Flexiheat FH50ECP User manual

1

02/04/2019Page

INSTALLATION INSTRUCTIONS

Wood Warm Air Heaters

FH50ECP and FH100ECP

Please read carefully the precautions for use and the instructions for use before any installation andcommissioning.

Nominal thermal power kW 50 100

Flow at + 20ºC m3/ h 1700 3,400

TREATED AIR Static pressure

useful

mm.ca 5 5

Thermal jump º C 45 45

Number of fans Nº 1 1

rpm 900 900

Electric tension V 230 230

Weight Kg. 240 440

Maximum load (dry wood) Kg. 10 20

Hearth Dimensions (Long, Wide, High) cm 83x50x60 115x70x65

Hatches Dimensions (Long, Wide) cm 64x28 89.2x28

Heating power dry wood = 4000 kcal / kg

• Recommendations

-Carefully read the warnings that appear in the instructions, knowing that they contain important

according to the manufacturer's instructions, by professionally qualified personnel or by a technical platform

approved by the manufacturer. An error during installation can cause damage and risks to people and

equipment, for which the manufacturer cannot be held responsible.

-Check the packaging and the integrity of the contents. If in doubt, do not use the device and contact the

distributor or the manufacturer.

-Do not leave the packaging elements within the reach of children, as they represent a source of

danger.

-Keep the suction grilles free.

-In the event of a breakdown or malfunction of the appliance, unplug it, refraining from any attempt

to repair it, and contact your distributor.

-As soon as you decide to stop using the appliance, you must not use parts that could constitute a

-Make sure that these instructions are always included with the device.

-The regulatory protection of the device must be ensured in accordance with the classification standards for the

professional premises where it is installed.

If the appliance is installed in a place where there are disabled people and / or accompanied by

children, it must be installed with protections in accordance with the regulations in force.

In the event of overloading: Risk of deformation of the floor crosspieces and cracks in the

brickwork Damage to the exchanger tubes, temperature rise, general deformation and damage to

the device.

2

02/04/2019

FH50ECP FH100ECP

1TECHNICAL CHARACTERISTICS:

Page

Never load more than 10 kg of log wood or briquettes for FH50ECP and 20Kg for FH100ECP, i.e. 50

and 100 kW.

source of danger.

-This appliance must be used for the use for which it is intended. Any other use will be considered inadequate and,

if necessary, dangerous, relieving the manufacturer of responsibility and thereby voiding the manufacturer's

warranty.

indications relating to the safety of the installations, their use and maintenance.

-Use wood as a priority to ensure good combustion of Heater.

-The installation must be carried out according to the standards in force in the country where it will be used,

This hot air generator works with solid vegetable fuels; it is a device whose operating principle is

the production of direct heat through the use of thermal energy produced by combustion.

Heat exchange is produced when a flow of air generated by a fan is passed through the internal

surfaces of the heat exchanger, without the aid of any intermediate fluid so called direct

exchange. In addition, part of the thermal energy is produced by the low temperature radiation of

the machine.

The gaseous residues resulting from the combustion (fumes), when the heat exchange is carried out,

are expelled outside through the flue gas pipe at a temperature of approximately 280 ° C at maximum

developed power.

The solid residues of gasoline combustion (ash) fall naturally thanks to a stainless steel grate in an

ashtray drawer in the lower part.

This appliance is used for heating industrial environments and meets these standards. It can also

be used for any other application, in this case, refer to the specific standards.

To) A rectangular-shaped combustion chamber briquetted by refractory elements.

b) A tilting hatch for loading solid fuels.

vs) A tubular heat exchanger with a large surface area with natural ventilation fairing.

d) A perforated ash collection drawer with adjustable primary combustion air intake ruler.

e) A chimney nozzle fitted with a draft key through which the combustion residues pass to be

expelled through the smoke duct outside the heated enclosure.

• Ventilation group

The device is equipped with a medium pressure centrifugal fan which allows the connection of a

distribution duct.

• Chimney nozzle

The appliance is equipped with a circular outlet of a standard diameter where it is possible to connect and

securely fix a metal flue (preferably insulated) to evacuate the gaseous residues resulting from the

combustion to the outside. The draft key integrated into the nozzle allows the power to be regulated by

limiting the natural depression.

This duct must have the following characteristics:

