fully grounded before use.

!!

!

Periodically check that all bolted connections

are tight, as they might become loose in transit

or during operation.

CAUTION

!

CAUTION

!

DANGER

!

DANGER

!

!

!

!

!

!

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 7 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

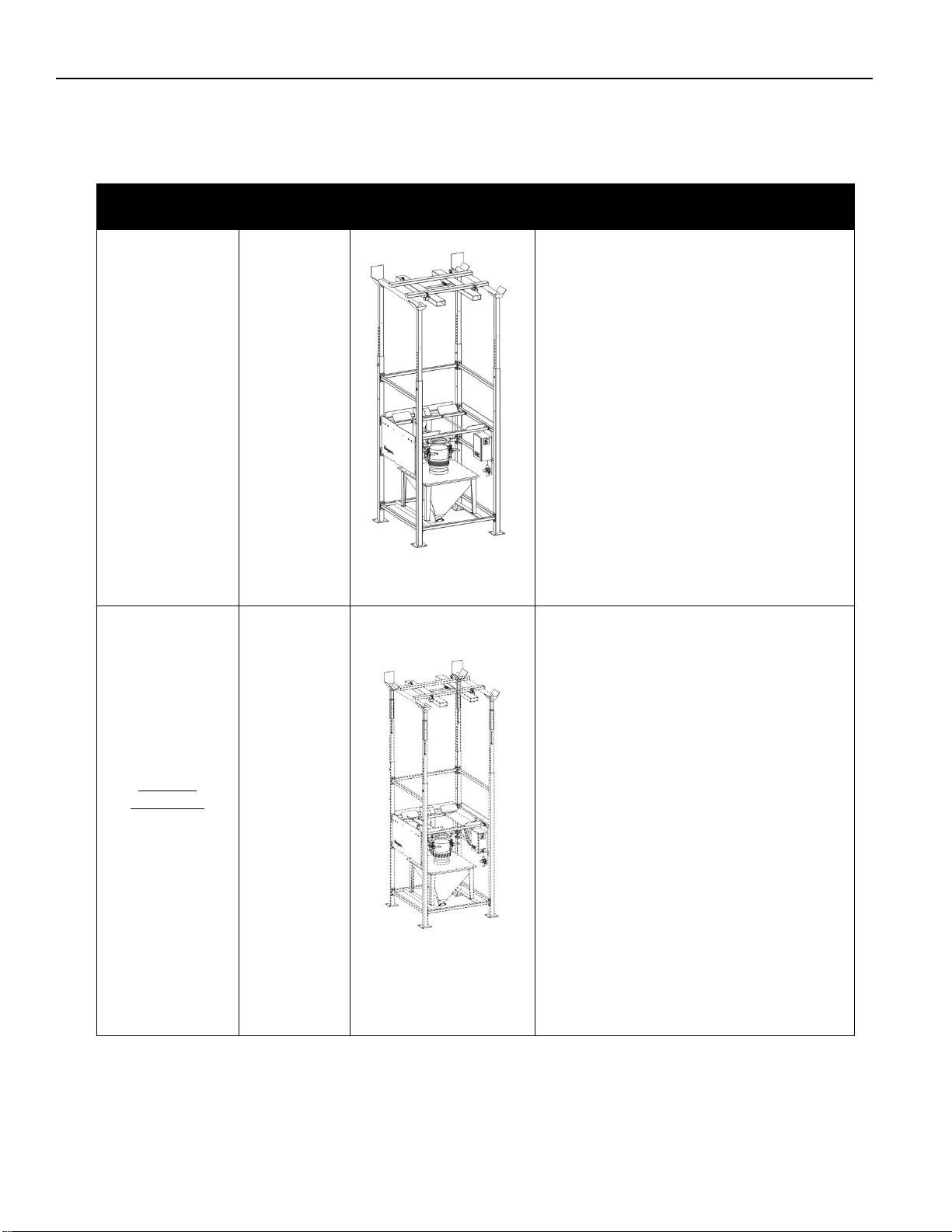

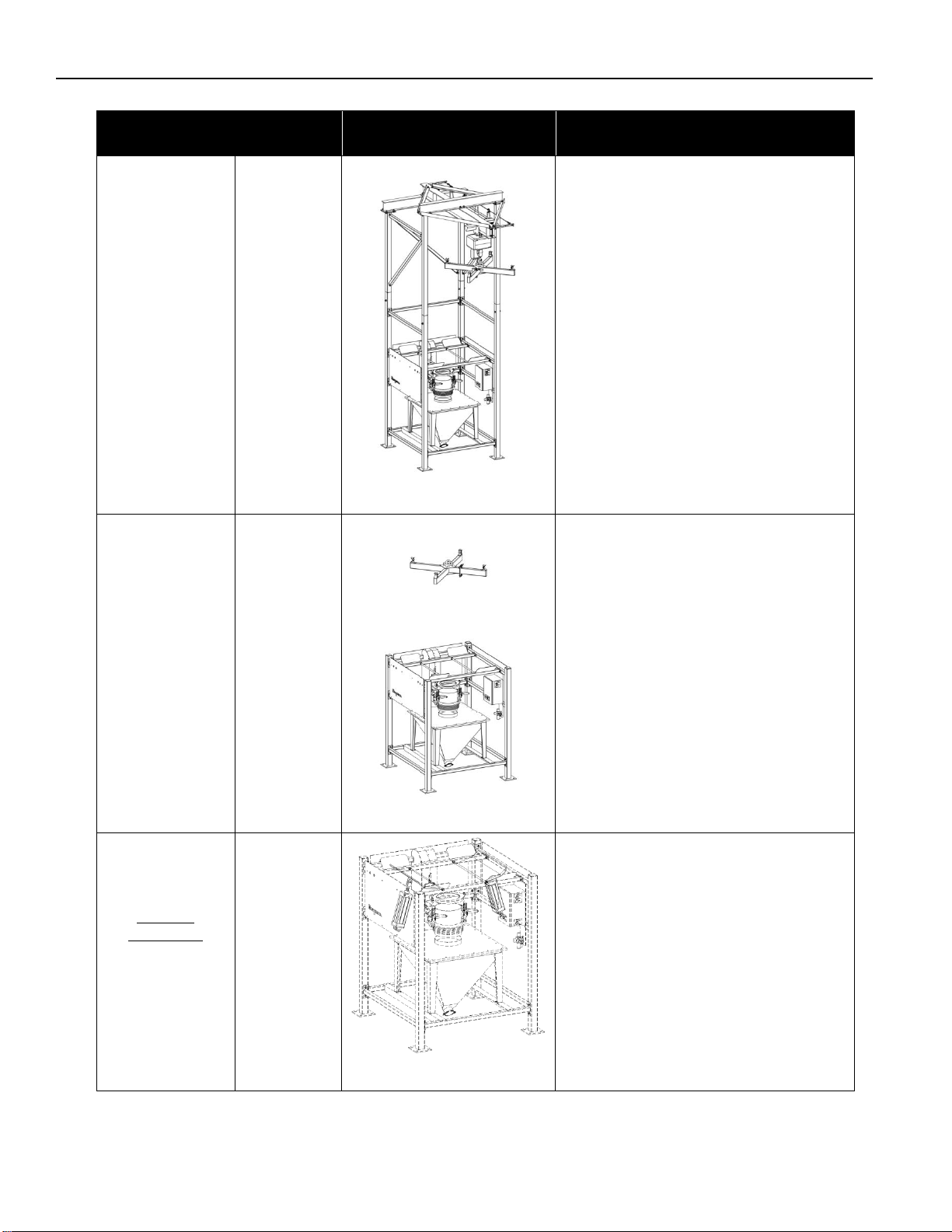

Applicable FLEXICON®Equipment

Equipment

Model

Reference

Overview

BULK-OUT®

Bulk Bag

Discharger

BFF

BFF-X-X

Front View

The BFF BULK-OUT®Bulk Bag

Discharger incorporates a

forkliftable bulk bag lifting frame

which facilitates loading of the bulk

bag into the frame as well as

support it during the emptying

process. The BFF includes four

independent, adjustable extension

arms which accommodate bags

weighing up to 4000lb and ranging

from 36”to 84” high with a maximum

width of 36” at the bag seam and

48” at the widest parts when full.

Optional

Equipment

POP-TOP®

PTP-X

Front View

This option replaces the standard

extension arms with periscoping

extension arms that incorporate a

gas spring mounted inside each.

These four independent, adjustable,

periscoping extension arms

compensate for bulk bag elongation

during the emptying process. As the

weight of the material in the bulk

bag decreases, the arms

compensate by raising the bag lifting

frame that is attached to the straps

of the bulk bag. The POP-TOP®

accommodates bags weighing up to

4000lb and ranging from 36” to 84”

high with a maximum width of 36” at

