Flexiheat ELIS B-W-100 User manual

EN

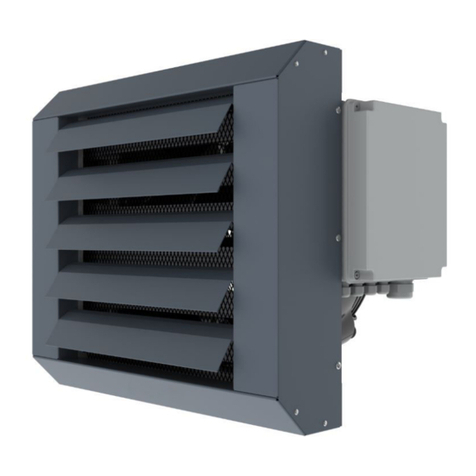

AIR CURTAIN

TECHNICAL DOCUMENTATION OPERATION MANUAL

ТЕХНИЧЕСКАЯ ДОКУМЕНТАЦИЯ

РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ

ELIS B | W 100 | W 100 2R | N 100 | E 100 | W 150 | W 150 2R |

N 150 | E 150 | W 200 | W 200 2R | N 200 | E 200

2 |

TABLE OF CONTENTS

1. GENERAL INFORMATION...................................................................3

2. TECHNICAL DATA...............................................................................4

2.1. CONSTRUCTION..............................................................................4

2.2. DIMENSIONS....................................................................................5

2.3. ACOUSTIC PRESSURE LEVEL/ ACOUSTIC POWER LEVEL..........5

2.4. AIR VOLUME....................................................................................5

3. INSTALLATION....................................................................................6

4. CONTROL SYSTEM ............................................................................8

4.1. CONTROL SYSTEM ELEMENTS......................................................8

4.2. CONNECTING GUIDE ....................................................................10

4.3. DRV ELiS CONTROL SYSTEM.......................................................11

4.3.1. REGULATION TS-ELIS B-W/N WIRING DIAGRAMS ...................12

4.3.2. REGULATION TS-ELIS B-E WIRING DIAGRAMS........................13

4.3.3. REGULATION T-box –ELIS B-W/N WIRING DIAGRAMS ............14

4.3.4. REGULATION T-box –ELIS B-E WIRING DIAGRAMS.................15

4.3.5. CONTROL SYSTEM –MASTER-SLAVE COMMUNICATION.......16

4.3.6. CONTROL SYSTEM- DRV CHAINING.........................................17

4.3.7. CONTROL SYSTEM –BMS CONNECTION.................................17

4.3.8. CONTROL SYSTEM –SETTING BMS ADDRESS .......................18

5. DOOR CONTACT INSTALLATION.....................................................18

6. GUIDELINES FOR CONNECTION WITH POWER SUPPLY..............19

7. GUIDELINES FOR CONNECTION WITH PIPELINE ..........................19

8. OPERATION......................................................................................20

9. CLEANING AND CONSERVATION....................................................21

10. OUTLET GRILL ADJUSTING...........................................................22

11. SERVICE.........................................................................................22

12. CONFORMITY WITH WEEE DIRECTIVE 2012/19/UE .....................24

| 3

1. GENERAL INFORMATION

Purpose of Eils B is to minimalize heat losses (or unwanted heat

gains) by door openings. Elis B is a recessed type and can be a part

suspended ceiling.

ELiS types:

ELIS B-W-100 –curtain with water heat exchanger max. range 5 m;

ELIS B-N-100 –curtain without heat exchanger (ambient);

max. range 5 m;

ELIS B-E-100 –curtain with electrical heat exchanger max. range 5 m;

ELIS B-W-100 2R –curtain with two-row heat exchanger

max. range 5 m

ELIS B-W-150 –curtain with water heat exchanger max. range 5 m;

ELIS B-N-150 –curtain without heat exchanger (ambient);

max. range 5 m;

ELIS B-E-150 –curtain with electrical heat exchanger max. range 5 m,

ELIS B-W-150 2R –curtain with two-row heat exchanger

max. range 5 m

ELIS B-W-200 –curtain with water heat exchanger max. range 5 m;

ELIS B-N-200 –curtain without heat exchanger (ambient);

max. range 5 m.

