Thermal Edge A2W30120 User manual

User & Technical Manual

Air to Water Heat Exchanger

Rev 1.0

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 2 |P a g e

Title: Air to Water Heat Exchanger Technical Manual

Department: Product Management

Objective: To provide important information for maintenance, diagnostics and advance operations of the

Thermal Edge Air to Water Heat Exchangers.

Revision History:

Rev

Date

Owner

Description of Changes

1.0

10-03-22

L. Biru

Initial Release

Statement of Confidentiality

The Manual and other materials contain proprietary information, comprising Thermal Edge Inc.'s trade secrets.

Please maintain the confidentiality of all proprietary information during and after the term of the use agreement.

Also, please refrain from using this proprietary information in any other manner, including in any other

business, without Thermal Edge Inc.’s written approval.

Thermal Edge Inc. reserves the right to revise and otherwise modify the Manual to reflect changes in the

requirements, standards, and operating recommendations. The Manual is the sole property of Thermal Edge

Inc. It must be returned upon the expiration or the termination of the term of use agreement.

By accepting the Manual you have read and understand the Statement of Confidentiality and will abide by its

terms and conditions.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 3 |P a g e

TABLE OF CONTENTS

Overview ........................................................................................................................................................... 4

Unpacking and Inspecting the Heat Exchanger ....................................................................................................... 4

Moving the Heat Exchanger ................................................................................................................................. 5

Unit Label.......................................................................................................................................................... 5

Operation .......................................................................................................................................................... 5

Mounting the Heat Exchanger .............................................................................................................................. 6

Water Quality .................................................................................................................................................... 7

Unit Specifications .............................................................................................................................................. 8

Options ............................................................................................................................................................. 9

System Faults .................................................................................................................................................. 11

Digital Temperature Controller Programming ........................................................................................................ 11

Preventative Maintenance .................................................................................................................................. 15

Field Serviceable Parts ...................................................................................................................................... 16

Safety Information ........................................................................................................................................... 17

Troubleshooting Guide ...................................................................................................................................... 17

Physical Dimensions .......................................................................................................................................... 18

Warranty Information........................................................................................................................................ 20

Return Material Authorization (RMA) Procedure .................................................................................................... 21

Phoenix Contact Power Connection Instructions .................................................................................................... 22

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 4 |P a g e

Overview

Thank you for your purchase of the Thermal Edge Air to Water Heat Exchanger. Our equipment is carefully

designed to cool and dehumidify the air in electronic component enclosures. Thermal Edge has designed air

to water heat exchangers for all types of electronic equipment enclosures providing capacity from 2,000 to

20,000 BTUH.

This manual will guide you through the installation, maintenance, diagnostics and advance operations of the

Air to Water Heat Exchanger. This manual contains important information for the end-user who installs,

maintains and/or operates the Air to Water Heat Exchanger.

Technical Support

By Phone: 972-580-0200 / 888-580-0202

(Monday –Friday, 7:30 am –5:00 pm Central Time)

By Email: support@thermal-edge.com

Our goal is to have continuous improvement for both our equipment and our documentation. We rely on and

appreciate your feedback to help us achieve our goal. Our technical support team is glad to work with you if

you require additional technical information not provided in this manual.

Unpacking and Inspecting the Heat Exchanger

Thermal Edge air conditioning equipment is designed, manufactured, and packed to prevent damage from

normal handling, shock and vibration during shipment. It is necessary to inspect your equipment upon receipt

to ensure that there is no visual or hidden damage.

All physical damage to packing or signs of damage to the equipment must be noted on the freight bill of lading.

Packages must be opened after receipt and inspected for any internal or concealed damage to the equipment

and to verify proper count and order fulfillment. Delivery without the pallet, other freight on top, damaged or

wet should be refused.

If the unit is to be transported after initial unpacking, place heat exchanger back in original packing to prevent

damage.

For shipment by UPS or freight carrier, repack as received and re-band to the pallet.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 5 |P a g e

Moving the Heat Exchanger

Heat exchangers are not designed to be shipped attached to an equipment enclosure. Heat exchangers

shipped which have internal damage due to shipping while attached to enclosures are warranty voided.

Unit Label

Each heat exchanger has a unit label. Be sure to record the data from the label to the template below and

keep this information in a safe place for warranty and ordering parts. To prevent damage to equipment,

electrical panel and wiring, and to prevent personal injury, assure that the power source is compatible with the

equipment before operating.

Operation

Thermal Edge heat exchangers, when sized correctly, will provide cooling to lower the air temperature inside

an enclosure to ensure its proper operating temperature. Thermal Edge heat exchangers operate as a “closed

loop” system with no exposure to, or introduction of, outside air. This ensures that the enclosure is separated

from, and is not contaminated with, ambient air, dirt, chemicals, dust, moisture or foreign matter so that

sensitive enclosure components are protected.