the bag seam and 48” at the widest

parts when full.

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 8 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

Equipment

Model

Reference

Overview

BULK-OUT®

Bulk Bag

Discharger

BFC

BFC-X-X

Front View

The BFC BULK-OUT®Bulk Bag

Discharger incorporates a

cantilevered I-beam with a

powered hoist and trolley to lift

and position a bulk bag into the

frame. The BFC frame, hoist &

trolley, and lifting frame

accommodate bags weighing up

to 3200lb and ranging from 36” to

72” high with a maximum width of

36” at the bag seam and 48” at

the widest parts when full.

BULK-OUT®

Bulk Bag

Discharger

BFH

BFH-X-X

Front View

The BFH BULK-OUT®Bulk Bag

Discharger requires a customer

supplied lifting mechanism to

elevate and suspend a bulk bag

over the frame. The BFH

includes a standard hoist style

bag lifting frame and a safety

frame with all provisions for

mounting a FLOW-FLEXER®. It

is designed for a maximum

3200lb capacity bulk bag with a

maximum width of 36” at the bag

seam and 48” at the widest point

when full.

Optional

Equipment

FLOW-FLEXER®

Bulk Bag

Agitation Device

FFX-XX

Front View

The FLOW-FLEXER®Bulk Bag

Agitation Device is designed to

increase bulk bag discharge for

difficult, semi to non-free flowing

materials. Two pneumatically

driven ‘paddles’ raise and lower

the bottom edges of a bulk bag to

direct material into the bag outlet

spout. They also raise the bag

into a steep ‘V’ shape to promote

total evacuation of material.

