Installation and Operational Instructions for

EAS®-lastic clutches Type 437._ _ _.0 (B.4.11.GB)

23/05/2006 K/TK/GC/RJ Chr. Mayr GmbH + Co. KG Tel.: 08341 / 804-0

Eichenstraße 1 Fax: 08341 / 804-421

87665 Mauerstetten http://www.mayr.de

Page 2 of 3 Germany eMail: info@mayr.de

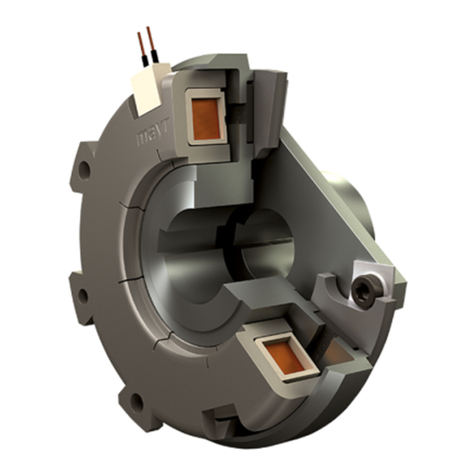

Function

EAS®-lastic clutches are positive-locking, torque-limiting

overload clutches used to connect two shafts.

Under compensation of longitudinal, transverse or angular

misalignment, the EAS®-lastic is capable of transmitting the

torque from the input to the output safely and reliably in normal

operation. On overload or on reaching the set limit torque, the

clutch immediately separates input and output. The mayr®-limit

switch registers the overload and transmits a signal to stop the

drive or other control functions.

Designs

1. EAS®-lastic ratchetting clutch Type 437._00.0

On overload, this device ratchets and gives electrical contact

free to stop the drive. As it is ratchetting, the torque is much

lower than the set disengagement torque. Re-engagement takes

place automatically.

2. EAS®-lastic synchronous clutch Type 437._05.0

On overload, this device gives an electrical contact free to stop

the drive, releases it mechanically and then connects the drive

elements after one turn (360°) mechanically again. Re-

engagement takes place automatically at the same point at

which it disengaged.

3. EAS®-lastic overload clutch Type 437._14.0

On overload, this device switches off the drive electrically and

disengages mechanically on free run-out. Re-engagement takes

place manually or via a re-engagement device.

4. EAS®-lastic synchronous overload clutch Type 437._03.0

On overload, this device switches off the drive electrically and

disengages mechanically on free run-out. Re-engagement takes

place manually or via a re-engagement device to re-engage after

a 360°turn at the same point at which it disengaged.

5. EAS®-lastic torque sensor clutch Type 437._01.0

On overload, this device gives an electrical contact free or a

signal to stop the drive. However, this component continues to

transmit the torque mechanically. Re-engagement takes place

automatically.

Characteristics of Individual Designs

On the overload clutch, the synchronous overload clutch, the

ratchetting clutch and the synchronous clutch, please observe

the starting torques. High speeds can therefore only be reached

by gradual speed increase, otherwise the clutch will disengage in

the start-up phase and stop the drive.

On the EAS®-torque sensor clutch, the limit switch must be

bridged during start-up, in case the starting torque is higher than

the set clutch torque. Otherwise the clutch will disengage during

start-up.

Limit Switch

On overload, the mayr®-limit switch registers the clutch

disengagement quickly and precisely and emits a signal to

switch off the drive or other control functions (for more, see

catalogue K.407.0_.GB).

