Flexiheat LEO S1 Guide

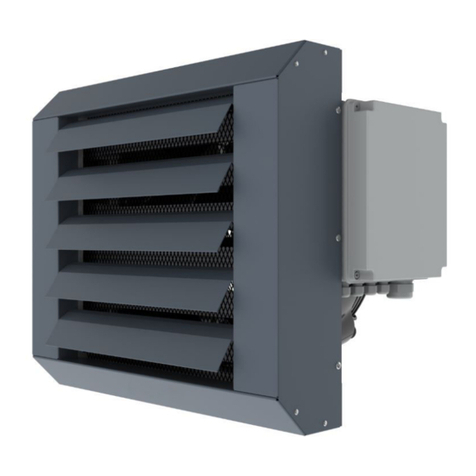

LEO

S1 I S2 I S3 / BMS

L1 I L2 I L3 / BMS

XL2 I XL3 / BMS

(INOX / ST)

FAN HEATER

TECHNICAL DOCUMENTATION OPERATION MANUAL

TABLE OF CONTENTS

1. Application ...............................................................................................4

2. Technical Data.........................................................................................5

3. Installation ...............................................................................................8

3.1. Installation –bracket..........................................................................8

3.2. Assembly instructions .......................................................................8

3.3. U-Profiles..........................................................................................8

4. Connection diagrams ...............................................................................9

5. Start-Up and Operation ..........................................................................11

6. Service and warranty terms....................................................................15

7. Conformity with WEEE directive 2012/19/UE .........................................17

LEO heaters make up a decentralised heating system. The air

streaming through the heat exchanger filled with hot water is warmed

up. Fan heaters are used for heating large volume buildings: general,

industrial and public buildings etc.

The casing of LEO heaters is made from extended polypropylene EPP.

LEO in special version ST has a casing made from powder coated steel.

The devices LEO in special version INOX have casing and air blades

made of austenitic stainless steel.

The devices are designed for indoor use where maximum air dustiness

does not exceed 0,3 g/m

3

. Units are built using copper, aluminum and

galvanized steel. It is prohibited to install units in the areas where

environment inside can causes in rusting. The devices can not be used

in an environment where there is oil mist.

Water heat exchanger could be supply by water or glycol solution up to

60%.

1. APPLICATION

LEO S1 | S2 | S3 / BMS

LEO S1 INOX / ST | S2 INOX / ST | S3 INOX / ST

LEO S1 LEO S2 LEO S3

2300 1900 1500 2000 1600 1250 1800 1400

1000

230/50

0,5 0,4 0,3 0,6 0,4 0,3 0,6 0,4 0,3

120 90 70 130 90 70 130 90 70

54 /F

56,3 50,7 43,9 56,3 50,7 43,9 56,3 50,7 43,9

16,0 13,0 10,0 14,0 11,0 8,5 12,5 9,5 7,0

6,0 5,1 4,1 5,3 4,4 3,5 4,9 3,9 2,9

120 (INOX / ST: 130)

1,6

1/2”

60

9,5 (INOX: 13,1, ST: 13,1) 10,4 (INOX: 13,8, ST: 13,8) 10,8 (INOX: 14,3, ST: 14,3)

10,2 (INOX: 13,8, ST: 13,8) 11,6 (INOX: 14,0, ST: 14,0) 12,2 (INOX: 15,7, ST: 15,7)

Speed III II I III II I III II I

Max airflow [m

3

/h ]

Power supply [V/Hz]

Max current consumption [A]

Max power consumption [W]

IP/ Insulation class

Max acoustic pressure level [dB(A)]*

Vertical range*** [m]

Max heating water temperature [

o

C]

Horizontal range** [m]

Max operating pressure [MPa]

Connection

Installation Indoor

Max working temperature [

o

C]

Device mass [kg]

Mass of device filled with water [kg]

* Acoustic pressure level has been measured 5m from the unit in a 1500m3 space with a medium sound absorption coefficient

