FlexiForce Frequenz 400-100 User manual

Instruction Manual

Frequenz400-100 / Frequenz400-140

REV:03

Contents

1General Safety Information........................................................................................- 2 -

2Product Description ...................................................................................................- 3 -

3Technical Data ...........................................................................................................- 3 -

4Drawing of appearance and dimension .....................................................................- 4 -

5Warnings – Symbols ..................................................................................................- 5 -

6Safety information of operation..................................................................................- 5 -

7Safety information for installation ..............................................................................- 6 -

8Proper Use.................................................................................................................- 7 -

9Scope of delivery .......................................................................................................- 7 -

10 Components introduction...........................................................................................- 8 -

11 Layout of control unit .................................................................................................- 9 -

12 Installation................................................................................................................- 10 -

12.1 Install the torque bracket .....................................................................................- 10 -

12.2 Install the feature key...........................................................................................- 10 -

12.3 Secure the door operator.....................................................................................- 11 -

12.4 Install the emergency release cord......................................................................- 12 -

12.5 Check the emergency operation..........................................................................- 12 -

13 Wiring.......................................................................................................................- 13 -

13.1 Additional accessories wiring guideline ...............................................................- 14 -

13.2 230V single-phase operation...............................................................................- 19 -

14 Operator Programming ............................................................................................- 20 -

14.1 Set Password.......................................................................................................- 21 -

14.2 Load Settings.......................................................................................................- 22 -

14.3 Door Positions .....................................................................................................- 23 -

14.4 Safety Devices.....................................................................................................- 31 -

14.5 Operation Mode ...................................................................................................- 33 -

14.6 Inputs / Outputs ...................................................................................................- 34 -

14.7 Automatic Close...................................................................................................- 40 -

14.8 Service.................................................................................................................- 41 -

14.9 Expert Settings ....................................................................................................- 42 -

14.10 Motor settings ..................................................................................................- 44 -

15 Special Applications.................................................................................................- 45 -

15.1Two-Way-Traffic Function (full setup) ..................................................................- 45 -

15.2 Airlock Function (simple setup) ...........................................................................- 48 -

15.3 Airlock Function (full setup) .................................................................................- 49 -

15.4 Smoke Alarm System ..........................................................................................- 52 -

15.5 Connecting a Door-Lock with return channel ......................................................- 53 -

16 Connectors Pin Assignment ....................................................................................- 55 -

17 Error Code Table......................................................................................................- 56 -

18 EC Declaration.........................................................................................................- 58 -

- 2 -

1 General Safety Information

⚫The door operator may only be used under the conditions described in these

instructions. Any other use will be considered improper usage and therefore

dangerous. The manufacturer is not liable for damage resulting from improper,

incorrect or inappropriate usage.

⚫Failure to observe the information contained in these instructions may lead to personal

or material damage. The instructions must be passed on to all future users and

operators of the door operator.

⚫Only use the door operator if no maintenance or adjustment measures are required to

do so. Disconnect the operator from the power supply for cleaning or maintenance.

⚫Only use the door operator if the entire area of movement is fully visible. During

operation, be aware of other people who may be within the operating range of the

product or who may enter this area. Do not drive or walk underneath the door while it

is moving.

⚫Do not use the door operator to lift up objects and/or people.

⚫Ensure that children are kept away from the area around the door.

⚫Children over the age of 8 and persons with reduced physical, sensory or mental

capabilities may operate the door operator when supervised or if they have been

instructed in the safe handling of the equipmentand are aware of the associated risks.

⚫Keep remote controls and/or other controls out of reach of children to prevent the

accidental activation of the door operator.

⚫Cleaning work on the door operator or the door or any maintenance measures may

only be performed by children when supervised.

Dispose the operator according to your local environmental regulations.

Electrical parts must not be disposed as domestic waste !

- 3 -

2 Product Description

The door operator has been developed for industrial doors.

The door operator can be equipped with the following additional safety devices, such as:

-Photocells,Light curtains,Safety edges

-Radar

-Loop detector

-Remote control,Push buttons,Pull switches

-Traffic light

The door operator is operated via the control unit.

You can choose different operating settings for the operator (e.g. automatic, semi-

automatic or hold to run).