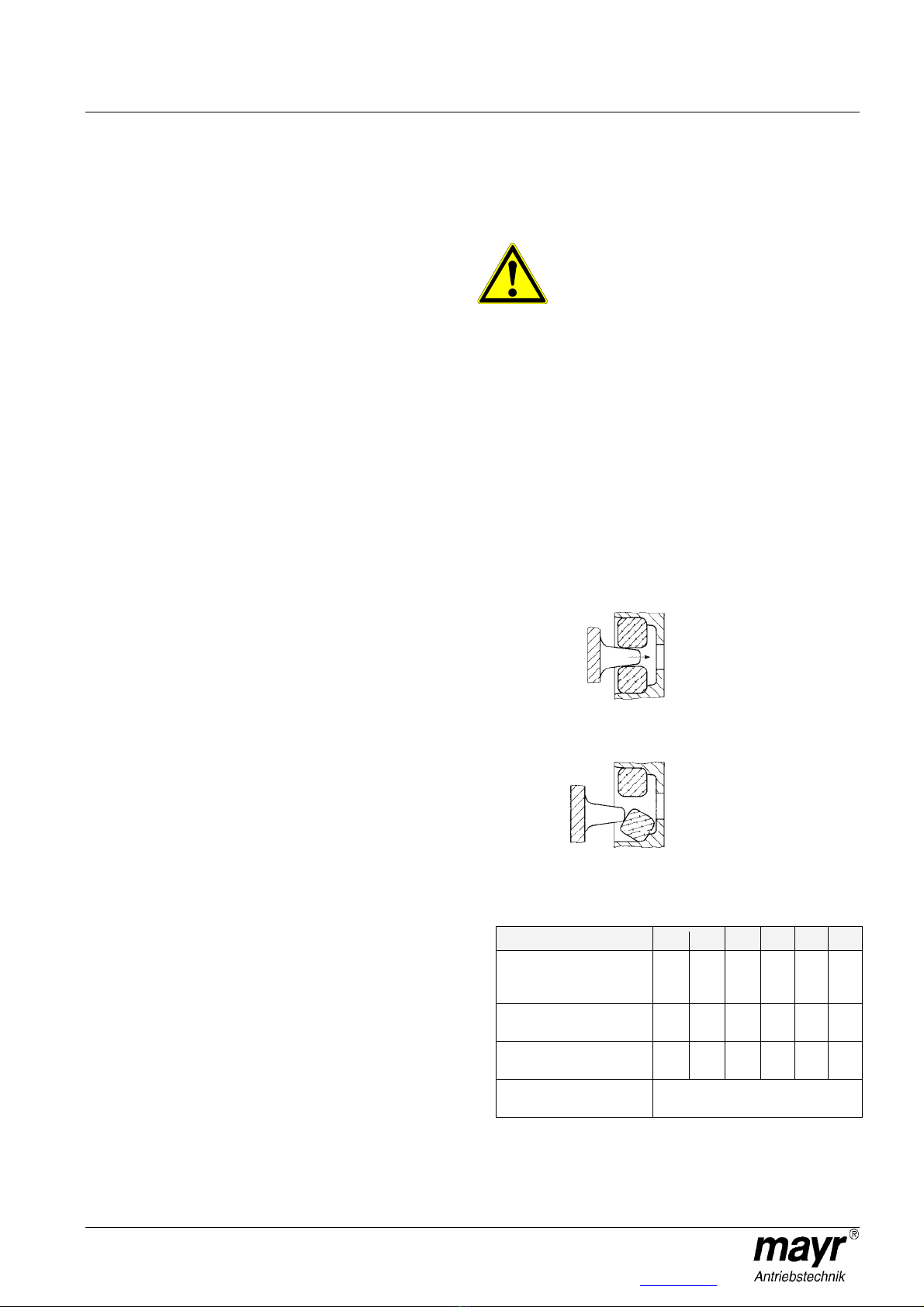

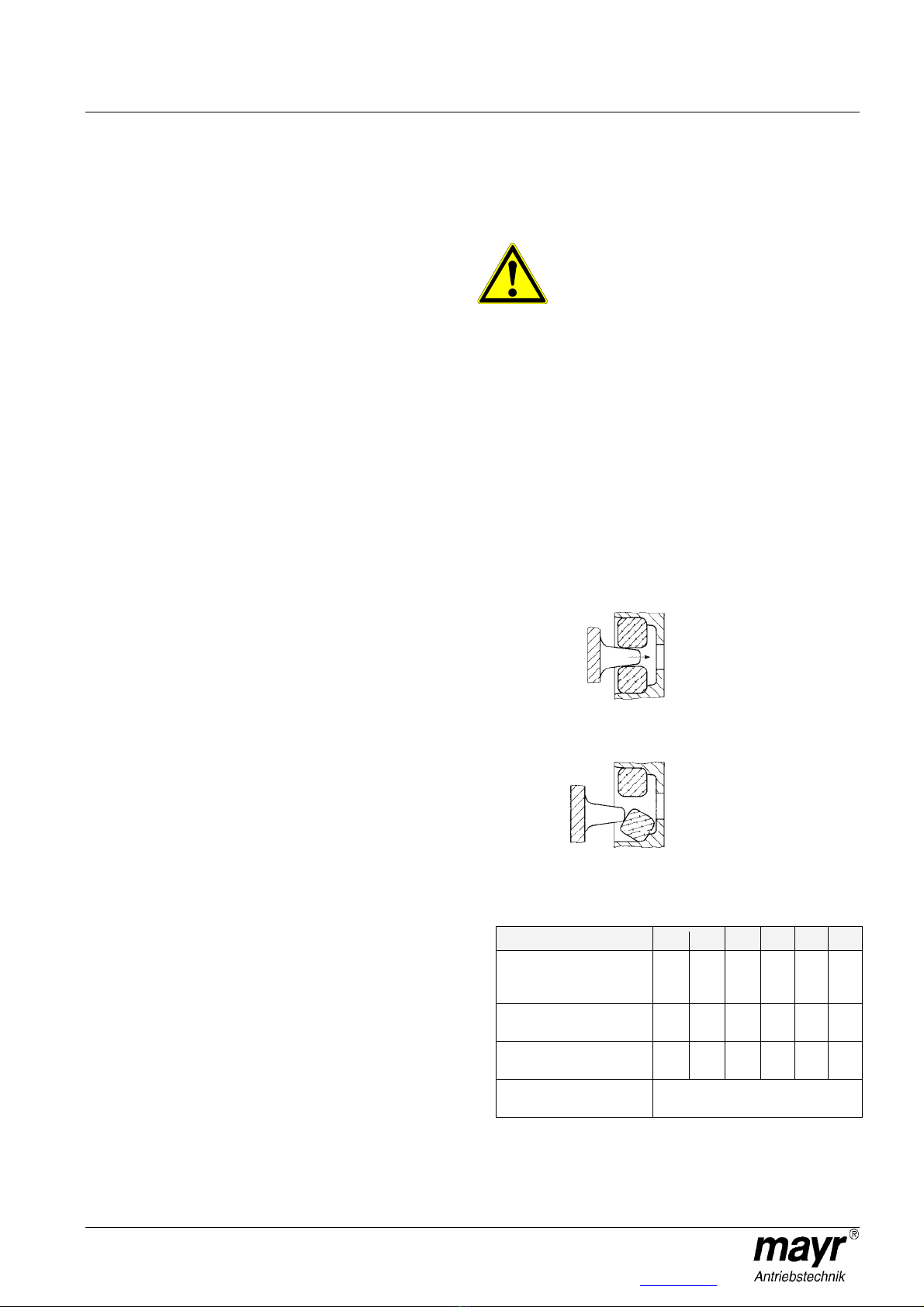

Clutch / Coupling Installation

The flexible coupling is designed as a simple plug coupling. The

pocket element (4) on the flexible coupling and the EAS®-clutch

(1) are pushed onto the shaft and fixed axially e.g. with a press

cover or a set screw. The coupling bores are standard-fitted with

an H7 tolerance. (Tolerance of keyways JS9).

We recommend a k6 tolerance for the shaft.

Warning!

If the EAS®-clutch part (1) is delivered pilot bored, the

claw element (2) will only be partly assembled,

meaning that the fixing screws (2.1) are lightly

tightened.

After finish-boring the EAS®-clutch part, (1) the fixing

screws (2.1) must be tightened to the torque shown in

Table 1 and secured using Loctite 243 (medium hard).

Assembly of the Coupling Halves

The rubber buffers (3) are pressed into the pocket element (4)

and greased lightly. The claw element (2) is designed so that

there is no backlash between the claw and the rubber buffer (3),

but rather a light pre-tension. This means that some axial force is

needed to push the coupling halves together. The force needed

can be greatly decreased by putting a thin layer of acid-free

grease onto the claws of the claw element (2).

When joining the coupling halves, please make sure that the

claws are between and not on the rubber buffer, or the rubber

buffer may tilt (see Fig. 2). Also, please make sure that the

distance dimension “Z” is observed (see Table 1 or Fig. 1) when

joining the coupling halves, otherwise the permitted

misalignment possibilities become very limited.

Fig. 2

Table 1

Size 0 1 2 3 4 5

Tightening torque for

fixing screws

(Item 2.1, Fig. 1) [Nm]

5.5 5.5 9.5 23 46 80

Distance dimension „Z“

(Fig. 1) [mm]

4 4 4 4 4 4

Number of

rubber buffers 12 12 12 12 12 12

Temperature resistance

of rubber buffer +90 °C / -30 °C

Correct