ELIS B-E-200 –curtain with electrical heat exchanger max. range 5 m,

ELIS B-W-200 2R –curtain with two-row heat exchanger

max. range 5 m.

* according to ISO 27327-1

4 |

* B-W temperature increase at inlet air 10ºC and heating agent temperature 90/70ºC / B-E temperature increase at inlet air 10ºC

▪Fan –motor with plastic rotor;

▪Heat exchanger –copper-aluminium, connecting stub ½”;

electrical heaters PTC;

▪Casing–sheet steel RAL; color white RAL 9016,

–back elements - expanded polypropylene EPP;

colour –grey;

–air inlet fins - anodized aluminum

2. TECHNICAL DATA

B-W-

100

B-N-

100

B-E-

100

B-W-

100 2R

B-W-

150

B-N-

150

B-E-

150

B-W-

150 2R

B-W-

200

B-N-

200

B-E-

200

B-W-

200 2R

Power supply [V/Hz] |

230/ 50

3x400

/ 50

230 /

50

230 / 50

3x400

/ 50

230 /

50

230 / 50

3x400

/ 50

230 /

50

Power consumption [kW]

0,34

0,42

7,5

0,34

0,36

0,44

11,5

0,36

0,38

0,49

15,5

0,38

Current consumption [A]

1,5

1,9

11

1,5

1,6

2

16,6

1,6

1,7

2,2

22,4

1,7

IP/insulationclass

IP 21 / F

Connecting stub [”]

½

-

½

½

-

½

½

-

½

Max. water temperature [oC] |

95

-

95

95

-

95

95

-

95

Max. water pressure [MPa]

1,6

-

-

1,6

1,6

-

-

1,6

1,6

-

-

1,6

Temperature increase (∆T) [ºC]*

15

-

11

28

15

-

12

31

16

-

13

33

Weight [kg]

32,3

31,7

34,5

33,7

41,2

38,9

42,4

43,7

50

47,2

53,2

53,2

Weight of unit filled with water [kg]

33,1

-

-

35,2

42,4

-

-

45,7

51,6

-

-

56,4

2.1. CONSTRUCTION

| 5

2.2. DIMENSIONS

A

B

C

D

E

F

ELiS B-W/N/E/2R-100

1057 mm

600 mm

561 mm

770 mm

297*/284** mm

96 mm

ELiS B-W/N/E/2R-150

1546 mm

600 mm

561 mm

1207 mm

297*/284** mm

84 mm

ELiS B-W/N/E/2R-200

2034 mm

600 mm

561 mm

1621 mm

297*/284** mm

157 mm

* height for B-W ; ** height for B-E/N

2.3. ACOUSTIC PRESSURE LEVEL/ ACOUSTIC POWER LEVEL

step

B-W-100;

B-E-100;

B-N-100;

B-W-150;

B-E-150;

B-N-150;

B-W-200;

B-E-200;

B-N-200;

B-W-100

2R

B-W-150

2R

B-W-200

2R

3

58 dB(A) /

73 dB(A)

65 dB(A) /

80 dB(A)

62 dB(A) /

77 dB(A)

65 dB(A) /

80 dB(A)

63 dB(A) /

78 dB(A)

66 dB(A) /

81 dB(A)

57 dB(A) /

72 dB(A)

60 dB(A) /

75 dB(A)

61 dB(A) /

76 dB(A)

2

57 dB(A) /

72 dB(A)

63 dB(A) /

78 dB(A)

59 dB(A) /

74 dB(A)

63 dB(A) /

78 dB(A)

61 dB(A) /

76 dB(A)

62 dB(A) /

77 dB(A)

56 dB(A) /

71 dB(A)

58 dB(A) /

73 dB(A)

59 dB(A) /

74 dB(A)

1

55 dB(A) /

70 dB(A)

61 dB(A) /

76 dB(A)

57 dB(A) /

72 dB(A)

58 dB(A) /

73 dB(A)

58 dB(A) /

73 dB(A)

59 dB(A) /

74 dB(A)

55 dB(A) /

70 dB(A)

56 dB(A) /

71 dB(A)

56 dB(A) /

71 dB(A)

* Acoustic power level according to ISO 27327-2 |

.

