Flexiheat LEO EL S BMS User manual

LEO

EL S | L BMS

TABLE OF CONTENTS

1. Application...................................................................................... 2

2. Technical Data ............................................................................... 3

3. Installation ...................................................................................... 5

3.1. Installation – bracket ............................................................... 5

3.2. Assembly instructions.............................................................. 5

3.3. U-profiles (optional) ................................................................. 5

4. Connection diagrams...................................................................... 6

5. Start-Up and Operation................................................................... 8

6. Service and warranty terms .......................................................... 10

7. Conformity with WEEE directive 2012/19/UE................................ 12

1. APPLICATION

LEO EL heaters make up a decentralised heating system. Fan heaters

are used for heating large volume buildings: general, industrial and

public buildings etc. The devices are designed for indoor use where

maximum air dustiness does not exceed 0,3 g/m

3

.

2 |

| 3

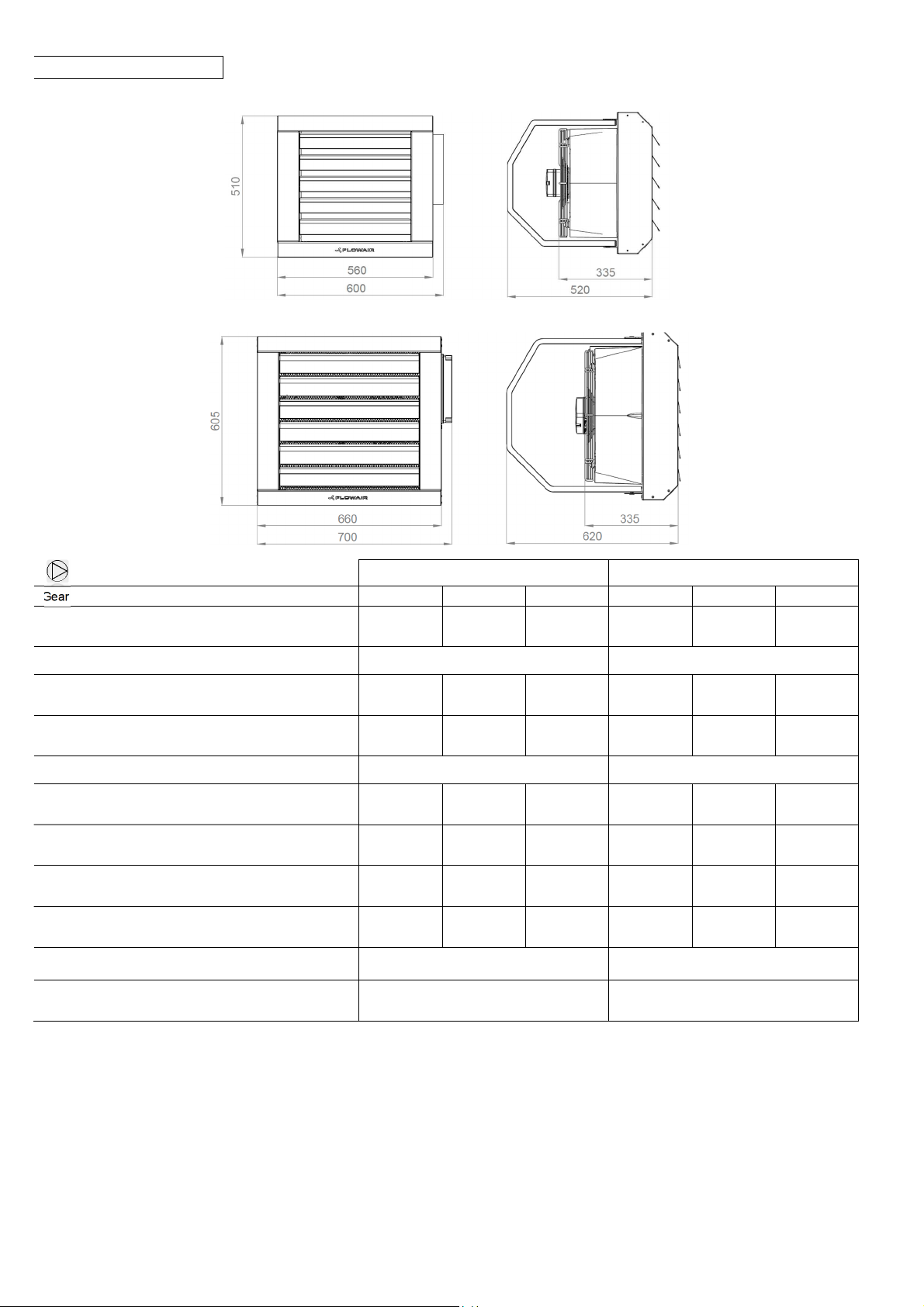

2. TECHNICAL DATA

EL S BMS

EL L BMS

LEO EL S BMS LEO EL L BMS

Gear |

III

II

I

III

II

I

Max airflow [m

3

/h ] |

2000 1600 1250 4250 2800 1700

Power supply [V/Hz]

3x400/50 3x400/50

Max current Fan consumption [A]

0,6 0,4 0,3

1,4 1,2 0,6

Max Fan power consumption [W]

130 90 70

330 240 120

Fan IP/ Insulation class

54 /F 54 /F