For units with the digital controller and solenoid valve option, the digital controller will monitor air temperature

inside the electrical enclosure via the temperature sensor and regulate function of the solenoid valve. The

valve controls the flow of water through the coil. As water flows through the coil it absorbs heat from air in the

electrical enclosure while also dehumidifying it. This process lowers the temperature of the air in the electrical

enclosure. The fan draws the hot air from the electrical enclosure and pulls it through the coil and back into

the electrical enclosure at a lower temperature.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 6 |P a g e

Mounting the Heat Exchanger

Before mounting the heat exchanger to the enclosure, test for proper operation. Follow the steps below prior

to installation.

WARNINGS

Check the unit label to assure the electric power available to the heat exchanger is the proper voltage

and phase. Check the electric power source for proper ground wire and neutral wire installation per

2008 NEC. Assure that the electric power is protected by a circuit protection device; refer to the Unit

Specification section in this manual for proper circuit protection sizing.

Using the template supplied, determine where the heat exchanger is to be mounted and assure that all

required cuts and holes will not interfere with or damage the enclosure or its contents. Mount the heat

exchanger high on the enclosure in order to cool the hot air in the top of the enclosure. Position the unit where

the cold air can circulate across the width of the enclosure to cool it all the way across.

Once proper mounting placement is determined, turn the enclosure equipment off, if possible, to prevent

damage. Drill and cut the holes as indicated on the mounting template. Install insulation gasket as required to

ensure an airtight closed loop seal. Be cautious not to let any cutting debris fall into the enclosure.

Hang the heat exchanger on the Easy Hang Tabs and from inside the enclosure use the fasteners supplied to

attach the heat exchanger to the enclosure. Screw all fasteners hand tight. Then torque to 25-30 in-lbs.

These fasteners should be checked periodically to ensure that they have not become loose due to vibration.

The heat exchanger is provided with a power terminal block. A power cord is optional. Ensure that the power

supplied is compatible with the heat exchanger’s power requirements. Properly connect the unit to a power

circuit that meets the equipment requirements and provide a circuit protection device based on the Unit

Specifications section of this manual. See Appendix A for power terminal block instructions.

The cooling water connection must be made with 0.5-inch ID pressure resistant flexible hoses which should be

secured with clamps. Note the direction of flow and check for absence of leaks.

The units have no separate air-bleed. With pressure-sealed systems, corresponding air bleed facilities are to

be installed on the water side. Protect the water circuit from contamination and excess pressure (100 psi

max.).

Install a 3/8-inch ID hose to the condensation drainage connector and secure in place with a clamp.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 7 |P a g e

To ensure reliable drainage of condensation water, the drain hose must not be kinked. The hose cross-section

must not be constricted in any way. The drainage hose must slope in the right direction.

To minimize the production of condensation water, only use the heat exchanger on sealed electrical

enclosures. Set the desired temperature only as low as is necessary to avoid the cooled air temperature from

dropping below the dew point.

After mounting the heat exchanger, replace/close the enclosure door and start heat exchanger; test for air

leaks to assure a proper closed air loop seal and run test the unit to assure proper operation after mounting. If

any cold air leaks are found, check for proper mounting and apply silicone-free Lexel seal if leaks persist.

CAUTION

If mounting the heat exchanger to the enclosure door, confirm with the enclosure manufacturer that

the door’s hinges will support the heat exchanger’s added weight (see equipment specifications).

Ensure that when the door is fully open that the enclosure will not topple over due to the off-center

load.

Water Quality

The use of untreated or improperly treated water could result in scaling, erosion, corrosion, algae or slime. It is

recommended that the services of a qualified water treatment specialist be engaged to determine what water

treatment, if any, is required. Equipment damage that results from untreated or improperly treated water, or

saline or brackish water will not be covered by the warranty.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 8 |P a g e