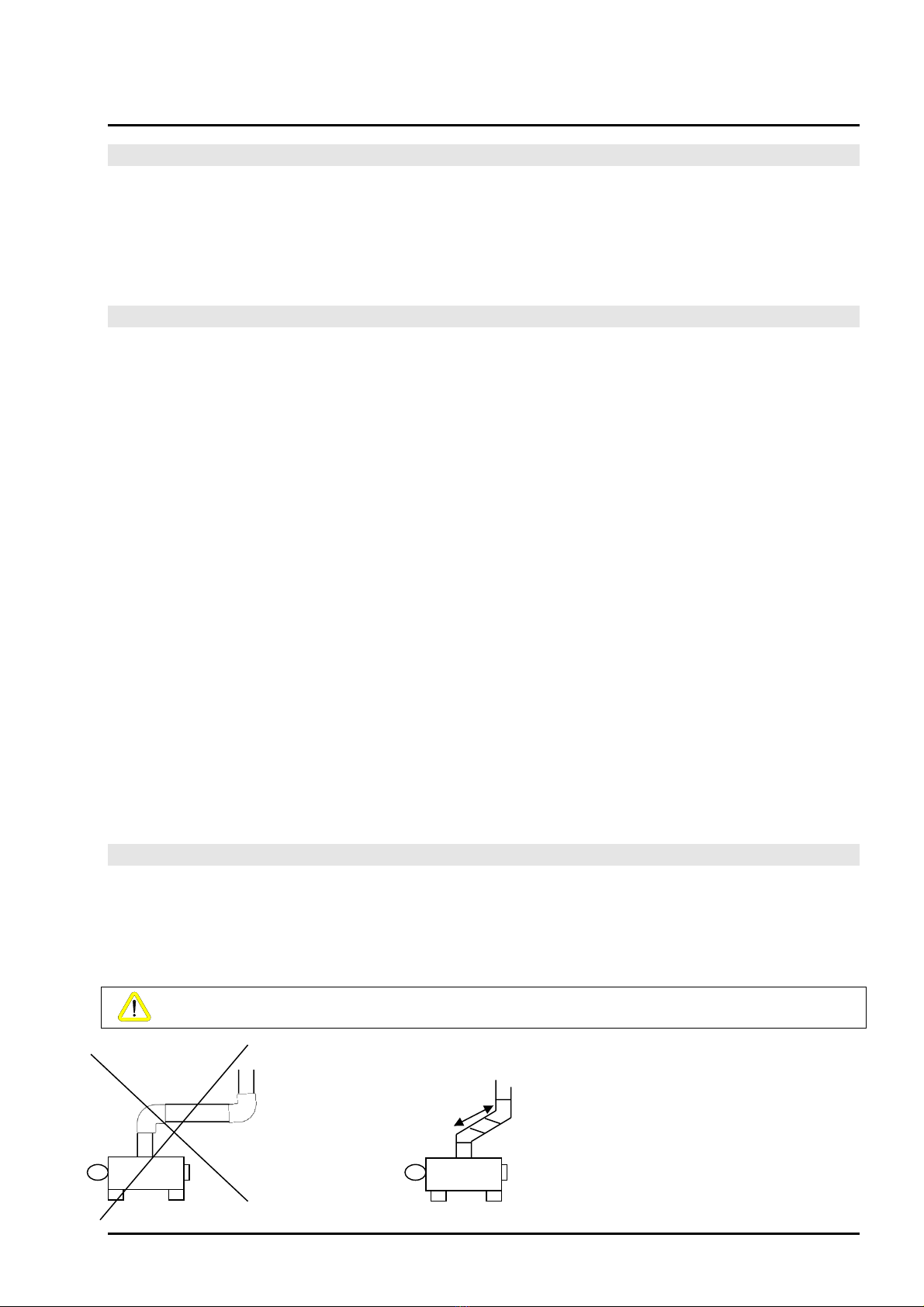

• Do not add elbows with more than a 45 ° angle and raise the duct in this case by 1m per 45 °

elbow

• Have an end part of the duct fitted with a cap.

3

02/04/2019

1.1 PRINCIPLE OF FOOPERATION:

2CONSTRUCTION OF THE APPLIANCE:

• Diameter equal to or greater than the nozzle of the device and without section reductions. (Ø 153 mm

for FH50ECP and Ø 200 mm for FH100ECP)

Page

The heater is made of carbon steel sheet, developed according to European standards. Easy

to access for normal cleaning and maintenance operations. It is composed of :

It cannot be installed in direct contact with explosive agents or in a flammable

environment.

Hot air generators are shipped with plastic bubble wrap. The accessories are packed separately in

cardboard packaging. Transport and unloading must be carried out with great care to avoid

possible damage. Before accepting the packages, it is advisable to unpack the equipment in the

presence of the carrier in order to ascertain the condition of the goods and therefore to avoid any

dispute.

- Provide a safety distance of at least 1 meter from any obstacle around the device.

- Do not obstruct the fan's suction grilles.

- Check that no obstacle hinders the distribution of hot air.

- Make sure that maintenance and cleaning operations can be carried out easily.

• Electrical connection

The device must be installed in accordance with all standards and laws in force in the

geographical area of use of the device.

The installed chimney will comply with the regulations relating to its use and will have a draft

regulator. This duct will be insulated as far as possible in double skin to avoid the dew point. (1m

after the discharge nozzle). We offer an optional STAINLESS STEEL starter kit with buffer to

facilitate maintenance by relocating the duct.

Never horizontal part with 90 ° elbows

Elbow

open 45 °

Elbow

90 °

Elbow

90 °

- 1m

Elbow

open 45 °

NO YES

4

02/04/2019

2.1 PACKAGING AND TRANSPORT:

2.2 INSTALLATION INSTRUCTION:

The position of the wood heaters must be defined by considering the following indications:

• Installation protocol

- Position of the device level, stably installed on a slab made for this purpose.