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 9 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

INSTALLATION

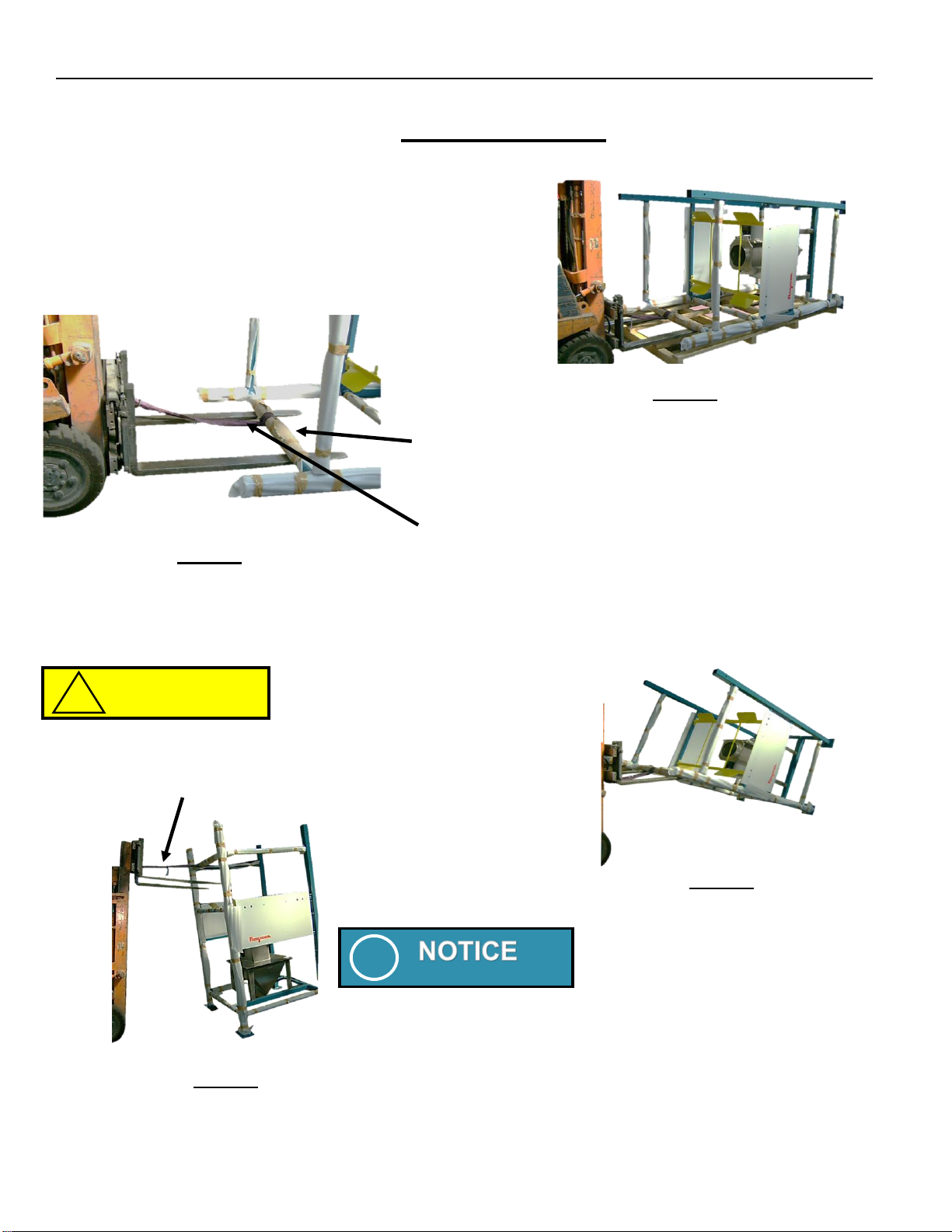

Standing up the base frame

Once the frame is standing upright

it is important to note the

orientation of operator access and

bag load side. With a standard

configuration the bulk bag is

loaded from the same side as

operator access.

Ensure that a safety strap is attached to the frame

and the fork lift. It must be at located at least 12

inches SHORTER than the fork length to assure

the frame will be secured to the fork lift truck.

Use a suitable fork lift truck that is capable of lifting to

a height of no less than 8 feet. Raise both ends of the

frame just enough to slide out the pallet.

Insert Forks centrally under the horizontal cross

bar that is opposite the foot pads as shown.

Avoid making contact with the Safety Frame.

Raise forks while driving forward slowly until

the balance point is reached.

STEP 1

STEP 3

STEP 2

STEP 4

Keep moving forward slowly and

beware that frame will swing

forward. Avoid a rapid descent.

CAUTION

!

The strap will hold the frame from dropping too rapidly.

!

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 10 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