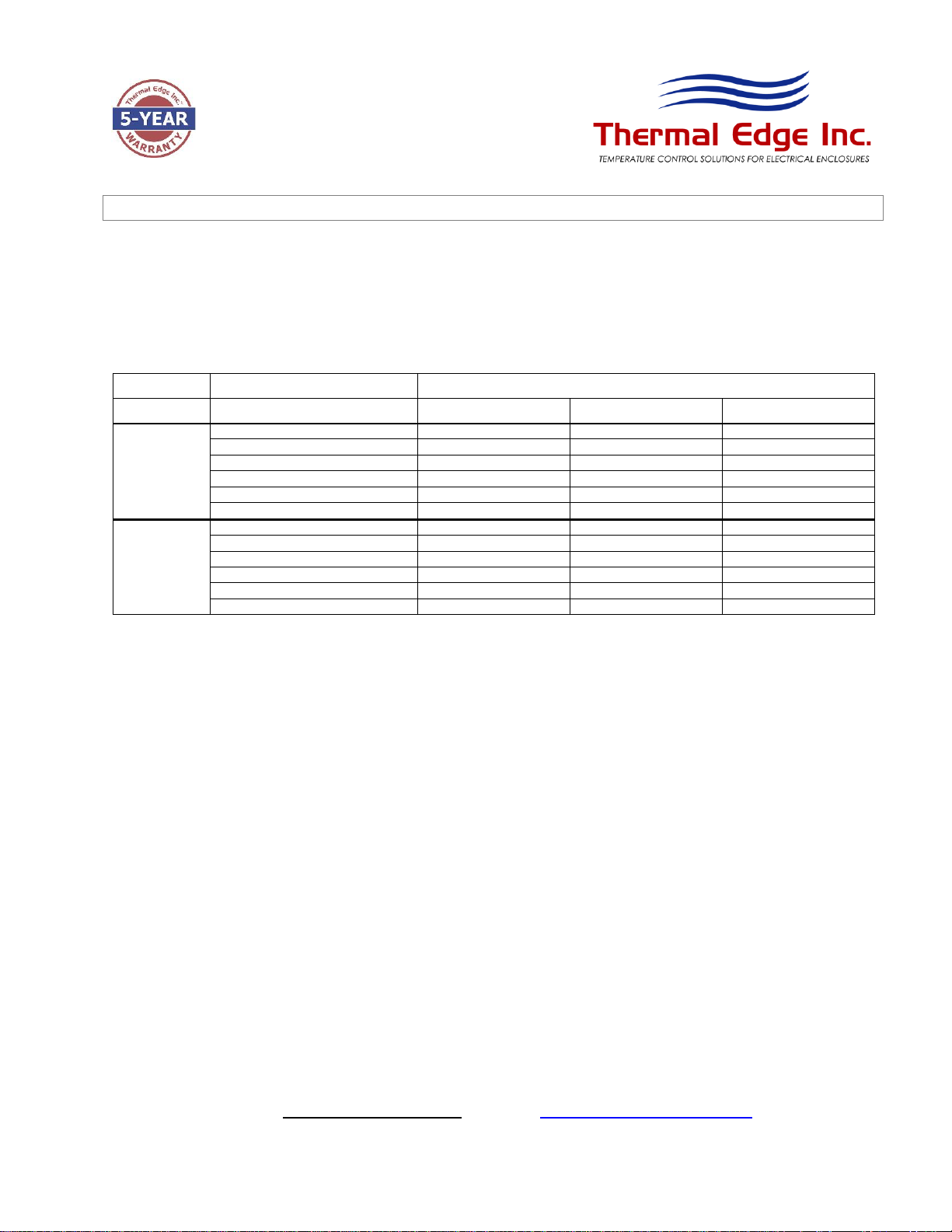

Unit Specifications

The following tables provides electrical and refrigeration specifications for the Air to Water Heat Exchangers.

A2W30 Unit

Nominal Capacity Rating: 3,960 BTUH

Standard Maximum Ambient: 140°F

Unit Weight: 21.4 lbs

Model

Operating

Voltage Range

(Volts)

Loading Current

(Running

Current)

(Amps)

SCCR

(Short Circuit

Current

Rating)

(Amps)

Recommended

Fuse Selection

(Amps)

VA

Rating

A2W30120

103.5-126.5

0.37

*2

15 Amp Class CC,

CCMR Time Delay

*

44

A2W30230

207-253

0.23

*2

15 Amp Class CC,

CCMR Time Delay

*

53

A2W60 Unit

Nominal Capacity Rating: 7,773 BTUH

Standard Maximum Ambient: 140°F

Unit Weight: 34 lbs

Model

Operating

Voltage Range

(Volts)

Loading Current

(Running

Current)

(Amps)

SCCR

(Short Circuit

Current

Rating)

(Amps)

Recommended

Fuse Selection

(Amps)

VA

Rating

A2W60120

103.5-126.5

0.59

*2

15 Amp Class CC,

CCMR Time Delay

*

71

A2W60230

207-253

0.38

*2

15 Amp Class CC,

CCMR Time Delay

*

87

* HACR Type Circuit Breakers or Time-delay Fuses with the following electrical characteristics are recommended. Fast-

acting fuses are not recommended.

% of Ampere Rating

Opening Time

110 %

15min Minimum

125 %

1hr Maximum

200 %

12sec Minimum

4min Maximum

*2 SCCR rating is based on the SCCR rating for the circuit protection device installed in the panel / enclosure per UL50

& UL508a to protect the AC unit. Typically, 100KA –200KA for Time-Delay Fuses.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 9 |P a g e

Options

Thermal Edge Air to Water Heat Exchangers may be ordered with the following options. Review the

list below for the specifications and functions of the option(s) that apply to your unit.

