Endecotts M100 User manual

USER GUIDE

M100

The M100 User Guide

Test Sieve Shaker

_______________________________________________

Contents

Description

Pages 1 - 2

Setting Up

Unpacking

Electrical Connections

Clamping Arrangement

Sieve Stacking

Page 3

Page 4

Page 5

Page 5

Operations Instructions

Position and Function of Controls

Mains Inlet

Mains Connected Indicator

Fuse

Process Timer

Pages 6-7

Page 6

Page 6

Page 6

Page 7

Maintenance

Cleaning

Page 8

Fuse Replacement

Page 8

Spring Replacement

Page 9

General Advice

Page 10

Specification

Page 11

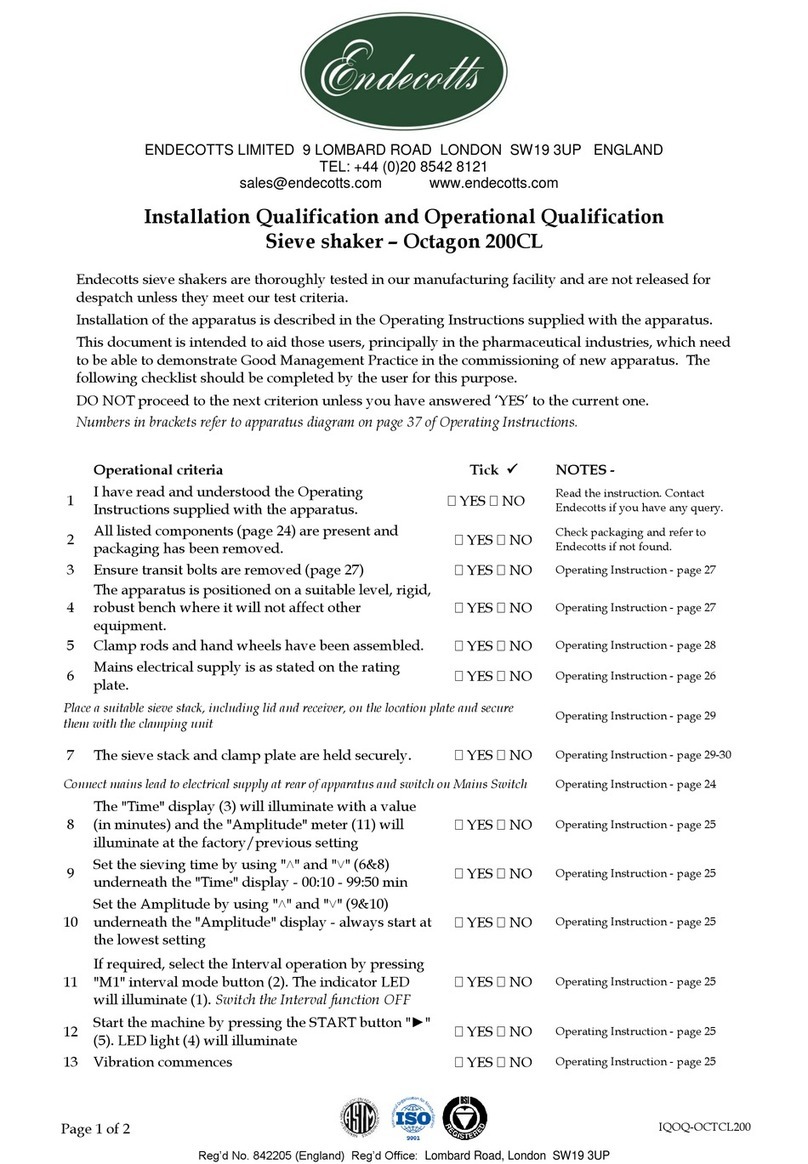

1

Description

The Endecotts M100 is an economical, compact and portable vibrating shaker

designed to conduct sieve tests in conjunction with sieve stacks for particle sizing

of various material samples. By utilizing an electromagnetic drive and natural

rubber spring mounts the power required is extremely low to produce the

movement needed for basic sieve tests.

The M100 is a variable amplitude shaker, operated by a combined on/off switch,

process timer providing a range of incremental periods or continuous running and

an amplitude controller.

The M100 is fully EMC and LVD

compliant and complies with all

relevant European directiv

The M100 is not recommended for the

Wet Sieving operation

2

Description

CLAMP KNOBS

SIEVE STACK

AMPLITUDE CONTROLLER

CLAMP PLATE

CLAMP RODS

PROCESS TIMER

L.E.D (indicates

mains power to

instrument)

3

Setting Up

Unpacking

The shaker should be set up according to the following procedure and the

diagram on page 3.

The following items should be removed from the case and checked before the

M100 is operated:

Take Care the shaker weighs 10 kg

1 off Instruction Manual

1 off Mains Cable

1 off Clamp Plate

2 off Clamp Knobs

2 off Clamp Rods

2 Off M6 Lock Nuts

4 off 6mm Washers

1 off M100 Shaker

Position on a level, rigid bench, suitable for the operation of the sieve shaker,

being placed on a level surface ensures symmetrical distribution of the sample

over the sieves, during operation.

4

Setting Up

Electrical Connections

Ensure that the voltage and frequency on the Rating Label, at the rear of the

M100 correspond with the local electrical mains supply, if any discrepancy occurs

please consult your supplier or a qualified electrician.

Do Not Connect to any supply other than

that stated on the nameplate

Important

This equipment must be connected to

mains earth

The M100 sieve shaker is provided with a detachable 2 metre long mains cable,

incorporating an IEC moulded connector and plug suitable for connecting to the

local mains supply. Certain models may be supplied with a fused plug. In the event

of failure the fuse must be replaced with a fuse of identical rating.

