Flexologic FAMM User manual

1

H. Kamerlingh Onnesweg 2

2408 AW Alphen aan den Rijn

The Netherlands

CONFIDENTIAL - THIS DOCUMENT MAY NOT BE DISCLOSED TO ANY THIRD PARTY OR USED FOR ANY

OTHER PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF AV FLEXOLOGIC BV

CONFIDENTIAL

User manual

FAMM

Full-automatic mounting machine

Summary

This document is the user manual for the Full-Automatic flexo plate mounting machine FAMM

of AV Flexologic BV and explains the procedures required for general operation of the FAMM.

Revision history

Date

Change

Revision

Name

20-jun-2016

Creation of document

V01-01

DaBe

NOTE: Document may only be used if the revision history states a “RELEASED” status

2

H. Kamerlingh Onnesweg 2

2408 AW Alphen aan den Rijn

The Netherlands

CONFIDENTIAL - THIS DOCUMENT MAY NOT BE DISCLOSED TO ANY THIRD PARTY OR USED FOR ANY

OTHER PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF AV FLEXOLOGIC BV

CONFIDENTIAL

Contents

1. Introduction .............................................................................................................................................2

2. Safety information ...................................................................................................................................2

3. Liability.....................................................................................................................................................3

4. Contact information.................................................................................................................................3

5. Tools list ...................................................................................................................................................3

6. Starting the machine................................................................................................................................3

7. Emergency shutdown procedure.............................................................................................................5

8. Light pillar.................................................................................................................................................6

9. Adding a new job .....................................................................................................................................7

10. Adding plates to the cylinder...................................................................................................................8

11. Preparation before mounting ..................................................................................................................9

12. Mounting plates.......................................................................................................................................9

13. Printing mounting information (reports)...............................................................................................10

14. Microdot not recognized at pickup position..........................................................................................10

15. Microdots not recognized at mount position........................................................................................11

16. Adobe AcrobatTM Plug in........................................................................................................................14

17. ESKO graphics® PlatepatcherTM..............................................................................................................14

18. Importing a MOM file ............................................................................................................................14

19. External job creation..............................................................................................................................16

20. Non-disclosure .......................................................................................................................................17