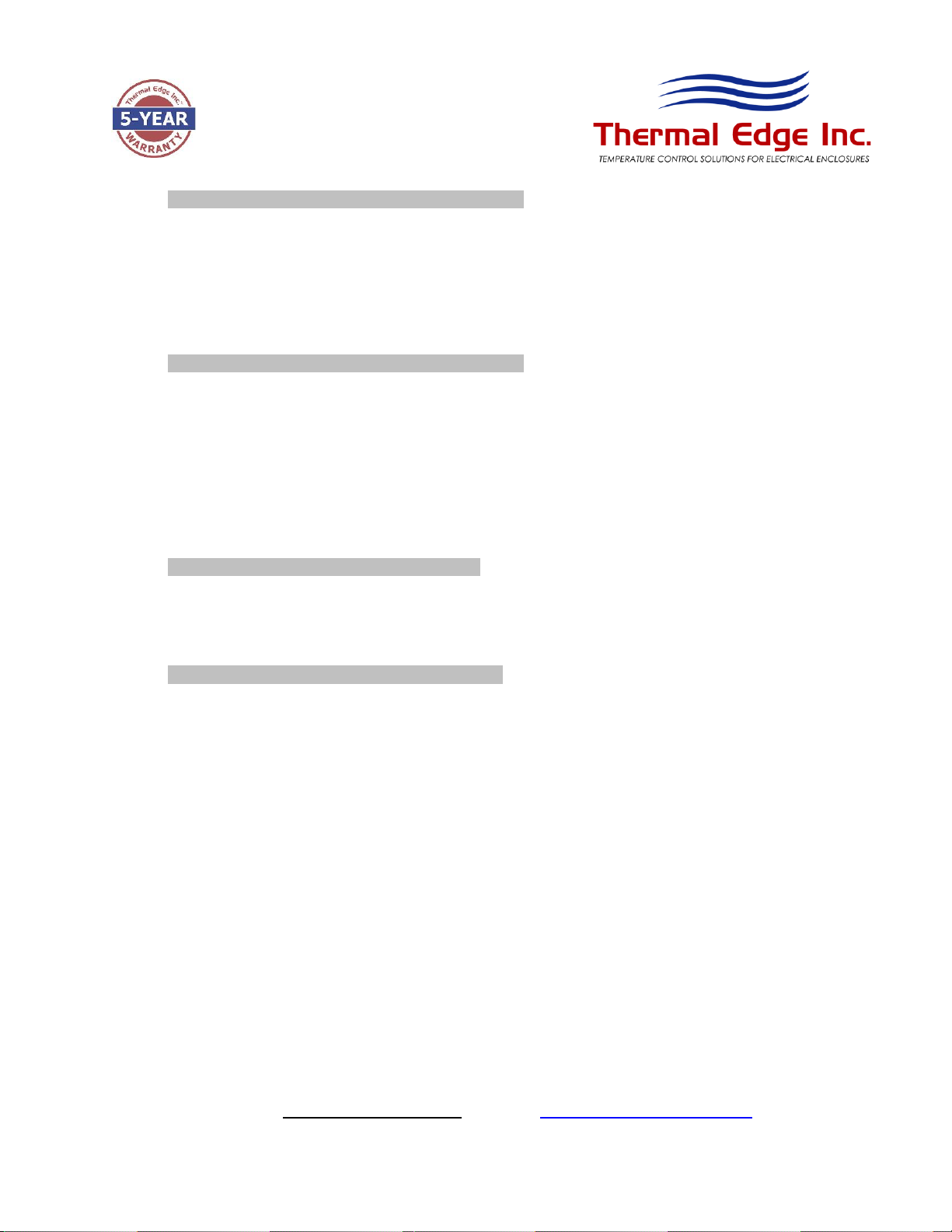

Digital Programmable Controller and Solenoid Valve

This option provides a method for customers to control the temperature of their enclosure with a

digital controller as opposed to using their water supply. When this option is selected, the flow of

water through the heat exchanger is managed based on cooling needs.

Dry Contact

This option provides an early warning capability to your enclosure to aid in the protection of your

expensive equipment. The Dry Contact is programmed with an individual dry contact set point to

monitor the enclosure temperature limit that you require. When the enclosure temperature has

exceeded the maximum limit, the Form C gold plated contact will activate to notify you that there is

a problem in achieving your cooling set point.

Default Settings:

•105°F Dry Contact High Temperature Alarm Set Point

At the default settings the Dry Contact initial conditions are normally open and/or normally closed.

When the unit is powered on and the temperature exceeds 105°F for a period longer than 3 minutes

the Dry Contact will activate. At this time the normally open contact will close and the normally

closed contact will open. This state will remain until the temperature has decreased to 103°F.

Note: The dry contact is not a power status indicator, rather a high temperature alarm alerting you

that the unit is unable to meet the cooling set point.