5

Setting Up

Clamping Arrangement

Fit one M6 nut and washer onto each clamp rod, then screw the pair of clamp

rods into the location plate and tighten the locknuts

Sieve Stacking

Place the receiver centrally on the location plate in the appropriate recess. Stack

the required sieves on top of the receiver. Put the sample under test in the top

sieve and fit the lid.

Place the clamp plate with the rubber pads on the underside on top of the sieve

stack.

Place a 6mm washer on each clamp rod.

Screw the two M6 clamp knobs down the rods until the stack is clamped.

6

Operation Instructions

Position and Function of Controls

Operators should be familiar with, and fully understand the controls and

indicators before operating the machine. This should be done in conjunction with

the diagram on page 8.

1. Mains Inlet - Mains inlet with integral line filter. Ensure the IEC connector on

the mains lead is pushed fully into the mains inlet at the rear of the machine.

2. Fuse - This is a 2Amp. 1¼ inch long, quick acting ceramic fuse. It is important

that the recommended current rating is not exceeded and the fuse is replaced

with the same type and size. If the fuse blows after replacement then a fault

exists in the equipment which must be rectified.

3. Mains Connected Indicator - This is a green l.e.d that indicates electrical power

is connected to the equipment. The l.e.d. is illuminated when the IEC connector is

pushed fully into the inlet and power is switched on at the local outlet. If the l.e.d.

fails to light with the local outlet switch in the ON position then the fuse (3) has

blown or power is not present at the mains.

4. Amplitude Controller - Variable amplitude from 0 to 1½ mm (Max) depending

on number of sieves and sample weight.

7

Operation Instructions

Position and Function of Controls

5. Process Timer - This is a mechanical 0-60 minute timer which also provides

continuous running (for settings of less than 15 minutes rotate the knob past the

15 minute mark then back to the desired setting). Operating periods are increased

by rotating clockwise and decreased by rotating anticlockwise (the timer will

commence timing down as soon as the knob is released, regardless of electrical

power being connected or not).

When the knob is turned anti-clockwise from Off position to the continuous

running mark ‘׀’, the shaker will continue running until the knob is returned to the

Off position

Do not release the clamp latches or buckles

while the shaker is vibrating

Do not attempt to remove sieves before the shaker

has come to a halt

Turning timer knob allows

the M100 to run for 1 min

to 60 minutes clockwise

Turning timer knob anti-

clockwise allows the M100 to

run continuously

Take care that there are no loose

sieves on the shaker

8

Maintenance

The Endecotts M100 sieve shaker is maintenance free other than keeping external

surfaces clean.

Cleaning - The machine can be cleaned with a soft damp cloth using a solution of

water and a mild liquid detergent.

Fuse - Should a fuse require replacement this must be of the identical type and

rating as the original (see Page 7). The rating of the fuse is marked on a label

above the fuse. Disconnect from the mains supply. Unscrew the central cap of the

fuse holder with a suitable coin or screwdriver, extract the cap and the fuse

together. Remove the blown fuse and place the new fuse in the metal spring

within cap. Fit the cap and fuse back into the holder and screw fully.

Do not over tighten

All replacement parts must be ordered by quoting the shaker serial number and

the correct part number.

Part numbers can be obtained from our sales or technical department

Do not use any solvents for cleaning

9

Maintenance

Rubber Spring Replacement - If a problem develops with one of the springs it is

recommended that all three are replaced.

1. Remove the clamp rods.

2. Stand the shaker upside down on the location plate.

3. Unscrew the three M8 cap screws to release the location plate and

spring columns.

4. Turn the shaker over to stand the correct way up. Lift the location plate

off with the spring columns, which will pass through the cover opening.

5. Unscrew the spring columns from the underside of the location plate.

6. Replace the three rubber springs, for 60Hz versions,ensure the single

rubber spring (brown spot) supplied is fitted in the rear column position

and the pair of rubber springs (green spot) are fitted in the front column

position.

7. To reassemble the shaker, reverse the order of 1 to 5 above.

10

General Advice

Endecotts shakers are fully tested and factory checked before shipping to

customers. No parts require lubrication or resetting unless disturbed.

The sieve shaker has been constructed and factory tested to ensure correct

operation when connected to the specified electricity supply indicated on the

machine rating plate.

Use of unapproved spares or any alteration to the machine would invalidate all

warranties and compliance with the European directives for ‘CE’ marking.

Endecotts Ltd. does not accept any

responsibility if the operating instructions

contained in this manual are not strictly

followed.

Warning Note

The M100 is not recommended for

use with liquid

11

Specification

Model: M100

Voltage: 230 110

Frequency: 50 Hz 60 Hz

Phase: 1 1

Power consumption: 80 VA 60 VA

Class: 1 (earthed) 1 (earthed)

Vibration speed: 3000 per 3600 per min

min at 50 Hz min at 60 Hz

Approx Amp: 1.5 mm 1.5 mm

Process time: 0 to 60 or Continuous

Sieve Diameters: Max.No. of Sieves in Stack:

3 Full Height 100mm

3 Full Height 4”

3 Full Height 3”

The M100 has been designed to accommodate Diamond Industry Sieve Stacks.

Dimensions: 24 cm (diameter) x 32cm (overall height)

Weight: 10.5 Kg

Endecotts policy is one of continuous development and we reserve the right to

modify future models.

Table of contents

Other Endecotts Laboratory Equipment manuals