** Horisontal isothermal range for 0,5 m/s border air stream speed

*** Vertical nonisothermal range for ΔT = 5oC and for 0,5 m/s border air stream speed

2. TECHNICAL DATA

LEO L1 | L2 | L3 / BMS

LEO L1 INOX / ST | L2 INOX / ST | L3 INOX / ST

LEO L1 LEO L2 LEO L3

4250

2800 1700 3800 2400 1400 3400 2100 1200

230/50

1,4

1,2 0,6 1,5 1,2 0,6 1,5 1,2 0,6

330

240 120 340 240 120 340 240 120

54 /F

64,1 54,5 42,1 64,1 54,5 42,1 64,1 54,5 42,1

24,0

15,0

9,5

21,5

13,0

8,0

19,0

11,5

6,5

8,3

5,6

3,7

7,5

4,9

3,1

6,8

4,4

2,8

120 (INOX / ST: 130)

1,6

3/4”

60

14,9 (INOX: 19,4, ST: 19,4) 16,2 (INOX: 20,8, ST: 20,8) 17,8 (INOX: 22,7, ST: 22,7)

15,9 (INOX: 20,4, ST: 20,4) 18,2 (INOX: 22,8, ST: 22,8) 20,5 (INOX: 25,4, ST: 25,4)

Speed

III

II

I

III

II

I

III

II

I

Max airflow [m

3

/h ]

Power supply [V/Hz]

Max current consumption [A]

Max power consumption [W]

IP/ Insulation class

Max acoustic pressure level [dB(A)]*

Horizontal range** [m]

Vertical range*** [m]

Max heating water temperature [

o

C]

Max operating pressure [MPa]

Connection | Przyłącze

Installation

Max working temperature [

o

C]

Device mass [kg]

Mass of device filled with water [kg]

Indoor

* Acoustic pressure level has been measured 5m from the unit in a 1500m3 space with a medium sound absorption coefficient

** Horizontal isothermal range for 0,5 m/s border air stream speed

*** Vertical nonisothermal range for ΔT = 5oC and for 0.5 m/s border air stream speed

2. TECHNICAL DATA

LEO XL2 | XL3 / BMS

LEO XL2 INOX / ST | XL3 INOX / ST

LEO XL2 LEO XL3

5800

4600

2900

5300 4100

2500

230/50

2,3

1,8

1,4

2,4 1,8

1,4

520

370

270

550 370

270

54 /F

67,5 61,1

52,3

67,5 61,1

52,3

26,0

20,5

13,0

23,5

18,0

11,0

8,5

7,0

4,7

7,7

6,2

4,1

120 (INOX / ST: 130)

1,6

60

23,2 (INOX: 29,9, ST: 29,9) 26,2 (INOX: 34,2, ST: 34,2)

25,9 (INOX: 32,6, ST: 32,6) 30,3 (INOX: 38,3, ST: 38,3)

Speed

III

II

I

III

II

I

2. TECHNICAL DATA

Max airflow [m

3

/h ]

Power supply [V/Hz]|

Max current consumption [A]

Max power consumption [W] |

IP/ Insulation class

Max acoustic pressure level [dB(A)]*

Horizontal range** [m]

Vertical range*** [m]

Max heating water temperature [

o

C]

Max operating pressure [MPa]

Connection 3/4”

Max working temperature [

o

C]

Device mass [kg]

Mass of device filled with water [kg]

Installation Indoor

* Acoustic pressure level has been measured 5m from the unit in a 1500m3 space with a medium sound absorption coefficient

** Horisontal isothermal range for 0,5 m/s border air stream speed

*** Vertical nonisothermal range for ΔT = 5oC and for 0,5 m/s border air stream speed

S1 S2 S3 L1 L2 L3 XL2 XL3

A

<3,0 <3,0 <3,0 2,5-8,0 2,5-8,0 2,5-8,0 2,5-8,0 2,5-8,0

B

2,5-7,0 2,5-6,0 2,5-6,0 2,5-9,5 2,5-8,5 2,5-8,0 2,5-9,5 2,5-9,0

C

>0,3 >0,3 >0,3 >0,3 >0,3 >0,3 >0,3 >0,3

D

>0,5 >0,5 >0,5 >0,5 >0,5 >0,5 >0,5 >0,5

Fan heaters can be

mounted to vertical or

horizontal partitions in any

position. During the

montage, the minimal

distances from the walls

and ceiling have to be

kept.

