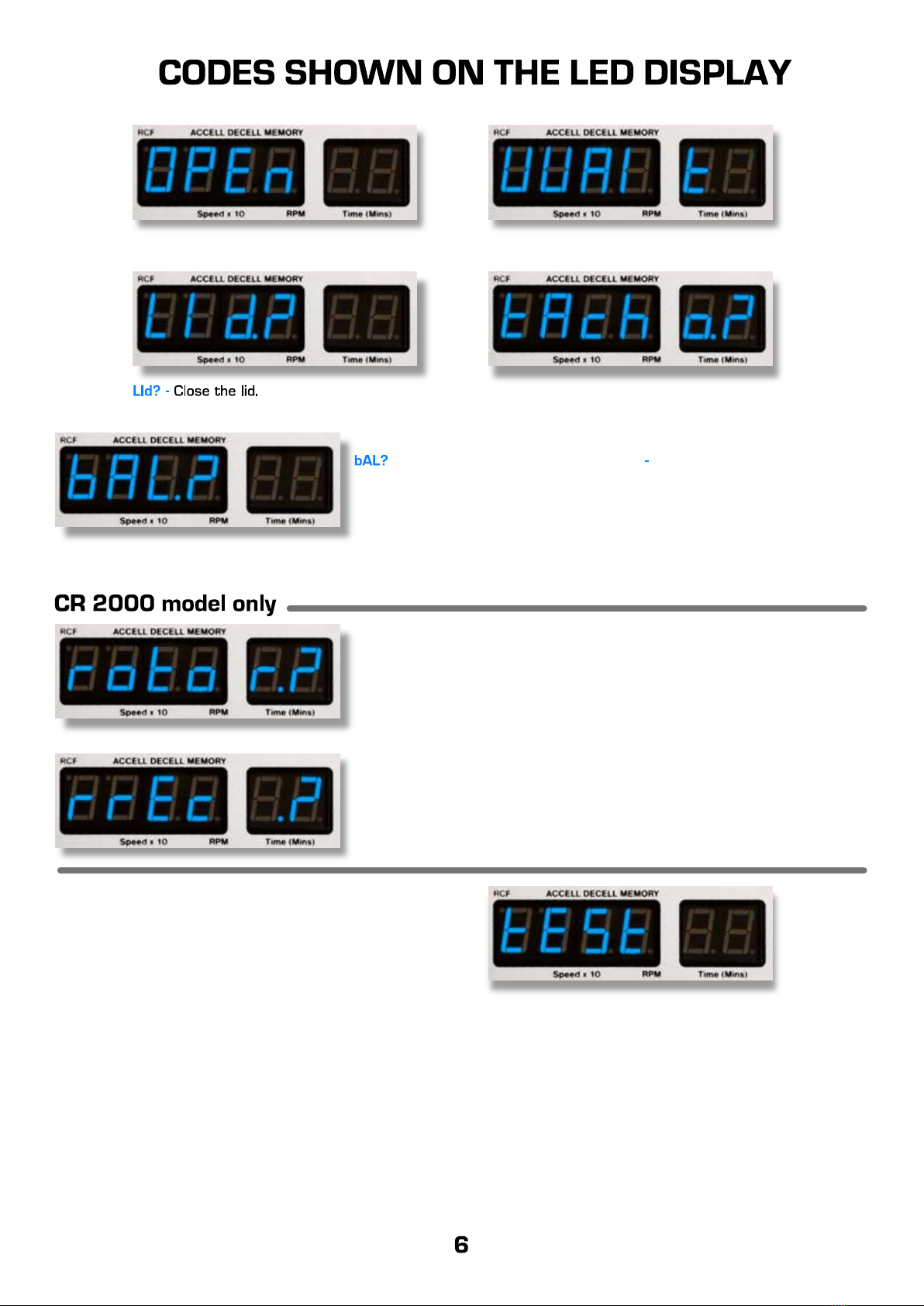

Above shows 12000 (Rpm see dot bottom right) IE: 1200 x 10 and 30 minutes of time

Above shows Acceleration rate of 9, Decelleration rate of 9 and Memory number 1

To set speed in Rpm

Press up or down arrows below speed display.

To set in Rcf (G)

Press Function button (keep held down) then press Lid open button.

NOTE the direction of blue dot in the speed display

Top left for RCF program, bottom right for Rpm.

To set time

Press up or down arrows below time display.

To set:

acceleration or deceleration rates

Press Function button (keep held down) then

Press Speed Down arrow for acceleration

Press Speed Up arrow for Decelleration (brake)

Both show 0-9 inclusive, 9 is the highest rate

To set:

memory and store

(first set speed or rcf &time)

Press Function button (keep held down) then

Press Pulse button to select number 0-9

inclusive

Press Time down arrow to store

To recall memory

First recall memory number (see above)

Press Function button (keep held down) then

Press Time up arrow to recall memory

To use the centrifuge Follow safety instructions on previous pages. Always load samples evenly.

Load samples, Fit lid (if applicable) Set Speed or Rcf(G) then designated time.

Close the Centrifuge lid. Press down firmly on both left & right sides.

Press Start button (bottom left), the motor will now accelerate to the designated setting.

When time has counted down (time display right) the rotor will decelerate (brake).

According to the setting you have made (9 is fastest) the rotor will stop and OpEn will appear on the display.

Press Lid open button and retrieve your samples.

You can stop the run at any time by pressing the Start / Stop button.

To use Pulse (short run)

This method allows very short runs mainly for “Pelleting” purposes.

Set your desired speed or RCF (G) Time is not relevant.

Load your samples. Fit lid (if applicable).

Press Pulse button (bottom right) keep held down, you will see the Time display counting up in seconds.

As long as you keep the button held down time will increase. On releasing the button centrifuge will brake.

Press Lid open when OpEn appears on the display , and retrieve your samples.