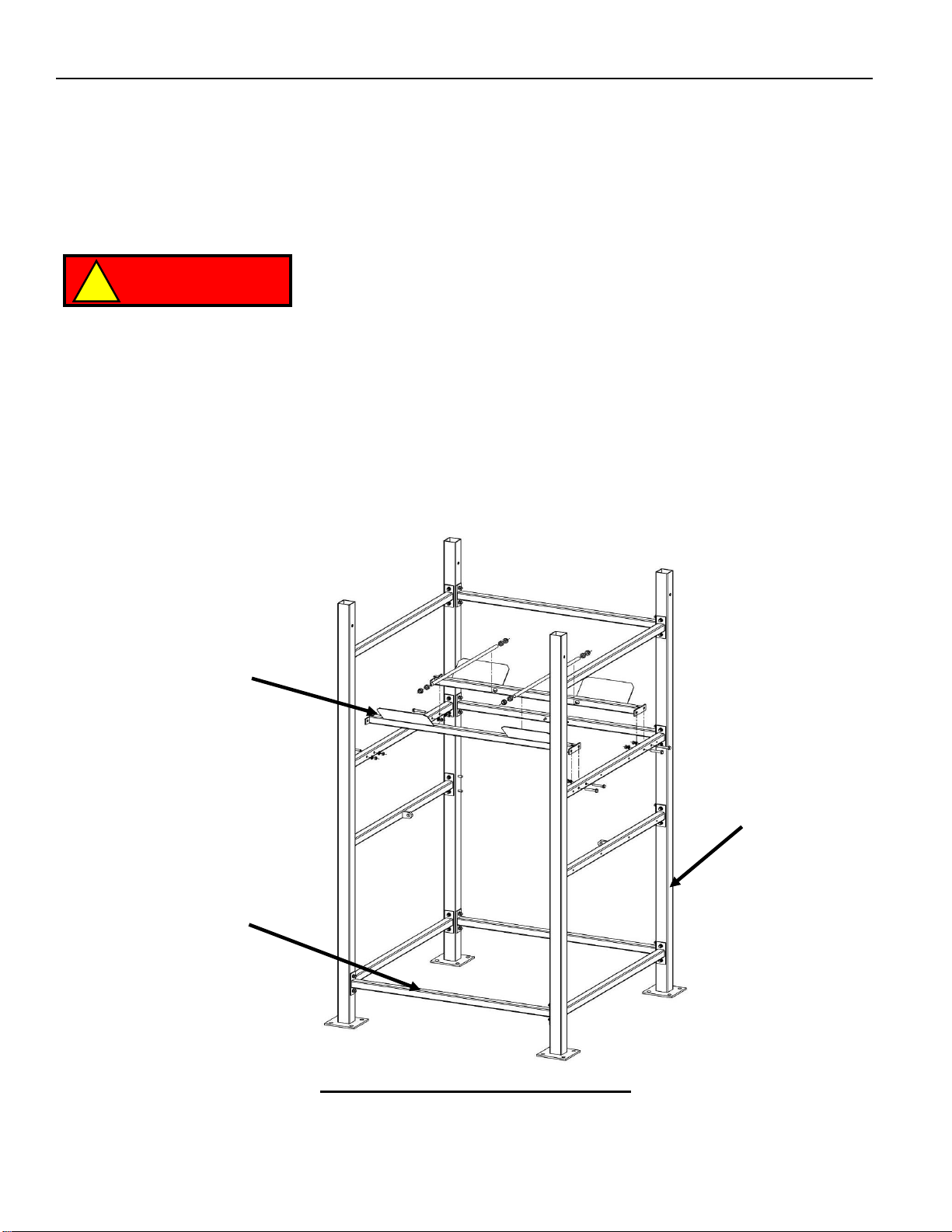

Locating the Base Frame

Ensure that the foundations are suitable to withstand the full load of the frame. If applicable, see the

Load Cell information located in the ‘Optional Equipment’ section of this manual.

Anchoring the Base Frame

Anchor the base frame to the foundation using the appropriate SAE Grade 5 (or better) hardware.

Flexicon®recommends that the customer consults with a civil engineer or local professional engineer

to evaluate floor substrates and specify the type and depth of floor anchors required. (16)

bolts/anchors are typically needed.A standard FLEXICON® BULK-OUT®Bulk Bag Discharger base

frame is shown below in Figure 6. It can be assembled into either a BFC or BFF Frame. There is a

removable cross brace on the operator access side which can be unbolted and removed temporarily

to allow for easier installation of other components that are to be located inside the frame such as a

floor hopper or similar items. The brace is to be bolted back in place after the component(s) has

been installed inside the frame.

Figure 2: Base Frame Arrangement

Safety

Frame

Standard

Base Frame

Once the Base Frame is located it must then be anchored to

the foundation using the appropriate hardware. Failure to

do so could result in the frame tipping over.

DANGER

!

Removable

Brace

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 11 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