Refer to Advanced Digital Temperature Controller Programming section for details on changing these

parameters.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 10 |P a g e

Celsius Programming

Celsius Programming option allows the user to control the Thermal Edge heat exchanger in SI units. This

feature can be programmed into the digital temperature controller at time of manufacturing.

Special Programming

All Thermal Edge products have a Special Programming option for selecting unique pre in programmed

settings for special requirements. Although most parameters are accessible in our digital controller, this option

allows you to receive a unit preset to your requirements without the need to manually configure the unit. Refer

to Advanced Digital Temperature Controller Programming section for details on all default settings.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 11 |P a g e

System Faults

Thermal Edge Air-to-Water Heat Exchangers are equipped with temperature probes and alarms to

monitor and alert the user of extreme temperature conditions of the water supply and their electrical

enclosure. The conditions that will trigger an alarm on the controller are:

•Enclosure high temperature alarm (default setting 105°F)

•Enclosure low temperature alarm (default setting 45°F)

•Supply water low temperature alarm (default setting 34°F)

•Supply water high temperature alarm (default setting 85°F)

In the event the supply water temperature or enclosure temperatures reaches the low or high

temperature alarm setting, the dry contact relay will close signaling an alarm to the user.

Digital Temperature Controller Programming

For the end user this section will provide all the necessary information to view and change all functions

and parameters available to you.

HOW TO SEE THE SETPOINT……..

1. Press and immediately release the SET key. The display will show the setpoint value.

2. Press and immediately release the SET key or wait for 15 seconds to display the enclosure temperature

again.

HOW TO CHANGE THE SETPOINT……..

1. Press the SET key for more than 2 seconds to change the setpoint value.

2. The value of the setpoint will be displayed and the “F” LED starts blinking.

3. To change the SET value, press the UP or DOWN arrow key within 15 seconds.

4. To store the new setpoint value, press the SETkey again or wait 15 seconds.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 12 |P a g e

Note: The set value is stored even when the procedure is exited by waiting for the time-out to expire.

HOW TO ACCESS HIDDEN MENU 1……..

1. Enter the Programming mode by pressing the SET + DOWN arrow keys simultaneously for 3 seconds.

The “F” LED starts blinking.

2. Select the required parameter by pressing the UP or DOWN arrow key. Press the SET key to display

its value.

3. Use the UP or DOWN arrow key to change its value.

4. Press SET to store the new value and move to the following parameter.

To exit: Press SET + UP arrow keys or wait 15 seconds without pressing a key.

Note: The set value is stored even when the procedure is exited by waiting for the time-out to expire.

HOW TO ACCESS HIDDEN MENU 2……..

1. Enter the Programming mode by pressing the SET + DOWN arrow keys simultaneously for 3 seconds.

The “F” LED starts blinking.

2. Release the keys, then push the SET + DOWN arrows keys simultaneously, again for more than 7

seconds.

The Pr2 label will be displayed immediately followed by the HY parameter.

3. Select the required parameter by pressing the UP or DOWN arrow key. Press the SET key to display

its value.

4. Use the UP or DOWN arrow key to change its value.

5. Press SETto store the new value and move to the following parameter.

To exit: Press SET + UP arrow keys or wait 15 seconds without pressing a key.

Note: The set value is stored even when the procedure is exited by waiting for the time-out to expire.

HOW TO LOCK THE KEYPAD……..

1. Press and hold the UP and DOWN arrow keys simultaneously for more than 3 seconds.

2. The POF message will be displayed and the keyboard will be locked.

At this point, it will be possible only to see the setpoint or the MAX or MIN temperature stored.

3. If a key is pressed for more than 3 seconds the POF message will be displayed.

HOW TO UNLOCK THE KEYPAD……..

1. Press and hold the UP + DOWN arrow keys simultaneously for more than 3 seconds until the Pon

message is displayed.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 13 |P a g e