U-profiles should be mounted in corners as drawing

shows. Is not allowed to screw profiles in other

places.

!!!

3. INSTALLATION

3.1. INSTALLATION –BRACKET

3.2. ASSEMBLY INSTRUCTIONS

M8 screws are in set with bracket

3.3 U-PROFILES (optional)

| 9

SRQ3d

4. CONNECTION DIAGRAMS

4. CONNECTION DIAGRAMS 4. SCHEMATY PODŁĄC EŃ

4. AANSLUITSCHEMA'S 4. СХЕМЫ ПОДКЛЮЧЕНИЯ

BMS

have to binary set addresses on each (each DRV must have individual

address) DRV module by DIP-switch SW1. To address modules check if

the power supply is turned off, than set then the addresses as shown in the

table, than turn on the power supply .|

one T-box controller .|

System). |

WARNING: The connection must be carried out with 3-wire (recommended

UTP) to connectors DRV IN

BMS /

BS

It is possible to connect up to 31 modules DRV and control them with

DRV modules can be connected to the BMS (Building Management

When connecting DRV modules to the T-box controller or BMS, you

5

.

START

-

UP AND OPERATION

Guidelines for System Connection

The connection should be executed in a way which does not induce

stresses.

It is recommended to install vent valves at the highest point of the

system.

The system should be executed so that, in the case of a failure, it is

possible to disassemble the device. For this purpose it is best to use

shut-off valves just by the device.

The system with the heating medium must be protected against an

increase of the heating medium pressure above the permissible value

(1.6 MPa).

While screwing exchanger to pipeline - connecting stubs has to be hold

by wrench.

Start Up

Before connecting the power supply check the correctness of connection

of the fan motor and the controllers. These connections should be

executed in accordance with their technical documentation.

Before connecting the power supply check whether the mains voltage is

in accordance with the voltage on the device data plate.

Before starting the device check the correctness of connection of the

heating medium conduits and the tightness of the system.

The electrical system supplying the fan motor should be additionally

protected with a circuit breaker against the effects of a possible short-

circuit in the system.

Starting the device without connecting the ground conductor is forbidden.

Operation

The device is designed for operation inside buildings, at temperatures

above 0

o

C. In low temperatures (below 0ºC) there is a danger of freezing

of the medium.

The manufacturer bears no responsibility for damage of the heat

exchanger resulting from freezing of the medium in the exchanger. If

operation of the device is expected at temperatures lower than 0º, then

glycol solution should be used as the heating medium, or special

automatic systems should be used for protecting against freezing of the

medium in the exchanger.

It is forbidden to place any objects on the heater or to hang any objects

on the connecting stubs.

The device must be inspected periodically. In the case of incorrect

operation of the device it should be switched off immediately.

It is forbidden to use a damaged device. The manufacturer bears no

responsibility for damage resulting from the use of a damaged device.

If it is necessary to clean the exchanger, be careful not to damage the

aluminium lamellas.

For the time of performing inspection or cleaning the device, the electrical

power supply should be disconnected.

In case water is drained from the device for a longer period of time, the

exchanger tubes should be emptied with compressed air.

It is not allowed to make any modification in the unit. Any modification

causes in warranty loss.

Periodic inspections

To keep proper technical parameters Flowair recommends periodic

service (every 6 months) of fan heaters on behalf of the user.