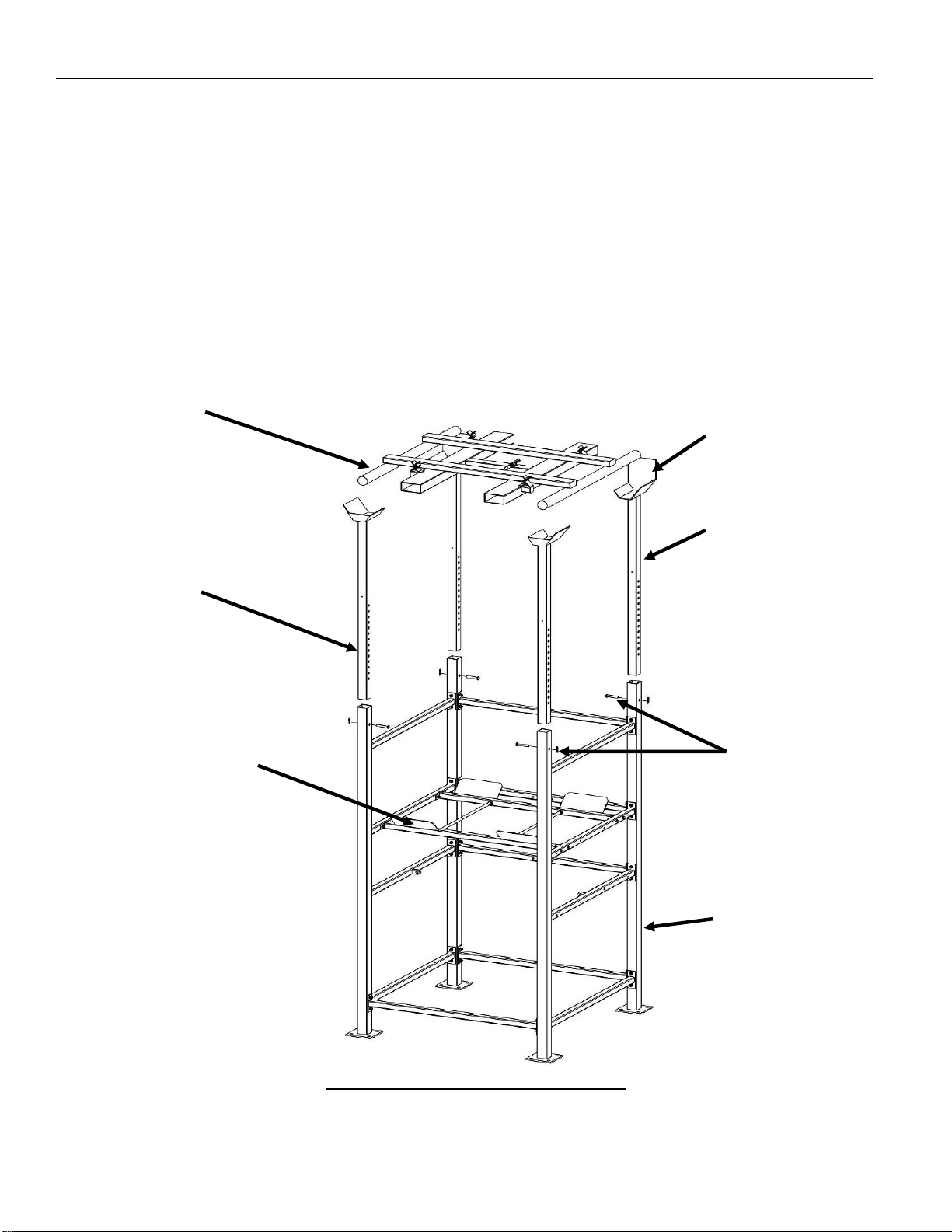

Assembling the BFF Frame

The POP-TOP®or Extension Arms are inserted into the Base Frame to the lowest height setting and

secured with (4) 5/8” diameter x 3 ½” long clevis pin/safety clips.

Note: there are (2) Rear Extension Arms (Left and Right) and (2) Front Extension Arms (Left and

Right) which must be positioned as shown in Figure 7.

The height of the Extension Arms are adjusted (in 2” increments) to accommodate the size of bulk

bag. The height is correctly set when the bottom of the bulk bag is 1” to 2” above the center of the

Safety Frame (with or without a FLOW-FLEXER®).

Figure 3: BFF Frame arrangement

BFF Forkliftable Bag

Lifting Frame

(2)-Rear

Extension Arms or

POP-TOP®

Extension Arm

(Left and Right)

Standard Base

Frame

(2)-Front

Extension Arms or

POP-TOP®

Extension Arm

(Left and Right)

(4) Receiving Cups

Safety Frame

(4) Clevis Pins /

Safety Clips

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 12 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

Assembling the BFC Frame

Figure 4: BFC Frame arrangement

Hoist I-Beam

Back Cross

Beam

(2)Rear

Extension Arms

(2)Horizontal Cross

Braces

(3) Diagonal

Cross Braces

(2)Front

Extension Arms

Front Cross

Beam

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 13 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

•Begin by installing the (4) extension arms (See Figure 4). There are (2) identical front

extension arms, (1) left hand back extension arm and (1) right hand back extension arm. The

front extension arms are longer than the rear arms and have only two tabs at the top. The

right hand back arm has two tabs 90 degrees opposed to each other at the bottom of the arm.

The left hand back arm has three tabs, one located at the bottom and the other two located at

the top which are 90 degrees opposed to each other.

•Assemble the arms in their respective legs. Be sure to orient them as shown in Figure 8.

Secure them in place with (1) 3/4”-10 bolt, (2) 3/4”-10 flat washers, (1) 3/4”-10 split lock washer

and (1) 3/4”-10 hex nut per leg. Torque the hardware to 130 ft/lbs for stainless steel and 270

ft/lbs for carbon steel.

•Assemble the back cross beam to the top of the rear extension arms (See Figure 5). Attach

using (8) 3/4”-10 bolts, (16) 3/4”-10 flat washers, (8) 3/4”-10 split lock washers and (8) 3/4”-10

hex nuts.

•Assemble the front cross beam to the top of the front extension arms (See Figure 5).

Assemble using (8) 3/4”-10 bolts, (16) 3/4”-10 flat washers, (8) 3/4”-10 split lock washers and

(8) 3/4”-10 hex nuts.

•Install both horizontal cross braces to the frame tabs provided using (4) 1/2”-13 bolts, (8) flat

washers, (4) split lock washers, and (4) 1/2”-13 hex nuts (See Figure 8).

•Install the (2) rear end stops onto the hoist beam using (2) 1/2”-13 bolts, (4) 1/2”-13 flat

washers, (2) 1/2”-13 split lock washer and (2) 1/2”-13 hex nuts.

•Assemble the hoist beam to the front and rear cross beams (See Figure 6).

•Assemble using (8) 3/4”-10 bolts, (16) 3/4”-10 flat washers (8) 3/4”-10 split lock washers and

(8) 3/4”-10 hex nuts.

•Assemble the (3) diagonal cross braces (see figure 3). The orientation of the braces will be

self-evident. Attach using (6) 1/2”-13 long bolts, (12) 1/2”-13 flat washers, (6) 1/2”-13 split lock

washer and (6) 1/2”-13 hex nuts.

•Assemble the (2) rear hoist beam braces which connect between the outside bolt on the front

cross beam/front extension arm assembly, to the holes provided on top of the hoist beam at

the back (See Figure 5). There is (1) left and (1) right hand rear hoist brace. There is an angle

cut on one end of each brace and it will be self-evident as to the proper orientation.

Throughout this entire procedure, whenever a connection is made with

either ½”-13 or ¾”-10 hardware, DO NOT fully tighten it to the final

torque spec unless otherwise specified. Thread the nut only to the point

where it engages the split lock washer then, using a wrench, tighten the

nut ½ turn! This allows for final alignment before tightening to final

torque.

!

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 14 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

•Install the (2) front hoist beam braces to the top of the frame assembly in the same manner as

above (See Figure 5).