Acoustic power level [dB(A)]*

71,4 65,8 59,0 79,2 69,6 57,2

Acoustic pressure level [dB(A)]**

56,3 50,7 43,9 64,1 54,5 42,1

Horizontal range***[m]

14,0 11,0 8,5

24,0 15,0 9,5

Vertical range**** [m]

5,3 4,3 3,4

8,3 5,5 3,5

Device mass [kg]

19,7 27,8

50 50

Max working temperature [

o

C]

* Acoustic power level according to EN ISO 3744:2011

**Acoustic pressure level has been measured 5m from the unit in a 1500m

3

space with a medium sound absorption coefficient

**** Vertical nonisothermal range for ΔT = 5oC and for 0.5 m/s border air stream speed |

***Horizontal isothermal range for 0,5 m/s border air stream speed

4 |

LEO EL S BMS

Tp1 V PT PC Tp2

[°C] [m

3

/h] [kW]* [A]* [°C]

1st step of heating

0

1250/1600/2000

5,5/5,9/6,0 7,9/8,5/8,6 15/10/9

10 5,4/5,7/5,9 7,8/8,2/8,4 22/19/17

20 5,3/5,6/5,8 7,7/8,0/8,3 30/28/26

2nd step of heating

0

1250/1600/2000

9,5/10,2/10,8 13,6//14,7/15,6 28/25/19

10 9,2/9,8/10,3 13,2/14,0/14,8 32/29/24

20 8,9/9,6/10 12,8/13,8/14,4 38/34/30

LEO EL L BMS

Tp1 V PT PC Tp2

0

1700/2800/4250

7,5/8,1/8,8 10,6/11,6/12,5 11/8/6

10 7,1/7,8/8,3 10,1/11,1/11,9 20/17/15

20 6,8/7,6/8,0 9,8/10,8/11,4 29/26/24

1700/2800/4250

13,7/15,1/16,3 19,3/21,4/23,3 24/19/14

10 13,0/14,2/15,4 18,6/20,5/22,2 27/24/21

20 12,4/13,7/14,7 17,8/19,9/21,2 33/30/28

3rd step of heating

0

1700/2800/4250

18,0/20,3/22,8 26,0/29,2/33,3 29/24/18

10 17,2/19,6/21,2 24,5/28,0/31,0 36/30/26

20 16,6/19,1/20,6 24,0/27,5/30,1 44/38/34

2. TECHNICAL DATA

V – air flow

PT – heating capacity

PC – current consumption

Tp1 – inlet air temperature

Tp2 – outlet air temperature

* including Fan parameters

2nd step of heating

0

[°C] [m

3

/h] [kW]* [A]* [°C]