3 Technical Data

Model

Frequenz 400-100

Frequenz 400-140

Rated Voltage/Frequency

400V 3-phase/ 50Hz

400V 3-phase / 50Hz

Rated input power in KW

0.8

1.1

Torque in Nm

100

140

Speed in RPM

30

30

Frequency converter

NA

Diameter hollow shaft in mm

25.44mm

25.44/31.75mm

Max cycles per hour

35c/h

Emergency release

Chain hoist

Limit setting of door travel

Digital encoder

- 4 -

4 Drawing of appearance and dimension

Hyper lift-model

Frequenz 400-100

Frequenz 400-140

Door operator L*W*H(mm)

431*180*280

488*180*280

Control box L*W*H(mm)

420*122*162

420*122*162

Packing L*W*H(mm)

573*510*200

573*510*200

Door operator

Control box

- 5 -

5 Warnings – Symbols

Note: Technical information must be observed

Fig. 1 Number of a figure

Caution: Warns of a risk to a person / risk of injury

Warning: Warns of a risk to material / risk of damage

6 Safety information of operation

The door may only be operated if:

⚫Conformity in accordance with Machinery Directive 2006/42/EC was declared

following assembly.

⚫The door complies with the standards EN 12605, EN 12604 and DIN EN 13241-1.

⚫The door operator has been assembled in accordance with EN 12453, EN 12445 and

EN 12635.

⚫Any additionally installed safety equipment is functioning properly.

⚫There is an internally operated emergency release for garages that have no second

access.

⚫Any pass door set within the door is equipped with a safety device that prevents

switch-on while the door is open.

⚫The emergency release cannot be caught on any vehicle parts (e.g. roof structures).

⚫It is insured that the installation is conform with the national safety regulations.

Keep the instruction manual at a safe place!

- 6 -

7 Safety information for installation

Important:

The door must move easily and be functional and well-balanced in accordance with the

manufacturer's specifications.

It must be possible to open and close the door by hand easily.

Assembly must be carried out by trained and specialized personnel.

Electrical installation work must only be performed by authorized and specialized

personnel.

The suitability and bearing capacity of the supporting structure of the building in which the

door operator is to be installed must be checked and confirmed by expert personnel.

The door operator must be securely fastened at all the mounting points provided. The

mounting material must be chosen according to the material characteristics of the

supporting structure to ensure that a minimum tensile force of 900 N can be withstood.

If these requirements are not fulfilled, the door operator may fall down or the door may

move without control. This means there is a risk of personal injury or material damage.

When mounting the door operator, it must be secured by appropriate means against falling

until it is completely and safely attached.

Observe the relevant occupational health and safety regulations during the installation.

- 7 -

8 Proper Use

This door operator is suitable for use with balanced sectional doors and sectional

doors equipped with spring-break protection and/or safety catch.

The maximum dimensions given in the technical data must be complied with.

Before installing the door operator, any existing locking mechanisms for the door must be

disassembled or taken out of operation.

Use in an explosion-proof environment is not permitted.

Any other use above and beyond this is considered as improper use.

All the below activities performed without the expresswritten approval of the manufacturer:

⚫Expansions or modifications

⚫Use of non-original replacement parts

⚫Performance of repairs by persons or operators that have not been authorized by the

manufacturer may result in the loss of the warranty.

No liability can be accepted for damages that result from the following causes:

⚫Technical defects on the door to be operated and structural deformations occurring

during operation

⚫Improper maintenance of the door

⚫Failure to observe the operating instructions

9 Scope of delivery

1

Door operator with emergency release (chain)

2

Control unit with main switch

3

Torque bracket

4

Assembly fasteners

5

External power cable with plug

6.

Signal cable

7.