**Acoustic pressure level has been measured 5m from the unit in a 1500 m3space with a medium sound absorption coefficient |

2.4. AIR VOLUME

S

step

B-W-100

B-E-100

B-N-100

B-W-150

B-E-150

B-N-150

B-W-200

B-E-200

B-N-200

B-W-100

2R

B-W-150

2R

B-W-200

2R

3

2600 m3/h

3500 m3/h

4000 m3/h

4800 m3/h

5200 m3/h

6600 m3/h

2400 m3/h

3800 m3/h

4900 m3/h

2

2500 m3/h

2700 m3/h

3500 m3/h

4000 m3/h

4300 m3/h

4300 m3/h

2300 m3/h

3200 m3/h

4100 m3/h

1

2200 m3/h

2300 m3/h

3200 m3/h

3200 m3/h

4000 m3/h

3600 m3/h

2000 m3/h

3000 m3/h

3800 m3/h

6 |

3. INSTALATION

1.

ELiS

B [mm]

A [mm]

B-..-100

572

1024

B-..-150

572

1510

B-..-200

572

2000

2.

ELiS

C

[mm]

D

[mm]

E

[mm]

F

[mm]

B-..-100

133

770

121

561

B-..-150

182

1207

122

561

B-..-200

256

1621

123

561

3.

4.

5.

6.

| 7

7.

8.

9.

10.

11.

12.

13.

14.

8 |

TS - 3-speed fan switch

with room thermostat

Temperature range::

+10 … +30oC

Operating temperature

range:

0 … +40oC

IP/Insulation class:: IP30

Max current:

inductive 5 A, resistive 6 A

Power supply:

230 V/ 50Hz

T-box

Temperature range:

+5 … +35oC

Operating temperature

range: -10 … +60oC

IP/Insulation class: IP30

Power supply: 24 VDC

4. CONTROL SYSTEM

DRV CONTROL:

▪Connecting curtains –controlling up to 5 units with one

controller;

▪Connecting to curtain room thermostat*, door contact*,

valves with actuator*, speed controller*;

▪BMS connection;

▪SYSTEM Flowair connection

*optional equipment

4.1. CONTROL SYSTEM ELEMENTS

| 9

SRQ3d ½” – three-way

1/2 valve with actuator

IP/Insulation class: IP20

Power supply:

200 –240 V 50/60 Hz

Max water temperature:

+93oC

Max water pressure:

2,1 MPa

Kvs: 3,4 m3/h

Opening time: 18 s

SRQ2d ½” – two-way 1/2

valve with actuator

IP/Insulation class: IP20

Power supply:

200 –240 V 50/60 Hz

Max water temperature:

+93oC

Max water pressure:

2,1 MPa

Kvs: 3,0 m3/h

Opening time: 18 s

DCe –magnetic door

switch with relay

Operating temperature

range:

-5 … +60°C

IP/Insulation class: IP 64

Connectors: NO

Max current:

inductive/resistive 0,5 A

Max relay current:

inductive 3 A

Max operating contactors

distance: 6 mm

DCm –mechanical door

switch

Operating temperature

range:: -10 - +80°C

IP/Insulation class: IP 65

Connectors: 1xNC i 1xNO

Max current: resistive 4 A,

inductive 10 A

Max Power load:

300 VAC or 250 VDC

10 |

1.

2.

3.

4.

5.

6.

7. ELiS B-W/N

8. ELiS B-E

4.2. CONNECTING GUIDE

| 11

4.3. DRV ELiS CONTROL SYSTEM

*K1 programme –Signal from

door switch or thermostat is main

signal for the device to run

**K2 programme –Signal from

door switch is main signal for the

device to run and thermostat is in

charge of valve/heaters

Power supply 230 V/50 Hz;

Connectors for thermostat and

fan step switch;

Door contact connector;

Valve actuator connector

ELIS-…W; heaters contactor

connector ELiS-…-E;

BMS system connection;

T-box connectors;

MASTER-SLAVE connectors;

PT-1000 connectors;

LED INDICATORS:

G1, G2, G3 –signalize number

of fan speed operating

S1, S2, S3 –signalize number of

set fan speed

T –signalize of valve set

DC –signalize of door contact set

OPEN, CLOSE –signalize valve

actuator

WORK –signalize of software

working

SW3 –operating mode switch

(default settings)

12 |

4.3.1. REGULATION TS-ELIS B-W/N WIRING DIAGRAMS

Power supply 230 V/50 Hz (OMY 3x1 mm2)