1st step of heating (only with T-box)

| 5

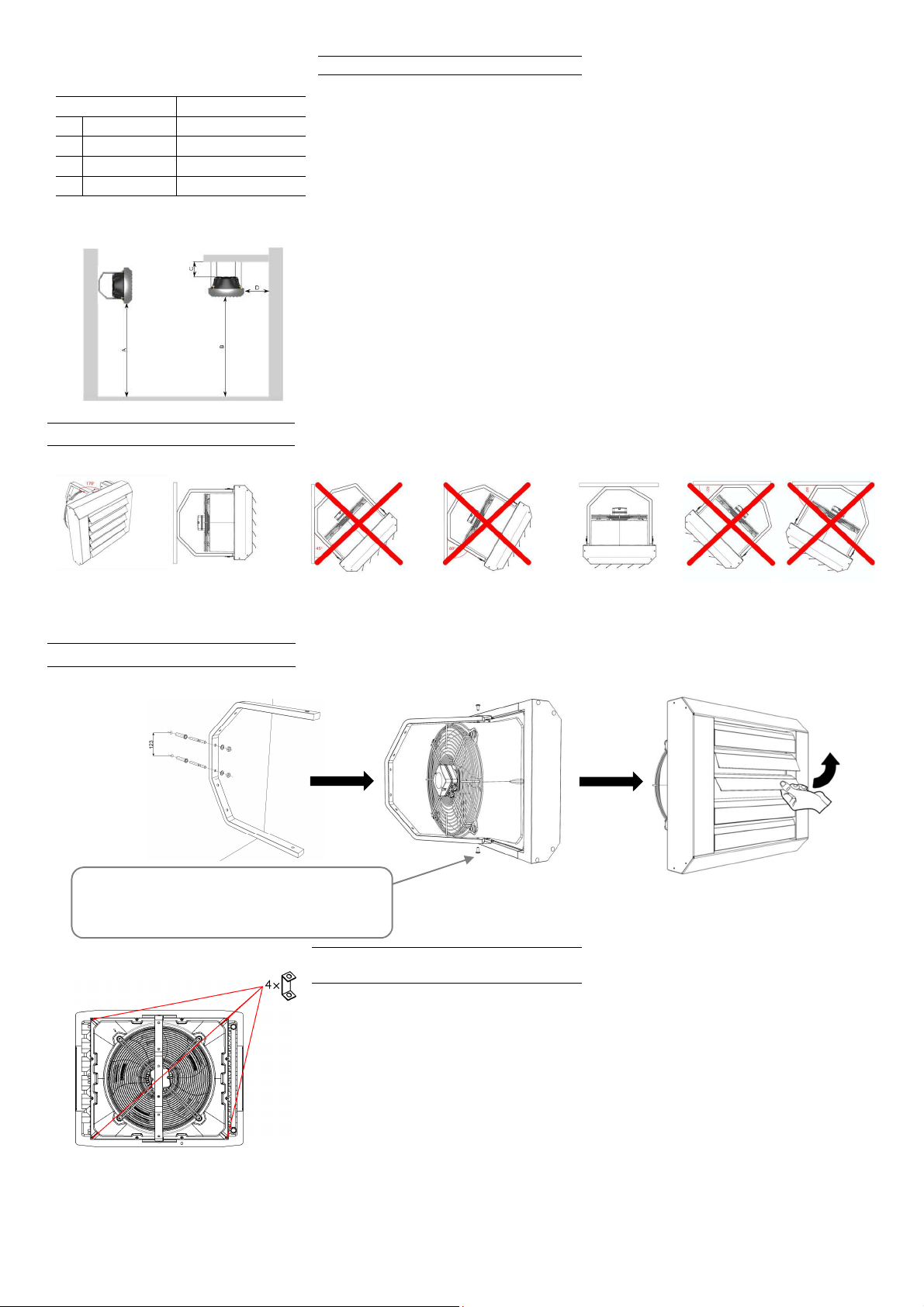

1.