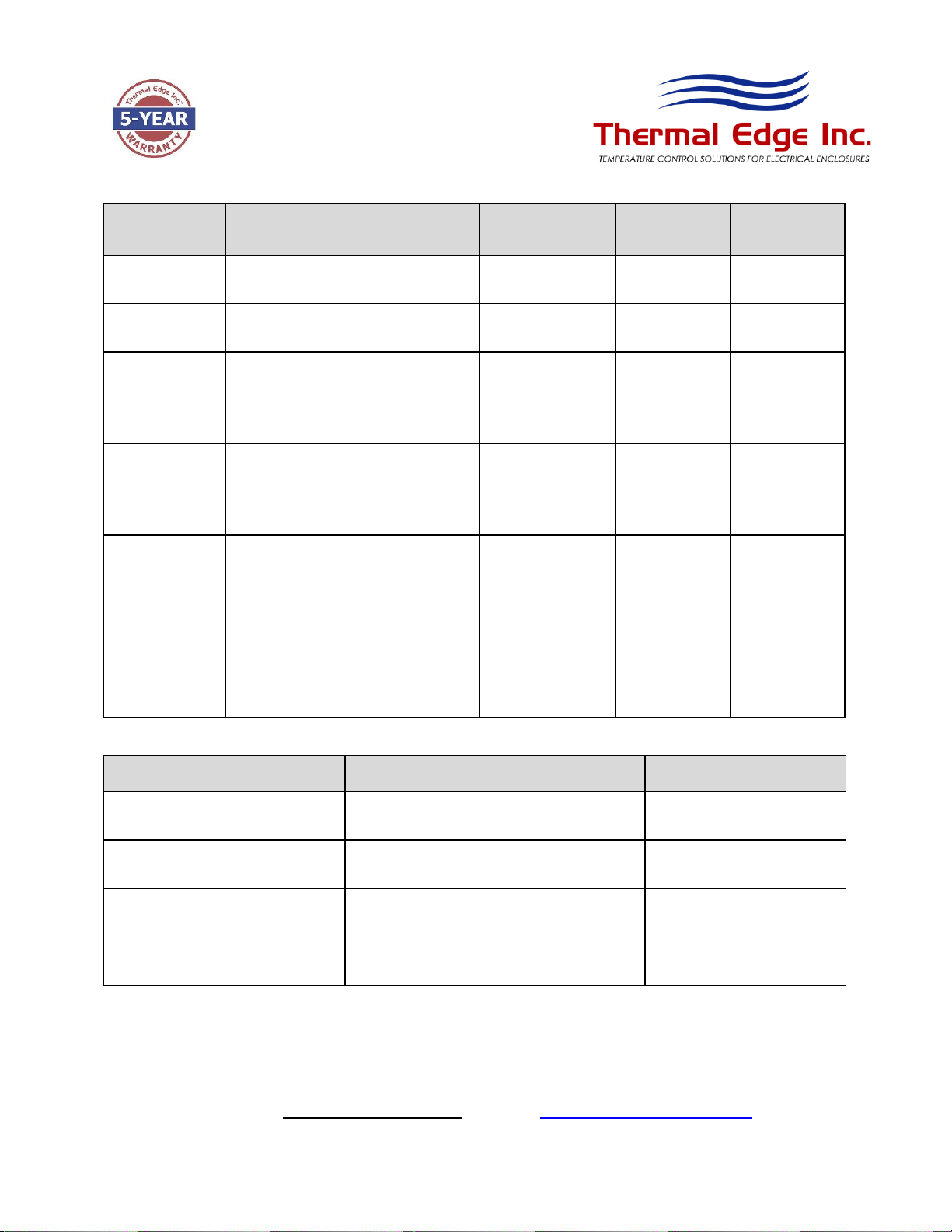

Functions and Parameters

Function

Operation

Parameter

Menu Location

Factory

Default

Unit

Cooling Setpoint

Set Desired Cooling

Temperature

SET

Main

90

°F

Cooling

Differential

Control Hysteresis

Hy

Hidden Menu 1

2

°F

Maximum

Enclosure

Temperature

Alarm

Alerts with “HA”

when enclosure

temperature has

exceeded maximum

value

ALU

Hidden Menu 2

105

°F

Minimum

Enclosure

Temperature

Alarm

Alerts with “LA” when

enclosure

temperature has

exceeded minimum

value

ALL

Hidden Menu 2

45

°F

Maximum

Supply Water

Temperature

Alarm

Alerts with “HA2”

when supply water

temperature has

exceeded maximum

value

AU2

Hidden Menu 2

85

°F

Minimum

Supply Water

Temperature

Alarm

Alerts with “LA2”

when supply water

temperature has

exceeded minimum

value

AL2

Hidden Menu 2

34

°F

Alarm Signals

Message

Cause

Actions

“HA”

Maximum Temperature Alarm: Enclosure

temperature > 105°F

No Action/Alarm Only

“LA”

Minimum Temperature Alarm: Enclosure

temperature < 45°F

No Action/Alarm Only

“HA2”

Maximum Temperature Alarm: Supply water

temperature > 85°F

No Action/Alarm Only

“LA2”

Minimum Temperature Alarm: Supply water

temperature < 34°F

No Action/Alarm Only

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 14 |P a g e

Alarm Recovery

•Temperature alarm HA automatically clears as soon as the enclosure temperature returns to 103°F

(ALU set point - 2°F).

•Temperature alarm LA automatically clears as soon as the enclosure temperature returns to 47°F

(ALL setpoint + 2°F).

•Temperature alarm HA2 automatically clears as soon as the supply water temperature returns to

below 85°F.

•Temperature alarm LA2 automatically clears as soon as the supply water temperature returns to

above 34°F.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 15 |P a g e

Preventative Maintenance

Refer to Field Serviceable Parts section in this manual for details on parts that can be changed to help

increase the uninterruptable life of the Heat exchanger.