2.3 COMBUSTION GAS EVACUATION:

Page

This device has been manufactured according to the EEC 73/23 directive and operates under a

current of 240V single phase 50Hz.

• Key and draft moderator

- To regulate the draft, it is essential to install a draft moderator on the flue gas pipe

- In order to regulate combustion, a regulation key is integrated on the flue gas nozzle which

will limit combustion when the generator is fully loaded and reduce combustion in order to

increase autonomy, particularly at night.

DRAW

The draft of a chimney is determined by the following formula:

T = H (YA - YB)

T = Draft in mm.ca

H = Height of the vertical chimney in meters. YA =

Specific weight of the outside air in kg / m³.

YB = Specific weight of the combustion gases expelled in kg / m³.

SECTION

The section of the chimney for the two series is determined by the following formula:

S = 8.61 Q / H½

S = Section of the chimney in cm²

Q = This is the power of the boiler in kW / h. H =

The reduced height expressed in meters.

The reduced height of the chimney is defined by the following formula:

Hr = H - (N. 0.5 + L + R)

Hr = Reduced height

H = Actual height of the chimney. N

= Number of elbows.

L = Horizontal length.

R = Generator back pressure.

R = 1mm up to 50,000 kcal / h. R =

2mm up to 160,000 kcal / h.

NOTE: These values must be increased by 6% depending on the region for every 500

meters of elevation above sea level.

DUCT DEPRESSION

The draft measurement must be carried out under the shutter, which will allow the shutter to be

balanced during the measurement.

The flue gas pipe must never be reduced to a diameter smaller than that of the

outlet nozzle. However, there is no problem if the duct is of a larger diameter. In the

event of installation on an old masonry duct, it is essential to pipe the duct.

5

02/04/2019Page

During installation, at the time of commissioning, it is recommended to have a draft

measurement called "depression" carried out in order to check the water column of the

chimney's depression.

This measurement is carried out while hot when the device is at its normal output after

approximately half an hour of operation.

This depression should be 2 mm WC after the pull key.

It is therefore recommended for this result a vertical height of 5m for an FH50ECP and 6

to 7m for an FH100ECP.

In order to stabilize the draft, it is necessary to install at the outlet of the Ø 153mm nozzle for

FH50ECP and 200mm for FH100ECP, a tee fitted with a regulator flap.

If you notice after several hours of use that smoke is coming out of the

the sides of the loading hatch closed, the duct does not have enough draft. It must

therefore be enhanced. It is imperative that the duct exceeds at least 50 cm the

highest point of the roof called "ridge" and in any case, higher than 50 cm of any

obstacle around the duct. (building nearby)

The chimney will be insulated and will never have a horizontal part according to the

regulations in force.

Depending on the regulations in force in the geographical area concerned, it may

be necessary to install particle filtration on the smoke evacuation network.

In the event of an electrical fault or fan malfunction, first make sure that:

• The power supply is correct.

• There are no voltage variations greater than + 10% or -15%.

• The fuses are in good condition.

• There is no shortage of solid fuel.

NOTE: Any repairs must be carried out by qualified technical personnel using original

spare parts. It is forbidden to open or manipulate the components of the generator, with

the exception of those provided for maintenance.

NEVER TURN ON THE GENERATOR WITHOUT CONNECTING THE

ELECTRIC NETWORK FAN

NEVER DISCONNECT THE POWER WHEN THE APPLIANCE IS HOT

Since the thermal energy accumulated in the combustion chamber and the heat exchanger

can damage the electric fan unit and the heat exchanger.

DO NOT TOUCH THE PARTS EXPOSED TO HEAT RADIATION in particular the

loading door, the nozzle and the uninsulated duct.

WARNING :

It is imperative to keep a respectable distance when opening the hatch to avoid

any risk of burns.

6

02/04/2019

2.4 IRREGULARITIES IN OPERATION AND PRECAUTIONS

CAUSES AND SOLUTIONS

Page

3 - Deterioration of the steel or carbon heat exchanger tubes 4

- Perforation of the walls or heat exchanger tubes

5 - Deterioration of the high temperature coating

• Ventilation in summer

To obtain ventilation only from the generator, proceed as follows: Switch the

inverter to the summer position.

For normal operation and proper aging of the device over time, it is regulatory that qualified

technical personnel carry out, at least once a year and preferably at the end of the season,

annual maintenance operations, including including the sweeping of the flue. In the event of a

claim, the insurance company will request the annual certificate of chimney sweeping carried

out by a professional.

Any work on the device must be carried out cold.

• Cleaning the exchanger at the end of the season

Proceed as follows:

- Unscrew the exchanger / fireplace assembly bolts

- Remove the exchanger

- Clean the outside of the heat exchanger tubes, if necessary by steam washing using a high

pressure cleaner.

- Empty and clean the ash drawer

- Vacuum the soot in the combustion chamber, clean the brickwork

- Periodically replace damaged bricks (see spare parts list).

• Maintenance of the flue gas pipe

Disassemble the duct components and carefully sweep the flammable deposit film.

• Electric fan unit

Blow out the inside of the engine with compressed air.