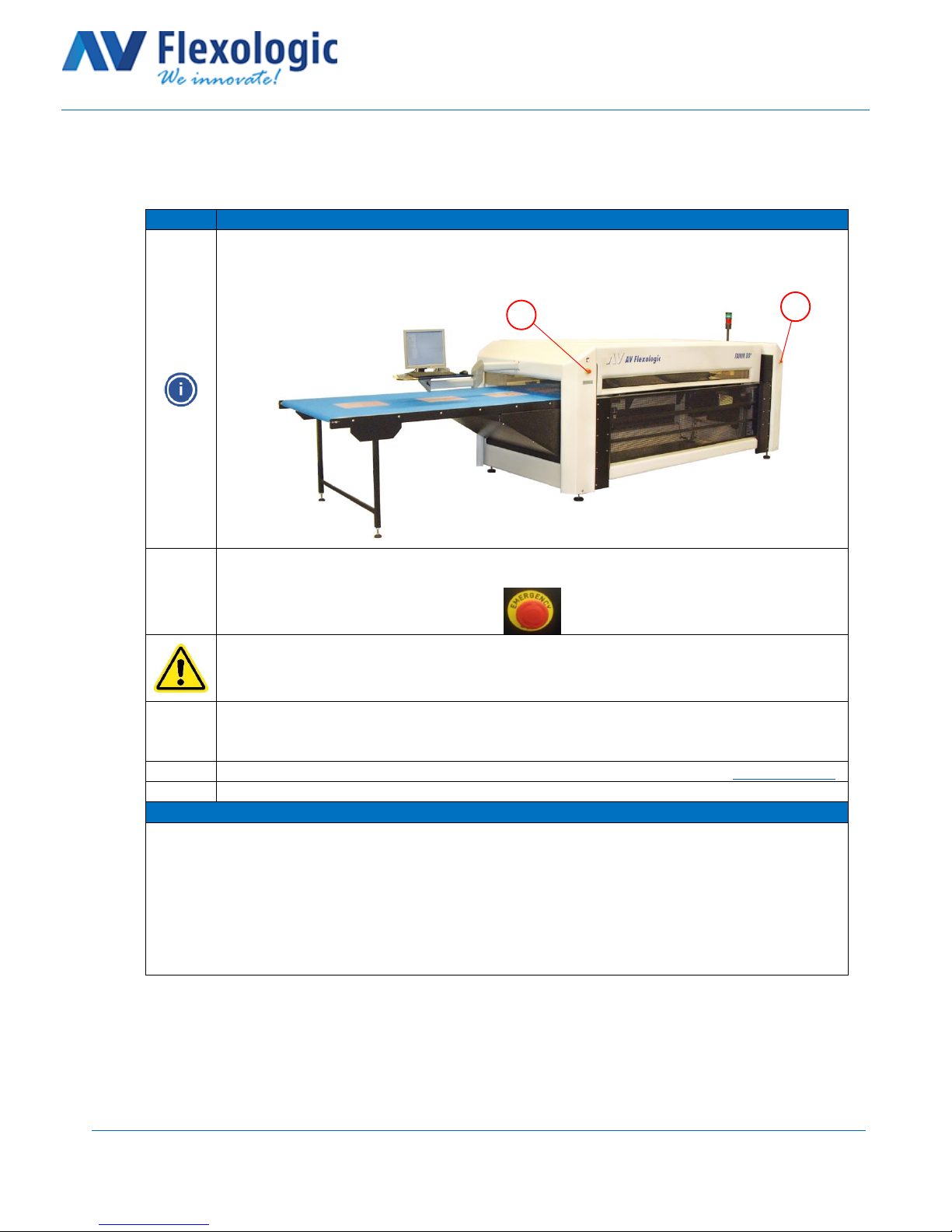

1. Introduction

This is the user manual for the Fully Automatic Mounting Machine (FAMM), a mounting machine which

eliminates the human factor in the mounting process. This manual describes the operation of the FAMM.

The intended audience is the client, or client’s service/operational personnel. All steps in this manual are

required to be followed in detail. If there are any deviations, a remark can be placed in the comments

sections in this document and please contact the service department at AV Flexologic BV.

2. Safety information

Sound emission of this machine does not exceed 70 dB (A).

While using the FAMM the following personal protective equipment (PPE) is required:

#

Description

Qty

1

Steel toe boots

pair

2

NOTE: Please check the user manuals of the above PPE on responsible use of these PPE.

3

H. Kamerlingh Onnesweg 2

2408 AW Alphen aan den Rijn

The Netherlands

CONFIDENTIAL - THIS DOCUMENT MAY NOT BE DISCLOSED TO ANY THIRD PARTY OR USED FOR ANY

OTHER PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF AV FLEXOLOGIC BV

CONFIDENTIAL

3. Liability

AV Flexologic BV is not accountable for injuries sustained from using the FAMM, if personnel is not

properly schooled, if steps in this manual were not followed in detail, if incorrect tooling was used, or if

proper personal protective equipment was not used.

4. Contact information

If there are any questions or obscurities during the use of this manual and there is no

means of continuing, please contact the service department of AV Flexologic at Support@AVflexologic.com

5. Tools list

The following tools are required to operate the FAMM. Please make sure the tools are available before

starting. If these tools are not available, please do not use the FAMM.

#

Description

Qty

1

NONE

2

3

NOTE: Images are indicative, colours and/or shapes may vary.

6. Starting the machine

This section describes the power-up of the FAMM.

Step

Action

1

Make sure the machine has been powered down for at least 5 minutes.

2

Make sure the emergency stop button(s) are not activated (See section 7)

3

Turn the main power switch located on the front of the machine to the “ON” position:

4

Wait for the system to power up.

5

Enter username: Operator

Enter password: avmom

6

Wait for the software to completely boot up.

A

B

I: POWER ON POSITION (A)

O: POWER OFF POSITION (B)

4

H. Kamerlingh Onnesweg 2

2408 AW Alphen aan den Rijn

The Netherlands

CONFIDENTIAL - THIS DOCUMENT MAY NOT BE DISCLOSED TO ANY THIRD PARTY OR USED FOR ANY

OTHER PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF AV FLEXOLOGIC BV

CONFIDENTIAL

7

Press the blue or white RESET button. (After reset the light of the button will go off)

8

The FAMM control software will automatically start-up and show the main screen.

Wait 30 seconds until the red bars disappear.

9

Click on Initialize (A) and wait for everything to turn green.

12

The machine is now fully powered up and ready to be used

13

DONE

Comments

A

5

H. Kamerlingh Onnesweg 2

2408 AW Alphen aan den Rijn

The Netherlands

CONFIDENTIAL - THIS DOCUMENT MAY NOT BE DISCLOSED TO ANY THIRD PARTY OR USED FOR ANY

OTHER PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF AV FLEXOLOGIC BV

CONFIDENTIAL

7. Emergency shutdown procedure

This section describes the procedure for an emergency shut down.

Step

Action

The FAMM is equipped with 2 emergency stop buttons (A). These buttons are situated at the

front of the machine, one on the left and one on the right side of the machine. These buttons

are for situations in which the FAMM needs to immediately stop all actions.

1

In case of an emergency, press an emergency stop button firmly. The FAMM will immediately

stop all actions.

Use of the emergency stop buttons is only allowed in an emergency situation and may not

be used under normal operational conditions to switch off the machine. Use of the

emergency stop button can potentially lead to the need to (re) calibrate the machine.

2

After the emergency situation is resolved, rotate the red part of the activated pushbutton, as

indicated on the button, until it “pops” out to release it.

3

After resetting the emergency stop button, reset the machine as described in section 6 step 7.

4

DONE

Comments

A

A

Table of contents