To avoid frost damage, the minimum permissible water temperature of 34°F (+1°C) must be complied with at

any point in the water cycle. Any damage due to freezing is not covered by the warranty.

During storage at temperatures below water freezing temperatures and transportation, the water should be

completely drained from the heat exchanger to prevent damage to coil. Disconnect the water lines and use

compressed air to remove all water.

Thermal Edge heat exchangers use high efficiency, long life, sealed ball bearing fans engineered for optimum

performance that require no maintenance. Keep fan blades clean for optimal performance. Fans are

removable and attached by plug in connections.

Note: Do no use solvents to clean the digital controller when supplied. Wipe with mild soap and water.

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 16 |P a g e

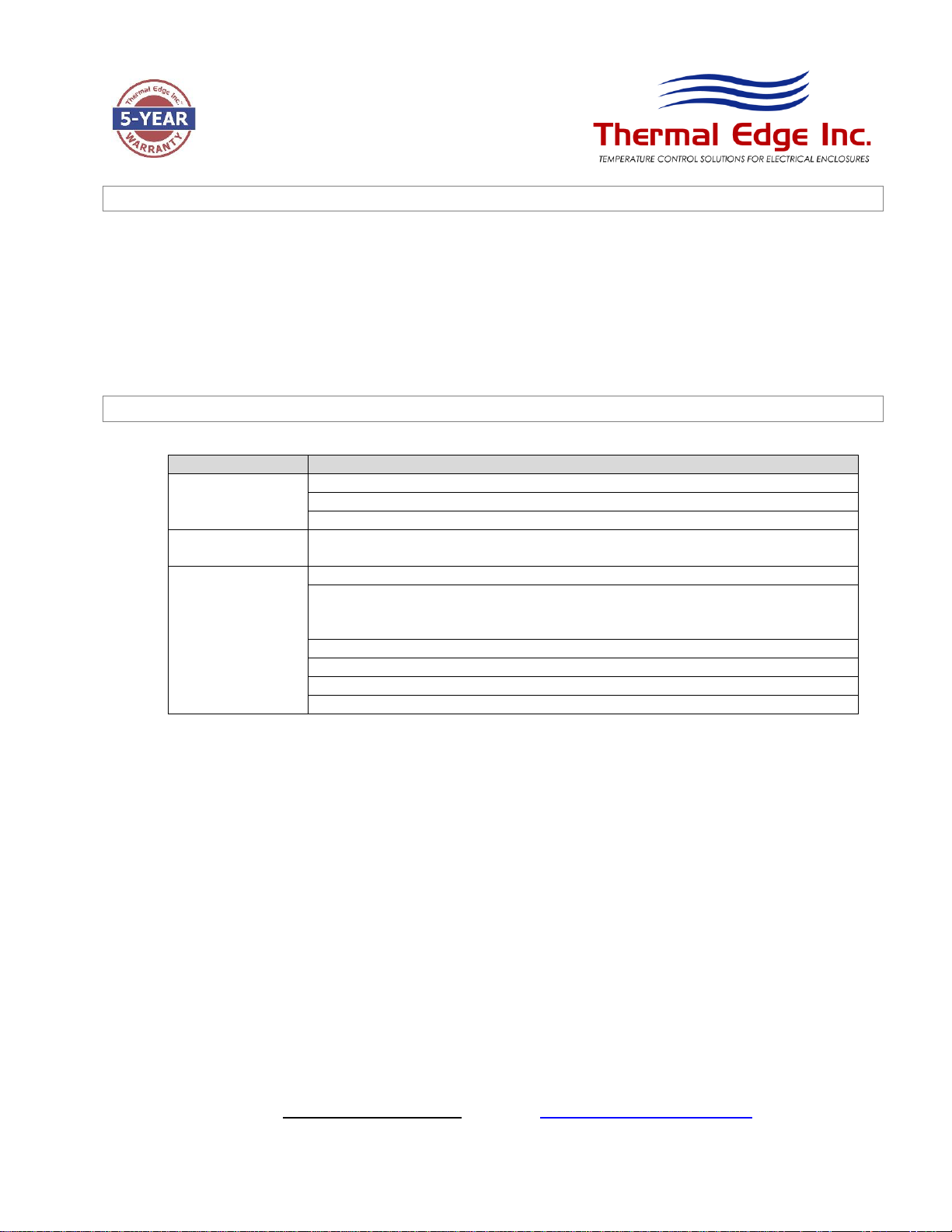

Field Serviceable Parts

Thermal Edge carefully designs and selects components with the maximum life expectancy. Due to OEM

manufacturing tolerances, poor unit maintenance or extreme operating conditions, components may fail before

their maximum life expectancy. The table below lists parts that are serviceable in the field by a heat exchanger

technician.