During inspections user should:

Check heat exchanger, if is it filled with dirt or dust. If necessary - use

pressurized air stream to clean the exchanger’s lamellas,

Check heat exchanger, if is it filled with dirt or dust. If necessary - use

pressurized air stream to clean the exchanger’s lamellas,

Check fan blades, in case of dirt use damp cloth and remove dirt,

Check bracket installation,

Check heat exchanger and hydraulic connection correctness,

Check wires insulation,

Check power supply,

Check medium flow,

Check levelling of the unit.

6. SERVICE AND WARRANTY TERMS

Please contact your dealer in order to get acquitted with the

warranty terms and its limitation.

In the case of any irregularities in the device operation, please contact

the manufacturer’s service department.

The manufacturer bears no responsibility for operating the

device in a manner inconsistent with its purpose, by persons not

authorised for this, and for damage resulting from this!

7. CONFORMITY WITH WEEE DIRECTIVE 2012/19/UE

Running a business without harming the environment and observing

the rules of proper handling of waste electrical and electronic

equipment is a priority for FLOWAIR.

The symbol of the crossed out wheeled bin placed on the

equipment, packaging or documents attached means that the

product must not be disposed of with other wastes. It is the

responsibility of the user to hand the used equipment to a

designated collection point for proper processing. The symbol

means at the same time that the equipment was placed on the

market after August 13, 2005.

For information on the collection system of waste electrical and

electronic equipment, please contact the distributor.

R E M E M B E R :

Do not dispose of used equipment together with other waste! There

are financial penalties for this. Proper handling of used equipment

prevents potential negative consequences for the environment and

human health. At the same time, we save the Earth's natural

resources, reusing resources obtained from the processing of

equipment.

www.flowair.com

| 19

Deklaracja zgodności / Declaration Of Conformity / Conformiteitsverklaring / Декларация осоответствии

FLOWAIR

ul. Chwaszczyńska 135, 81-571 Gdynia

tel. +48 58 669 82 20, fax: +48 58 627 57 21

FLOWAIR Nederland

Kantoor: Minervum 7268, 4817 ZM Breda, The Netherlands

tel. +31(0)76 - 581 53 11, fax. +31(0)76 - 587 22 29

e-mail: info@flowair.nl ; www.flowair.nl

Niniejszym deklarujemy, iżwodne nagrzewnice powietrza / FLOWAIR hereby confirms that heating unit / FLOWAIR verklaart

hierbij dat verwarmingsunits /

Компания FLOWAIR д клариру т, что водяны воздухонагр ват ли:

•LEO: S1, S1 BMS, S2, S2 BMS, S3, S3 BMS, (ST/INOX)

•LEO: L1, L1 BMS, L2, L2 BMS, L3, L3 BMS, (ST/INOX)

•LEO: XL2, XL2 BMS, XL3, XL3 BMS, (ST/INOX)

zostały wyprodukowane zgodnie z wymaganiami następujących Dyrektyw Unii Europejskiej /

were produced in accordance to the following Europeans Directives / zijn geproduceerd in overeenstemming met de volgende

Europese Richtlijnen /

произв д ны согласно тр бованиям Дир ктива Европ йского Союза

:

1.

2014/30/UE – Kompatybilności elektromagnetycznej / Electromagnetic Compatibility (EMC)

/

Elektromagnetische

compatibiliteit (EMC)

/ Электромагнитная совместимость (ЭМС) технических средств,

2. 2006/42/WE – Maszynowej / Machinery / Machine

/ Машины иМеханизмы,

3.