Use a brush and compressed air to clean the fan blades

7

02/04/2019

2.5 MAINTENANCE:

Page

Any load greater than the maximum load corresponding to the power of the

device, i.e. 10 kg for FH50ECP and 20 kg for FH100ECP, irreparably implies

overheating of the device in the short term, which causes damage:

1 - The crack in the refractory brickwork

2 - Deformation of the floor cross members which support the INOX floor grid.

This deformation gradually causing the impossibility of opening the ash drawer.

Improper installation of the flue gas can cause the same damage caused by

overheating of the lower part of the appliance due to the lack of draft.

This device is intended for the heating of industrial buildings, or others in compliance

with legislation, safety and fire.

It cannot be installed in direct environmental contact with explosive agents (paints,

solvents, etc.).

The device must be installed in accordance with all standards and laws in force in the

geographical area of use of the device.

After these 2 operations, the stove can be loaded normally.

• Device shutdown at the end of the season

Disconnect the device and carry out maintenance (Paragraph 9).

10Kg of bricks = 50 Kw or 5 Kw per kg of bricks. A standard brick has an average weight of 1.8

kg, or 9 kW of energy.

8

02/04/2019

2.6 COMMISSIONING AND USE OF THE APPLIANCE:

• Use

Page

Note: If these operations are not carried out, there is a risk of cracking certain elements of the

brickwork.

CAUTION: never shock the briquetting at high temperature when filling (risk of cracking the

briquetting elements).

• Firing refractory briquetting at first use

When using for the first time, it is essential to carry out the briquetting firing procedure so

that it takes on its refractory characteristics.

To do this, during the first commissioning,

Connect the fan to the 240V + T electrical network, load the fireplace to 30% of its capacity, i.e.

around 3 to 4 kg with low-density wood, but with rapid combustion of species (wood from pallets,

poplars, offcuts, wooden logs ...)

After the total combustion of this charge, repeat the operation with 50% of the charge (draft key

open to the max.)

• Commissioning after briquetting

- Load the appliance with wood or any other non-polluting solid fuel (for FH50ECP with a

maximum of 10kg, for wood, which represents a combustion of 50KW / for FH100ECP with a

maximum of 20Kg, for wood, which represents a combustion of 100Kw)

- Connect the fan to the 240V + T electrical network.

- Light the selected wood or solid fuel.

- The fuel load must never exceed the rated power of the heater. Do not start the heater without

connecting the fan to the electrical network.

• Fuel (concerns FH50ECP)

The calorific value of dry wood is about 10 kg or (4.7 kW to 5.3kW per kg) 50 kW at 45/50 °

humidity.

The filling for 50 Kw is therefore 10Kg

Each time the wood heater is put into service, it must be lit with a first load of wood in order to

obtain active embers

When reloading, it is possible to incorporate chips or chip brick. The compressed chip brick can be

used for reloading. It is advisable to incorporate a briquette by validating the total load weight

given the high calorific value of the reconstituted briquette.