EL S BMS EL L BMS

A max 3,0 max 6,0

B max. 6,0 max 9.5

C min. 0,2 min. 0,2

D min. 0,5 min. 0,5

3

. INSTALLATION

1. Fan heaters can be mounted to vertical or

horizontal partitions. During the montage, the

minimal distances from the walls and ceiling

have to be kept.

2. U-profiles should be mounted in corners as

drawing shows. Is not allowed to screw profiles

in other places.

2.

3.3 U-PROFILES (optional)

U-profiles should be mounted in corners as drawing shows. Is

not allowed to screw profiles in other places.

3.1. INSTALLATION – BRACKET

3.2. ASSEMBLY INSTRUCTIONS

!!!

M8 screws are in set with bracket

6 |

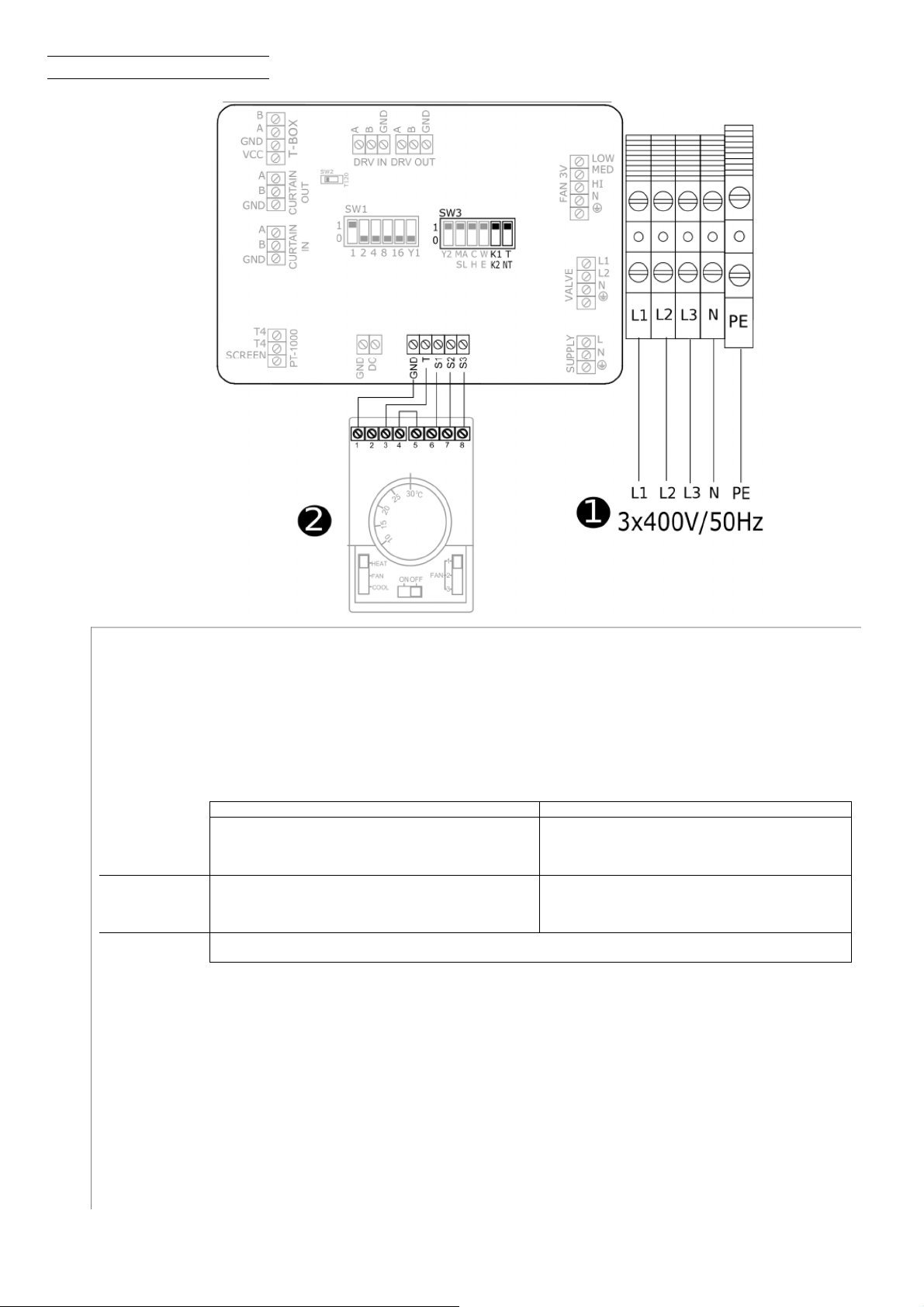

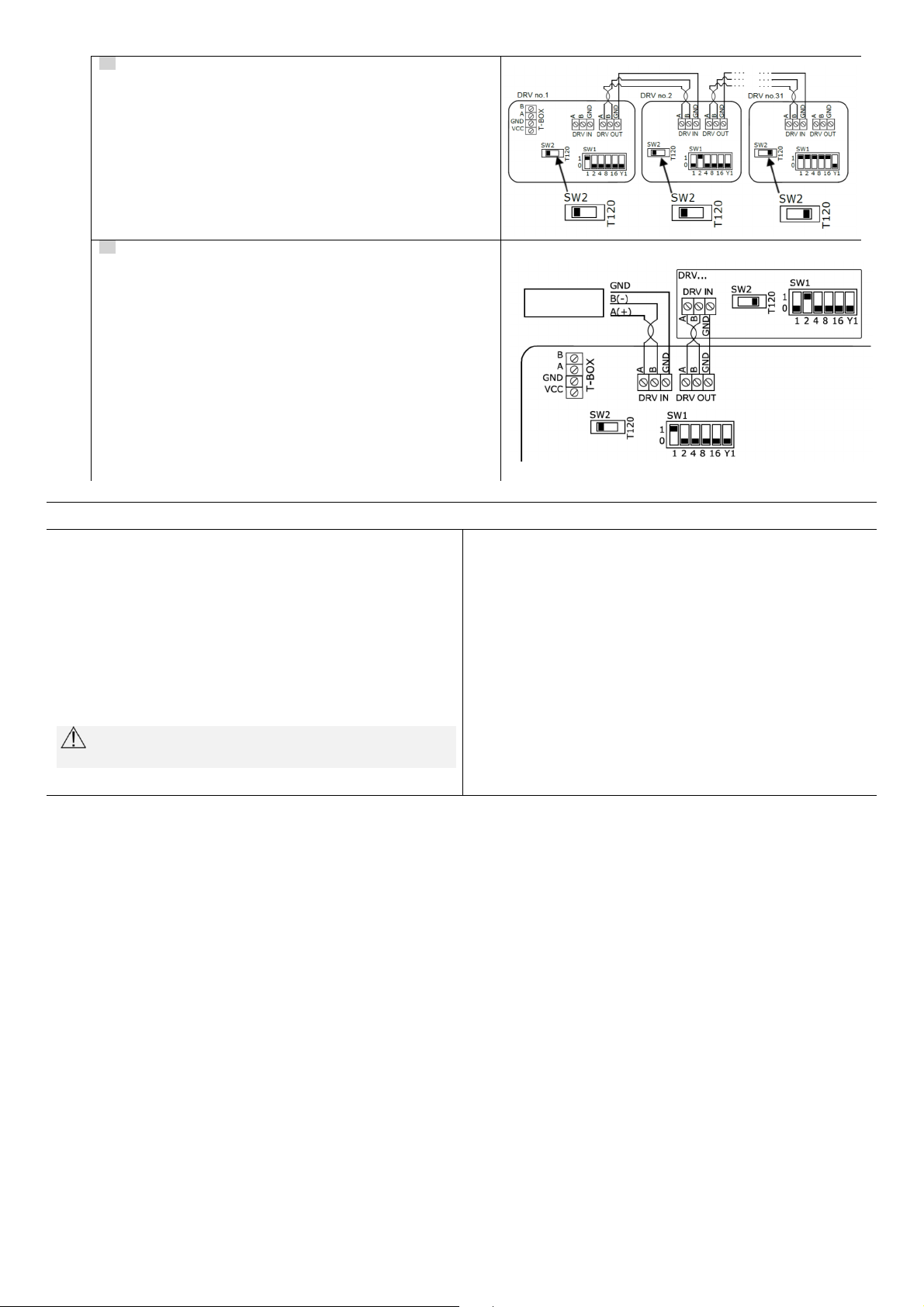

4. CONNECTION DIAGRAMS

V

3- step fan speed regulator with thermostat TS (OMY 5x0,5 mm

2

).

LEO EL S

LEO EL L

•1

1

st

step of heating; 2

nd

fan step

2

nd

step of heating; 2

nd

fan step

•2

2

nd

step of heating; 3

nd

fan step

3

rd

step of heating; 3

rd

fan step

•3 Ventilation (fan operate on 3

rd

step)

SW3:

T- Thermostatic mode (After reaching the temperature, turning off the fans and heating elements)|

NT - Continuous mode (After reaching the temperature, turning off the heating elements and continuous operation of the fan)|

K1 – LEO EL L BMS

K2 – LEO EL S BMS

Each time the device is switched off the heaters are being cooled for next 30 seconds

Power supply

•LEO EL S BMS (OMY 5x4,0 mm

2

) (Circuit protection B20)

•LEO EL L BMS (OMY 5x6,0 mm

2

) (Circuit protection B40)