•Square the various components of the BFC upper section and tighten all hardware to the

following final torque specification:

Stainless Steel: Carbon Steel:

1/2”-13 to 40 ft/lbs 1/2”-13 to 75 ft/lbs

3/4”-10 to 130 ft/lbs 3/4”-10 to 270 ft/lbs

•Assemble the hoist onto the hoist beam as per the manufacturer’s manual supplied.

•Install the (2) front end stops onto the hoist beam using (2) 1/2”-13 bolts, (4) 1/2”-13 flat

washers, (2) 1/2”-13 split lock washer and (2) 1/2”-13 hex nuts.

Figure 5: BFC Hoist Beam Arrangement

Note bolt

orientation

(2) Rear

Hoist Beam

Braces

(2) Front

Hoist Beam

Braces

(2)End

Stops

Hoist Beam

Note height

difference between

extension arms

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 15 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

•Install the hoist festooning assembly as shown on Figure 6.

Electric Hoist Wiring

The main power cord for the hoist will require a connection to a customer supplied junction box that is

to be located on the back of the frame near the top. Note that with a standard hoist, FLEXICON®will

provide enough cord to be draped through the festooning cable assembly and extend to the back of

the frame near the top. Customer must run their main power supply to this location.

Pneumatic Hoist (Optional)

If your system is supplied with an optional pneumatic hoist it will require an air hose connection

directly into the hoist. FLEXICON®provides the festooning assembly only. The air connection for a

pneumatic hoist must include a customer supplied filter and lubricator installed between the air source

and air hose running to the hoist. (Where applicable see hoist manufacturer’s manual).

Hoist

Main Power Cord

Wire Rope

Tensioner

Wire Rope

Tensioner

Cable

Pulleys

Wire Rope

Figure 6: BFC Hoist Festooning Assembly

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 16 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

OPERATION

Connecting Bag to Z-CLIP™Bag Loop Retainers

The Z-CLIP™ Bag Loop retainer is shown in Figure 7. Slide bag strap through all (4) Z-CLIP™ bag

loop retainers until the bag strap is sitting correct as per Figure 8.

Connection of bulk bag Liner

If the bulk bag being used is supplied with a liner then the bulk bag liner should be connected to the

liner clamp supplied. Figure 9 shows the bulk bag Liner attached to the liner clamp.

Liner Clamp

Figure 9: Bag Liner Clamp

Figure 7: Z-CLIP™ Bag Loop Retainer

DANGER

!

Figure 8: Bag Loop Location in Z-CLIP™

It is the responsibility of the owner/user to install, inspect, test,

maintain, and operate all lifting equipment in accordance with

local, national, and international regulations. All personnel that

interact with lifting equipment must read and understand any

and all operating instructions or manuals that pertain to this

equipment. If the owner/user requires additional information, or

if any information provided in the manuals is unclear, contact the

manufacturer for clarification or further instructions. Do not

install, inspect, test, maintain, or operate any lifting equipment

unless the information is fully understood.

A regular schedule of inspection of lifting equipment should be

established and records maintained in accordance with any and

all applicable regulatory requirements.

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 17 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

Loading a bulk bag onto a BFF Frame

•Remove the bulk bag lift frame from the receiving cups using a forklift truck. Note that the

length of the forks on the forklift truck must be a minimum of 61 ½” long.

•Position the bulk bag lift frame a short distance over the top of the bulk bag.

•Pass the loops of the bulk bag over and onto the self-retaining Z-CLIP™bag loop retainers.

•Raise the bulk bag lift frame and bulk bag with a forklift truck and position over the receiving

cups on top of each Extension Arm.

•Lower the bulk bag lift frame into the cradles, which self-centers the bulk bag in the BULK-

OUT®Bulk Bag Discharger.

•The bulk bag should sit 1” to 2” above the safety frame.

Loading a bulk bag onto a BFC Frame

•With the hoist and trolley positioned all the way out on the overhung end of the beam, lower

the Bag Lift Frame via the hoist. Always position the bulk bag so that the center of the bag is

as close to the centerline of the Bag Lift Frame as possible. See Figure 10. The acceptable

window of operation is no more than 6 inches of misalignment between the center lines of the

bag and the frame when beginning the lift.

•Position the bag lift frame a short distance over the top to the bulk bag and Pass the loops of

the bulk bag over and into the self-retaining Z-CLIP™ bag loop retainers. Note the orientation

of the Bag Lift Frame which should be positioned square to the Discharger. See Figure 11.

•Raise the bulk bag and lift frame with the hoist only to a height of 2 inches off the ground and

stop lifting. Ensure the bulk bag is not swaying in any direction before proceeding.

•Raise the bulk bag and bag lift frame and bulk bag via the hoist then traverse the hoist and

trolley to the center of the frame.

•Lower the bag lifting frame and bulk bag via the hoist until the bulk bag sits 1” to 2” above the

safety frame.

Lift and traverse the bulk bag in a smooth continuous

fashion. Starting and stopping can cause undesirable

swaying of the bag. See Figure 12.

At no time should an operator stand under the bulk

bag when it is being lifted into or out of the frame.

CAUTION

!

DANGER

!

WARNING

!

Do not rest a Bulk Bag on the safety frame cross brace.

Doing so can interfere with proper operation of the

equipment and potentially create an unsafe condition.