Unit

Part Description

Thermal Edge Part #

115VAC

230VAC

460VAC

A2W30

Digital Controller

52110-1

52112-1

52110-1

Solenoid Valve

33000-1-1

33000-2-1

33000-1-1

Temperature Probe, 1.5m

52126-2-2

52126-2-2

52126-2-2

Temperature Probe Mounting Clip

52126-500C

52126-500C

52126-500C

Gasket Installation Kit

71440-A2W30

71440-A2W30

71440-A2W30

Fan

41005-1-2

41005-2-2

41005-1-2

A2W60

Digital Controller

52110-1

52112-1

52110-1

Solenoid Valve

33000-1-1

33000-2-1

33000-1-1

Temperature Probe, 1.5m

52126-2-2

52126-2-2

52126-2-2

Temperature Probe Mounting Clip

52126-500C

52126-500C

52126-500C

Gasket Installation Kit

71441-A2W60

71441-A2W60

71441-A2W60

Fan

41037-1-2

41037-2-2

41037-1-2

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 17 |P a g e

Safety Information

Unit is carefully designed to restrict access to movable parts to minimize any potential injury. This Heat

exchanger has been tested by UL to meet the safety requirements of the UL484 specification. When working

with the Thermal Edge Heat exchanger always makes sure shroud is installed. Verify proper voltage is

applied to unit as specified in the UL label of the Heat exchanger. In the event of a field service repair, power

down unit using the power on/off switch and disconnect power from unit. It is always recommended to use a

licensed heat exchanger technician for internal diagnostics and repairs issues.

Contact Thermal Edge technical support for further details on opening the unit and troubleshooting tips.

Troubleshooting Guide

SYMPTOM

POSSIBLE CAUSE

Unit will not run

Check that the power is connected

Verify that power switch is in ON position

Verify that input power meets voltage requirements shown in UL label

Fan is not

working

Fan faulty –Replace the fan

The fan is

working, unit is

not cooling

Controller set point is set too high –Adjust set point

Insufficient water flow –Check that the flow rate corresponds to the

prescribed flow

rate on the unit nameplate

Controller faulty –Replace controller

Solenoid valve faulty –Replace solenoid valve

Water temperature too high –Adjust the water temperature

Obstructed airflow in enclosure –Remove airflow blockage

1800 Hurd Drive ● Irving, Texas 75038 ● (972) 580-0200 ● (888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-ENG-211-000-20 Rev 1.0 20 |P a g e

Warranty Information

Thermal Edge products are warranted to be free of defects in workmanship, materials and components. The warranty

period applies from date of shipment for five years. Replacement components have a one year warranty period,

except for hermetic system components, which have a 90 day warranty period.

The above warranty applies when the equipment is operated under the following conditions:

•Ambient temperature not in excess of performance rating in normal atmosphere or as stated on product

nameplate

•Voltage variation within limits stated in User & Technical Manual

•Frequency variation no greater than ± 3Hz from nameplate rating

•Maximum cooling load no higher than heat exchanger nameplate rating

•Compliance to all other installation, maintenance and operating instructions, as supplied

Thermal Edge cannot assume responsibility for misapplication of its products or the erroneous selection of an

inappropriate product by a non-authorized Thermal Edge representative. Our applications engineers will gladly assist

in the selection of the proper product provided all required details of the application are furnished.

Thermal Edge assumes no liability beyond the repair or replacement of its own product. This Warranty does not

cover:

•Labor or reimbursement of labor for evaluation, removal, installation, repair, or cost of any warranted part,

except at the Thermal Edge factory in Dallas, Texas

•Use of equipment for other than its designed purpose or operating conditions

•Operation in harsh, oily, corrosive or other abnormal environmental conditions, without the proper filtration,

sealing, protective coatings and/or weather protection, or cosmetic corrosion that does not affect operation

•Improper or negligent maintenance

•Damage resulting from untreated or improperly treated water, or saline or brackish water.

•Customer modification or abuse

•Shipping damage or other accident

•Repair or service by unauthorized personnel.

Thermal Edge must be notified of a claim in writing not later than fourteen (14) days from the date when buyer has

become aware of such occurrence, or immediately, when the defect is such that it may cause damage.

If heat exchanger is to be shipped or transported at any time, it is best to pack in original packaging and strap to

pallet to prevent damage. Heat exchangers that have internal damage due to shipping are not covered under the

Warranty. Claims for shipping damage are the responsibility of the Consignee. Damage must be noted on Bill of

Lading at time of receipt. Timely claims must be filed with the freight carrier.

The purchaser assumes the responsibility of grounding the unit and installing it in accordance with local electrical and

safety codes, as well as the 2008 National Electric Code (NEC) and OSHA.

THIS WARRANTY CONSTITUTES THE ENTIRE WARRANTY WITH RESPECT TO THE PRODUCT AND IS IN LIEU

OF ALL OTHERS, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE AND IN NO EVENT IS THERMAL EDGE

RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY NATURE WHATSOEVER.

This manual suits for next models

3

Table of contents