•HEAT- heating mode

•FAN - room thermostat deactivated

•COOL - cooling mode

| 7

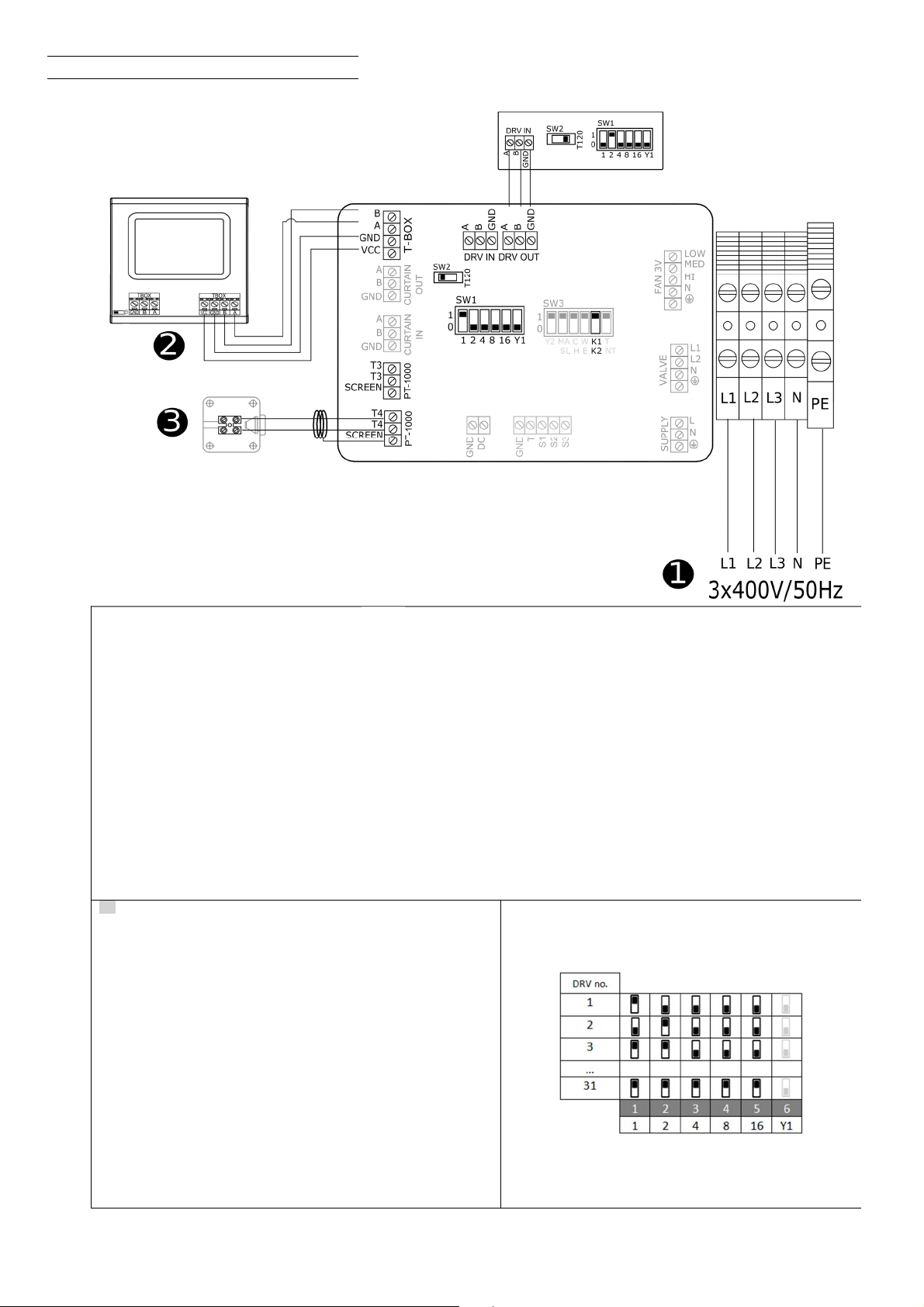

4. CONNECTION DIAGRAMS

B

M

S

T-box - intelligent controller with touch screen

PT-1000 connectors

SW3:

K1 – LEO EL L BMS

K2 – LEO EL S BMS

Each time the device is switched off the heaters are being cooled for next 30 seconds

EN

:

When connecting DRV modules to the T

-

box controller or BMS, you

have to binary set addresses on each (each DRV must have individual

address) DRV module by DIP-switch SW1. To address modules check if

the power supply is turned off, than set then the addresses as shown in the

table, than turn on the power supply .

.

)

•LEO EL L BMS (OMY 5x6,0 mm

2

) (Circuit protection B40)

Power supply 3 x 400V/50Hz:

•LEO EL S BMS (OMY 5x4,0 mm

2

) (Circuit protection B20)

8 |

EN

:

It is possible to connect up to 31modules

DRV and control them with

one T-box controller .|

EN

:

DRV modules can be connected to the BMS (Building Management

System).

5

.

START

-

UP AND OPERATION

Start-up

•supply and controls have to be connected as shown in technical manual

•before connecting supply check that current is same as on the nameplate

•start-up without grounding cable is forbidden

Operation

•unit designed to indoor operation

•never place any things on the casing while operating

•unit should be serviced periodically; in case of failure the unit should be

switched off immediately

Never operate a failure unit. The producer does not take any

responsibility for damages caused by failure operation.

Switch off the electrical supply while servicing or cleaning.

Periodic inspections

To keep proper technical parameters Flowair recommends periodic

service (every 6 months) of fan heaters on behalf of the user.

During inspections user should:

Check heating elments , if is it filled with dirt or dust. If necessary - use

industrial vacuum cleaner or pressurized air stream to clean the

exchanger’s lamellas.

Excessive dirt on the heaters can cause

permanent loss of the rated parameters,

Check fan blades, in case of dirt use damp cloth and remove dirt,

Check bracket installation,

Check wires insulation,

Check power supply,

Check levelling of the unit.

| 9

10 |

6. SERVICE AND WARRANTY TERMS

Please contact your dealer in order to get acquitted with the

warranty terms and its limitation.