Internal power cable

- 8 -

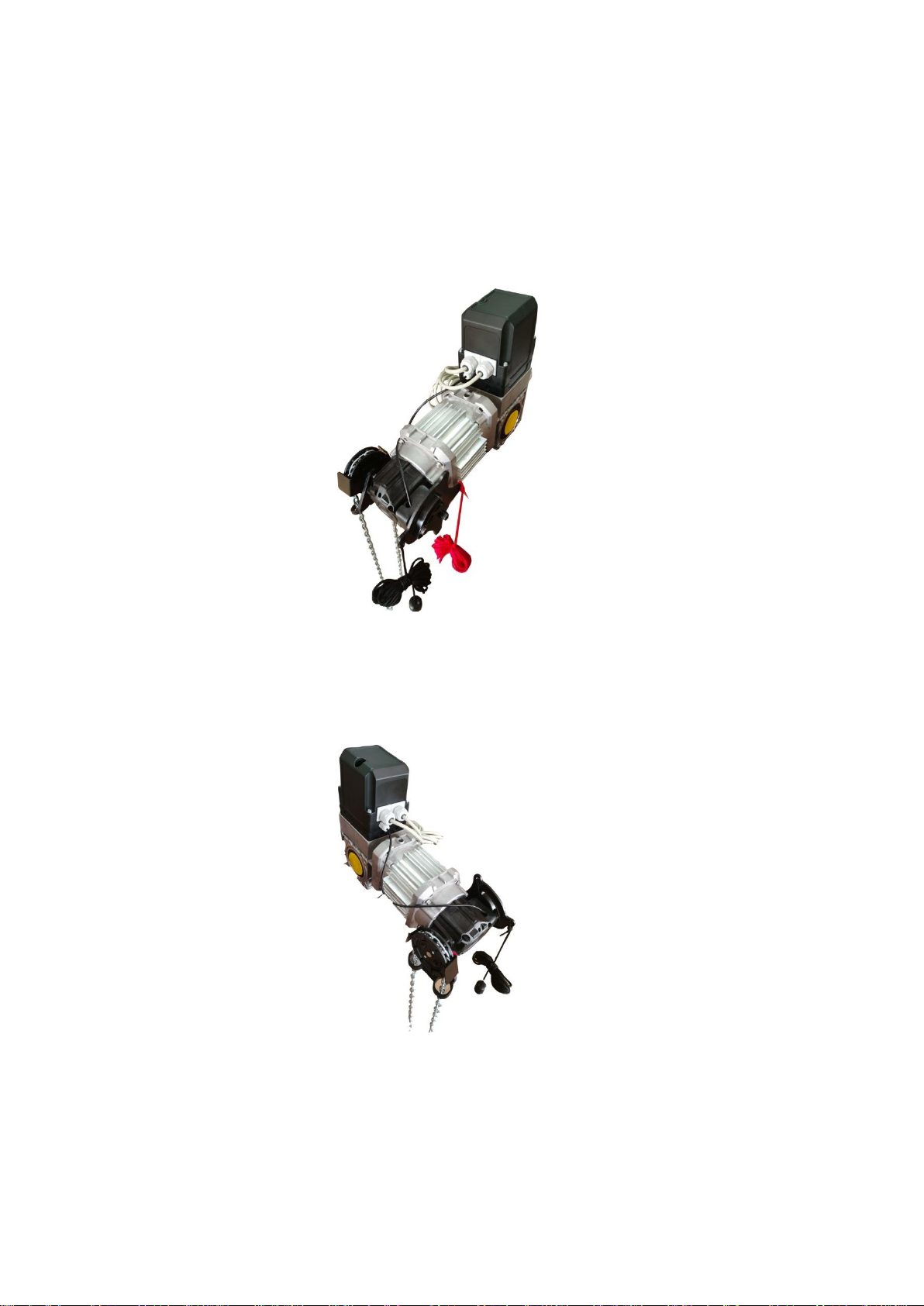

10 Components introduction

1

Motor

2

Emergency release (Chain)

3.

Gear box

4.