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 18 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

Figure 12: Swaying Bulk Bag

Figure 11: Bag Lift Frame Orientation

Figure 10: Bag Lift Position

Top View

Front View

Front View

FLEXICON®BULK-OUT®Bulk Bag Discharger Installation and Operation Manual - 19 -

FLEXICON CORPORATION 2400 Emrick Boulevard ■ Bethlehem, PA 18020-8006 USA

Tel: 1-888-FLEXICON ■ Tel: 1-610-814-2400 ■ Fax: 1-610-814-0600 ■ www.flexicon.com

Copyright 2003 FLEXICON®

OPTIONAL EQUIPMENT

Available options for the FLEXICON® BULK-OUT®Bulk Bag Discharger:

•FLOW-FLEXER®Bulk Bag Agitation Device

•POP-TOP®Bulk Bag Elongation Option (BFF only)

•POWER-CINCHER®Flow Control Valve

•TELE-TUBE®Telescoping Tube (Single and double wall)

•Iris Valve and CVD Interface

•Load Cells

•Hoist and Trolley Option (BFC only)

FLOW-FLEXER®Bulk Bag Agitation Device (Option)

Two pneumatically driven ‘paddles’ raise and lower the bottom edges of a bulk bag to direct material

into the bag outlet spout. The bag is also raised into a steep ‘V’ shape to promote total evacuation of

material.

FLOW-FLEXER®Operation

To operate the FLOW-FLEXER®, turn the selector switch to ‘ON’ and ‘Off’ as required. Where

applicable the operation may also be controlled automatically from a remote PLC or control panel.

The timer is factory set at 3 seconds “On” with 7 second “Intervals”.

The operator who is in control of the FLOW-FLEXER®should be

aware at all times of other personnel in the immediate area.

Figure 13 : FLOW-FLEXER®Arrangement

Side Safety

Shields

FLOW

FLEXER®

Control

Panel

(Optional)

Hopper

(2) FLOW

FLEXER®

Paddles

(Optional)

Teletube

CAUTION

!

This manual suits for next models

2

Table of contents

Other Flexicon Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT567639 Operation manual