2014/35/UE – Niskonapięciowe wyroby elektryczne / Low Voltage Electrical Equipment (LVD) / Laagspanningsrichtlijn

(LVD)

/ Низковольтное оборудование (LVD),

4. 2009/125/WE – Produkty związane z energią/ Energy-related products (ErP 2015) / Richtlijn energiegerelateerde

producten (ErP 2015) / Эн ргопотр бляющи продукты

oraz zharmonizowanymi z tymi dyrektywami normami / and harmonized norms ,with above directives /en geharmoniseerde

normen, met de bovenstaande richtlijnen / атакж всо дин нии сданными дир ктивами стандартами

PN-EN ISO 12100:2012 Bezpieczeństwo maszyn -- Ogólne zasady projektowania -- Ocena ryzyka i zmniejszanie ryzyka /

Safety Of Machinery - General Principles For Design - Risk Assessment And Risk Reduction /

Veiligheid van Machines - Basisbegrippen voor ontwerp - Risicobeoordeling en risicoreductie /

Б зопасность машин – Общи принципы про ктировки – Оц нка риска иум ньш ни риска.

PN-EN 60204-1:2018-12 Bezpieczeństwo maszyn — Wyposażenie elektryczne maszyn — Część 1: Wymagania ogólne /

Safety of machinery − Electrical equipment of machines − Part 1: General requirements / Veiligheid

van machines - Elektrische uitrusting van machines - Deel 1: Algemene eisen /

Б зопасность

машин. Эл ктрооборудовани машин им ханизмов.

Часть 1. Общи тр бования.

PN-EN 60034-1:2011 Maszyny elektryczne wirujące – Część 1: dane znamionowe i parametry / Rotating electrical

machines — Part 1: Rating and performance / Roterende elektrische machines - Deel 1:

Beoordeling en prestatie

/ Вращающи ся эл ктрич ски машины. Номинальны данны и

характ ристики.

PN-EN 61000-6-2:2008 Kompatybilność elektromagnetyczna. Część 6-2: Normy ogólne. Odporność w środowiskach

przemysłowych / Electromagnetic compatibility (EMC). Generic standards. Immunity for industrial

environments / Elektromagnetische compatibiliteit (EMC). Algemene normen Immuniteit voor

industriële omgevingen /

Эл ктромагнитная совм стимость (ЭМС) - Часть 6-2: Общи стандарты -

Пом хоустойчивость для промышл нных обстановок.

Gdynia, 14.01.2019

Product Manager

20 |

COMMISSION REGULATION (EU) 2016/2282

Information relevant for disassembly, recycling and/or disposal at end-of-life:

Unassembly should be carried out by a person with appropriate authorizations. After disassembly, waste should be segregated:

housing: made of EPP or steel or INOX - recyclable

heat exchanger: copper, aluminum, steel - recyclable

fan: dispose of in accordance with the rules for the disposal of electrical equipment"

Unit name: LEO

Capacity control: 3-speed

Model

Item

Symbol

Value

Unit

LEO S1

Heating

capacity P

rated,h

2,7**

kW

LEO S2 5,7**

LEO S3 7,0**

LEO L1 6,9**

LEO L2 10,8**

LEO L3 13,9**

LEO XL2 20,2**

LEO XL3 25,7**

** heating capacity for parameters: inlet water temp. 45°C, water

temperature drop 5°C, room air temp. 20°C.

Model

Item

Symbol

Value

Unit

LEO S1

Total

electric

power input

P

elec

0,12

kW

LEO S2 0,13

LEO S3 0,13

LEO L1 0,33

LEO L2 0,34

LEO L3 0,34

LEO XL2 0,52

LEO XL3 0,55

Model

Item

Symbol

Value

Unit

LEO S1

Sound

power level

L

WA

71,4

dB

LEO S2 71,4

LEO S3 71,4

LEO L1 79,2

LEO L2 79,2

LEO L3 79,2

LEO XL2 82,6

LEO XL3 82,6

This manual suits for next models

15

Table of contents

Other Flexiheat Heater manuals

Popular Heater manuals by other brands

Clatronic

Clatronic HL 3761 instruction manual

Fox

Fox PCH-3150 Manual instruction

Lasko

Lasko 5812 Important instructions & operating manual

Thermor

Thermor Riva 4 mixte Installation and operating manual

Black Body

Black Body AIR FLASH Assembly instructions

Rinnai

Rinnai RHFE-1510F Operating and installation instructions