Emergency release deactivate cord

5

Emergency release activate cord

6

LCD display

7

“UP” button

8

“STOP” button

9

“DOWN” button

10

Main switch

11

Power plug

1

2

4

5

3

6

7

8

9

10

11

- 9 -

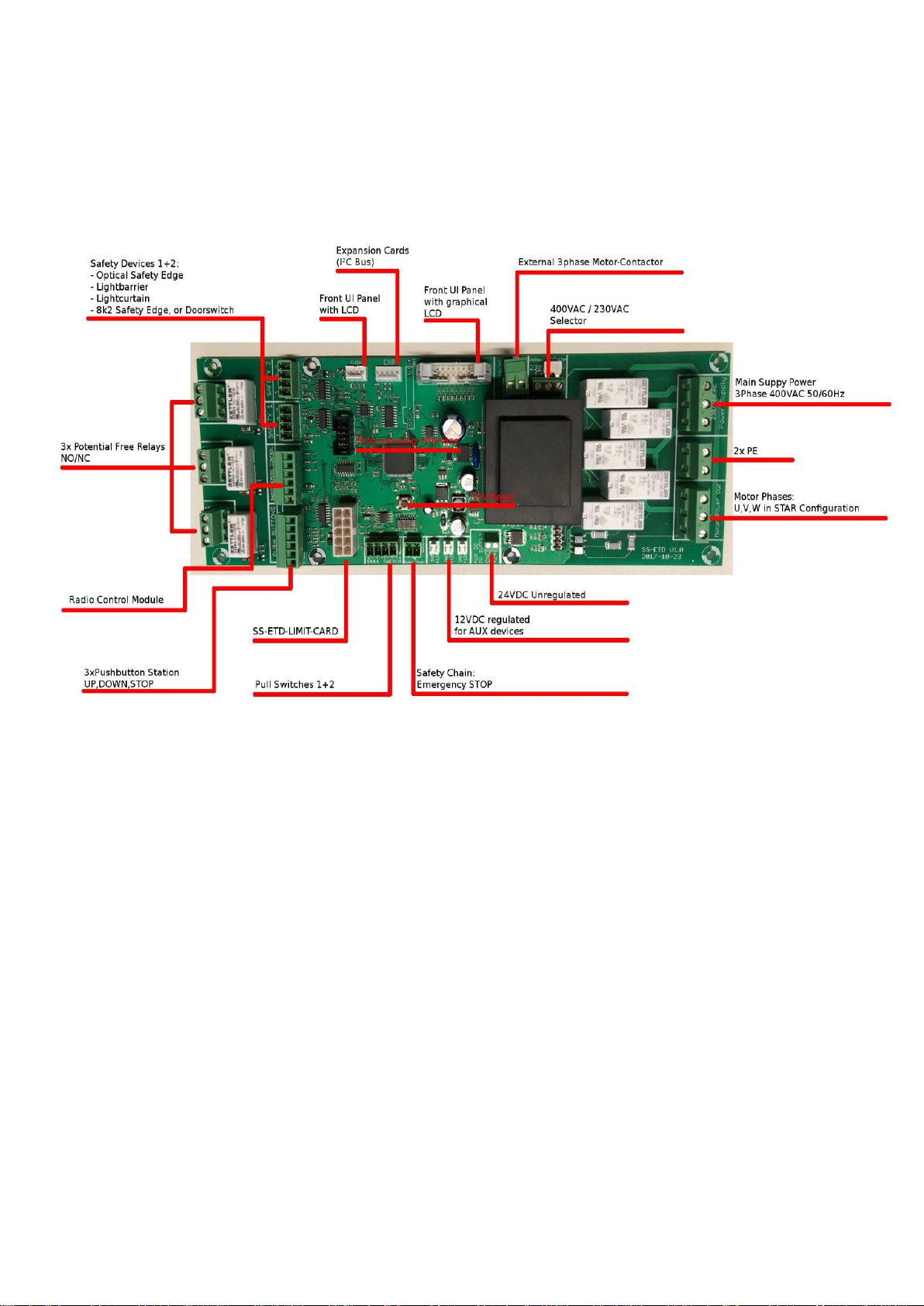

11 Layout of control unit

Frequenz 400V

- 10 -

12 Installation

The door operator shown is similar to sectional door operators type with chain

drive. Unless described otherwise, the assembly steps also apply to high speed

door operators with crank.

Preparation for installation

Risk of personal injury and/or material damage due to electrical voltage. Have a

specialized electrician open and close the cover for the motor controller.

Determine the installation location of the door operator

The door operator must be positioned 100% above the door drive shaft.

Make sure that neither the emergency manual operation chain nor crank

(depending on version) can impair the normal operation of the door (clearance)

and that they can be used at any time.