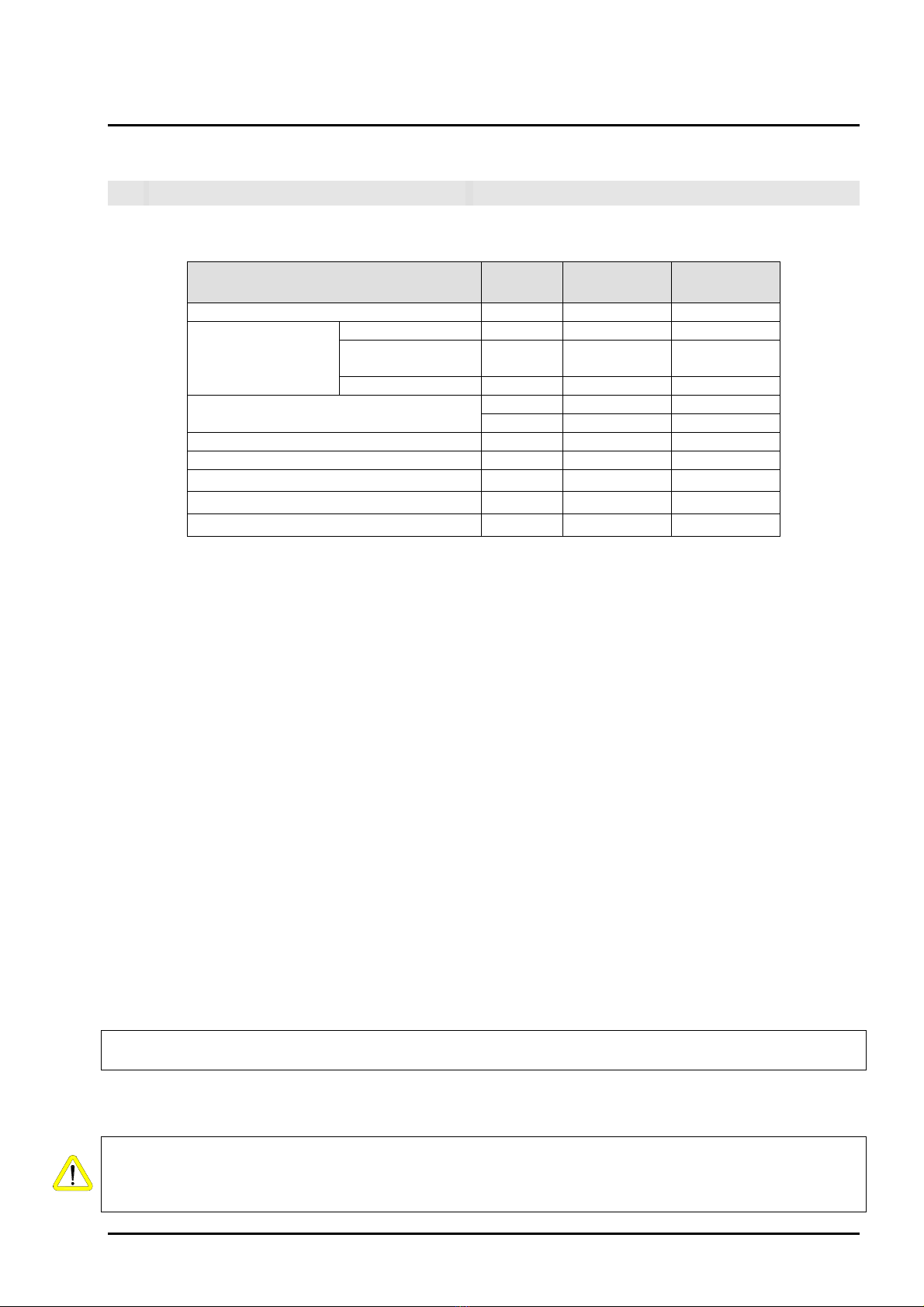

Smoke outlet

with pull key

Draft regulation key

Group

electro-fan

Fairing

exchanger

heat

Brickwork

refractory

ground

Hopper

air distribution

Door of

loading

Drawer

collection ofRoom of

combustion

9

02/04/2019

2.7 EXPLODED VIEW OF THE UNIT:

Stainless steel grid

Page

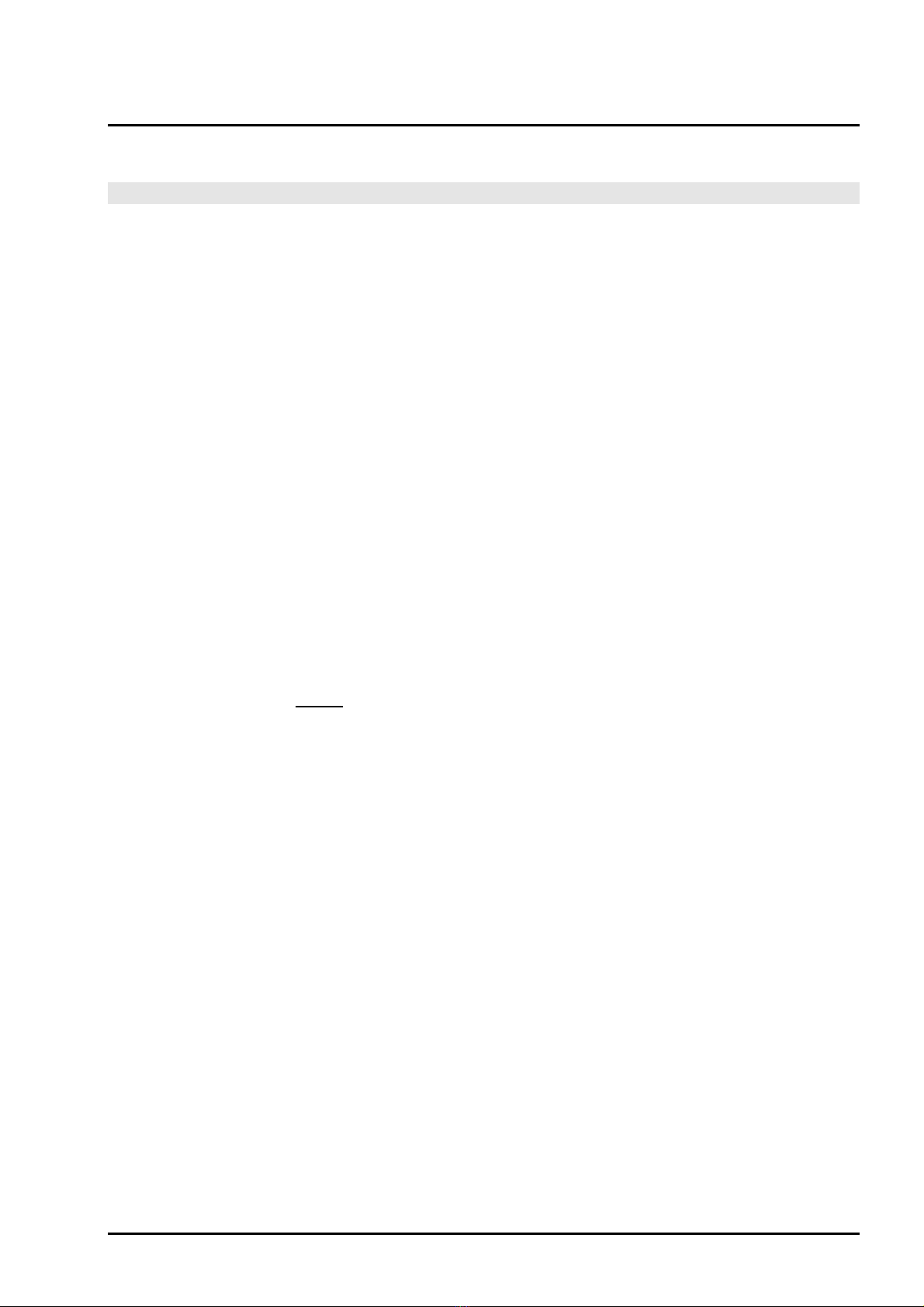

180 mm

700 mm

1110 mm

1180 mm

780 mm

620 mm 970 mm

182 mm

900 mm

1286 mm

1790.50 mm

845 mm 1340.50 mm