In the case of any irregularities in the device operation, please

contact the manufacturer’s service department.

The manufacturer bears no responsibility for operating the

device in a manner inconsistent with its purpose, by persons

not authorised for this, and for damage resulting from this!

| 11

12 |

7. CONFORMITY WITH WEEE DIRECTIVE 2012/19/UE

For information on the collection system of waste electrical

and electronic equipment, please contact the distributor.

R E M E M B E R :

Do not dispose of used equipment together with other waste! There

are financial penalties for this. Proper handling of used equipment

prevents potential negative consequences for the environment and

human health. At the same time, we save the Earth's natural

resources, reusing resources obtained from the processing of

equipment.

Running a business without harming the environment and

observing the rules of proper handling of waste electrical and

electronic equipment is a priority for Flexiheat.

The symbol of the crossed out wheeled bin placed on the

equipment, packaging or documents attached means that the

product must not be disposed of with other wastes. It is the

responsibility of the user to hand the used equipment to a

designated collection point for proper processing. The symbol

means at the same time that the equipment was placed on the

market after August 13, 2005.

| 13

14 |

ww

•LEO EL L BMS; LEO EL S BMS

PN-EN ISO 12100:2012

Safety Of Machinery - General Principles For Design - Risk Assessment And Risk Reduction

PN-EN 60204-1:2018-12

Safety of machinery − Electrical equipment of machines − Part 1: General requirements

environments

Gdynia, 14.01.2019

Product Manager

Flexiheat hereby confirms that heating unit / Flexiheat

Declaration Of Conformity /

were produced in accordance to the following Europeans Directives / zijn geproduceerd in overeenstemming met de volgende

1.

2014/30/UE – Electromagnetic Compatibility (EMC)

2. 2006/42/WE – Machinery

3.

2014/35/UE – Low Voltage Electrical Equipment (LVD)

4. 2009/125/WE – Energy-related products (ErP 2015)

and harmonized norms ,with above directives

PN-EN 60034-1:2011 Rotating electrical machines — Part 1: Rating and performance

PN-EN 61000-6-2:2008 Electromagnetic compatibility (EMC). Generic standards. Immunity for industrial

om

| 15

COMMISSION REGULATION (EU) 2016/2281

Capacity control: 3-speed

LEO EL S LEO EL L

Item Symbol Value Unit

Rated heating capacity P

rated,h

10,8 22,8 kW

Minimum capacity P

min

5,5 7,5 kW

Envelope loss factor F

env

0 0 %

Emission efficiency η

s, flow

93,3 95,6 %

Seasonal space heating energy efficiency η

s, h

35,7 36,6 %

Information relevant for disassembly, recycling and/or disposal at end-of-life.

isassembly should be carried out by a person with appropriate authorizations. After disassembly,

waste should be segregated:

housing: steel - recyclable

heating elments: aluminum,

fan: dispose of in accordance with the rules for the disposal of electrical equipment

Unit name: LEO EL

16 |

www.flowair.com

52383

MT-DTR-LEO-EL-S-L-EN-PL-NL-RU-V1

This manual suits for next models

1

Table of contents

Other Flexiheat Heater manuals

Popular Heater manuals by other brands

Bionaire

Bionaire BOH1503 instruction manual

Herschel

Herschel Inspire Comfort IC-400 Installation & operating instructions

Gabarron

Gabarron CP Series Installation instructions and user guide

WMT

WMT Y-Panel User information

Henley Stoves

Henley Stoves Athens 400 Installation & operating instructions

Euromate

Euromate 107446 Original instructions

L.B. White

L.B. White CP350AK owner's manual

DELTACALOR

DELTACALOR DROP Operation and installation manual

Bio Green

Bio Green Phoenix 2.8 Installation and operating instruction

TESY

TESY MC 20111 Operation and storage manual

Pro-Elec

Pro-Elec PELL0206 manual

Frico

Frico ICW Series Assembly and operation instructions