Air curtain step switch with thermostat TS (OMY 5x0,5mm2)

Door contact DCe/DCm (door closed –contacts opened; door

opened –contacts closed) (OMY 2x0,5 mm2)

Valve with actuator SRSQ2d (OMY 3x0,75 mm2) or

SRQ2d (OMY 3x0,75 mm2)

A –Exchanger water supply

AB –Valve water supply

B –Return pipe water supply

•HEAT- heating mode

•FAN - room thermostat deactivated

•COOL - cooling mode

•1;2;3 –step switch

| 13

4.3.2. REGULATION TS-ELIS B-E WIRING DIAGRAMS

Power supply 3x400V/50Hz

•ELiS B-E-100 (min. 5x2,5 mm2) (Overcurrent B16)

•ELiS B-E-150 (min. 5x4,0 mm2) (Overcurrent B20)

•ELiS B-E-200 (min. 5x4,0 mm2) (Overcurrent B25)

Door contact DCe/DCm (door closed –contacts opened; door

opened –contacts closed) (OMY 2x0,5 mm2)

ATTENTION:

Switch 4 on SW3 to the position “E” and then restart the system

switching it off for 5 seconds. Each time the device is switched off the

heaters are being cooled for next 30 seconds

Air curtain step switch with thermostat TS (OMY 5x0,5 mm2)

•HEAT- heating mode

•FAN - room thermostat deactivated

•COOL - cooling mode

•1;2;3 –step switch

14 |

4.3.3. REGULATION T-box - ELIS B-W/N WIRING DIAGRAMS

Power supply 230V/50Hz (OMY 3x1 mm2)

T-box (LIYCY-P 2x2x0,5mm2)

Door contact DCe/DCm (door closed –contacts opened; door

opened –contacts closed) (OMY 2x0,5 mm2)

Valve with actuator SRSQ2d (OMY 3x0,75 mm2) or

SRQ3d (OMY 3x0,75mm2)

A –Exchanger water supply

AB –Valve water supply

B –Return pipe water supply

NOTE: In last DRV in line, dipswitch SW2 has to be switched to the

right –T120.

| 15

4.3.4. REGULATION T-box - ELIS B-E WIRING DIAGRAMS

Power supply 3x400V/50Hz

•ELiS B-E-100 (min. 5x2,5 mm2) (Overcurrent B16)

•ELiS B-E-150 (min. 5x4,0 mm2) (Overcurrent B20)

•ELiS B-E-200 (min. 5x4,0 mm2) (Overcurrent B25)

T-box (LIYCY-P 2x2x0,5 mm2)

Door contact DCe/DCm (door closed –contacts opened; door

opened –contacts closed) (OMY 2x0,5 mm2)

ATTENTION:

Switch 4 on SW3 to the position “E” and then restart the system

switching it off for 5 seconds. Each time the device is switched off the

heaters are being cooled for next 30 seconds.

NOTE : In last DRV in line, dipswitch SW2 has to be switched to the

right –T120.

16 |

4.3.5. CONTROL SYSTEM –MASTER-SLAVE COMMUNICATION

Electrical air curtain chaining provides control from 1 to 5 devices

using one TS and DC.

Electrical air curtain chaining might be done by cable OMY 3x0,5mm2

using connectors CURTAIN IN; CURTAIN OUT

Connecting units among themselves ensure transfer of

controlling signals. Whatever each curtain need to be supplied

directly.

Switch 2 on SW3 set In position:

–For MASTER curtain

–For SLAVE curtain

In case to connect several devices to one T-box and independent (

local ) work of curtains with door switches use DRV IN ; DRV OUT

connectors.

| 17

4.3.6. CONTROL SYSTEM- DRV CHAINING

4.3.7. CONTROL SYSTEM –BMS CONNECTION

It is possible to connect up to 31modules DRV and control them with one T-

box controlle

NOTE: In last DRV in line, dipswitch SW2 has to be switched to the right –

T120. The maximum length of the connecting cable 50 m

(LIYCY-P 2x2x0,5 mm2).

DRV driver has a possibility to be connected to integrated Building

Management System (BMS). Connection can be done in two ways:

1. To DRV pcb board(in case of work without T-box)

2. To T-box controller (LIYCY-P 2x2x0,5 mm2)

Physical layer

RS485

Protocol

MODBUS-RTU

Baud rate

38400 [bps]

Parity

Even

Data bits

8

STOP bits

1

1.