10

02/04/2019

2.8 DIMENSIONS:

Page

Model FH50ECP

Model FH100ECP

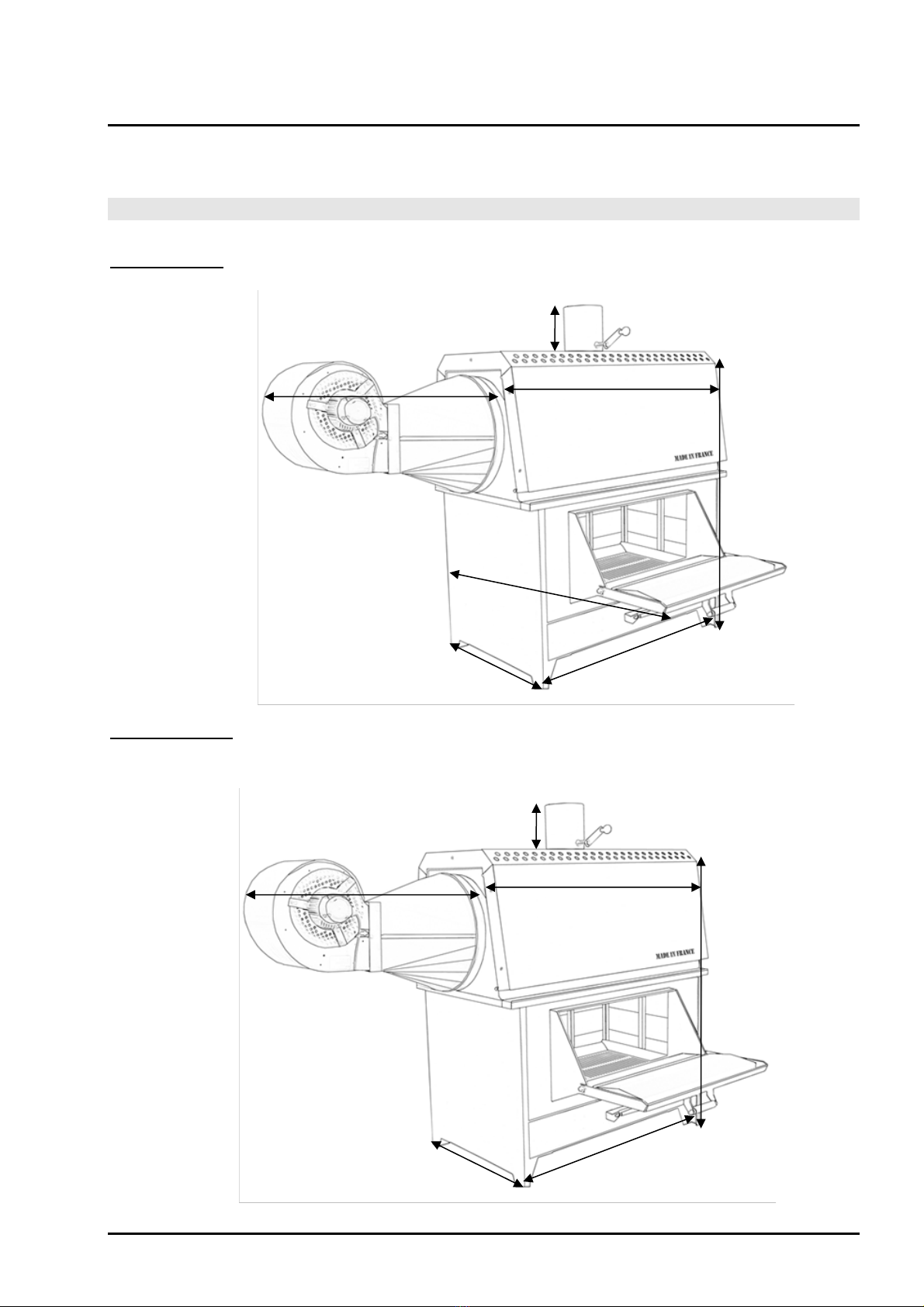

The fan regulation allows the fan to be started up at the set temperature (i.e. around 30 ° C). As soon as

the thermal heating circuit is at this temperature, the fan will start up (inverter in winter position). When

the appliance cools down, the fan will stop at the set temperature in order to prevent the circulation of

fresh air during the mass heating cycle.