WEISS

WEISS NR Series Mounting instructions

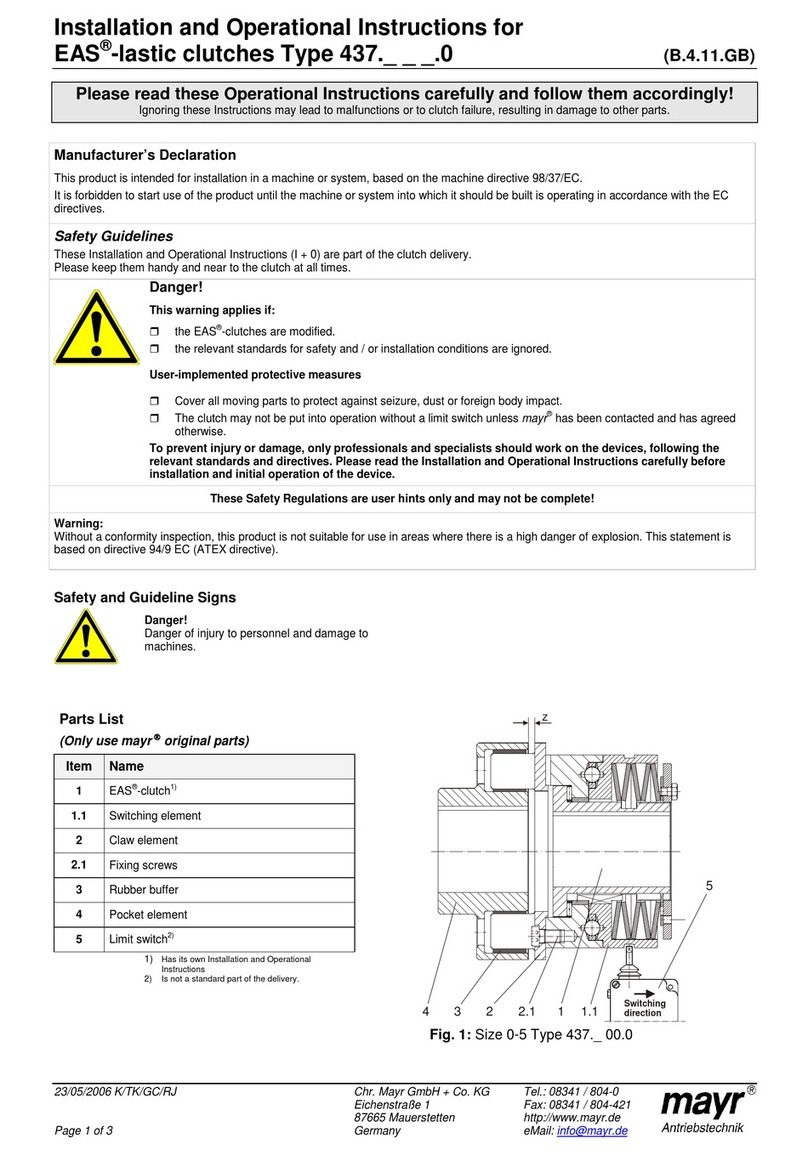

Mayr

Mayr EAS 437 Series Installation and operation instructions

stellar labs

stellar labs TireMan 4110 owner's manual

Siemens

Siemens SINUMERIK ONE NCU 1760 Equipment manual

Hypertherm

Hypertherm EDGE Ti Lifter Repair Field Service Bulletin

Yamaha

Yamaha SIGMA-G5SII Service information

Thermal Edge

Thermal Edge A2W30120 User's & technical manual

Doosan

Doosan 7/124 Operation & maintenance manual

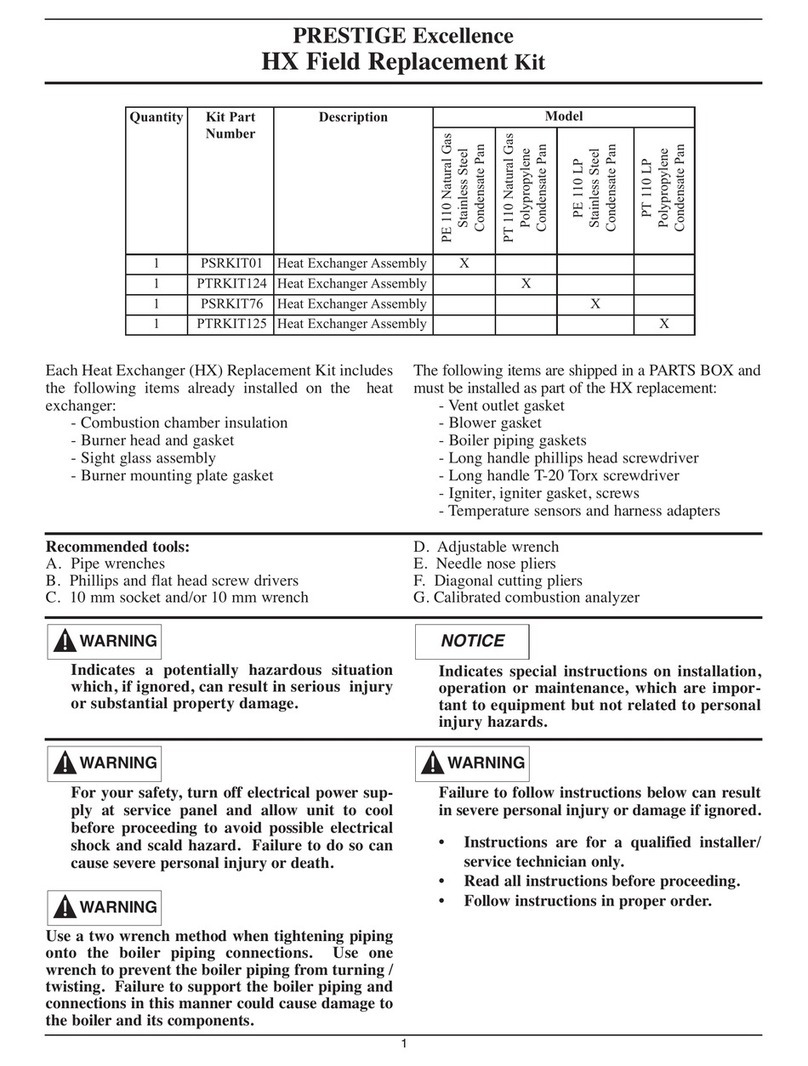

TriangleTube

TriangleTube PRESTIGE Excellence Series manual

Graco

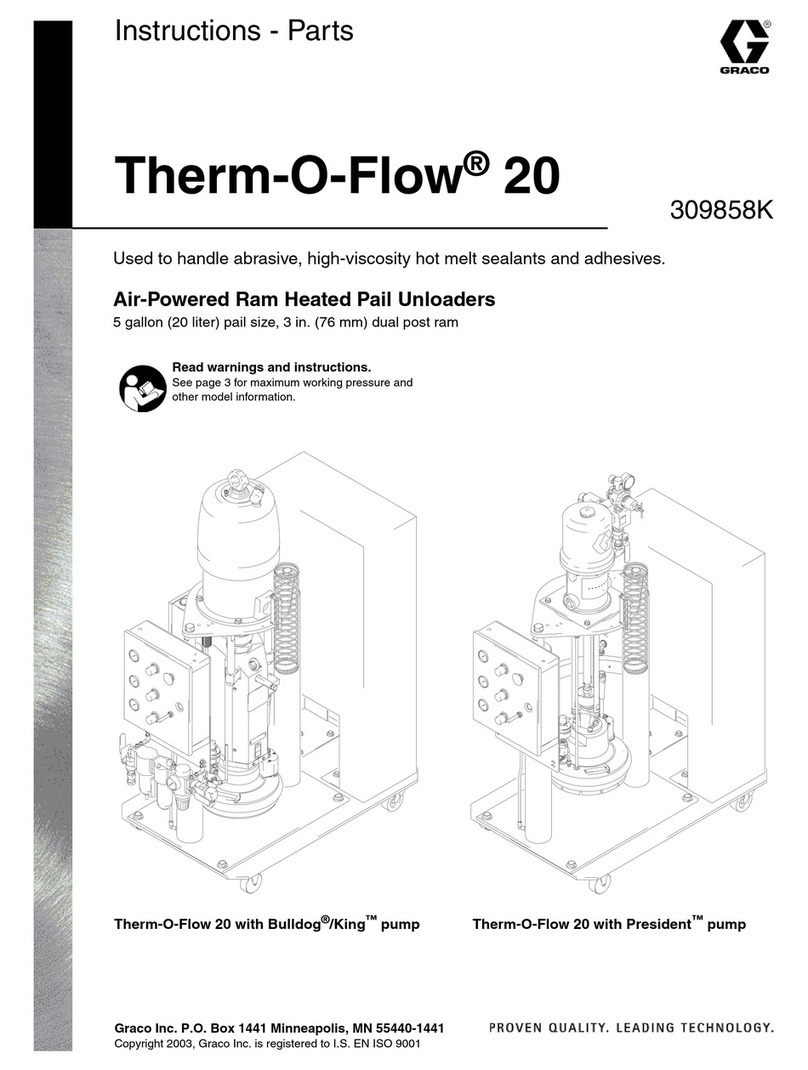

Graco Therm-O-Flow 20 Instructions - parts

HEIDENHAIN

HEIDENHAIN M12 Mounting instructions