Physical layer

RS485

Protocol

MODBUS-RTU

Baud rate

9600-230400 [bps]

Parity

Even

Data bits

8

STOP bits

1

2.

ATTENTION: In last DRV in line, dipswitch SW2 has to be switched to the

right –T120

Description

Name

Description

Name

18 |

When connecting DRV modules to the T-box controller or BMS, you

have to binary set addresses on each (each DRV must have individual

address) DRV module by DIP-switch SW1. To address modules,

check if the power supply is turned off, then set the addresses as

shown in the table, then turn on the power supply.

DRV

1

2

3

…

31

1

2

3

4

5

6

1

2

4

8

16

Y1

4.3.8. CONTROL SYSTEM –SETTING BMS ADDRESS

Sample of door contact installation.

DCm –In case of installation in way which is

show on drawing below, connectors 21 and 22

need to be used.

5. DOOR CONTACT INSTALLATION

| 19

6. GUIDELINES FOR CONNECTION WITH POWER SUPPLY

•Before connecting the power supply check the correctness of

controllers connection. These connections should be executed in

accordance with their technical documentation.

•Before connecting the power supply check whether the mains

voltage is in accordance with the voltage on the device data

shield.

•Starting the device without connecting the ground conductor is

forbidden.

•Controleer voordat u de stroomvoorziening aansluit of de

regelingen correct zijn aangesloten. Deze aansluitingen moeten

….. worden gemaakt in overeenstemming met de technische ….

…...documentatie.

•Controleer voordat u de stroomvoorziening aansluit of de

spanning van de netvoeding overeenkomt met de werkspanning

…..op het typeplaatje op de unit.

•Het is niet toegestaan om de unit op te starten zonder dat de

aarding aangesloten is.

7. GUIDELINES FOR CONNECTION WITH PIPELINE

•The connection should be executed in a way which does not induce

.stresses. It is recommended to use flexible pipes to deliver heating

.agent to the exchanger.

•It is recommended to install vent valves at the highest point of the

.system.

•The system should be executed so that, in the case of a failure, it

.is possible to disassemble the device. For this purpose it is best to

.use shut-off valves just by the device.

•The system with the heating medium must be protected against an

.increase of the heating medium pressure above the permissible

.value (1.6 MPa).

•While screwing exchanger to pipeline - connecting stubs has to be

.hold by wrench.

20 |

•The device is designed for operation inside buildings, at

temperatures above 0oC. In low temperatures (below 0ºC)

there is a danger of freezing of the medium.

The manufacturer bears no responsibility for damage

……of the heat exchanger resulting from freezing of the

……medium in the exchanger. It is forbidden to place any

……objects on the heater or to hang any objects on the

……connecting stubs.

•The device must be inspected periodically. In the case of

incorrect operation of the device it should be switched off

immediately.

•It is forbidden to use a damaged device. The manufacturer

bears no responsibility for damage resulting from the use of

a damaged device.

•If it is necessary to clean the exchanger, be careful not to

damage the aluminium lamellas.

•For the time of performing inspection or cleaningthe device,

the electrical power supply should be disconnected.

•In case water is drained from the device for a longer period

of time, the exchanger tubes should be emptied with

compressed air

8. OPERATION

This manual suits for next models

11

Table of contents

Other Flexiheat Heater manuals

Popular Heater manuals by other brands

Radialight

Radialight OASI Installation and operating manual

REMKO

REMKO ATK 25 Operation,technology,spare parts

CALOR

CALOR EN 2 User instructions

Verine

Verine Fontana HE MK2 NPHL**RN2 Installation, maintenance & user instructions

Herschel

Herschel Select S3 Installation & operating instructions

DeLonghi

DeLonghi HFS70B manual

Sunrise Medical

Sunrise Medical DeVilbiss 9200 Series Instruction guide

Toyotomi

Toyotomi 4963505711078 operating manual

Klarstein

Klarstein WONDERWALL 96 manual

DeLonghi

DeLonghi OIL FILLED RADIATORS instructions

Pinnacle International

Pinnacle International Remington HH-18-PCH user manual

Jaga

Jaga Clima Canal H8 installation instructions