Electrical cabinet

V1: Indicator

voltage presence

P2: Inverter

summer Winter

Th: Thermostat

fan

Description of the dashboard Thermostat

Summer

Fuse

Stop

Winter Voltage presence indicator

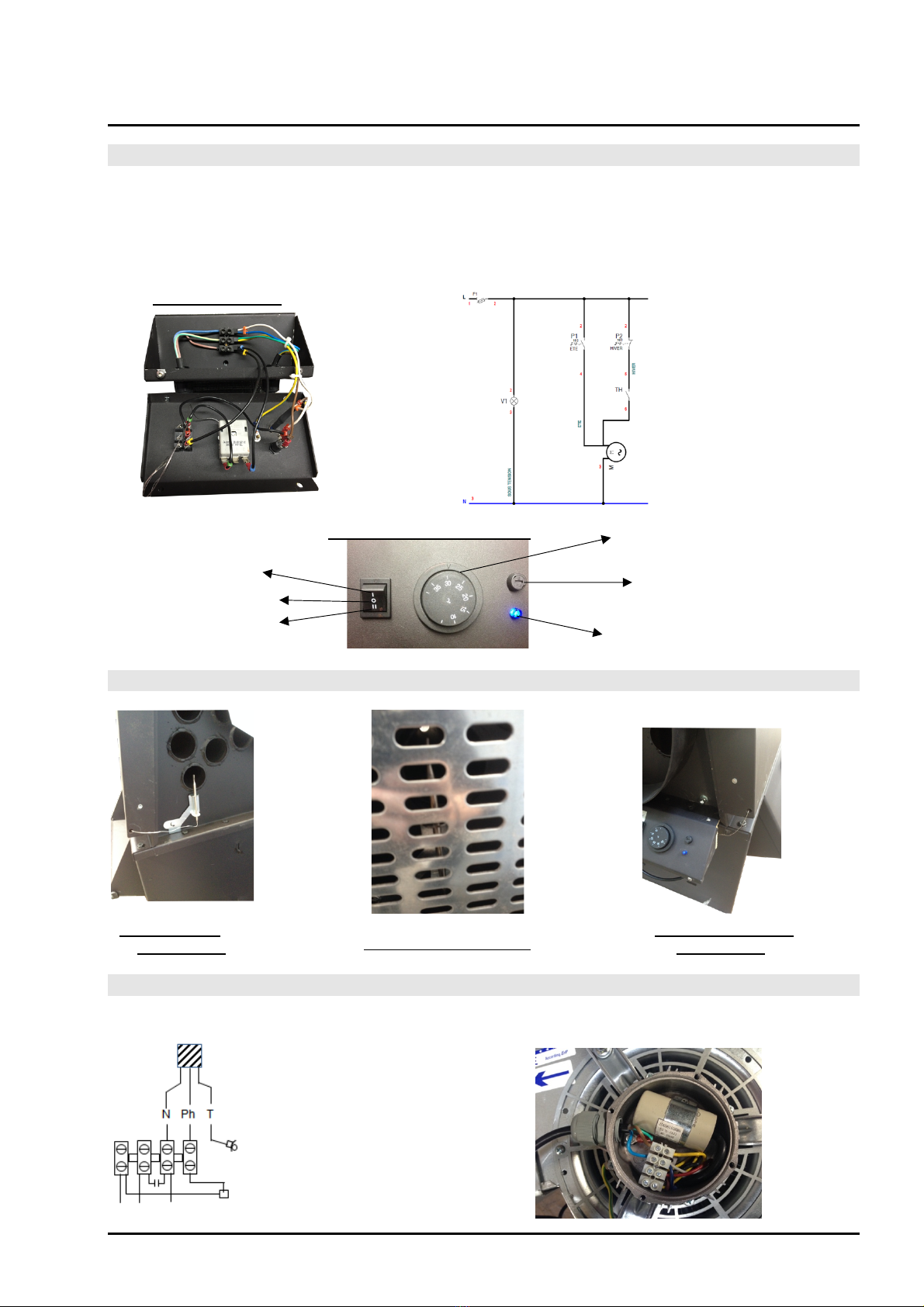

Probe position

thermostatic

Passage of the probe

thermostatic

Position behind the grid

In the 220 V mono motor connection box

Power cable

departure from the cabinet

Earth lug

11

02/04/2019

2.9 DESCRIPTION, CABINET OPERATION (OPTIONAL) AND DIAGRAM

2.10 POSITIONING OF THE ELECTRICAL CABINET AND THE PROBE

2.11 FAN CABLE CONNECTION DIAGRAM

Page

Assembly

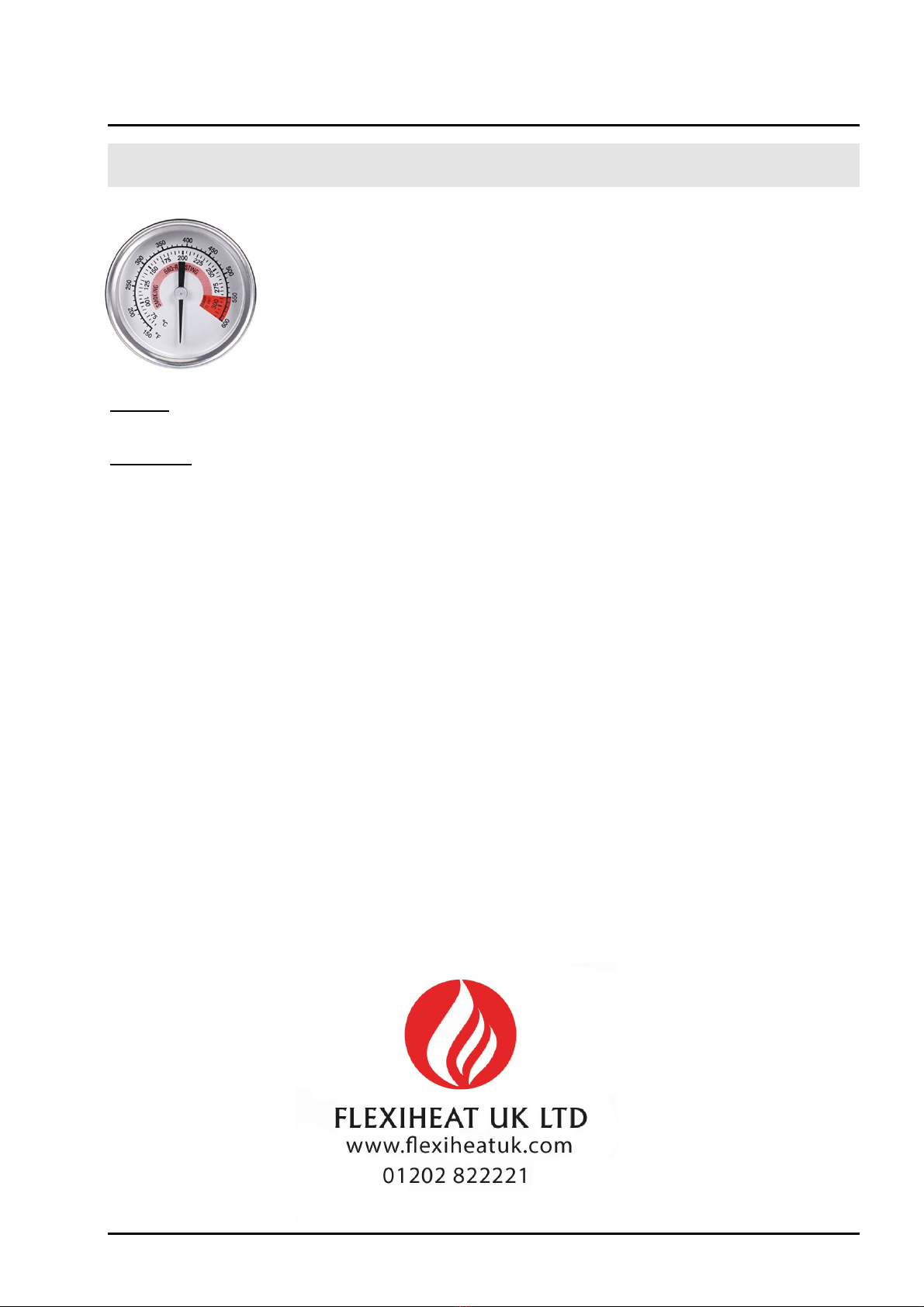

Position the thermometer in the housing provided for this purpose in the chimney nozzle

12

02/04/2019

2.12 DESCRIPTION AND OPERATION OF THE VISUAL THERMOCONTROLE

(OPTION)

Indeed, at full power, the flue gas temperature is around 270 ° for a compliant

chimney installation (2mm / cc of depression)

The visual thermo-control is a thermometer which allows to control

the power produced according to the loading, that is to say 10 kg of

wood for the model FH50ECP or 20 kg of wood for the model

FH100ECP.

Page

At 50% power, i.e. around 150 ° C, you can reload the wood heater with fuel to develop the maximum

power, i.e. 5 kg for the FH50ECP or 10 kg for the FH100ECP, of additional fuel.

Functioning

As soon as the vegetable fuel is burnt, the flue gas temperature is indicated on the visual thermal

control.

The maximum power can be viewed by the red zone of the thermometer dial at 280°

In the event of overheating, spread the fuel in the fireplace and allow the temperature of the flue

gases to drop below 270°

This manual suits for next models

1

Table of contents

Other Flexiheat Heater manuals

Popular Heater manuals by other brands

Thermon

Thermon Caloritech EX Series Installation, operation & maintenance instructions

Truma

Truma Combi operating instructions

Everdure

Everdure HPE221W Operation, maintenance and safety instructions

Frico

Frico IR3000 Original instructions

Midea

Midea NF20-16BA instruction manual

Sealey

Sealey CD2005T.V2 instructions