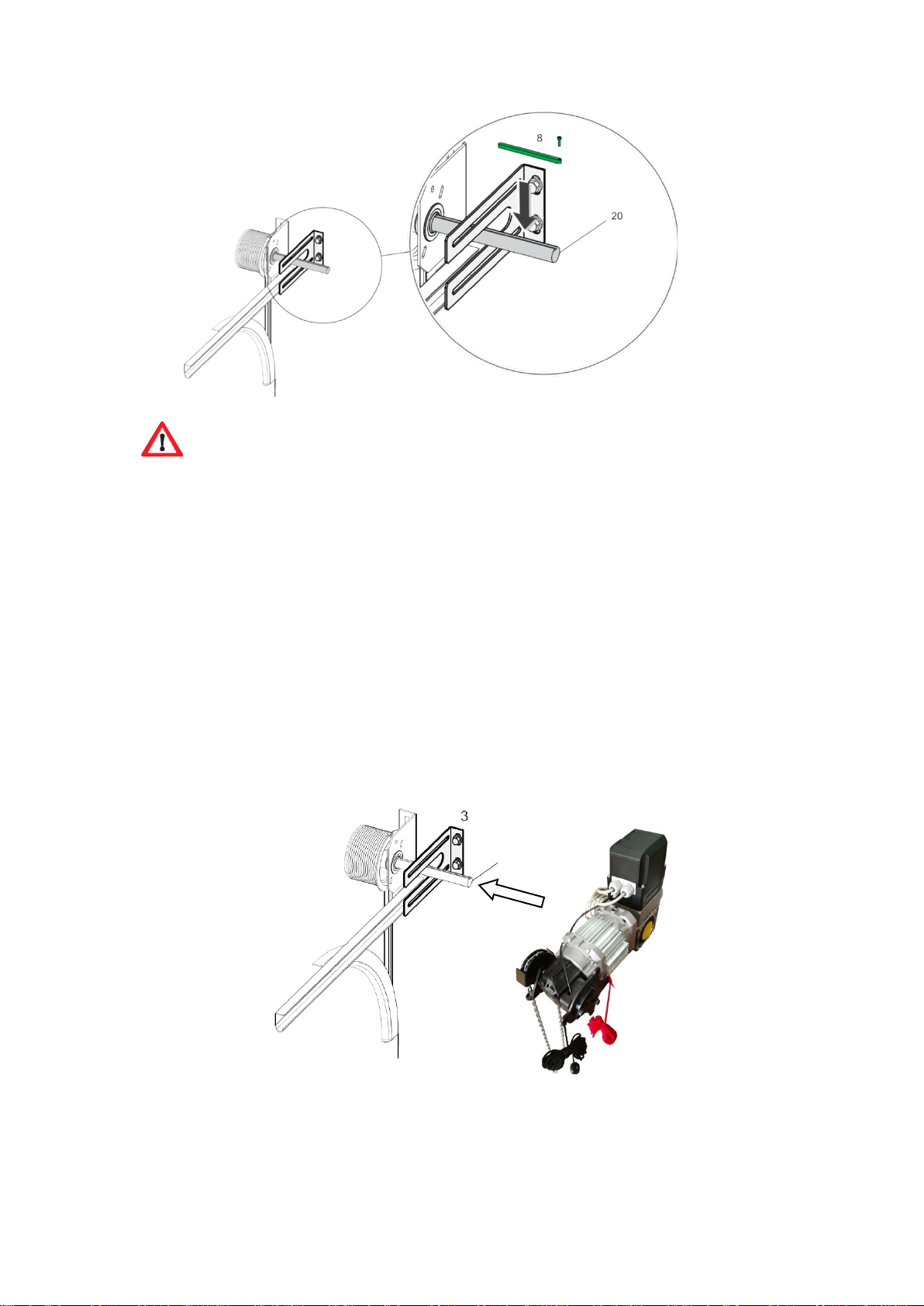

12.1 Install the torque bracket

Install the torque bracket (3) as shown in Fig. 1. Make sure that the drive shaft for the door

can extend at least 135 mm (dimension A) in the door operator to be installed.

Fig. 1

12.2 Install the feature key

Install the key (8) in the groove of the drive shaft for the door so that is secured against

movement in Fig2.

- 11 -

Fig.2

The door operator is heavy, which may falls and causes personal injury and/or material

damage. A suitable hoist must be used to bring it into the installation location.

⚫Do not supply power to the door operator yet. Do not connect any plugs.

⚫Position the drive shaft for the door operator such that it is suitable for the position of

the anti-twist device (key, position 8 in Fig. 2). To do this, turn the transmission via

the emergency operation.

⚫Grease the drive shaft for the door such that the door operator can be easily

connected.

12.3 Secure the door operator

Slide the door operator onto the door drive shaft (20)in Fig. 2. Secure the door operator

with the 4 screws and washers (13) in Fig. 3.

Fig. 3

- 12 -

12.4 Install the emergency release cord

⚫Secure the emergency release cord such that the emergency release can be activated

by using the red emergency release cord.

⚫The emergency release is activated when the chain wheel (3) has been moved by

pulling down the red emergency release cord in Fig. 4.

⚫Make sure that the emergency release can be deactivated again by pulling the black

cord.

Fig. 4

12.5 Check the emergency operation

Make sure that the door can be opened and closed without any problems by pulling on the

chain in Fig. 5.

Fig. 5

If the door can be opened and closed without any problems, this confirms the functional

reliability of the emergency operation. The door operator can be commissioned.

- 13 -

13 Wiring

Door Operator

400V Power input

Control Box

Power from Main Switch

Connect to Emergency

release sensor

Signal cable

- 14 -

13.1 Additional accessories wiring guideline

•Must use NC mode safety devices.

•After connecting additional devices, activate them in the operator menu if

necessary (see section 14)

•Maximum combined current draw (12V): 300 mA

•All safety devices may be connected to either SAFETY 1 or SAFETY 2. Both

connectors are equivalent. Examples will show only connections to SAFETY 1 for

the sake of simplicity.

13.1.1 Push buttons

Connect additional buttons, key-switches and other command sources to the

PUSH BUTTONS row. The input functions and logic are programmable (see 14.6.2).

Default settings are:

Input

Default logic setting

Default function

UP

NO (normally open)

Open door

DOWN

NO (normally open)

Close door

STOP

NC (normally closed)

Stop door

Multiple buttons can be connected in parallel as shown below:

13.1.2 Light curtain

Activate light curtain in MENU ➔SAFETY DEVICES ➔SAFETY 1 or SAFETY 2 ➔LIGHT

CURTAIN then pick the correct TEST MODE for your light curtain (See 14.4).

See below for FSS type light curtain example:

- 15 -

13.1.3 Safety edges

Activate safety edge in MENU ➔SAFETY DEVICES ➔SAFETY 1 or SAFETY 2 ➔

SAFETY EDGE then pick the correct TEST MODE (See 14.4).

OSE:

8k2Ωresistive edge:

The 8k2Ωresistive edge is tested before each downwards movement.

A connection between SIG and TEST must be present.

8k2Ωair pressure switch:

- 16 -

13.1.4 Photocell

Activate photocell in MENU ➔SAFETY DEVICES ➔SAFETY 1 or SAFETY 2 ➔

PHOTOCELL then pick the correct TEST MODE (See 14.4).

See below for PHOTOCELL in mode 4-WIRE: TEST (-):

13.1.5 Remote control / radar / induction loop

Connect radio remotes or other additional command sources (for example: radar, induction

loops) to the RADIO REMOTE CONTROL row of inputs.

The inputs functions are programmable (see 14.6.3).

Default settings are:

Input

Default logic setting

Default function

CH1

NO (normally open)

Open door

CH2

NO (normally open)

Close door

CH3

NO (normally open)

Impulse (UP –STOP –DOWN –STOP sequence)

- 17 -

13.1.6 Traffic light

Connect traffic light as shown below:

Some example setups for using the red/green traffic light:

Example 1: Red light stays on while door is closed:

1. red light: MENU ➔INPUTS/OUTPUTS ➔RELAY OUTPUTS ➔RELAY 1 ➔

ENDPOSITION ➔NOT OPEN

2. green light: MENU ➔INPUTS/OUTPUTS ➔RELAY OUTPUTS ➔RELAY 1 ➔

ENDPOSITION ➔OPEN ENDPOSITION

Example 2: Blinking red light with a warning time before movement:

1. red light: MENU ➔INPUTS/OUTPUTS ➔RELAY OUTPUTS ➔RELAY 1 ➔

MOVEMENT ➔BOTH DIRECTIONS ➔BLINKING ➔[set pre run delay as required]

2. green light: MENU ➔INPUTS/OUTPUTS ➔RELAY OUTPUTS ➔RELAY 1 ➔

ENDPOSITION ➔OPEN ENDPOSITION

- 18 -

13.1.7 Impulse function pull switches / push buttons

The impulse function (UP –STOP –DOWN –STOP sequence) allows to control the door

with a single button.

Connect NO-type pull switches or push buttons to either PS1 or PS2 (both are equivalent).

13.1.8 Safety Chain

This connector allows for adding devices into the safety chain in series.

When the NC-type safety chain is opened at any point, all motor relays will disengage

immediately.

Note: A bridge must be placed in this connector when it is not used. Door

movement is not possible while this connector remains open. Error code [96] will be

shown while safety chain is open at this connector.

- 19 -

13.2 230V single-phase operation

This operator may be used in single-phase, 230V configuration, to drive a capacitor motor.

To prepare the operator for 230V single-phase mode, perform the following steps:

(0) Make sure to fully disconnect the operator from supply power!

(1) Move the ‘Voltage-Selector’ bridge into the 230V + COM position as shown below.

(2) Connect phase N to input L3, phase L to input L1. Leave input L2 open.

(3) Connect capacitor motor to motor out, so that the capacitor is placed between

motor phases V and W.

This manual suits for next models

1

Table of contents